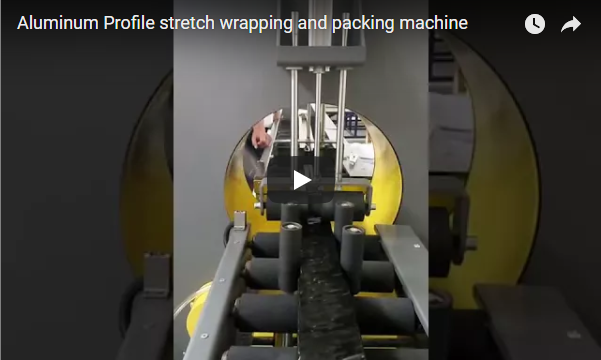

Handling and packaging long, often delicate aluminum rods and extruded profiles presents unique challenges in manufacturing and distribution. Ensuring product integrity while maintaining high throughput requires specialized automated solutions. This horizontal fully automatic wrapping and packing machine line is engineered specifically to address these needs, providing secure, unitized bundles optimized for shipping and storage. It efficiently handles various aluminum shapes, including angles, channels, flats, rounds, and complex custom extrusions.

1. Operational Workflow and Process Automation

The system employs a synchronized workflow to achieve continuous, high-speed operation:

- Infeed Conveying: Aluminum profiles are loaded onto the powered infeed conveyor. This section automatically aligns and spaces the products, preparing them for the wrapping cycle. Sensors detect product presence and dimensions to initiate the sequence.

- Wrapping Cycle: The core of the system is the orbital stretch wrapping unit. As the aligned profiles pass through the rotating ring, stretch film is applied orbitally around the bundle. The machine precisely controls film overlap and tension.

- Film Sealing and Cutting: Upon completion of the wrapping cycle (programmable based on length or sensor input), the film is automatically clamped, heat-sealed, and cut, ensuring a secure and tidy package finish.

- Outfeed Conveying: The fully wrapped bundle smoothly transitions onto the powered outfeed conveyor, ready for removal, labeling, or further downstream processing.

2. Key Design Features and Structural Components

The machine's robust design incorporates high-quality components for reliability and performance:

- Frame Structure: Constructed from heavy-duty welded steel for maximum stability and vibration damping during high-speed operation.

- Conveyor System: Motorized roller or belt conveyors (customizable) with variable speed drives (VSDs) ensure smooth product transfer and synchronization with the wrapping ring speed.

- Wrapping Ring Assembly: Features a durable ring drive system (often gear or belt-driven) supporting the film carriage. Advanced models include electromagnetic brakes or servo drives for precise start/stop positioning.

- Film Carriage & Pre-Stretch Unit: Equipped with a powered pre-stretch mechanism (typically 150-300%), significantly reducing film consumption while enhancing load containment force. Adjustable film tension control accommodates different product types and bundle requirements.

- Clamping and Pressing Devices: Pneumatic or hydraulic top and side presses gently stabilize the bundle during the wrapping process, preventing shifting and ensuring a tight, uniform wrap, especially critical for stacked or irregularly shaped profiles.

- Control System: Managed by a Programmable Logic Controller (PLC) with a user-friendly Human-Machine Interface (HMI) touch screen. This allows operators to set parameters, select wrapping programs, monitor status, and perform diagnostics. Photo-eye sensors detect product entry/exit and control cycle timing.

3. Technical Specifications Overview

While exact specifications vary based on model and customization, typical parameters include:

- Product Dimensions:

- Length: 1000mm – 12000mm (or longer, depending on configuration)

- Cross-section (Bundle): Customizable, e.g., 100x100mm up to 500x500mm (Width x Height)

- Maximum Load Capacity: 500kg – 4000kg (depending on conveyor and frame design)

- Wrapping Ring Speed: 20 – 90 RPM (adjustable)

- Conveyor Speed: 5 – 20 m/min (adjustable, synchronized)

- Stretch Film:

- Type: LLDPE Stretch Film

- Width: 100mm / 250mm / 500mm (model dependent)

- Thickness: 17 – 35 microns

- Powered Pre-stretch Ratio: Up to 300% (variable)

- Control System: PLC (e.g., Siemens, Allen-Bradley, Omron) with Touch Screen HMI

- Power Requirements: 380V/50Hz/3Ph or customized (e.g., 480V/60Hz/3Ph)

- Air Pressure: 0.5 – 0.7 MPa

4. Performance Advantages and Engineering Benefits

Implementing this automated wrapping line offers significant advantages:

- Enhanced Product Protection: The tight stretch film wrap shields aluminum surfaces from scratches, dirt, moisture, and handling damage during transit and storage.

- Improved Load Stability: Unitizes bundles securely, preventing shifting and ensuring safer, more stable loads for handling and transportation.

- Increased Throughput: Automated continuous operation significantly boosts packaging speed compared to manual or semi-automatic methods.

- Reduced Labor Costs: Minimizes manual handling requirements, freeing up personnel for other tasks.

- Optimized Film Consumption: Powered pre-stretch maximizes film yield, lowering material costs per package.

- Consistency and Uniformity: Delivers consistent wrapping quality and package appearance for every bundle.

- Operational Flexibility: Programmable controls allow easy adjustment for different product dimensions, bundle configurations, and wrapping requirements.

5. User Experience and System Integration

Designed with the operator and plant integration in mind:

- Intuitive Operation: The HMI provides clear menus for parameter setup, recipe storage, and operational control.

- Ease of Maintenance: Components are designed for accessibility, simplifying routine maintenance like film roll changes and lubrication.

- Safety Features: Equipped with safety guarding, emergency stops, light curtains (optional), and interlocks compliant with relevant safety standards.

- Integration Capability: Can be seamlessly integrated into larger automated production or packaging lines, communicating with upstream and downstream equipment.

6. Typical Applications

This type of horizontal wrapping machine is essential in industries dealing with long aluminum products:

- Aluminum Extrusion Plants

- Metal Service Centers and Distributors

- Window and Door Manufacturers

- Building Material Suppliers

- Furniture Manufacturers

Conclusion: Enhancing Aluminum Profile Packaging Efficiency

The horizontal automatic wrapping machine represents a significant advancement in packaging technology for aluminum rods and profiles. By combining robust mechanical design, precise control systems, and efficient material handling, it delivers consistent, high-quality protective packaging. This full-automatic wrapping and packing line not only safeguards valuable products but also enhances operational efficiency, reduces costs, and improves overall supply chain performance for manufacturers and distributors handling aluminum extrusions. Its adaptability ensures it can meet diverse packaging needs within its operational capacity.