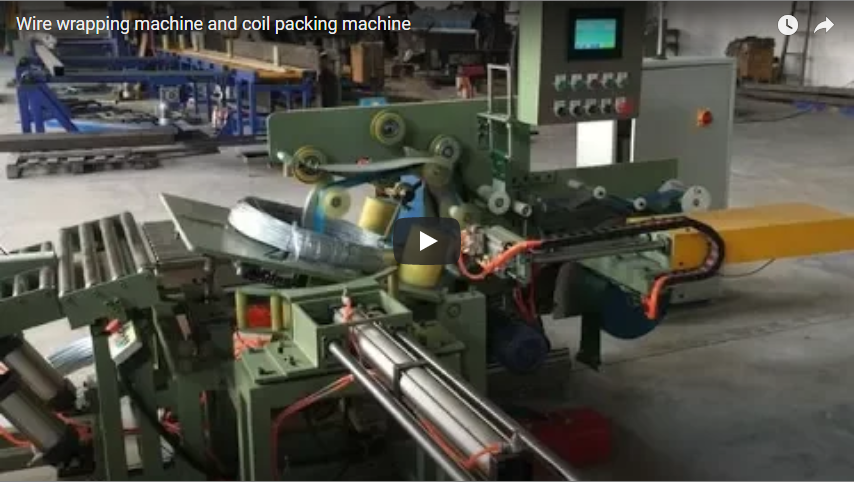

The steel wire coil compressing and rack take off machine is an innovative solution for steel wire packing line solutions. This compacting line includes various parts, such as an automatic compacting machine, wire coil strapping machine, carrier take off machine, carrier pusher, and roller station.

The automatic compacting machine is designed to compact steel wire coils with carriers, making it an ideal choice for companies looking to automate their packing process. The wire coil strapping machine ensures that the coils are securely strapped before being moved to the carrier take off machine.

The carrier take off machine is designed to turn the coil 90 degrees and move it forward and backward with track. The roller station is used for picking up the wire coil from the carrier. After the wire coil is taken off from the rack, the empty carrier is pushed to the recycle conveyor.

The steel wire coil compressing and rack take off machine is designed to handle a wide range of coil sizes and specifications. It can eye through wrap the steel wire coil automatically, making it a fast and efficient solution for wire packing.

In terms of replacing the strapping head, it is a simple task that can be done in about 15 minutes. All the electric connectors from the strapping head, two hydraulic connecting tubes, a pneumatic tube, and six screws should be released. Once taken off, the strapping head can be extracted by a crane from its position, and in order to mount it again, the same procedure should be done but in reverse.

In summary, the steel wire coil compressing and rack take off machine is an innovative solution for steel wire packing line solutions. With its advanced features, precise movements, and customizable design, this machine is an essential tool for any company looking to improve their steel wire packing process. Invest in the steel wire coil compressing and rack take off machine today and experience the benefits of this innovative technology.