Optimizing Coil Packaging: A Guide to Eye-Through Wrapping Machines

Properly securing coils of materials like pipe, hose, wire, or steel is crucial for protecting product integrity during storage and transportation. Eye-through coil wrapping machines offer a specialized and efficient method for achieving secure, comprehensive packaging. This guide explores the functionality, applications, and benefits of this packaging technology.

What is Eye-Through Coil Wrapping?

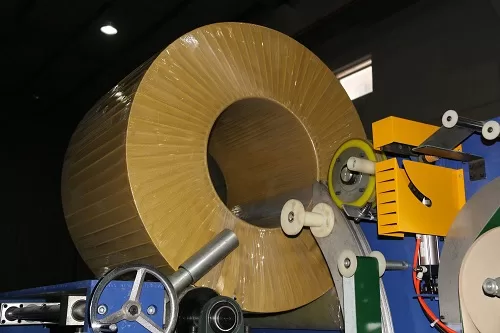

Eye-through wrapping, often performed by horizontal coil wrappers, involves passing the packaging material (such as stretch film, VCI paper, or polyethylene film) through the center opening, or "eye," of the coil. As the coil rotates, the wrapping material is dispensed from a shuttle that travels through the eye and around the outer circumference, effectively encasing the coil. This method differs from peripheral wrapping, which only covers the outside diameter.

How a Semi-Automatic Eye-Through Coil Wrapper Works

The typical operation of a semi-automatic eye-through wrapper involves several key steps:

- Loading: The coil is placed onto the machine's support rollers, often manually or with simple assistance.

- Material Feed: The leading edge of the wrapping material (e.g., stretch film) is manually attached to the coil.

- Wrapping Cycle: The operator initiates the cycle. The wrapping shuttle, carrying the material roll, passes through the coil's eye. Simultaneously, the support rollers rotate the coil.

- Overlap Control: The relative speeds of the shuttle's rotation around the coil and the coil's own rotation determine the amount of wrap overlap, ensuring complete coverage.

- Cutting and Clamping: Once the desired wrap is achieved, the machine (or operator, depending on automation level) cuts the material and secures the tail end.

- Unloading: The wrapped coil is removed from the machine.

This process provides a tight, stable, and protective layer around the coil.

Video Demonstration: Eye-Through Coil Wrapping in Action

The following video illustrates the operation of a typical semi-automatic eye-through coil wrapping machine:

Video caption: Semi-automatic horizontal coil wrapper demonstrating the eye-through wrapping process.

Key Applications and Industries

Eye-through coil wrappers are versatile and find use across various industries for products such as:

- Pipe Coils: Securing coils of plastic (PEX, HDPE) or metal tubing.

- Hose Coils: Packaging industrial, hydraulic, or garden hoses.

- Wire and Cable Coils: Wrapping electrical wire, communication cables, or wire rope.

- Steel Coils: Protecting smaller slit coils or wire rod coils.

- Copper Tube Coils: Ensuring cleanliness and protection for copper tubing used in plumbing or HVAC.

For more details on specific applications like hose and pipe packaging, see information on hose and pipe coil packaging machines. The general coil wrapping machine category covers various solutions, including these semi-automatic wrappers for copper tube and other materials.

Advantages of Eye-Through Wrapping

Utilizing an eye-through wrapping method offers several operational benefits:

- Enhanced Stability: Wrapping through the eye binds the coil together securely, preventing unwinding or shifting during handling.

- Comprehensive Protection: Provides full coverage over the inner and outer surfaces, protecting against dust, moisture, and surface damage.

- Improved Efficiency: Significantly faster and more consistent than manual wrapping methods, reducing labor requirements.

- Material Flexibility: Compatible with various protective materials, including stretch film for containment and VCI paper for corrosion inhibition.

Considerations When Selecting a Machine

Choosing the right eye-through wrapper depends on several factors:

- Coil Specifications: Inner diameter (ID), outer diameter (OD), width, and weight limitations of the machine must match your product range.

- Throughput Needs: Required wraps per hour will determine the necessary machine speed and level of automation.

- Automation Level: Semi-automatic machines require operator involvement for loading/unloading and cycle initiation, while fully automatic systems integrate into production lines.

- Wrapping Material: Ensure compatibility with the films or papers required for your application.

- Footprint and Integration: Consider available floor space and how the machine fits within your existing workflow.

Integration with Other Packaging Processes

Eye-through wrappers are often part of a larger packaging line. For higher volume operations, integration with automated systems upstream (like coil formation) and downstream (like strapping, labeling, or palletizing) is common. For instance, automating the initial coiling and subsequent strapping can further streamline operations. Explore options like an automatic hose and pipe coiling and strapping machine for integrated solutions.

Conclusion

Eye-through coil wrapping machines provide a robust solution for packaging coiled products across diverse industries. By passing the wrapping material through the coil's center, these machines deliver superior load containment and protection compared to simple peripheral wrapping. Understanding the operational principles, applications, and selection criteria helps manufacturers choose the appropriate equipment to enhance packaging efficiency and ensure product integrity during handling and transit.