Understanding the pricing of industrial coil upenders requires examining it from two distinct viewpoints: direct from the manufacturer and through the broader online marketplace. Each offers different insights into cost structures and purchasing processes.

I. Manufacturer Pricing Perspective: The "Request Quote" Model

Manufacturers of industrial coil upenders, particularly those producing heavy-duty, specialized, or highly customized units, typically do not publish fixed price lists. Instead, a "Request Quote" or "Build to Order" approach is prevalent. This methodology is driven by several key factors in coil upender price:

Extensive Customization and Configuration:

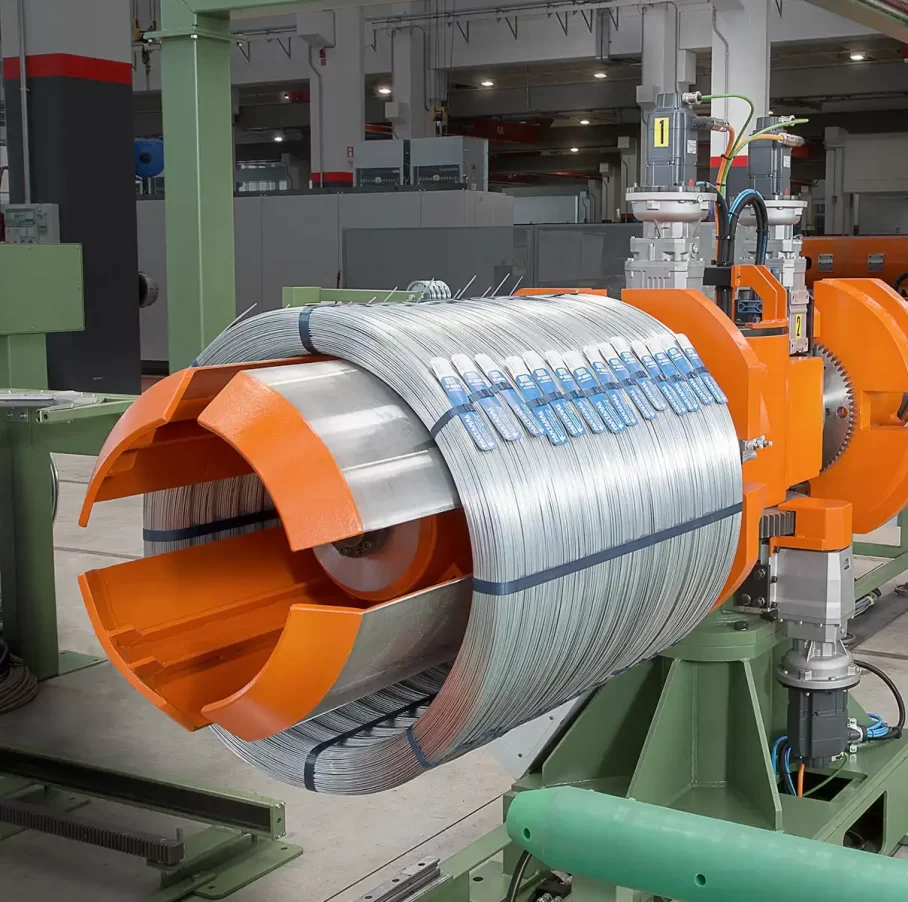

- Coil upenders can vary significantly in critical specifications such as capacity (ranging from a few tons to 70 tons or more), table size, drive mechanism (electric mechanical or hydraulic), control systems, and integrated safety features.

- A substantial number of units are engineered to precise customer requirements, making a standard price list impractical. For instance, MetalPress Machinery offers its MDR series with capacities from 5 to 70 tonnes and various optional features like rotating bases or forklift bases, all of which directly influence the final price.

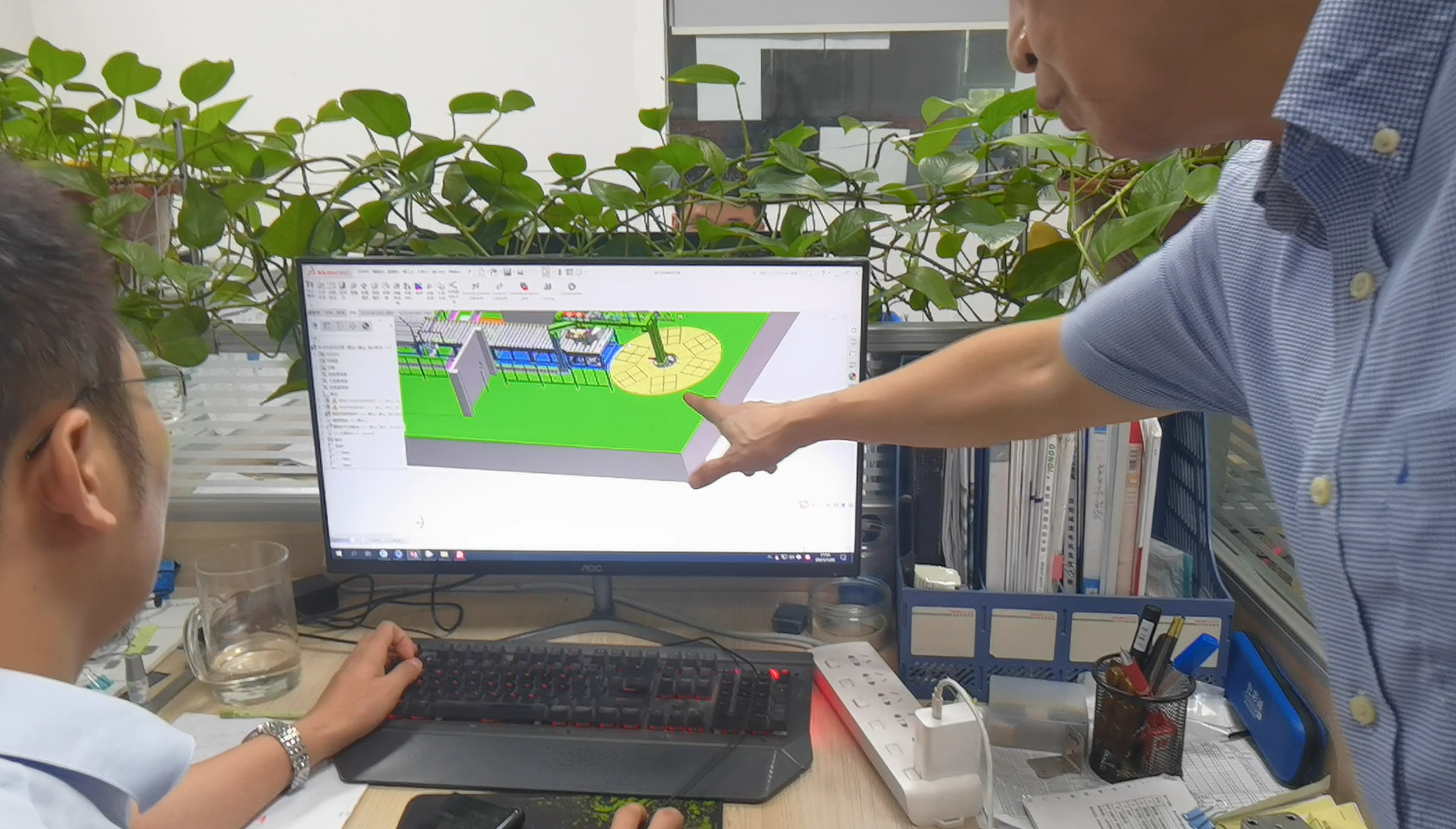

Consultative Sales Process:

- The acquisition of such machinery often necessitates detailed discussions between the buyer and the manufacturer (or their authorized distributor). This ensures the equipment precisely aligns with the intended application.

- This consultative approach helps define the exact specifications needed, which subsequently informs the price quotation.

Value-Based Pricing Strategy:

- Manufacturers may price their equipment based on the tangible value it delivers to the customer. This includes benefits like increased productivity, enhanced operational safety, and reduced maintenance requirements (e.g., all-electric designs that eliminate hydraulic leak concerns).

- This value proposition can be more effectively articulated and justified through direct interaction rather than a static price tag.

Competitive B2B Strategy:

- In a business-to-business (B2B) environment, manufacturers often prefer to discuss pricing directly. This allows them to better understand the competitive landscape for a specific sale and potentially negotiate terms.

- Companies like MetalPress Machinery, while promoting their upenders as "competitively priced" and "loaded with features and value," require potential buyers to "request more info" or "GET QUOTE." Similarly, distributors of brands like SXKH for larger or specialized mechanical or hydraulic flippers (which share technological similarities with upenders) also frequently employ a "Request Quote" system.

II. Market View Pricing: Online Marketplaces & General Listings

The broader market, particularly online B2B platforms such as Alibaba, provides more direct price visibility. This is primarily for more standardized or smaller-capacity coil upenders, often originating from Asian manufacturers. These listings offer a general benchmark for what basic or less customized units might cost.

Here's what the market view indicates:

Wide Price Spectrum: Prices can span significantly, from approximately $1,500 to $14,885 USD, and potentially higher, contingent on the specifications.

Entry-Level/Basic Units:

- A 0-90 degree hydraulic upender for flipping metal (suitable for some coil applications) can be found for around $1,500.

- Vertical-horizontal turnover machine coil upenders are listed in the vicinity of $2,500.

Mid-Range Units:

- 5-ton steel coil turnover machines (90-degree flip) are priced near $2,750.

- 180-degree mold and coil upenders/flippers can range from $5,400 to $6,000.

- 90-degree industrial flip machines or steel coil turnover machines (2,000-30,000kg capacity) are listed between $5,800 and $6,000.

Branded/Higher Capacity Units (on these platforms):

- WALTER 90-degree steel/aluminum coil tippers and upenders (3T-30T capacity) are listed in ranges like $3,355 - $8,855.

- "Chinese Top Brand WALTER 3T-30T Turn Over Steel Coil" machines show prices from $5,650 to $14,885.

Customized Units (on these platforms):

- Even on platforms like Alibaba, some listings mention "Customized" upenders. For example, a 50-ton 90-degree large die/mold flipper (which could potentially handle coils) is listed for around $3,000, though this price might represent a base figure for further customization.

III. Summary of Price Analytics

- Even on platforms like Alibaba, some listings mention "Customized" upenders. For example, a 50-ton 90-degree large die/mold flipper (which could potentially handle coils) is listed for around $3,000, though this price might represent a base figure for further customization.

Manufacturer Direct:

- Expect a consultative purchasing process with pricing provided via quotation. This is especially true for heavy-duty, high-capacity, or extensively customized coil upenders.

- Prices will reflect the specific engineering involved, features included, and the level of support offered. These solutions are generally positioned as higher-value and, potentially, higher-cost options.

Market (Online Platforms):

- Offers greater price transparency for a spectrum of generally smaller to medium-capacity coil upenders.

- Prices typically range from a couple of thousand dollars to the mid-teen thousands. This market segment is often more price-competitive for standard functionalities.

Conclusion:

To obtain an accurate coil upender price for a coil upender that meets specific industrial requirements, direct engagement with manufacturers or their authorized distributors is usually necessary. This allows for a detailed definition of needs and a formal quotation. Online marketplaces can serve as a valuable resource for a baseline understanding of pricing for more generic or lower-capacity options.