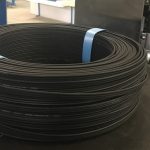

The video of the steel wire coiling and strapping machine for steel wire re-winding and coiling. It includes the automatic wire strapping machine.

https://www.fhopepack.com/Wire-coil-wrapping-machine/Automatic-steel-wire.html

1: meter counter:

2. coiling head:

3 .traverse:

4.portal cutter:

5. Strapping heads

Meter counter – Electronically measures and displays the length of wire being recoiled. Allows setting of target coil lengths.

Coiling head – Contains the spindle and casing that the wire is wound onto to form the coil. The spindle rotates and traverses in and out to control the coil diameter.

Traverse – Moves the coiling head in and out to vary the coil diameter as needed for different coil lengths and wire gauges. Precise control is required to maintain a consistent coil shape.

Portal cutter – Uses a cutting tool that pivots down to sever the wire after the target length has been wound onto the coil. Produces a clean, square end for the wire.

Strapping heads (automatic) – Apply steel or plastic straps around the finished coil to secure and contain it. Features include:

Strap feeding mechanisms

Tensioning and sealing systems to apply the straps tightly

Heads that rotate in synchronization with the coil to wrap the straps circumferentially

PLC control for repeatability and adjustment to different coil sizes

Other benefits of the machine include:

Higher output vs manual recoiling and strapping

More consistent coil diameters and shapes

Less waste from precision functions like auto-strapping and cutting

Safer operation due to automated strapping and guards over moving parts

So in summary, the key components allow the machine to reliably recoil steel wire into finished coils and then automatically apply straps to those coils. The automation provides benefits like higher throughput, greater consistency and reduced waste versus manual methods.