Optimizing Steel Coil Handling: Inside an Automated Packaging Line

The efficient and safe handling of steel coils is a critical aspect of modern metal production and processing. As demands for throughput, consistency, and worker safety increase, automated packaging lines have become essential. Understanding the components and capabilities of these systems is key for fabricators and processors looking to enhance their operations. Let's explore the typical structure and benefits of a modern coil packaging line.

The Need for Automation in Coil Packaging

Manually packaging large, heavy steel coils presents significant challenges:

- Safety Risks: Handling heavy coils carries inherent risks for personnel.

- Efficiency Bottlenecks: Manual processes can be slow, limiting overall plant throughput.

- Inconsistent Quality: Variations in manual strapping or wrapping can affect package integrity and product protection.

- Labor Intensity: Manual packaging requires significant manpower.

Automated systems address these challenges by integrating various processes into a seamless, efficient workflow.

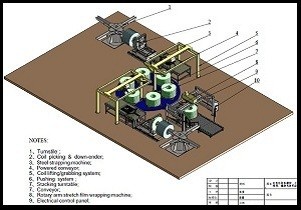

Key Components of an Automated Coil Packaging System

A comprehensive coil packaging line typically integrates several key stages:

Coil Receiving and Preparation:

- Coils arrive from upstream processes (e.g., slitters, annealing lines) often via conveyor, crane, or coil car.

- A feeding and stacking device receives the coils. Depending on the orientation required for packaging, this stage might include equipment like coil tilters or upenders.

- Indexing and centering mechanisms ensure proper positioning for subsequent operations.

Automated Strapping:

- Automatic strapping machines apply steel or PET straps circumferentially or through the eye of the coil.

- This secures the coil, prevents unwinding, and bundles multiple coils if required.

- Automated systems ensure consistent tension and strap placement, crucial for package stability during transport. Learn more about strapping standards from the Association of American Railroads (AAR) (Note: External link for illustrative purposes).

Robotic Palletizing:

- Once strapped, coils (or bundles) are often palletized for easier handling and storage.

- A palletizer robot, equipped with specialized grippers designed for coil handling, precisely picks the coils or coil packages.

- The robot places them onto pallets according to pre-programmed patterns, optimizing stability and space utilization. Robotic systems offer high repeatability and can handle significant weights safely.

Stack Forming and Output:

- A stack forming system organizes the loaded pallets into stable configurations suitable for warehousing or shipping.

- This may involve automated pallet dispensers and conveyors moving the completed stacks downstream.

- Additional steps like stretch wrapping or VCI (Volatile Corrosion Inhibitor) paper application can be integrated here for enhanced product protection.

automatic coil packing line Achieving High Throughput and Efficiency

Integrated, fully automated packaging lines can achieve significant throughput. Well-designed systems are capable of handling capacities in the range of 60-80 tons per hour, depending on coil size, weight, and the specific processes involved. This level of automation directly translates to:

- Increased Productivity: Minimizing manual intervention speeds up the entire packaging process.

- Improved Packaging Quality: Consistent application of straps and precise palletizing ensures package integrity.

- Enhanced Worker Safety: Automating heavy lifting and repetitive tasks reduces ergonomic risks and potential accidents.

- Reduced Operational Costs: Lower labor requirements and minimized product damage contribute to cost savings.

Visualizing the Process

Seeing these systems in action provides valuable insight into their operation.

(Video illustrating a typical automated coil handling and packaging sequence)

Conclusion

Automated steel coil packaging lines represent a significant technological advancement for the metal industry. By integrating feeding, strapping, robotic palletizing, and stack forming, these systems provide a robust solution for enhancing efficiency, ensuring packaging quality, and improving workplace safety. For facilities handling significant volumes of steel coils, investing in automation is a key strategy for maintaining competitiveness and meeting modern production demands.