Manual vs. Automated Steel Coil Packaging: Optimizing for the Modern Steel Industry

The packaging of steel coils is a critical stage in the manufacturing and logistics pipeline, directly impacting product integrity and operational efficiency. As the steel industry evolves amidst demands for higher throughput and cost optimization, the methods used for packaging are under scrutiny. A significant operational decision facing many facilities is the choice between traditional manual packaging and modern automated systems. What are the operational implications of this choice? Does automation represent the definitive future, or do manual methods retain value in specific contexts? This article examines the key differences between manual and automated steel coil packaging, analyzing the benefits and drawbacks of each approach and exploring the trajectory for packaging within the steel coil sector.

1. The Critical Role of Packaging in the Steel Coil Industry

Understanding the debate requires acknowledging the fundamental importance of packaging for steel coils. These products are typically large, heavy, and susceptible to damage during handling, storage, and transport. Effective packaging serves multiple essential functions:

- Protection: Shielding coils from physical damage (dents, scratches) and environmental factors like moisture, which can lead to corrosion (rust).

- Preservation: Maintaining the quality and surface finish of the steel, crucial for end-use applications.

- Logistics: Facilitating safer and more efficient handling, stacking, and transportation. Properly packaged coils reduce risks during movement and optimize storage space.

2. Defining Manual Steel Coil Packaging

Manual packaging involves human operators directly handling the tasks of wrapping, strapping, and securing steel coils. This traditional method typically utilizes hand tools, manually operated dispensers for stretch film or VCI paper, and banding tools for steel or plastic straps. The process relies heavily on human labor and skill for application and quality control.

3. Advantages of Manual Packaging

Despite the trend towards automation, manual packaging methods offer certain advantages, particularly relevant for specific operational scales and requirements:

- Lower Initial Investment: Setting up a manual packaging station requires minimal capital expenditure compared to automated lines. Costs are primarily associated with labor and basic tooling, making it accessible for smaller operations or those with low production volumes.

- High Flexibility: Manual processes can easily adapt to non-standard coil dimensions, varying customer specifications, or unique packaging requirements without significant reconfiguration. Operators can adjust techniques on-the-fly.

- Direct Quality Control: Skilled workers can provide meticulous attention to detail, ensuring specific handling or wrapping needs are met, which can be vital for sensitive materials or custom orders.

4. Disadvantages of Manual Packaging

Manual packaging processes also present significant challenges, particularly concerning efficiency, safety, and consistency as production scales:

- Labor-Intensive Nature: Packaging large, heavy steel coils manually is physically demanding, increasing the risk of worker fatigue and musculoskeletal injuries, contributing to higher occupational safety concerns and potential compensation costs.

- Inconsistent Quality: Variability in worker technique, materials application (e.g., inconsistent strap tension or film overlap), and attention levels can lead to inconsistent package quality, potentially compromising coil protection.

- Slower Throughput: Manual packaging is inherently slower than automated processes. This can create bottlenecks in the production line, limiting overall plant output and responsiveness, especially during periods of high demand.

- Higher Long-Term Labor Costs: While initial investment is low, ongoing labor costs can accumulate significantly, particularly in regions with high wages or for multi-shift operations.

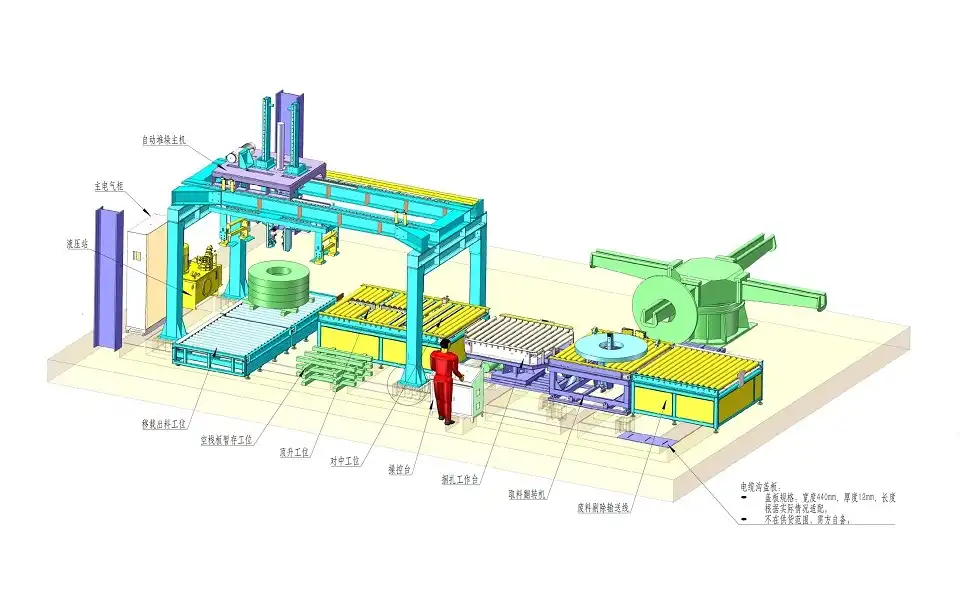

5. Defining Automated Steel Coil Packaging

Automated packaging employs integrated machinery and control systems to perform the wrapping, strapping, labeling, and conveying of steel coils with minimal human intervention. These systems often represent a complete packaging line solution.

Key components typically include:

- Conveying Systems: Automated conveyors (roller, chain, or walking beam) transport coils to and through the packaging stations.

- Coil Preparation: Systems may include automated centering, tilting, or lifting mechanisms.

- Wrapping Machines: Orbital stretch wrappers, through-eye wrappers using VCI paper, stretch film, or other protective materials.

- Strapping Machines: Automated systems apply circumferential or through-eye straps (steel or PET) with consistent tension.

- Control Systems: PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces) manage the sequence, parameters, and diagnostics of the entire line.

6. Benefits of Automated Steel Coil Packaging

The adoption of automated packaging systems is driven by compelling advantages, especially for medium-to-large scale producers:

- Increased Efficiency and Throughput: Automation drastically increases packaging speed and allows for continuous operation (24/7), significantly boosting overall productivity and enabling facilities to meet higher market demand.

- Consistent and Reliable Packaging Quality: Automated systems apply materials precisely and repeatably according to pre-set parameters, ensuring uniform package integrity and protection for every coil, meeting strict quality standards.

- Reduced Labor Costs: While requiring initial investment, automation significantly lowers long-term operational costs by reducing the number of manual laborers needed per shift.

- Enhanced Workplace Safety: Automating the physical handling and packaging of heavy coils dramatically reduces the risk of worker injuries associated with manual lifting, bending, and repetitive motions, contributing to a safer work environment.

- Optimized Material Usage: Automated wrappers and strappers can be programmed for optimal material consumption, reducing waste compared to manual application.

7. Drawbacks of Automated Packaging

Despite the significant benefits, automation also presents considerations:

- High Initial Capital Investment: The cost of purchasing, installing, and integrating a complete automated packaging line is substantial and can be a barrier for smaller businesses.

- Maintenance Requirements: Automated systems require skilled technicians for regular preventative maintenance and occasional repairs. Downtime can occur if systems are not properly maintained or if spare parts are not readily available.

- Reduced Flexibility for Non-Standard Coils: While modern systems offer some adjustability, they are typically designed for a specific range of coil dimensions and weights. Handling highly unusual or custom orders might require manual intervention or specialized (and potentially expensive) system modifications.

- Integration Complexity: Integrating a new automated line seamlessly with existing upstream and downstream processes can require careful planning and execution.

8. Comparing Costs: Manual vs. Automated Packaging

- Manual Packaging Costs:

- Initial Costs: Low (basic tools, consumables).

- Ongoing Costs: High (direct labor wages, benefits, potential injury costs, recruitment/training, higher material waste). Efficiency limitations cap potential revenue.

- Automated Packaging Costs:

- Initial Costs: High (machinery purchase, installation, integration, initial training).

- Ongoing Costs: Lower (reduced direct labor, optimized material usage, energy consumption, skilled maintenance personnel). Higher throughput increases revenue potential.

- Return on Investment (ROI): Calculated based on labor savings, increased throughput, reduced material waste, improved safety record, and enhanced quality consistency versus the capital outlay. ROI periods vary but are often compelling for high-volume operations.

9. How Automation Enhances Scalability

A key strategic advantage of automation in the steel coil industry is its inherent scalability. As a business grows or market demand fluctuates, automated systems provide the capacity to adapt efficiently:

- Adapting to Increased Demand: Automated lines can typically handle significantly higher volumes than manual stations without a proportional increase in labor. Production can often be scaled up by increasing operating hours or optimizing cycle times.

- Eliminating Production Bottlenecks: Manual packaging frequently becomes a limiting factor in the overall production flow. Automation speeds up this stage, ensuring smoother material movement from production to shipping and preventing backlogs.

- Consistent Performance at Scale: Automated systems maintain consistent speed and quality regardless of volume, unlike manual operations where fatigue or workforce limitations can impact performance during peak periods.

10. Impact of Automation on the Workforce: A Shift in Skills

Concerns about automation replacing jobs are common. However, the transition often involves a shift in workforce roles rather than outright elimination, requiring adaptation and new skill sets:

- Creation of New Roles: Automation necessitates skilled technicians for operation, monitoring, maintenance, and programming of the equipment. These roles are often higher-skilled and better compensated than manual labor positions.

- Upskilling Opportunities: Companies can invest in training programs to equip their existing workforce with the technical skills needed to manage automated systems, facilitating internal career progression.

- Improved Work Environment: Automation removes workers from physically strenuous and potentially hazardous tasks, allowing them to focus on oversight, quality assurance, and problem-solving in a safer environment.

- Optimized Labor Allocation: Automation allows businesses to allocate human resources to tasks requiring complex decision-making, quality inspection, or specialized handling, while machines handle repetitive, high-volume tasks.

11. Environmental Considerations and Sustainability Benefits

Automated packaging systems can contribute positively to environmental sustainability efforts:

- Reduced Material Waste: Precision application of wrapping films and straps minimizes overuse and scrap, leading to less material consumption and disposal compared to potentially inconsistent manual application. Many systems feature controls for optimizing film stretch ratios.

- Energy Efficiency: Modern automated machinery is increasingly designed with energy efficiency in mind, incorporating features like variable speed drives and energy-saving modes to reduce power consumption during operation and idle times.

- Optimized Logistics: Consistent package dimensions and integrity from automated systems can improve stacking efficiency in warehouses and during transport, potentially reducing the number of shipments required and associated fuel consumption.

12. Case Studies: Realizing the Benefits of Automation

Numerous steel processing facilities have successfully transitioned to automated coil packaging, achieving tangible results:

- Case Study 1: European Steel Service Center: Faced with rising labor costs and inconsistent package quality leading to customer complaints, this center implemented a fully automated packaging line. Results included a reported 30% increase in packaging throughput, a 40% reduction in packaging labor costs, and significantly improved package consistency, virtually eliminating transport damage claims.

- Case Study 2: North American Steel Mill: To meet growing demand for slit coils and improve shipping efficiency, this mill invested in an automated system featuring coil handling, wrapping, and strapping. The system enabled them to double their daily packaging capacity with the existing workforce size and achieved ROI within 2.5 years due to efficiency gains and labor cost stabilization.

13. The Future Trajectory: Smarter Steel Coil Packaging

The evolution of steel coil packaging points firmly towards increased automation and intelligence. Key future trends include:

- Integration with Industry 4.0: Expect deeper integration with plant-wide manufacturing execution systems (MES). Smart packaging lines will leverage IoT sensors for real-time monitoring, predictive maintenance alerts, and data analytics to continuously optimize performance and material usage.

- Advanced Robotics: Increased use of robotics for tasks like label application, corner protection placement, or even complex handling maneuvers, offering greater flexibility and precision.

- Enhanced Sustainability Features: Continued focus on developing machines that minimize energy consumption and work seamlessly with thinner, stronger, or more eco-friendly packaging materials.

- Improved Data Tracking: Automated systems will offer more sophisticated tracking and traceability features, recording packaging parameters and coil data for quality assurance and logistics purposes.

14. Conclusion: Is Automation the Inevitable Future for Steel Coil Packaging?

While both manual and automated packaging methods have their place, the overwhelming trend in the steel coil industry favors automation. The substantial benefits in efficiency, long-term cost-effectiveness, safety, quality consistency, and scalability present a compelling case for automation, particularly for medium to large-scale operations aiming for competitiveness in a global market.

Manual packaging will likely retain its relevance for niche applications: very small operations, facilities handling extremely diverse or custom coil types requiring high flexibility, or as a backup system. However, for most producers, the question is not if they should automate, but when and how.

The decision requires careful analysis of current operations, production volumes, budget constraints, and long-term strategic goals. As packaging technology continues to advance, offering smarter, faster, and more integrated solutions, embracing automation will be increasingly crucial for steel coil producers and processors seeking operational excellence and sustainable growth.