Enhancing Protection for Doors and Windows with Orbital Stretch Wrapping Technology

Fine doors and windows represent significant value, not just in materials but also in craftsmanship. Ensuring these products reach their destination – whether a distribution center, job site, or customer – in pristine condition is paramount. Damage during storage or transit leads to costly replacements, project delays, and potential harm to a manufacturer's reputation. This makes robust packaging solutions, particularly customized wrapping machines, essential for the fenestration industry.

Understanding the need for specialized protection, advancements in packaging technology offer effective methods. Orbital stretch wrapping has emerged as a highly efficient solution for safeguarding doors and windows.

The Role of Specialized Wrapping Machines

Wrapping machines designed specifically for doors and windows provide tailored protection against common hazards like scratches, impacts, moisture, and dust. Two primary configurations address different packaging needs within the production and shipping workflow:

1. Single Item Wrapping

This approach is ideal for applying a protective layer, often shrink film or stretch wrap, to individual doors or windows as they come off the production line.

- Process: Typically integrated directly into the production flow via conveyors. The machine wraps each unit securely.

- Benefit: Provides immediate, individual protection, readying the product for storage, local delivery, or the next stage of packaging (like unitizing). This method ensures each piece is shielded early in the process.

2. Unitizing Stacks with Horizontal Wrappers

For bulk handling and transport, unitizing multiple doors or windows into a single, stable stack is crucial. A horizontal wrapping machine performs this function effectively.

- Process: Doors or windows are stacked (often separated by protective material), and the entire stack is moved through the horizontal wrapper. An orbital ring dispenses stretch film, tightly securing the bundle.

- Benefit: Creates a stable, secure load unit, minimizing movement and potential damage during forklift handling, warehousing, and long-haul shipping. This method is key for efficient logistics and load integrity.

For more details on specific machinery designed for these applications, see examples of door packing machine solutions.

Orbital Stretch Wrapping: A Closer Look

Orbital stretch wrappers are particularly well-suited for long, flat, or awkwardly shaped items like doors and windows.

- Mechanism: The product passes horizontally through a rotating ring carrying the stretch film roll. The ring orbits the product, applying film under controlled tension.

- Advantages:

- Complete Coverage: Ensures film encases the entire product or stack.

- Tension Control: Applies consistent force for load stability without damaging the product.

- Versatility: Can handle varying product lengths and profiles, including horizontal sliding doors, vertical sliders, steel doors, and custom window shapes.

- Material Efficiency: Modern machines often feature pre-stretch capabilities, elongating the film before application, which can significantly reduce material consumption and cost.

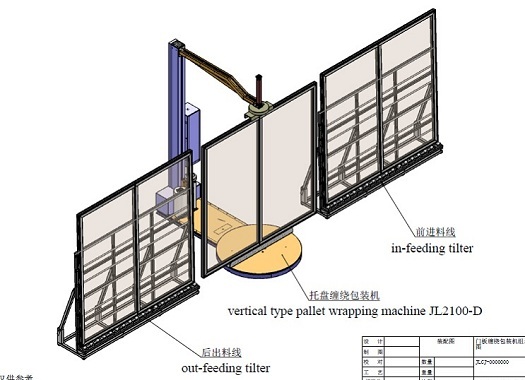

Here is an example demonstrating the orbital wrapping process, often used for securing larger items or palletized goods:

Key Considerations for Implementation

Selecting the right wrapping system involves evaluating several factors:

- Product Range: Dimensions, weight, and shape variations of doors/windows being produced.

- Throughput Needs: Required wrapping speed (units per hour) to match production output.

- Automation Level: Manual, semi-automatic, or fully automatic systems integrated with conveyors and potentially robotic handling.

- Film Type: Choosing the appropriate stretch film (gauge, width, properties) for the required protection and load stability.

- Space Availability: The machine's footprint and required clearance within the facility layout.

- Integration: Compatibility with existing upstream and downstream production line equipment.

Benefits Beyond Protection

Investing in an appropriate automated or semi-automated wrapping solution offers significant operational advantages:

- Reduced Damage: Consistent, high-quality wrapping minimizes transit and handling damage.

- Labor Savings: Automation reduces the manual labor required for wrapping.

- Increased Throughput: Automated systems can operate faster and more consistently than manual methods.

- Material Cost Reduction: Pre-stretch systems optimize film usage.

- Improved Safety: Creates stable loads, reducing risks during handling and transport.

- Professional Presentation: Well-wrapped products project quality and care.

Conclusion

For manufacturers of doors and windows, ensuring product integrity from the factory floor to the final installation point is critical. Orbital stretch wrapping technology, whether applied to single items or unitized stacks, provides a robust, efficient, and often customizable solution. By carefully considering production needs and evaluating the available wrapping systems, manufacturers can significantly enhance product protection, streamline operations, and ultimately safeguard their bottom line and reputation in a competitive market. Implementing the right packaging machinery is not just an operational choice; it's an investment in quality assurance and customer satisfaction. For further reading on packaging standards, consult resources from organizations like the Packaging Machinery Manufacturers Institute (PMMI).