Understanding Cable Coil Packing Machines with Film Wrapping

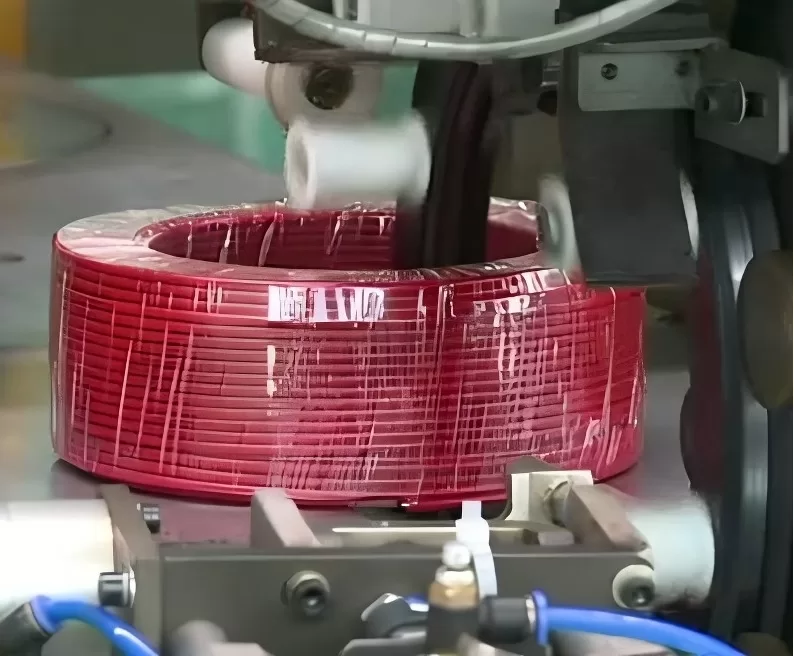

Packaging large or heavy cable coils presents unique challenges in manufacturing and distribution. Ensuring coils remain secure, protected from environmental factors, and stable during transport is crucial. A cable packing machine and cable coil wrapping machine utilizing stretch film offers a robust solution for these requirements.

How Stretch Film Cable Coil Packers Work

These machines automate or semi-automate the process of applying stretch film tightly around a cable coil. The core operation typically involves:

- Loading: The cable coil is placed onto a turntable or conveyed into the wrapping station.

- Film Application: A rotating ring or arm carries a roll of stretch film around the stationary or rotating coil. A film carriage mechanism controls the tension and pre-stretch of the film for optimal usage and load containment.

- Wrapping: The ring/arm orbits the coil, applying overlapping layers of stretch film around its circumference and often through the eye (depending on machine type), fully encapsulating it.

- Cutting and Sealing: Once the wrapping cycle is complete, the machine automatically clamps, cuts, and seals the film tail to the coil, ensuring a secure finish.

Watch the process in action:

Operational Modes: Automatic vs. Semi-Automatic

Cable coil packing solutions are available in different levels of automation to match varying production needs and budgets:

- Semi-Automatic: Requires an operator to load the coil, initiate the wrapping cycle, potentially attach the film initially, and unload the wrapped coil. Suitable for lower volume operations or where diverse coil sizes require frequent manual adjustment.

- Automatic: Integrates seamlessly into production lines. Coils are automatically conveyed into the wrapping station, wrapped, and then conveyed out, often incorporating features like automatic coil centering, top sheet application (for added protection), and integration with palletizing systems. Ideal for high-volume, standardized production environments.

Key Benefits of Using a Film Wrapping Machine

Employing a dedicated cable coil packing machine with film offers significant advantages over manual methods:

- Superior Protection: Tightly wrapped stretch film shields coils from dust, moisture, dirt, and minor impacts during handling and storage.

- Enhanced Load Stability: Prevents cable layers from shifting or unwinding during transit, maintaining coil integrity.

- Increased Packaging Efficiency: Dramatically faster and more consistent than manual wrapping, reducing labor requirements and bottlenecks.

- Optimized Material Usage: Controlled film pre-stretch ensures efficient film consumption, leading to material cost savings.

- Improved Safety: Reduces the need for manual handling of heavy coils during the wrapping process.

- Professional Presentation: Provides a neat, consistent, and professional appearance for finished products.

[Image: A neatly wrapped cable coil exiting a packing machine - Alt: Securely stretch-wrapped cable coil ready for shipment]

Customization and Configuration Options

To meet specific application demands, cable coil packing machines can often be customized. Common options include:

- Coil Handling Capacity: Machines can be specified to handle a wide range of coil diameters, widths, and weights.

- Automation Level: Choice between fully automatic or semi-automatic operation based on line speed and integration needs.

- Control Systems: Options range from basic controls to advanced PLC systems with HMI touch screens for recipe management, diagnostics, and variable parameter control.

- Integration Features: Can be designed to integrate with existing or new conveyor systems, weighing scales, automatic labeling systems, and robotic handling.

- Specialized Add-ons: Features like top press rollers (for unstable coils), specialized film cutting/sealing units, or top sheet dispensers can be incorporated.

- Material Handling Integration: Seamless connection with upstream and downstream equipment like coil tilters, stackers, or palletizers.

Selecting the Right Machine

Choosing the appropriate cable coil packing machine depends on factors like:

- Production volume and required throughput speed.

- Range of coil sizes and weights to be handled.

- Required level of automation and integration.

- Available floor space and facility layout.

- Budgetary constraints.

- Specific protection requirements (e.g., need for top sheets).

cable coil wrapping machine Conclusion

A cable coil packing machine that utilizes stretch film is an essential asset for manufacturers and distributors dealing with cable and wire products. By providing robust protection, load stability, and significant efficiency gains, these machines streamline the packaging process, reduce costs, and ensure products reach their destination in optimal condition. Careful consideration of operational needs and available customization options will ensure the selection of a system that delivers maximum value.

For more information on various cable packing solutions: