Understanding Panel and Board Shrink Packing Machines: Functionality and Applications

In modern manufacturing and logistics, protecting large, flat items like panels, boards, doors, and sheet materials during storage and transit is crucial. Damage from moisture, dust, or handling can lead to significant costs and delays. Panel and Board Shrink Packing Machines offer an efficient and reliable solution for safeguarding these valuable products.

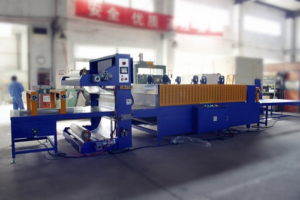

Below is an example showcasing the operation of such a machine:

What is a Panel and Board Shrink Packing Machine?

A panel and board shrink packing machine is specialized industrial equipment designed to wrap large, typically flat items in a protective layer of shrink film. This film, often made from materials like Polyolefin or PVC, conforms tightly to the product's shape when exposed to heat, creating a secure, weather-resistant barrier. These machines are engineered to handle a variety of product dimensions, making them versatile for industries dealing with items such as plywood, drywall, furniture components, and large panels.

How Does It Work? The Shrink Wrapping Process

Understanding the operational flow helps appreciate the machine's efficiency:

- Film Dispensing: The machine feeds the appropriate width of shrink film from a roll.

- Product Conveying: Panels or boards are transported into the wrapping zone via a conveyor system, often designed to handle heavy loads.

- Sealing: The film is draped over or around the product. A sealing mechanism (like an impulse sealer) creates a seam, fully encapsulating the item. Excess film is typically trimmed automatically.

- Heat Application (Shrink Tunnel): The wrapped product moves through an integrated heat tunnel. Controlled hot air circulation causes the film to shrink uniformly, conforming tightly around the panel or board.

- Cooling & Exit: After exiting the tunnel, the film cools, solidifying the tight wrap, ready for handling or shipment.

Key Specifications Example

While specifications vary based on the model and customization, here's a representative example of a semi-automatic configuration:

Disclaimer: The parameters below are illustrative and may not perfectly match the equipment shown in the video. For precise specifications tailored to your needs, please consult directly with suppliers.

- Machine Type: Semi-automatic Panel and Board Shrink Wrapper

- Maximum Product Dimensions:

- Length: 3000mm

- Width: 1200mm

- Thickness: 100mm

- Compatible Film Types: Polyolefin, PVC

- Operating Temperature: Adjustable, up to 300°C

- Conveyor Speed: Variable, typically up to 10 meters per minute

- Power Supply: 380V, 50Hz, Three Phase (common industrial standard, may vary)

- Sealing Type: Impulse seal with automatic film cutter

- Approx. Footprint (L x W x H): 4500mm x 1800mm x 1800mm

- Approx. Weight: 900kg

- Operational Noise: Generally below 80 dB

Key Industry Applications

The versatility of panel and board shrink wrappers makes them valuable across several sectors:

1. Construction and Building Supplies

Manufacturers of plywood, drywall, insulation boards, and other construction panels rely on these machines. The tight seal protects materials (up to specified thicknesses like 100mm) from environmental factors like moisture and dirt during yard storage and transportation to job sites, preventing warping and ensuring material integrity upon arrival.

2. Furniture Manufacturing

Large, flat components such as tabletops, cabinet sides, and shelving boards are susceptible to scratches and surface damage. Shrink wrapping provides robust protection while often allowing visual inspection through the clear film. This enhances product presentation and safeguards quality from the factory to the end-user.

3. Appliance Industry

Large panels used in appliances (e.g., refrigerators, washing machines, ovens) require pristine surfaces. Shrink wrapping ensures these components remain free from dust and scratches during internal logistics and final assembly, upholding the aesthetic standards critical for consumer satisfaction.

Core Benefits of Using Shrink Wrapping for Panels and Boards

- Enhanced Protection: Creates a barrier against moisture, dirt, dust, and superficial damage.

- Improved Load Stability: Tightly wrapped bundles are often more stable for handling and stacking.

- Increased Efficiency: Automates the packaging process compared to manual methods.

- Versatility: Capable of handling various sizes and product types within their specified limits.

- Professional Presentation: Offers a clean, tamper-evident packaging solution.

Conclusion

Panel and Board Shrink Packing Machines are indispensable assets in industries that produce or handle large, flat materials. By providing robust protection, enhancing logistical efficiency, and ensuring product integrity, these machines play a vital role in modern supply chains. Understanding their functionality, specifications, and applications can help businesses optimize their packaging operations for better results and reduced product loss.