Optimizing Steel Coil Packaging: A Guide to Wrapping Machines

Handling and packaging large, heavy steel coils presents significant challenges in the metals industry. Ensuring coils are protected from environmental damage, handling mishaps, and corrosion during storage and transit is crucial for maintaining product quality and preventing costly losses. Specialized equipment, specifically steel coil packing machines (often referred to as coil wrappers or orbital wrappers), provides an efficient and reliable solution.

This guide explores the function, benefits, and considerations surrounding steel coil packing machines, aligning with the practical, instructional focus valued by fabricators and metal processors.

What is a Steel Coil Packing Machine?

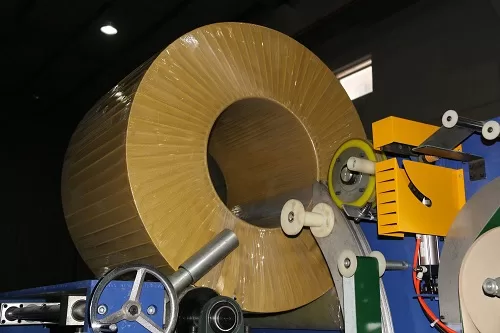

A steel coil packing machine is automated or semi-automated industrial equipment designed specifically for applying protective wrapping material around the circumference and often through the eye ("eye-through wrapping") of steel coils. These machines utilize various wrapping materials, including stretch film, VCI (Vapor Corrosion Inhibitor) paper or film, standard kraft paper, or woven plastic materials, depending on the required level of protection.

The core principle often involves an orbital wrapping mechanism where the wrapping material is dispensed from a shuttle that rotates around the coil as it is either stationary or rotated.

Key Operational Principles

While specific designs vary, the typical operational sequence for an automated eye-through steel coil wrapping machine involves:

- Coil Loading: The steel coil is typically placed onto a conveyor or tilting system that positions it correctly within the machine's wrapping ring.

- Wrapping Cycle Initiation: The machine starts the wrapping process. A ring or shuttle carrying the roll of packing material rotates around the coil's axis, passing through the coil's eye.

- Material Application: The packing material is dispensed and applied under controlled tension, ensuring a tight, secure wrap around the coil surfaces. Overlap percentages can often be adjusted.

- Material Cutting and Securing: Once the wrapping cycle is complete (based on preset parameters like wrap count or timer), the machine automatically cuts the wrapping material and secures the tail end (e.g., via heat sealing, tucking, or adhesive).

- Coil Discharge: The fully wrapped coil is moved out of the wrapping station, typically via conveyor, ready for the next stage of handling or shipment.

Featured Process: Steel Coil Wrapping with Paper

Paper, particularly VCI-treated paper, remains a common choice for steel coil packaging due to its protective properties and specific industry requirements. The following video demonstrates a steel coil packing machine utilizing paper as the primary wrapping material:

This specific setup showcases an eye-through wrapping process, ensuring comprehensive coverage of the coil surfaces.

Further machine details available at:

http://www.fhopepack.com/Coil_packing_machine.html

Core Benefits for Fabricators and Processors

Integrating a dedicated steel coil packing machine into operations offers tangible advantages:

- Preventing Costly Damage: Secure wrapping significantly reduces the risk of scratches, dents, moisture ingress, and corrosion during handling, storage, and shipping. This protects the value of the steel product.

- Boosting Operational Efficiency: Automated wrapping is considerably faster and more consistent than manual methods, increasing throughput and reducing labor costs associated with packaging.

- Enhancing Workplace Safety: Automating the wrapping process minimizes the need for personnel to manually handle heavy coils and awkward wrapping materials, reducing the risk of strains, sprains, and other injuries.

- Optimizing Material Usage: Machines apply wrapping materials with consistent tension and overlap, often leading to more efficient material consumption compared to manual application.

- Improving Package Presentation: A uniformly wrapped coil presents a more professional appearance and can be easier to handle downstream.

Considerations When Selecting a Coil Packing Machine

Choosing the right machine depends on several factors unique to your operation:

- Coil Specifications: Maximum and minimum coil Outside Diameter (OD), Inside Diameter (ID), width, and weight are critical parameters.

- Wrapping Material Requirements: Compatibility with required materials (stretch film, VCI paper, plastic strapping, etc.).

- Throughput Needs: Required number of coils to be wrapped per hour or shift.

- Level of Automation: Options range from semi-automatic (requiring operator assistance for loading/unloading) to fully automatic integrated lines.

- Available Footprint: Physical space constraints within the facility.

- Integration: How the machine will fit into the existing production or logistics flow.

steel packing machine6 Conclusion

Proper packaging is a non-negotiable aspect of steel coil processing and distribution. Steel coil packing machines provide a reliable, efficient, and safer method compared to manual alternatives. By automating the wrapping process, businesses can protect their valuable products from damage, improve operational speed, enhance worker safety, and optimize material costs. Understanding the operational principles and key benefits helps in evaluating how this equipment can contribute positively to the bottom line in demanding industrial environments.