Choosing the Right Prestressed Steel Wire Coil Packing Machine: Vertical vs. Horizontal Solutions

Prestressed steel wire coils, often large and heavy, present significant challenges for manual packaging. Ensuring these coils are securely wrapped is crucial for protection during transport and storage, as well as for operator safety. Manual methods are often slow, inconsistent, and carry risks.

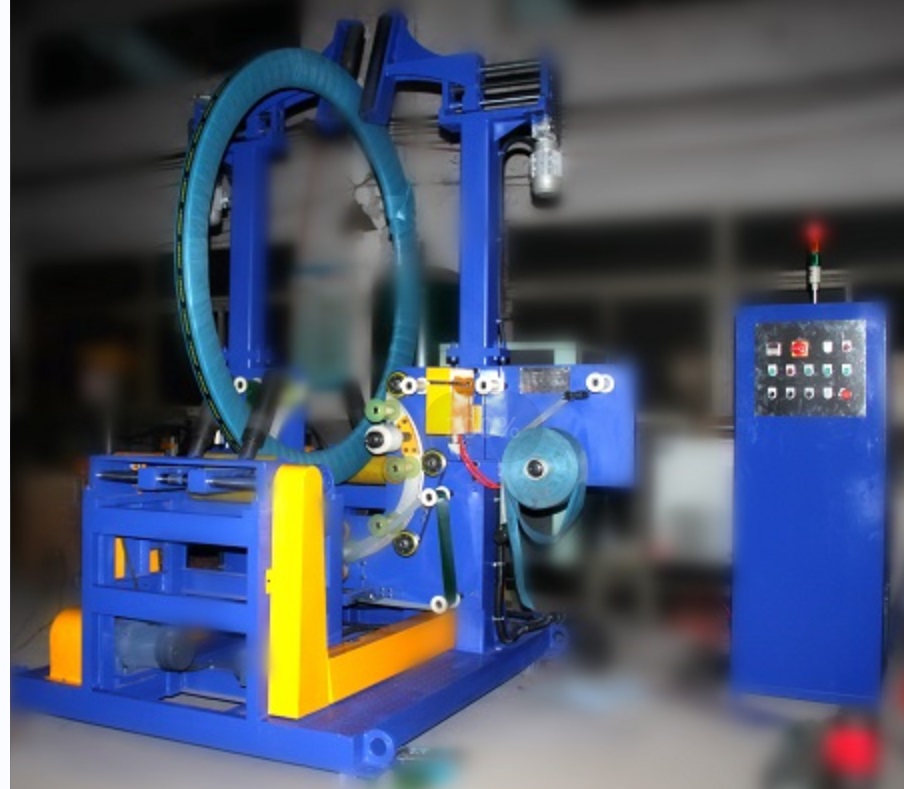

Automated packing machines offer a robust solution. FHOPE produces two primary types of steel wire coil packing machines designed specifically for prestressed wire, enhancing both packing speed and coil protection: vertical and horizontal wrappers. Understanding the differences, advantages, and disadvantages of each type is key to selecting the optimal solution for your operation.

Why Automate Prestressed Steel Wire Coil Packing?

Transitioning from manual to automated packing offers several key benefits:

- Improved Safety: Reduces manual handling of heavy and potentially unstable coils, minimizing injury risks.

- Enhanced Product Protection: Consistent stretch film application provides superior protection against moisture, dust, and physical damage.

- Increased Efficiency: Automated machines significantly speed up the packing process compared to manual methods, boosting throughput.

- Consistent Wrap Quality: Ensures every coil is wrapped to the same standard, improving load stability and appearance.

- Reduced Labor Costs: Frees up personnel for other tasks, optimizing workforce allocation.

A. Vertical Prestressed Wire Coil Packing Machines

Vertical packing machines wrap the coil while it remains in its standard "eye-to-the-sky" orientation.

How it Works:

The coil is typically loaded vertically onto the machine's wrapping station. A rotating ring or carousel carrying the stretch film then revolves through the eye of the coil and around its outer diameter, applying the film securely.

Key Considerations:

- Handling Height: Prestressed wire coils can have large outer diameters (OD), often exceeding 2000mm. A vertical machine's operating height can become substantial. The machine itself might be 1800-2200mm tall. Adding the coil height means the total handling height could reach approx. 4000mm, with the wrapping point potentially around 3000-3500mm. This height can pose challenges for crane operators during loading and unloading.

- Pit Installation: As shown in the video, installing the machine in a pit can lower the working table to floor level. This significantly improves the ease and safety of loading coils, especially when using cranes.

- Footprint: Vertical wrappers generally have a more compact machine footprint compared to horizontal models.

- Film Tension: Systems often incorporate idler rolls or powered film unwind mechanisms to maintain consistent and tight film application.

- Adjustments: Changing between different coil diameters may require manual adjustments to film guides and tensioners.

- Volume: Suitable for medium to high production volumes where continuous operation is needed.

B. Horizontal Prestressed Wire Coil Packing Machines

Horizontal machines handle the coil in a "lying down" or "eye-to-the-side" orientation, loading it onto support rollers.

a. Fixed Roller Station Solution

This configuration uses a fixed set of support rollers and a wrapping station that moves to accommodate loading/unloading.

How it Works:

The coil is placed horizontally onto a roller table. The wrapping station, which performs the eye-through wrapping, is designed to move in and out of position. This retraction allows clear access for loading and unloading the coil from above using a crane.

Features:

- Loading Access: The movable wrapping station simplifies placing large coils (OD > 2000mm) onto the rollers.

- Handling Aids: Specialized clamps compatible with cranes can further facilitate easier and safer coil handling during loading/unloading.

Explore more wire coil packing solutions: https://www.fhopepack.com/Wire-coil-wrapping-machine/

b. Adjustable Roller Station Solution

This horizontal design features adjustable support rollers, making it highly versatile for a wide range of coil diameters.

How it Works:

This PC wire coil packing machine demonstrates adaptability for large OD ranges (e.g., 1000-2500mm, and potentially up to 1500-3500mm or larger). The key feature is its four supportive rollers connected to lead screws and driven by motors. These rollers can automatically retract or extend to precisely accommodate different coil ODs.

Features:

- Versatility: Ideal for operations handling coils with significant variations in outer diameter.

- Application: A common solution for packaging extremely large cylindrical items, including PC wire, large bearings, flanges, and similar products.

General Considerations for Horizontal Machines:

- Loading Ease: The horizontal orientation generally makes loading and unloading easier, especially with forklifts or cranes, as the coil is handled in a more stable position.

- Film Tension: Achieving optimal film tension can be more complex than vertical wrapping, as gravity doesn't assist in pulling the film tight. Well-designed film unwind and tensioning systems are crucial.

- Coil Protection: Support rollers are often padded or made of non-abrasive materials to prevent scratching or damaging the coil surface during rotation for wrapping.

- Changeover: Adjusting for different coil diameters can be quicker and easier compared to vertical machines, especially with the adjustable roller solution.

- Footprint: Horizontal machines typically require more floor space than vertical models.

- Cycle Time: Wrapping cycle times may be slightly slower compared to some high-speed vertical configurations, making them potentially better suited for lower to medium production volumes unless highly automated.

Key Factors When Choosing a Machine

Selecting the right prestressed steel wire coil packing machine depends on several operational factors:

- Coil Specifications: Consider the typical range of Inner Diameter (ID), Outer Diameter (OD), width, and weight of the coils you handle.

- Production Volume: Assess your required throughput (coils per hour/shift) to ensure the machine speed meets demand.

- Handling Equipment: Factor in your existing or planned loading/unloading methods (crane type, forklift capacity).

- Available Space: Evaluate your factory floor space and ceiling height limitations for machine installation.

- Automation Level: Determine if the machine needs to be standalone or integrated into a larger automated production line.

- Packaging Material: Specify the type and specifications of the stretch film or other packing materials required.

Conclusion

Both vertical and horizontal prestressed steel wire coil packing machines offer effective solutions for automating a challenging packaging task.

- Vertical machines are often more compact and potentially faster but can present handling challenges due to height, sometimes requiring pit installations.

- Horizontal machines generally offer easier coil handling, especially for very large diameters, and faster changeovers, but may require more floor space and careful tension control design.

By carefully evaluating your specific coil dimensions, production requirements, handling capabilities, and facility constraints, you can choose the packing machine type that best optimizes safety, efficiency, and product protection for your prestressed steel wire operations.