Optimizing a Steel Coil Packing Line: A Case Study in Automation

In today's highly competitive manufacturing landscape, optimizing efficiency and productivity is crucial for success. This is particularly true in industries handling heavy and sensitive materials like steel coils, where the precision and reliability of packaging directly impact output quality and operational costs. This article examines how a major steel coil manufacturer addressed common industry challenges by upgrading their steel coil packing line, significantly boosting performance and operational efficiency through strategic automation and advanced technology integration.

1. Understanding the Manufacturer's Operational Challenges

Effective solutions begin with a thorough analysis of the existing problems. The manufacturer, handling a high volume of steel coils daily, faced several issues stemming from an outdated, labor-intensive packing system:

- Inconsistent Packaging Quality: Manual handling often resulted in uneven wrapping and strapping, increasing the risk of coil damage during transport and storage.

- High Labor Costs: Significant manpower was required to maintain packing throughput, leading to high operational expenditures.

- Slow Production Speed: Manual processes created bottlenecks in the packing line, limiting overall plant productivity and throughput.

- Safety Concerns: Manually handling heavy steel coils posed significant ergonomic risks and potential for accidents, impacting worker safety and leading to occasional injuries.

The primary objective was clear: implement an automated steel coil packing solution to resolve these issues and enhance overall operational efficiency.

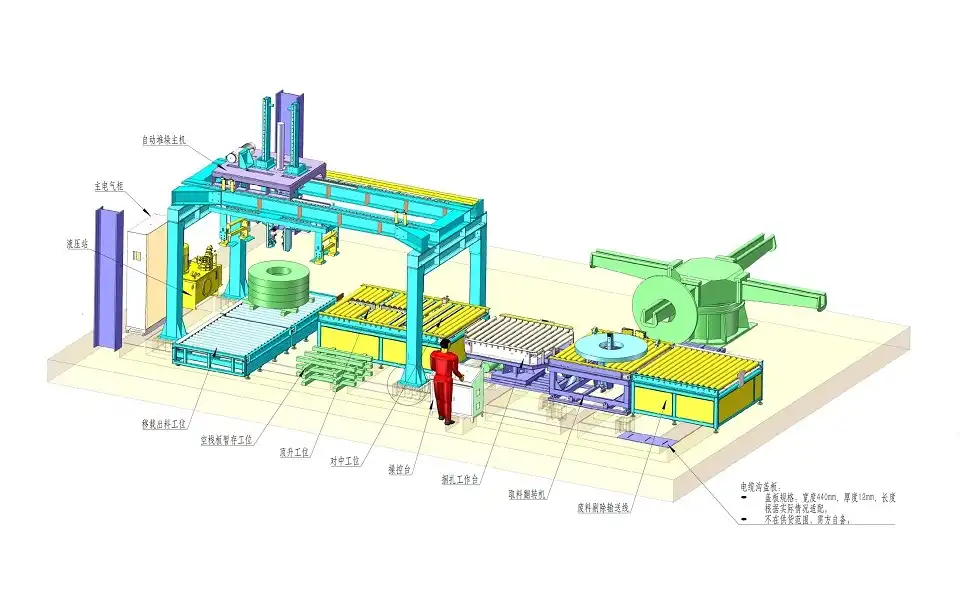

2. Designing an Effective Automated Steel Coil Packing Line

With a clear understanding of the pain points, the focus shifted to designing a customized automated solution tailored to the manufacturer's specific requirements. The design centered on three core objectives: increasing speed, ensuring consistent packaging quality, and improving worker safety.

Key Design Goals: Automation for Efficiency

Introducing automation was fundamental. Replacing manual tasks with automated systems drastically reduced the cycle time for packaging each coil. The engineered solution incorporated key automated components:

- Automated Coil Loading and Positioning: Precisely placed coils onto the line.

- Automated Strapping: Applied PET or steel straps consistently and securely.

- Automated Wrapping: Used stretch film or VCI paper for protection against elements and corrosion.

- Integrated Conveying System: Moved coils smoothly between stations.

These machines operated in a coordinated sequence, enabling continuous flow and minimizing human error.

Ensuring Consistent and Secure Packaging

A critical feature of the automated system was its capability to deliver uniform packaging for every coil. Automated strapping and wrapping machines were programmed for precise tension control and material application, securing coils effectively to minimize shifting during transit. This standardization enhanced product protection and reduced customer complaints related to shipping damage.

Enhancing Workplace Safety

Addressing worker safety was paramount. The implementation of automated coil handling systems—including lifting, tilting, and conveying—significantly reduced the need for manual interaction with heavy loads. This automation minimized the risk of musculoskeletal injuries and accidents associated with manual handling, contributing to a safer work environment, aligning with industry best practices promoted by organizations like OSHA.

3. Implementation Strategy and Overcoming Hurdles

Integrating a new automated system into an existing manufacturing environment requires careful planning and execution to overcome potential challenges.

Integration with Existing Infrastructure

A primary hurdle involved seamlessly integrating the new automated packing line with the manufacturer's existing production systems. Custom interfaces and communication protocols (often involving PLCs - Programmable Logic Controllers) were developed to ensure the packing line synchronized effectively with upstream processes. This meticulous integration planning minimized disruption during installation and facilitated a smooth transition.

Workforce Training and Adaptation

Transitioning the workforce to operate and maintain the new technology was crucial. Comprehensive training programs, combining classroom instruction with hands-on practice, were provided. This empowered employees to confidently manage the automated system, ensuring its optimal performance and fostering acceptance of the new processes.

4. Measurable Results: Improved Performance and Efficiency

Following the successful implementation, the manufacturer experienced significant and immediate improvements across key performance indicators:

Enhanced Productivity and Throughput

Automation dramatically increased packing speed, reducing the time required per coil by nearly 50%. This substantial throughput increase allowed the facility to handle higher production volumes and meet growing customer demand without proportional increases in labor.

Significant Cost Savings

The reduction in manual labor requirements led to an estimated 30% decrease in associated labor costs. Furthermore, the enhanced packaging consistency significantly reduced product damage rates, lowering costs related to rework, returns, and replacements, contributing positively to the bottom line.

Improved Workplace Safety

The automation of hazardous manual handling tasks resulted in a remarkable 70% reduction in reported workplace incidents related to coil packaging. This not only fostered a safer culture but also reduced costs associated with workers' compensation and lost time.

Higher Packaging Quality and Customer Satisfaction

Consistent application of strapping and wrapping materials ensured superior package integrity. Customers received coils in better condition, leading to fewer complaints and strengthening the manufacturer's reputation for quality and reliability.

5. Long-Term Value and Return on Investment (ROI)

While representing a significant capital investment, the automated steel coil packing line delivered substantial long-term value and a strong return on investment.

Reduced Maintenance Costs

Modern automated systems, coupled with a proactive preventive maintenance schedule, generally exhibit higher reliability and lower long-term maintenance costs compared to manual-intensive operations or older equipment. Predictive diagnostics can further minimize unplanned downtime.

Scalability and Future-Proofing

The modular design of the automated system provided inherent scalability. The packing line could be adapted or expanded to accommodate future increases in production volume or changes in packaging requirements, ensuring the investment remains viable and supportive of business growth. Industry analyses often suggest typical ROI periods for such automation projects range from 18 to 36 months, depending on scale and utilization (Source: MHI Annual Industry Report insights - conceptual link).

6. The Importance of Selecting the Right Automation Partner

This case underscores the value derived from collaborating with an experienced automation solutions provider. Key factors when selecting a partner include:

- Industry Expertise: Deep understanding of the specific challenges in steel coil handling and packaging.

- Customization Capability: Ability to design and implement solutions tailored to unique operational needs.

- Proven Track Record: Demonstrated success in similar automation projects.

- Comprehensive Support: Offering robust installation, training, and ongoing maintenance services.

Choosing a provider with these qualities is instrumental in achieving desired outcomes and maximizing the long-term benefits of automation.

Conclusion

By strategically implementing an automated steel coil packing line, the manufacturer successfully addressed critical operational challenges, achieving significant gains in performance, safety, and efficiency. The project demonstrated tangible benefits, from reduced labor costs and enhanced throughput to improved packaging quality and a safer working environment. This transformation highlights the power of automation within the steel industry. For manufacturers facing similar hurdles, investing in tailored automation solutions is not merely an upgrade—it's a necessary step towards achieving peak operational performance and maintaining a competitive edge in a demanding global market.