Optimizing Heavy Steel Coil Packaging: The Role of Roller Stations and Automated Wrapping

Handling and packaging large, heavy steel coils presents significant challenges in the metal fabrication and processing industry. Ensuring these coils are securely wrapped, strapped, and protected is crucial not only for preserving material quality during transport and storage but also for maintaining operational safety and efficiency. Roller stations are fundamental components in modern coil packaging lines, facilitating the controlled rotation and positioning necessary for effective automated or semi-automated packaging processes.

This article explores the function and importance of roller stations in heavy steel coil packaging, detailing their key components, operational processes, and considerations for implementation.

The Critical Importance of Proper Steel Coil Packaging

Inadequate packaging of steel coils can lead to costly consequences, including:

- Surface Damage: Scratches, dents, and abrasions compromise the coil's surface quality.

- Corrosion: Exposure to moisture and environmental factors can initiate rust and corrosion.

- Edge Damage: Improper handling or securing can damage the coil edges, affecting usability.

- Telescoping/Unwinding: Poorly secured coils can begin to unwind or telescope, creating handling hazards and material loss.

- Safety Risks: Unstable or improperly packaged coils pose significant risks during lifting, movement, and storage.

Robust packaging solutions, often centered around a well-designed roller station, mitigate these risks, ensuring coils arrive at their destination in optimal condition.

Understanding Roller Stations for Steel Coil Packaging

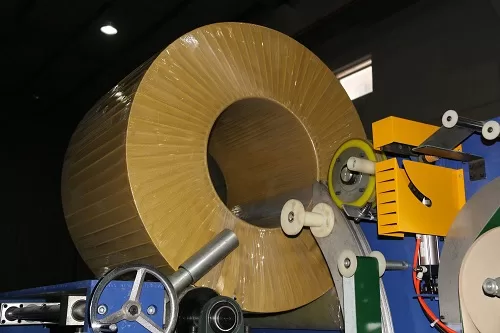

A roller station, in the context of coil packaging, is a specialized piece of equipment designed to support and rotate heavy steel coils. It typically forms part of a larger automated or semi-automated packaging line. Its primary function is to hold the coil securely while allowing it to rotate about its central axis (eye-to-sky or eye-to-wall orientation), enabling the application of various packaging materials like stretch film, paper, VCI (Volatile Corrosion Inhibitor) paper, and steel or plastic strapping.

Key Components and Features of Modern Roller Stations

Effective roller stations integrate several critical features designed for durability, efficiency, and safety:

- Heavy-Duty Construction: Given that steel coils can weigh anywhere from a few tons to over 30 tons, the station's frame, rollers, and bearings must be exceptionally robust and engineered to handle the maximum anticipated coil weight and dynamic forces during rotation.

- Powered Carrier Rollers: Strong, durable rollers, often driven by high-torque electric motors with variable frequency drives (VFDs), provide the necessary support and controlled rotation for the wrapping and strapping processes. VFDs allow for precise speed control, accommodating different coil sizes and packaging requirements.

- Integration with Coil Handling Equipment: Roller stations are designed to interface seamlessly with upstream and downstream material handling systems, such as overhead cranes, C-hooks, coil cars, turnstiles, and automated guided vehicles (AGVs), allowing for efficient loading and unloading of coils.

- Packaging System Integration: The station serves as the central point for various packaging operations. This can include:

- Wrapping: Integration with through-the-eye wrapping machines that dispense stretch film, VCI paper, or other protective wraps as the coil rotates.

- Strapping: Accommodating automatic strapping heads for circumferential or through-the-eye steel or PET strapping.

- Covering: Facilities for applying edge protectors (like H-protectors), full steel sheet covers, or other protective elements.

- Control Systems: Programmable Logic Controllers (PLCs) manage the sequence of operations, synchronizing roller rotation speed with wrapping and strapping equipment for automated cycles. Human-Machine Interfaces (HMIs) provide operator control and monitoring capabilities.

- Safety Features: Essential safety elements include emergency stop buttons, safety interlocks, light curtains or area scanners to detect personnel presence, physical guarding around moving parts, and overload protection mechanisms. Compliance with relevant safety standards (e.g., OSHA guidelines or equivalent regional standards) is paramount.

- Coil Centering and Support: Mechanisms may be included to ensure the coil is properly centered on the rollers and adequately supported to prevent wobbling or displacement during rotation.

- (Optional) Coil Measurement and Identification: Some advanced stations incorporate sensors or vision systems to measure coil dimensions (diameter, width) and integrate with tracking systems via barcode scanning or RFID tag reading.

steel coil packing machine for sale The Packaging Process on a Roller Station

A typical automated packaging sequence involving a roller station might include these steps:

- Loading: A coil is transported (e.g., by crane or coil car) and placed onto the carrier rollers of the station.

- Positioning/Centering: The coil is adjusted to the correct position for wrapping/strapping.

- Rotation & Wrapping: The PLC initiates rotation via the powered rollers. Simultaneously, the wrapping system (e.g., a through-eye wrapper) applies layers of stretch film or protective paper.

- Strapping: Once wrapping is complete (or at designated points), the strapping head(s) apply circumferential or through-eye straps to secure the coil and packaging materials.

- (Optional) Covering: Edge protectors or full covers might be applied manually or automatically.

- Unloading: The fully packaged coil is lifted or moved off the roller station for transfer to storage or shipping.

Considerations for Implementation

Selecting and implementing a roller station requires careful consideration of several factors:

- Coil Specifications: Maximum/minimum weight, diameter, and width of coils to be handled.

- Throughput Requirements: The number of coils needing packaging per shift or hour dictates the required level of automation and cycle time.

- Packaging Needs: Specific materials (film, paper, VCI, type of strap) and configurations required.

- Automation Level: Degree of automation desired (semi-automatic vs. fully automatic) impacts complexity and cost.

- Facility Layout: Space constraints and integration with existing production flow and material handling systems.

- Safety Standards: Ensuring compliance with all relevant local and industry safety regulations.

- Maintenance: Accessibility for routine maintenance and potential repairs.

coil packing equipment for steel packing Conclusion

Roller stations are indispensable assets in facilities handling large steel coils. By providing controlled rotation and integrating seamlessly with wrapping, strapping, and handling equipment, they enable safe, efficient, and effective packaging. This protects valuable steel assets from damage, ensures load stability for transport, and contributes significantly to overall operational productivity and safety in the demanding environment of metal processing and fabrication. As automation continues to advance, these stations will likely see further integration with plant-wide data systems and robotics for even greater efficiency.