1. Introduction: Automating Bearing Protection with Horizontal Wrapping Technology

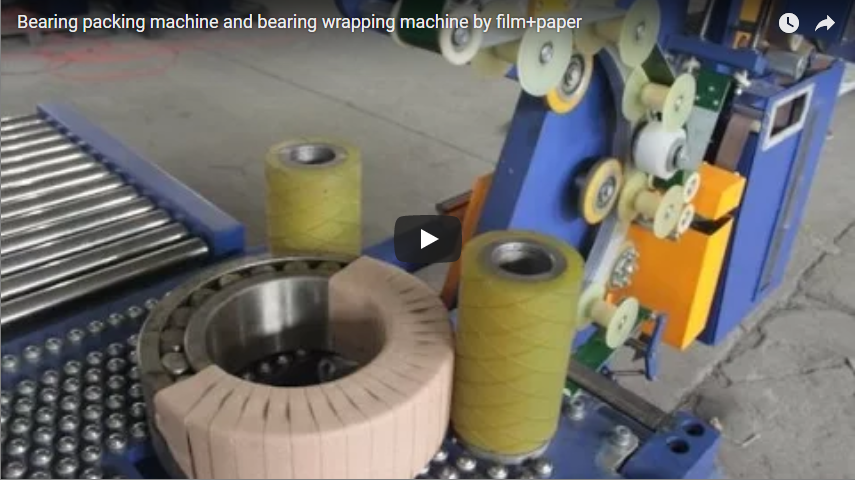

Bearings are critical components in countless industrial applications, demanding robust protection against corrosion, dust, and handling damage during storage and transit. The Horizontal Bearing Wrapping Packing Machine featured here represents an automated solution designed specifically for this purpose. This online system integrates seamlessly with production lines, utilizing orbital wrapping technology to apply protective materials like stretch film or VCI paper efficiently and consistently. This article delves into the design, components, technical specifications, and operational benefits of this type of packaging machinery.

2. Core Functionality: The Orbital Wrapping Process Explained

At its heart, this machine employs an orbital wrapping mechanism. Here’s a breakdown of the typical operational sequence:

- Infeed: Bearings arrive via an integrated in-feeding conveyor. Sensors detect the product's presence and position.

- Positioning: The bearing is automatically centered relative to the wrapping ring.

- Wrapping Cycle: The rotating ring, carrying the roll of packing material (e.g., stretch film, VCI paper), orbits around the stationary bearing. As it orbits, the material is dispensed and tightly wrapped around the bearing's outer and inner surfaces (depending on configuration).

- Material Feed & Cut: The packing material is automatically fed at the start of the cycle and automatically cut upon completion. Precise tension control ensures a snug, protective fit without damaging the bearing.

- Outfeed: The fully wrapped bearing is transferred onto the out-unloading conveyor, ready for the next stage (e.g., boxing, palletizing).

3. Key Design Features and Components

Understanding the core components illuminates the machine's capabilities:

- Wrapping Ring Assembly: This is the central element, housing the packing material roll holder, dispensing mechanism, and drive system. Its rotation speed is often adjustable to accommodate different bearing sizes and required wrap densities.

- Conveyor System: Features robust infeed and outfeed conveyors designed to handle the weight of various bearings. Support rollers, often coated with Polyurethane (PU) to prevent marking the bearing surface, ensure smooth transit. Some support roller designs are "motor-free" (idler rollers), relying on the main conveyor drive.

- Packing Material Delivery: Includes the spool holder, tension control system (critical for film stretch and wrap integrity), and an automatic cutting mechanism (typically heat-seal or mechanical blade).

- Control System: Usually managed by a Programmable Logic Controller (PLC) with a Human-Machine Interface (HMI) touch screen. This allows operators to set parameters (wrap counts, overlap percentage, conveyor speed), monitor the process, and troubleshoot issues.

- Frame and Structure: Built with heavy-duty materials to ensure stability, durability, and vibration damping during operation.

- Safety Features: Incorporates emergency stops, safety guards, and sensors to protect operators and the equipment.

4. Technical Specifications Overview

While exact specifications vary by model and manufacturer, typical parameters for a horizontal bearing wrapper include:

| Specification | Typical Range/Value | Notes |

|---|---|---|

| Bearing OD Range | 100 mm - 800 mm (or wider) | Defines the max/min outer diameter capacity |

| Bearing ID Range | 50 mm - 500 mm (or wider) | Defines the max/min inner diameter capacity |

| Bearing Width Range | 20 mm - 200 mm (or wider) | Defines the max/min width/height capacity |

| Wrapping Speed | 15 - 40 seconds/piece | Dependent on bearing size & wrap parameters |

| Ring Speed (RPM) | 50 - 150 RPM (Adjustable) | Impacts cycle time and wrap application |

| Conveyor Speed | 5 - 15 m/min (Adjustable) | Synchronized with line speed requirements |

| Packing Materials | Stretch Film, VCI Paper, Crepe Paper, PE | Compatibility depends on dispenser design |

| Material Roll Width | 50 mm - 100 mm | Standard widths for bearing wrapping |

| Material Roll OD | Up to 500 mm | Defines material roll capacity |

| Material Roll ID | 76 mm (Standard Core) | Standard core size |

| PLC/HMI | Siemens, Allen-Bradley, Omron, etc. | Common industrial automation brands |

| Power Supply | 380V/50Hz/3Ph (or custom) | Standard industrial power requirements |

| Air Supply | 0.5 - 0.7 MPa | For pneumatic actuators (cutter, clamps) |

| Machine Dimensions | Varies (e.g., 2500x1800x1700 mm) | Footprint depends on configuration |

(Note: These are representative values. Always refer to specific manufacturer documentation for precise data.)

5. Advantages of Automated Horizontal Bearing Wrapping

Implementing an automated wrapping solution offers significant benefits:

- Superior Product Protection: Provides a tight, uniform barrier against moisture, dust, corrosion (especially with VCI materials), and handling damage.

- Increased Throughput: Automated cycles are significantly faster and more consistent than manual wrapping, boosting overall packaging line efficiency.

- Reduced Labor Costs: Frees up personnel from repetitive manual tasks, allowing them to focus on higher-value activities.

- Consistent Packaging Quality: Eliminates variability inherent in manual wrapping, ensuring every bearing receives the same level of protection.

- Material Savings: Optimized tension control and overlap settings minimize material waste compared to manual methods.

- Improved Safety: Enclosed operation and automated handling reduce risks associated with manual wrapping and lifting.

6. User Experience and Integration Considerations

From an operational standpoint, these machines are designed for industrial environments:

- Ease of Operation: Modern HMIs provide intuitive interfaces for setup, operation, and basic troubleshooting. Recipe storage allows quick changeovers between different bearing sizes.

- Maintenance: Routine maintenance typically involves lubricating moving parts, checking sensor functionality, inspecting belts/chains, and periodically replacing the cutting blade. Access points are usually designed for convenient servicing.

- Integration: The online nature, facilitated by the infeed and outfeed conveyors, allows direct connection to upstream manufacturing processes (e.g., washing, marking) and downstream systems (e.g., boxing, palletizing), enabling fully automated production flow.

7. Industries Served

Horizontal bearing wrappers are indispensable in sectors where bearing integrity is paramount, including:

- Automotive Manufacturing (Wheel bearings, transmission components)

- Industrial Machinery Production

- Aerospace Component Manufacturing

- Railway Industry

- Heavy Equipment Manufacturing

- Bearing Production Facilities

8. Conclusion: A Vital Asset for Bearing Packaging Lines

The Horizontal Bearing Wrapping Packing Machine is a specialized, high-efficiency solution crucial for protecting valuable bearing assets. Its automated operation, robust design, use of appropriate protective materials, and seamless integration capabilities make it a cornerstone of modern packaging operations in bearing-intensive industries. By ensuring consistent, high-quality wrapping, this technology directly contributes to product longevity, reduced damage claims, and enhanced supply chain integrity.

9. Further Information

For more details on specific bearing packing solutions and technologies, explore related resources:

https://www.fhopepack.com/Bearing-packing-machine/

Or contact us directly for inquiries: coiler@fhopepack.com