Optimizing Hose Handling: The Role of Automatic Coiling and Strapping Lines

Handling long lengths of industrial hose or pipe presents significant challenges in manufacturing and distribution environments. Manual coiling and securing are often labor-intensive, time-consuming, and can introduce inconsistencies in package quality and potential ergonomic risks for workers. Automating this process with dedicated machinery offers a robust solution.

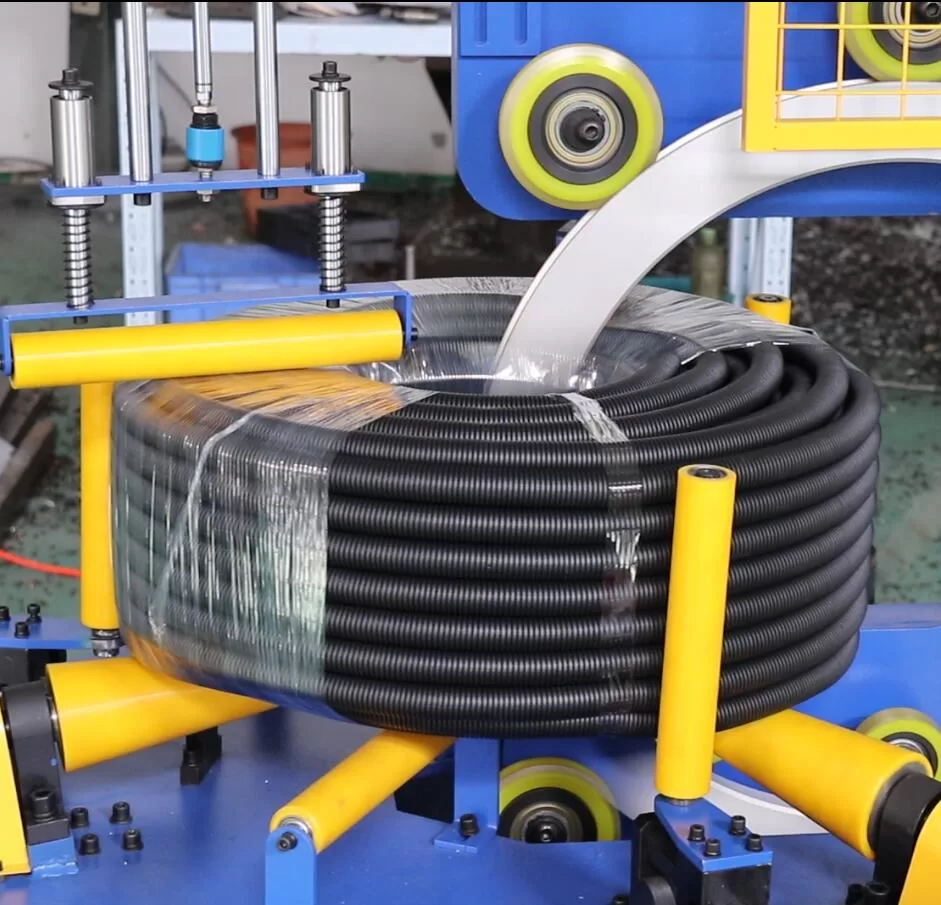

An Automatic hose coiling and strapping machine line integrates multiple functions to streamline the packaging of flexible products like hoses and pipes from production or extrusion lines directly into finished coils ready for storage or shipment.

Understanding Automatic Hose Coiling and Strapping Systems

These integrated lines typically perform two primary functions sequentially:

- Coiling: The machine automatically winds the hose or pipe to a predetermined length and diameter, ensuring consistency and neatness.

- Strapping/Securing: Once coiled, the machine applies straps (often plastic or metal) at set intervals around the coil's circumference to maintain its shape and prevent unwinding during handling and transport.

Modern systems are designed for integration into plant floors, often operating inline with extrusion or production processes, minimizing manual intervention and optimizing workflow. The adoption of such automation is crucial for facilities looking to enhance efficiency and reduce operational costs associated with manual packaging methods.

Key Benefits of Automated Hose Coiling and Strapping

Implementing an automatic hose coiling and strapping machine line offers several advantages for industrial operations:

Enhanced Efficiency and Throughput

Automation significantly accelerates the coiling and strapping process compared to manual methods. Consistent cycle times and continuous operation lead to higher throughput, allowing production facilities to meet demanding schedules and increase overall output without proportionally increasing labor.

Improved Workplace Safety

Manual coiling of heavy or lengthy hoses can lead to repetitive strain injuries and other ergonomic hazards. Automating this task removes operators from potentially strenuous physical activity, reducing the risk of workplace injuries and associated costs.

Consistent Coil Quality and Presentation

Automated systems produce uniformly sized and tightly secured coils every time. This consistency improves package appearance, aids in stacking and storage, and ensures that the product reaches the end-user in optimal condition.

Optimized Material Handling and Storage

Neatly coiled and securely strapped hoses occupy less space than loosely wound bundles. The compact nature of automatically processed coils simplifies handling, stacking, and storage within warehouses and during transit, optimizing logistical operations. Strapping can utilize various materials based on coil weight and handling requirements.

Labor Cost Reduction and Resource Allocation

By automating repetitive coiling and strapping tasks, businesses can reallocate valuable human resources to more complex, value-added activities. This leads to direct labor cost savings and improves overall operational productivity. Investing in such machinery can yield significant long-term savings, offsetting the initial capital expenditure.

Core Components and Considerations

A typical automatic hose coiling and strapping line comprises several key elements:

- Infeed/Accumulation: Manages the incoming hose or pipe from the production line.

- Measuring System: Accurately measures the required length for each coil.

- Coiling Head: Forms the hose into a coil of the specified diameter.

- Cutting Mechanism: Cuts the hose once the desired length is reached.

- Strapping Unit(s): Applies securing straps around the coiled product.

- Ejection/Outfeed System: Discharges the finished coil, often onto a conveyor for further handling.

- Control System (PLC): Manages all machine functions, allowing for parameter adjustments (coil size, strap number/position, etc.).

When considering implementation, factors such as the range of hose/pipe diameters and materials, required coiling speeds, coil weight limits, desired level of automation, and integration with existing production lines must be carefully evaluated.

Conclusion

In summary, an automatic hose coiling and strapping machine line represents a valuable investment for businesses involved in the production or handling of hoses and pipes. These systems deliver substantial improvements in efficiency, safety, product consistency, and space utilization. By streamlining packaging operations and reducing reliance on manual labor, manufacturers and distributors can enhance productivity, lower operational costs, and maintain a competitive edge in today's demanding industrial landscape. Carefully evaluating specific operational needs against the capabilities of available automated systems is key to selecting the right solution for optimizing hose packaging workflows.