# Upenders & Tilters: Enhancing Material Handling Safety and Efficiency

## 1. Introduction: Understanding Upenders and Tilters

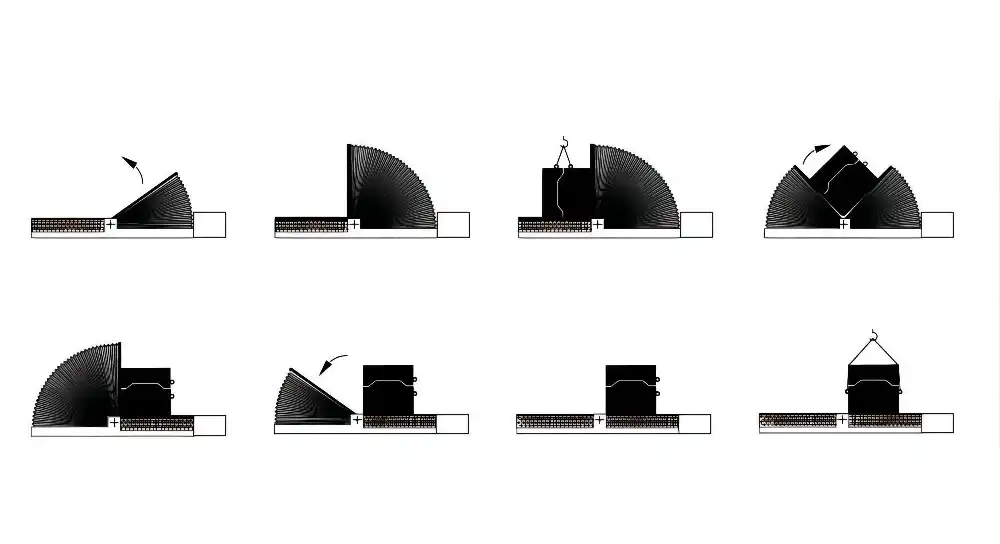

Upenders and tilters are essential pieces of material handling equipment designed to safely and efficiently rotate, tilt, or reposition heavy or unwieldy loads. Found in diverse industrial settings from manufacturing plants to logistics hubs, these machines play a critical role in optimizing workflows, enhancing workplace safety, and preventing product damage. Understanding their function, types, and applications is key to leveraging their full potential. This guide explores the fundamentals of upenders and tilters, showcasing their capabilities and benefits.

FHOPE, a manufacturer with extensive experience, offers a wide array of these solutions, tailoring equipment to specific operational needs. Their expertise spans various types, including hydraulic, mechanical, and electrical systems, designed for reliability and performance.

## 2. Types of Upenders and Tilters

Upenders and tilters come in various configurations, primarily driven by hydraulic, mechanical, or electrical systems, each suited for different requirements.

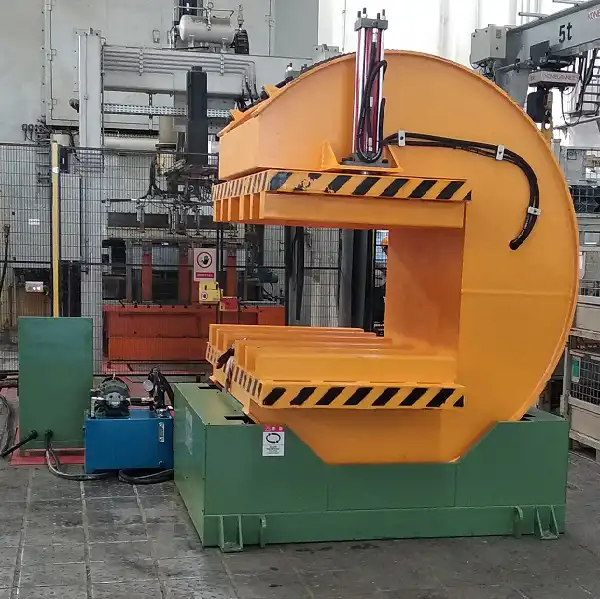

### 2.1 Hydraulic Upenders & Tilters

* **Mechanism:** Utilize hydraulic cylinders for powerful, smooth, and controlled lifting and tilting motions.

* **Best Suited For:** Heavy-duty applications requiring significant force and precise, gentle handling, such as large coils, molds, or engines.

* **Advantages:** High load capacity, smooth operation, robust construction.

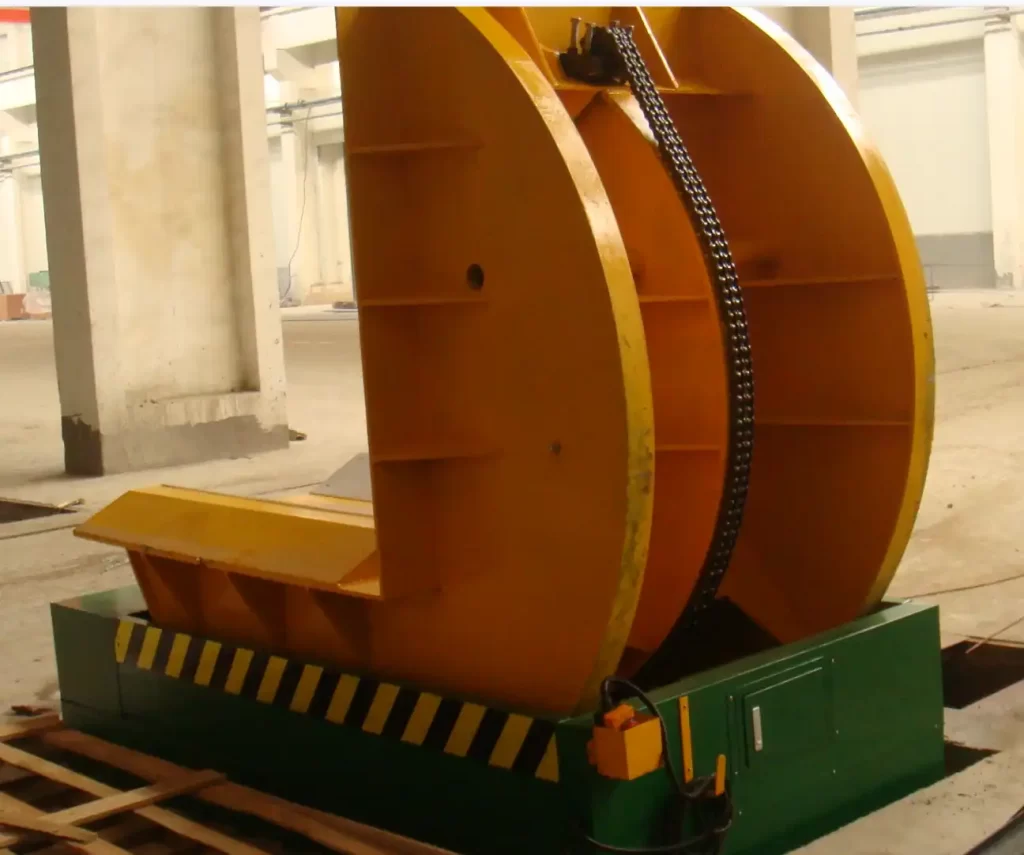

### 2.2 Mechanical Upenders & Tilters

* **Mechanism:** Employ mechanical components like gears, chains, screws, or linkages for rotation.

* **Best Suited For:** Applications demanding consistent positioning and potentially lower cost or simpler maintenance compared to hydraulics. Often used for specific rotation angles (e.g., 90 or 180 degrees).

* **Advantages:** Reliability, precise positioning (especially with screw mechanisms), potentially lower initial cost.

### 2.3 Electrical Upenders & Tilters

* **Mechanism:** Use electric motors and gearboxes for movement, offering excellent control over speed and positioning.

* **Best Suited For:** Operations requiring high precision, variable speed control, or integration into automated systems.

* **Advantages:** Precise control, programmability, easier integration with automation, cleaner operation (no hydraulic fluid).

## 3. Key Benefits and Applications

The integration of upenders and tilters into industrial processes offers significant advantages:

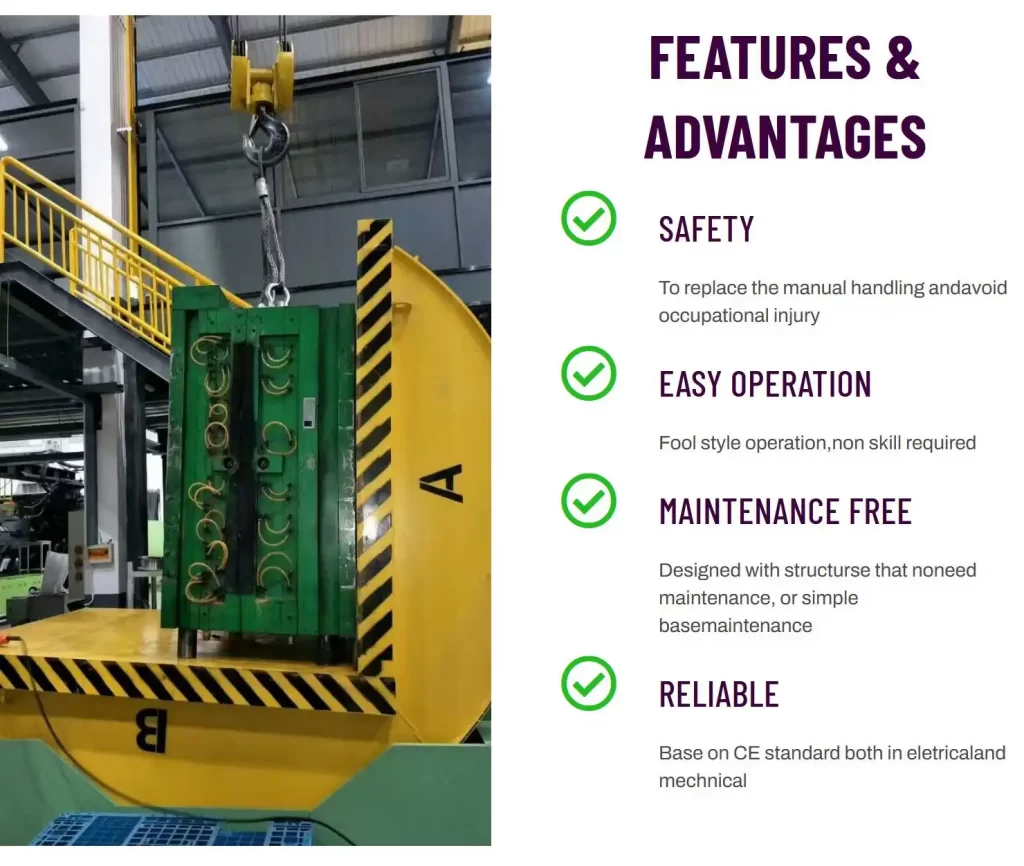

### 3.1 Enhanced Safety

* Reduces the need for manual handling of heavy or awkward loads.

* Minimizes the risk of musculoskeletal injuries associated with lifting and turning.

* Provides stable and controlled movement, preventing accidents caused by load shifting.

### 3.2 Increased Efficiency

* Speeds up material handling processes compared to manual methods or less specialized equipment.

* Streamlines workflows by quickly orienting parts for the next stage of production, assembly, or shipping.

* Reduces cycle times in manufacturing and logistics operations.

### 3.3 Product Protection

* Ensures gentle handling of sensitive or valuable goods (e.g., paper rolls, steel coils, molds).

* Prevents damage such as scratching, denting, or deformation during rotation.

### 3.4 Common Applications

Upenders and tilters are indispensable in various industries:

* **Metal Processing:** Rotating steel or aluminum coils, sheet stacks, or dies.

* **Manufacturing & Assembly:** Positioning heavy components like engines, chassis, or large assemblies.

* **Warehousing & Logistics:** Tilting loads for loading/unloading, pallet changing (using load inverters), or storage optimization.

* **Paper & Printing:** Turning large paper rolls or stacks of printed material.

* **Mold & Die Handling:** Safely rotating heavy molds for maintenance, cleaning, or setup.

* **Foundries:** Handling castings and related equipment.

## 4. Optimizing Operations with Upenders and Tilters

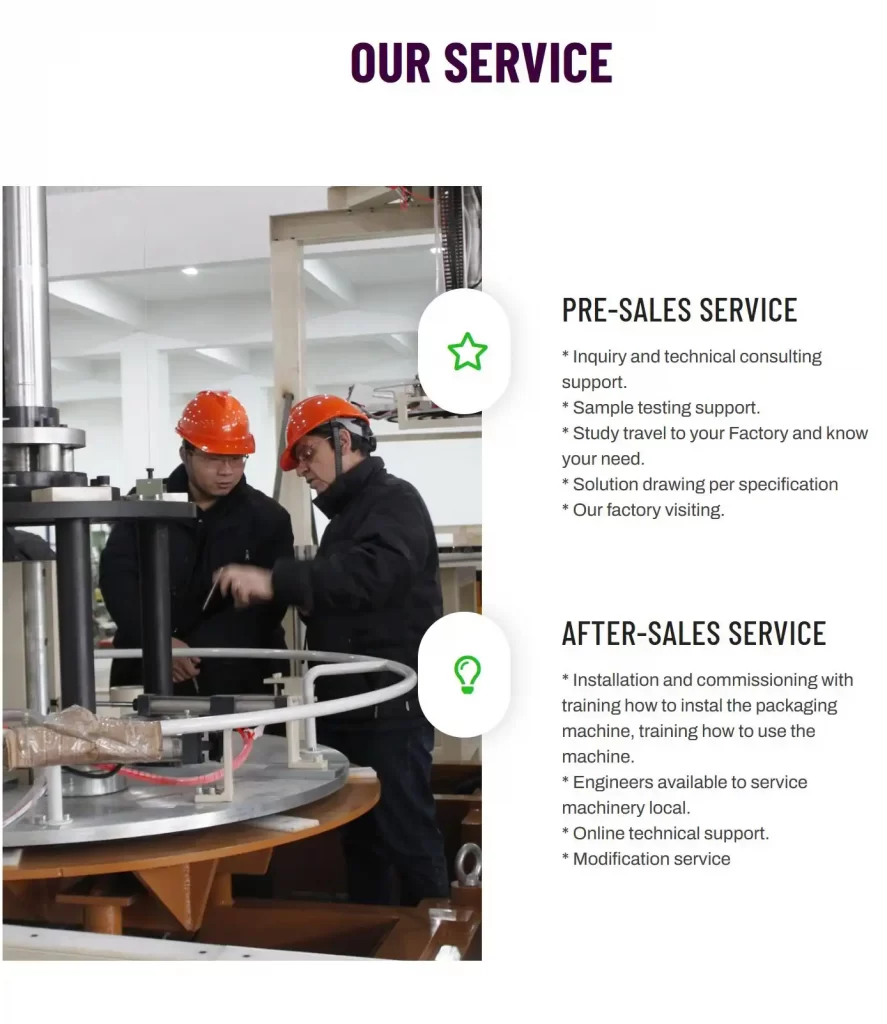

To maximize the benefits of this equipment:

### 4.1 Select the Right Machine

* **Load Characteristics:** Consider weight, dimensions, center of gravity, and sensitivity of the load.

* **Operational Needs:** Define the required rotation angle (e.g., 90°, 180°), speed, cycle frequency, and operating environment.

* **Power Source:** Choose between hydraulic, mechanical, or electrical based on performance needs, available utilities, and maintenance preferences.

* **Safety Features:** Ensure the machine includes necessary safety guards, interlocks, and controls.

### 4.2 Proper Training

* Ensure operators are thoroughly trained on safe operating procedures, load limits, and emergency protocols.

### 4.3 Regular Maintenance

* Implement a consistent inspection and maintenance schedule as recommended by the manufacturer (e.g., FHOPE) to ensure continued safe and efficient operation. Check hydraulic fluid levels, inspect mechanical components for wear, and verify electrical connections.

### 4.4 Customization

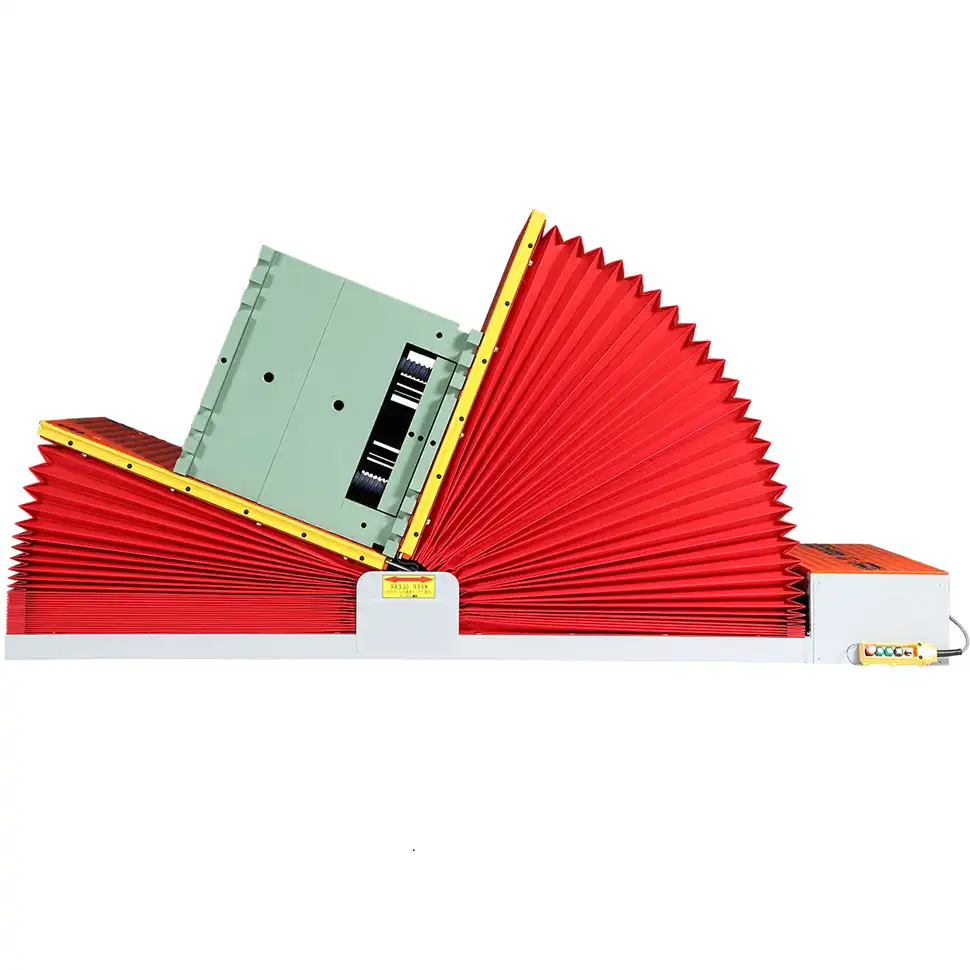

* Work with experienced manufacturers like FHOPE to explore customization options. Tailoring features like platform size, clamping mechanisms, control systems, or integration with conveyors can significantly enhance productivity for specific tasks. For instance, specific solutions exist for mold handling, like the Mold Flipper.

## 5. Conclusion

Industrial upenders and tilters are vital tools for modern material handling. By enabling the safe, efficient, and damage-free rotation and positioning of heavy loads, they contribute significantly to operational productivity and workplace safety across numerous industries. Choosing the right type of equipment, ensuring proper training, performing regular maintenance, and considering custom solutions are key steps to fully realizing the benefits these machines offer. Investing in high-quality upenders and tilters from reputable manufacturers is an investment in a smoother, safer, and more productive operation.

## 6. Upender & Tilter Showcase Gallery

Explore various types of Upender & Tilter equipment designed for diverse industrial applications.

*

* *Caption: Coil Tilter Upender 6*

*

* *Caption: Coil Transfer Car*

*

* *Caption: Coil Upender Tilter*

*

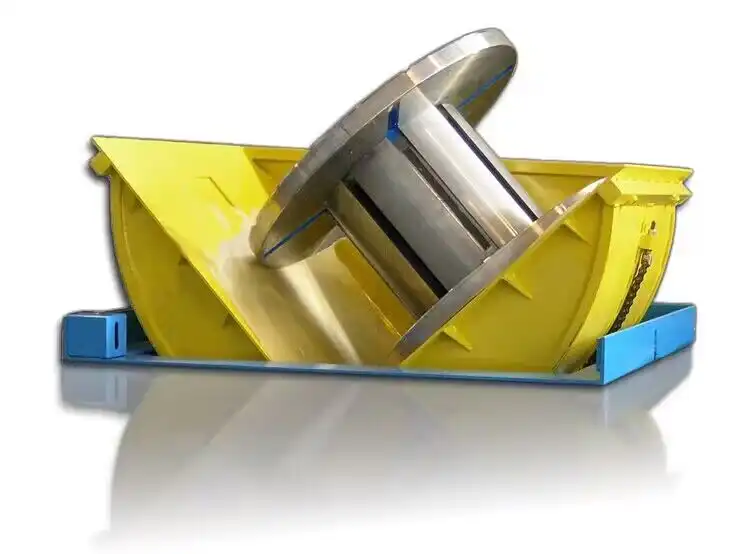

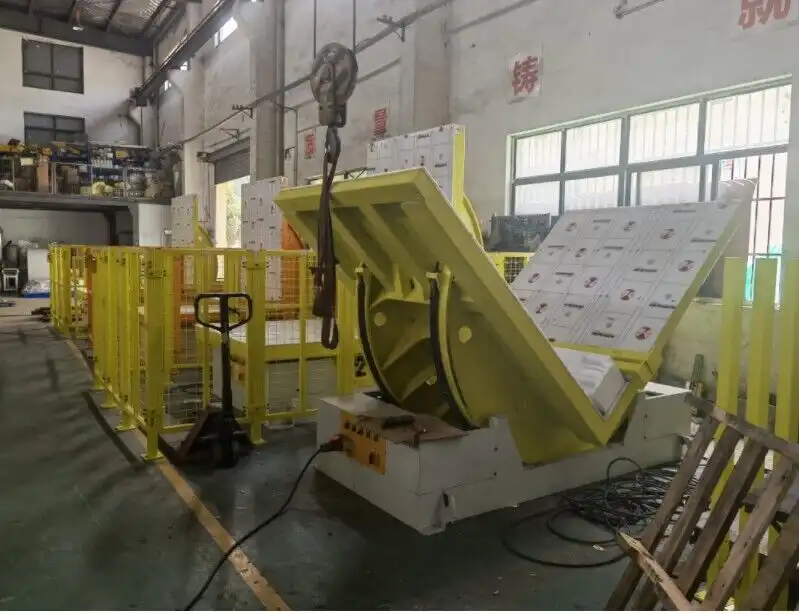

* *Caption: Die Mould Upender 2*

*

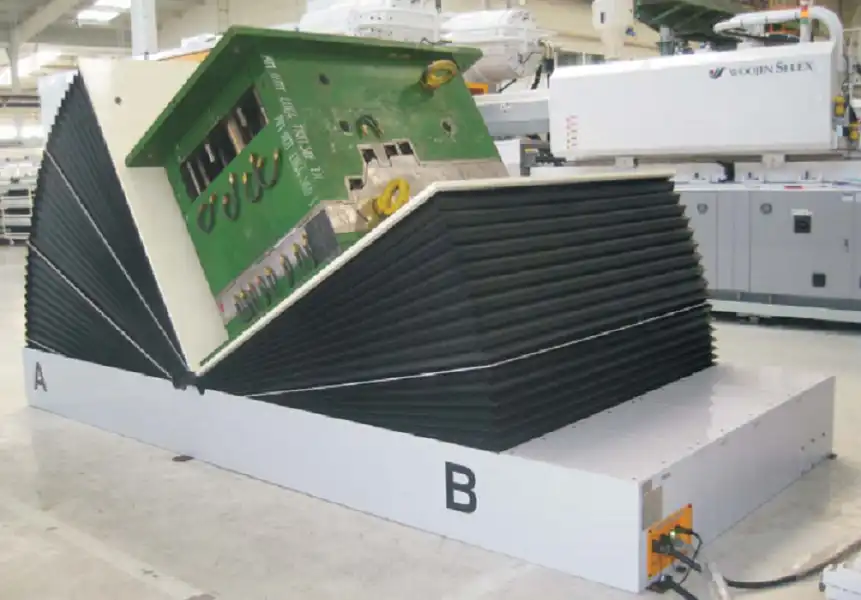

* *Caption: Flipper Lift Table*

*

* *Caption: Hydraulic Coil Upender for 10T*

*

* *Caption: Hydraulic Tilter*

*

* *Caption: Load Inverter*

*

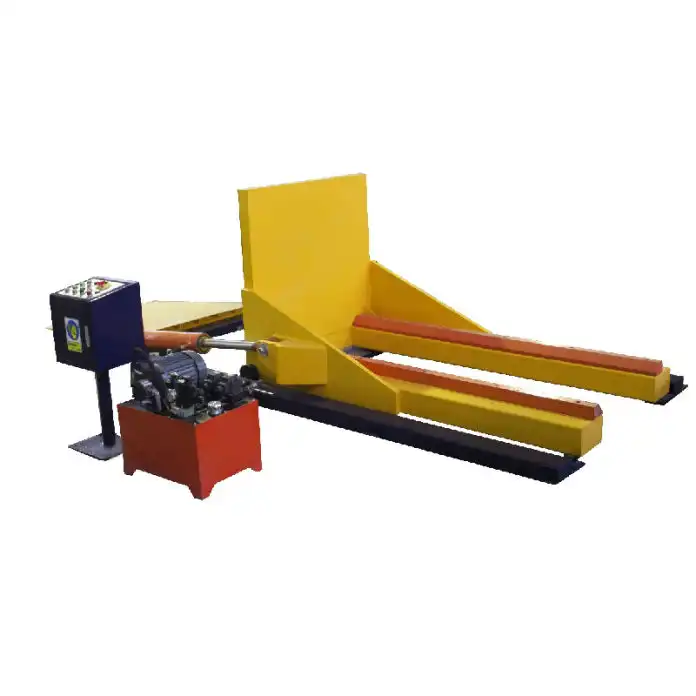

* *Caption: Mechanical Upender with Sliding Table*

*

* *Caption: Mold Flipper Table 180° Mold Flipper*

*

* *Caption: Mould Tilter*

*

* *Caption: Paper Pile Turner*

*

* *Caption: Roll Upender*

*

* *Caption: Special Designed Upender*

*

* *Caption: Spool Drum Tilter*

*

* *Caption: Steel Sheet Inverter Upender*

*

* *Caption: Upender with Conveyor*

*

* *Caption: Floor Base Hydraulic Upender*

*

* *Caption: Coil Tilter Upender*

*

* *Caption: Hydraulic Upenders*

*

* *Caption: Coil Tilter Upender*

*

* *Caption: Coil Tilter*

*

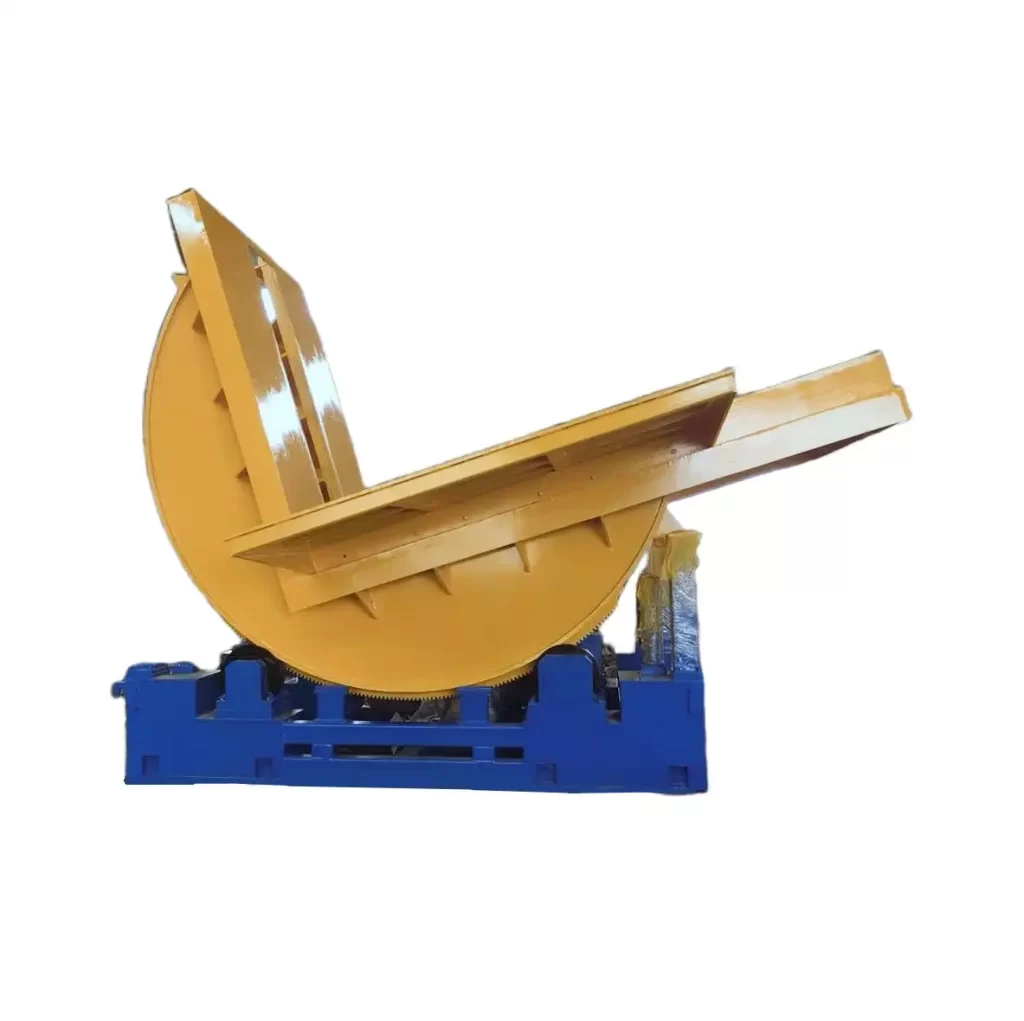

* *Caption: Mold Tilter*

*

* *Caption: 180° Load Inverter*

*

* *Caption: Die Mould Upender*

*

* *Caption: Mould Tilter Upender*

*

* *Caption: Coil Tilter*

*

* *Caption: Coil Tilter Upender*

*

* *Caption: Mould Tilter*

*

* *Caption: Die Mould Upender*

*

* *Caption: Mould Tilter*

*

* *Caption: Mould Tilter Upender*

*

* *Caption: Coil Tilter Upender*

*

* *Caption: Cable Coil Tilter*

*

* *Caption: Mould Tilter Upender*

*

* *Caption: Mould Tilter*

*

* *Caption: Coil Tilter Upender*

*

* *Caption: Steel Sheet Inverter & Upender1*

*

* *Caption: Steel Sheet Inverter & Upender*

*

* *Caption: Steel Sheet Inverter & Upender*

*

* *Caption: Steel Sheet Inverter & Upender*

*

* *Caption: Spool Drum Tilter*

*

* *Caption: Spool Drum Tilter*

*

* *Caption: Spool Drum Tilter*

*

* *Caption: Spool Drum Tilter*

*

* *Caption: Spool Drum Tilter*

*

* *Caption: Die Mould Upender*

*

* *Caption: Mechanical Upender with Sliding Table1*

*

* *Caption: Load Upender*

*

* *Caption: Die Mould Upender*

*

* *Caption: Special Designed Upender*

*

* *Caption: Die Mould Upender*

*

* *Caption: Mechanical Upender with Sliding Table*

*

* *Caption: Mechanical Upender with Sliding Table*

*

* *Caption: Mechanical Upender with Sliding Table*

*

* *Caption: Coil Transfer Car*

*

* *Caption: Coil Transfer Car*

*

* *Caption: Upender with Conveyor*

*

* *Caption: Upender with Conveyor*

*

* *Caption: Upender with Conveyor*

*

* *Caption: Upender with Conveyor*

*

* *Caption: Mould Flip Table*

*

* *Caption: Mould Tilter*

*

* *Caption: Mould Tilter*

*

* *Caption: Mould Tilter with Worm Gear Motor*

*

* *Caption: Flipper*

*

* *Caption: Hydraulic Tilter*

*

* *Caption: Hydraulic Upender 10T ZT*

*

* *Caption: Hydraulic Upender 10T*

*

* *Caption: Hydraulic Upender 10T*

*

* *Caption: Hydraulic Upender 10T*

*

* *Caption: Hydraulic Tilter*

*

* *Caption: Hydraulic Tilter*

*

* *Caption: Hydraulic Upenders*

*

* *Caption: Mold Flipper and Tipper*

*

* *Caption: Mold Flipping Table*

*

* *Caption: Flipper Table*

*

* *Caption: Fhopepack Pallet Inverter*

*

* *Caption: Stationary Pallet Inverter*

*

* *Caption: Stationary Pallet Inverter*

*

* *Caption: Stationary Pallet Inverter*

*

* *Caption: Stationary Pallet Inverter*

*

* *Caption: Stationary Pallet Inverter*

*

* *Caption: Stationary Pallet Inverter*

*

* *Caption: Stationary Pallet Inverter*

*

* *Caption: Stationary Pallet Inverter*

*

* *Caption: Mold Flipper Table 180° Mold Flipper*

*

* *Caption: Coil Upender Tilter*

*

* *Caption: Coil Upender Tilter*

*

* *Caption: Special Size Upender*