Enhancing Efficiency with Steel Wire Coil Packaging Machines: A Comprehensive Guide

Efficiently packaging steel wire coils is crucial for manufacturers and processors to ensure product integrity during transport and storage, streamline logistics, and enhance operational safety. Manual or semi-automated processes can be time-consuming, labor-intensive, and inconsistent. Implementing automated steel wire coil packaging machines offers significant advantages in productivity, consistency, and cost-effectiveness.

This guide explores the various types of steel wire coil packaging machines, their benefits, key features, and considerations for selecting the right solution for your specific needs.

1. The Importance of Automated Steel Wire Coil Packaging

Automating the packaging process for steel wire coils provides numerous benefits:

- Increased Efficiency: Machines operate significantly faster than manual methods, dramatically increasing throughput.

- Improved Consistency: Automated systems apply packaging materials (like stretch film, VCI paper, or strapping) uniformly every time, ensuring consistent protection and appearance.

- Enhanced Product Protection: Proper packaging safeguards coils from environmental factors like moisture, dust, and corrosion, as well as physical damage during handling and shipping.

- Labor Savings: Automation reduces the need for manual labor in repetitive and physically demanding packaging tasks, allowing personnel to focus on higher-value activities.

- Safety: Automated systems minimize manual handling of heavy or unwieldy coils, reducing the risk of workplace injuries.

- Material Optimization: Machines can be calibrated to use the optimal amount of packaging material, reducing waste and costs.

2. Types of Steel Wire Coil Packaging Solutions

Various machines cater to different stages and requirements of the packaging process. FHOPEPACK offers a comprehensive range, showcased below, including:

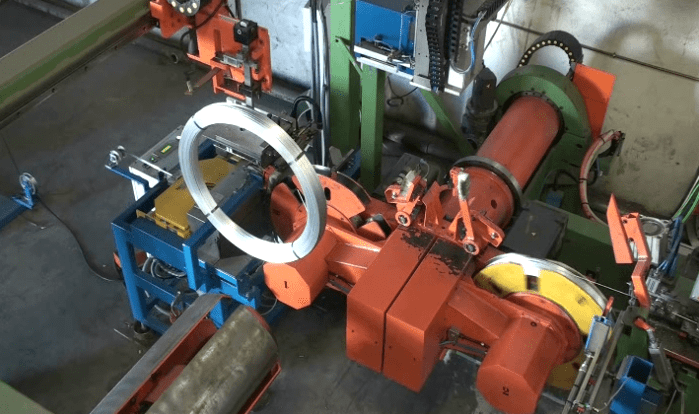

2.1. Automatic Wire Coiling and Strapping Machines

These integrated systems automate the process of winding wire into coils of specific sizes and then securing them with straps (typically PET or steel). This ensures coils are tight, uniform, and ready for the next packaging step or direct shipment.

-

Key Features: Precise coiling dimensions, automated strap feeding and tensioning, cutting, and sealing.

-

Models: Examples include FPCL-W500, FPCL-W800.

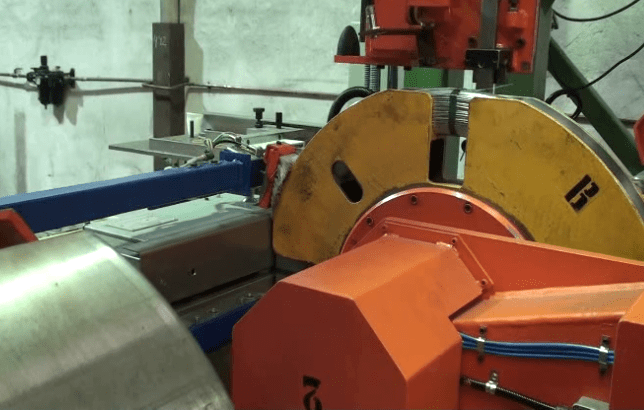

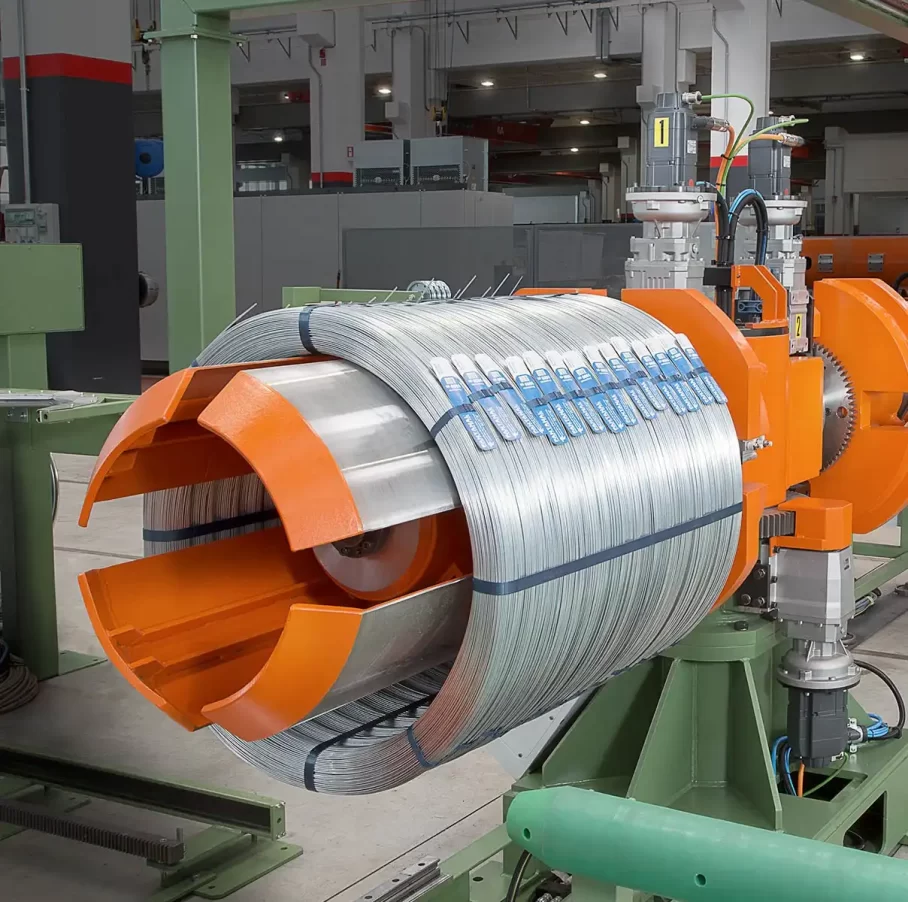

automatic cable winding coiling machine 2.2. Wire Coil Compacting and Strapping Machines

Designed for large or loose wire coils, these machines compress the coil radially to achieve a denser, more stable package before automatically applying straps. Compacting reduces the overall volume, saving space in storage and transit.

-

Key Features: Hydraulic or mechanical compaction, multiple strapping points, adjustable compaction force.

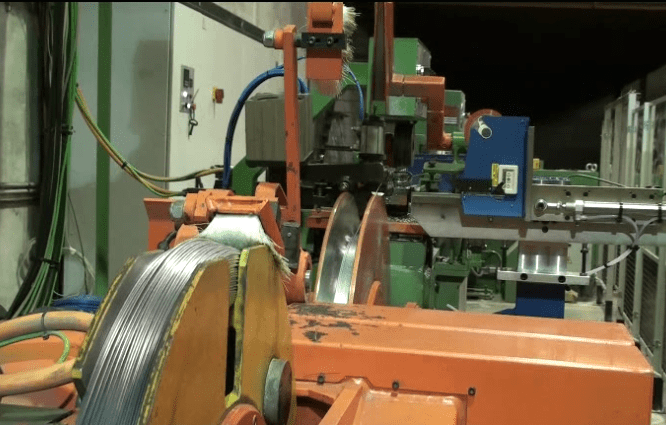

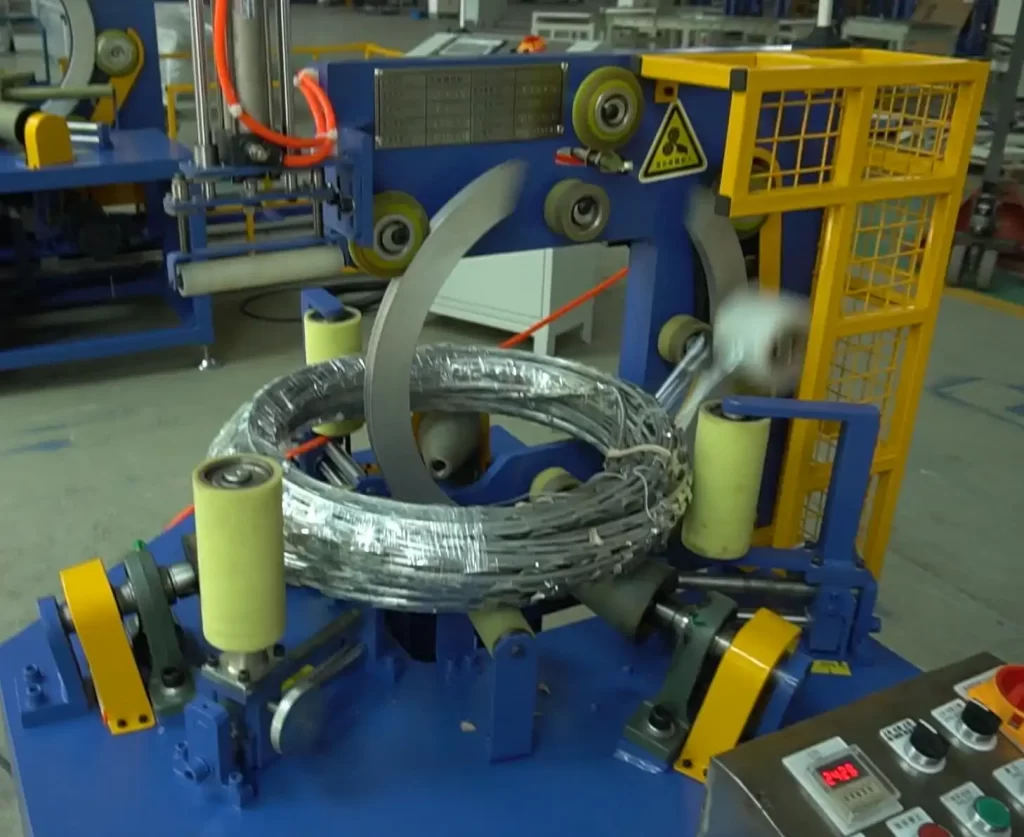

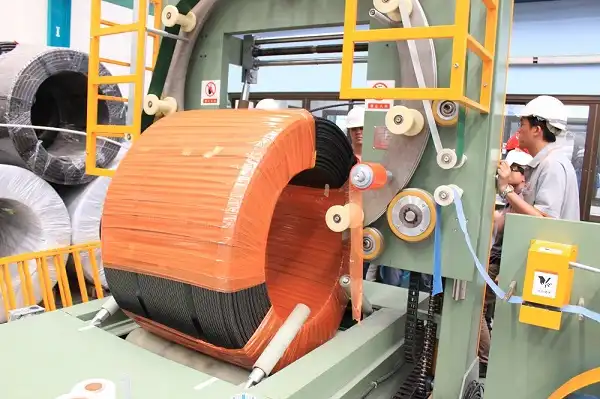

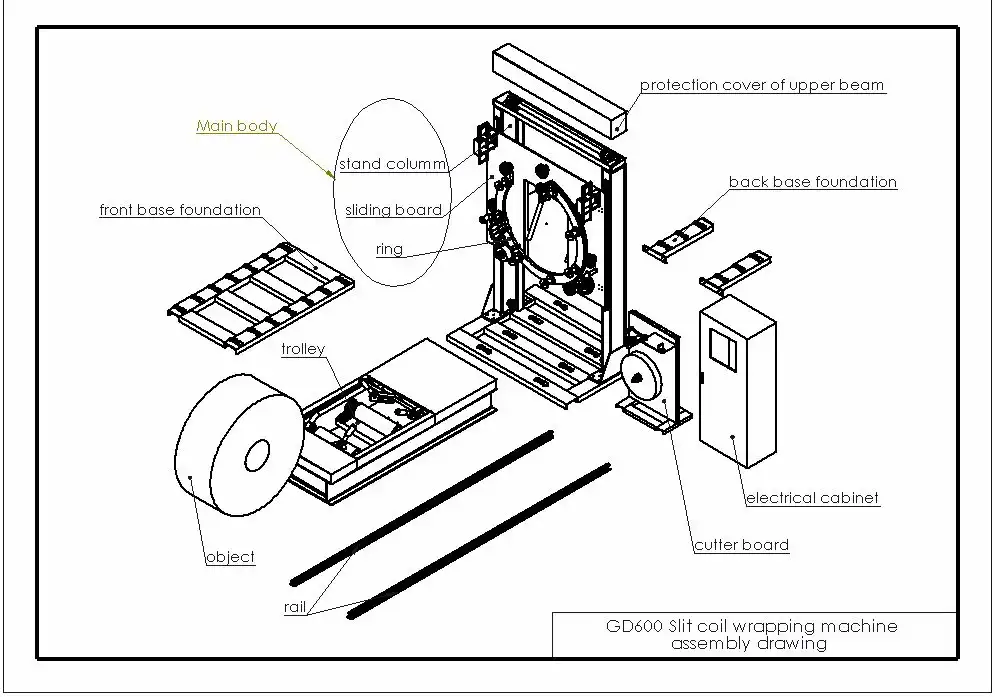

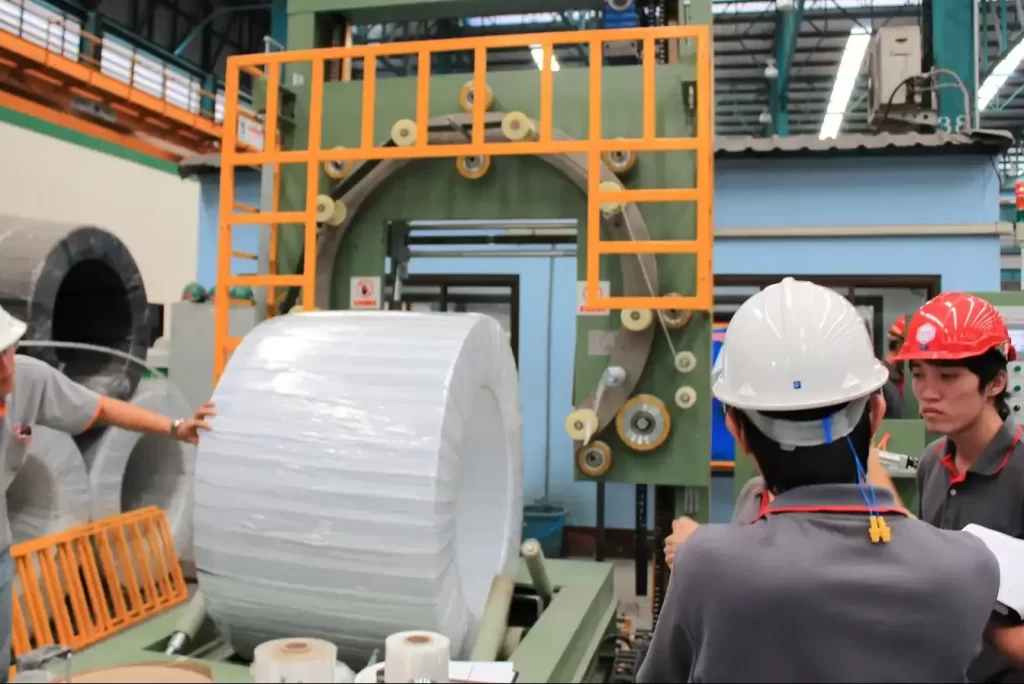

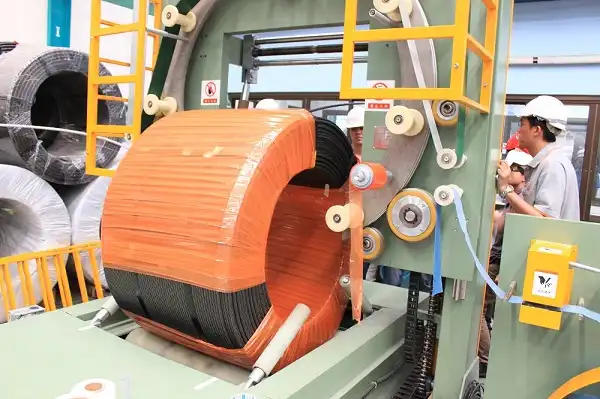

2.3. Steel Wire Coil Wrapping Machines (Orbital Wrappers)

These machines wrap steel wire coils by passing packaging material (stretch film, VCI paper, crepe paper) through the eye of the coil using a rotating ring. This provides excellent protection against environmental elements and secures loose ends.

- Key Features: Variable wrapping speeds, adjustable overlap, automatic film cutting and clamping, suitability for various coil sizes (ID/OD/Width).

- Models: Examples include FPW-300, FPW-400, FPW-500, FPW-600, FPW-800, tailored for different coil dimension ranges. Special versions exist for PC wire, razor wire, etc.

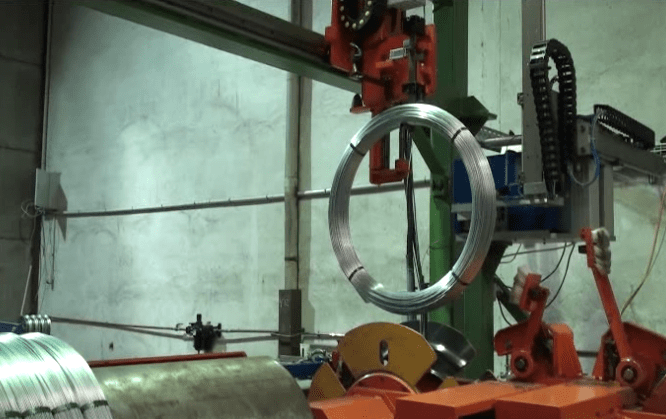

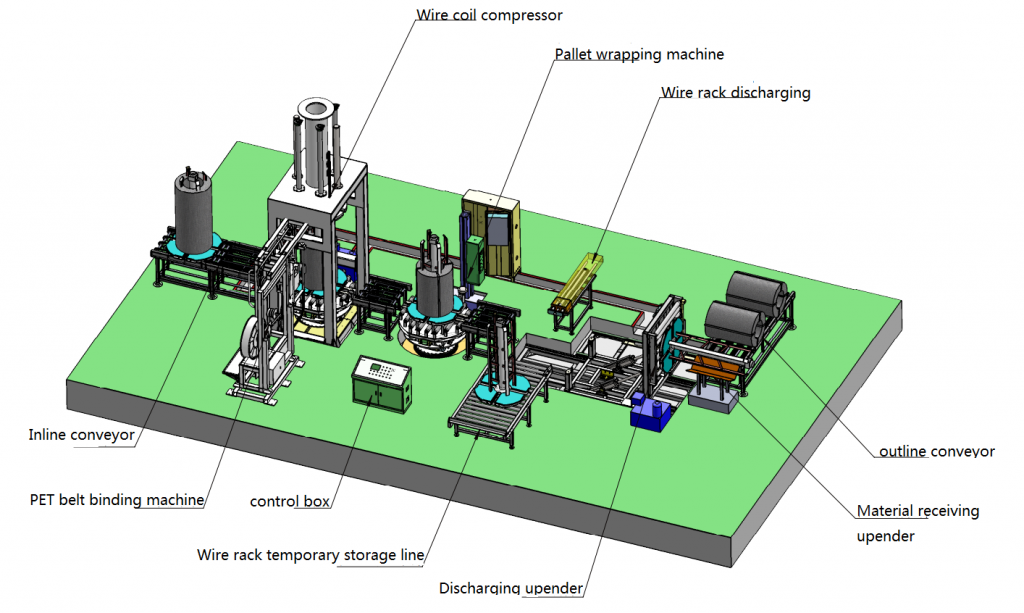

2.4. Integrated Packaging Lines

For high-volume operations, fully integrated lines combine multiple functions such as coiling, compacting, strapping, wrapping, weighing, labeling, and palletizing into a seamless automated process controlled by a central system.

3. Key Features and Technical Considerations

When selecting a steel wire coil packaging machine, consider these parameters:

- Coil Specifications:

- Inner Diameter (ID)

- Outer Diameter (OD)

- Width/Height

- Weight

- Packaging Material:

- Type (Stretch film, VCI paper, PET strap, steel strap)

- Width and roll diameter

- Performance:

- Required cycle time (coils per hour/minute)

- Level of automation (semi-automatic vs. fully automatic)

- Machine Construction:

- Durability and build quality

- Safety features (guarding, emergency stops)

- User interface (e.g., HMI touchscreen)

- Integration:

- Compatibility with existing production lines (conveyors, upstream/downstream equipment)

- Support:

- Manufacturer's warranty, technical support, and spare parts availability.

4. Visual Showcase: Steel Wire Coil Packaging Machine Gallery

Explore a diverse range of steel wire packaging solutions through our gallery. With over 50 different models, these images illustrate the various technologies available to meet diverse industrial needs. Note: For optimal accessibility and SEO, ensure descriptive alt text is added to all images within your WordPress media library.

5. Selecting the Right Manufacturer and Partner

Choosing the right equipment involves more than just technical specifications. Consider the manufacturer's experience, reputation, and commitment to innovation. FHOPE Machinery Co., Ltd, with over 20 years in the industry, focuses on providing reliable and efficient steel wire coil packaging solutions. Look for manufacturers offering:

- Proven Technology: Machines built with robust components and reliable automation technology.

- Quality Assurance: Adherence to international quality standards and certifications.

- Customization: Ability to tailor solutions to unique production requirements.

- Comprehensive Support: Availability of after-sales service, including warranty, maintenance programs, technical support, and operator training.

6. Conclusion

Automated steel wire coil packaging machines are essential investments for modern wire manufacturers and processors seeking to improve efficiency, ensure product quality, and maintain a competitive edge. By understanding the different types of machines available, key features, and selection criteria, businesses can choose the optimal solution to meet their specific operational needs.

Explore the range of Steel Wire Coil Packaging Machine options to find a system that aligns with your production goals and enhances your packaging process. A well-chosen machine delivers long-term value through increased productivity, reduced costs, and improved product protection.