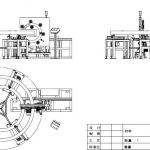

The customized coil packing solution for big coil by professional factory. The Big coil packaging machine is ring up type coil wrapper which loading and unloading the coil from top side by crane.

info@fhopepack.com

A big coil packaging machine is a specialized type of packaging equipment designed to package large coils. These machines are typically used in manufacturing and logistics industries where large coils need to be packaged for storage and transportation.

The big coil packaging machine is a ring-up type coil wrapper, which means that the coil is loaded and unloaded from the top side of the machine using a crane. This type of machine is typically designed and customized by a professional factory to meet the specific needs of different businesses.

One advantage of using a big coil packaging machine is that it can improve the efficiency and safety of the packaging process. By automating the packaging process and using a crane to load and unload the coil, businesses can reduce the amount of time and labor required to package each coil manually. Additionally, the machine can be designed to incorporate safety features, such as sensors and guards, to help prevent accidents and injuries during the packaging process.

The big coil packaging machine can be customized to handle different types of coils, including steel coils, aluminum coils, and other types of large coils. The machine can be designed to accommodate different coil sizes and weights, and can be customized to incorporate different types of wrapping materials, such as stretch film or other protective materials.

Some big coil packaging machines may also offer additional features, such as automatic loading and unloading, adjustable wrapping tension, or automatic cutting and sealing of the wrapping material.

Overall, a big coil packaging machine can be a valuable investment for businesses that need to package large coils on a regular basis. By improving efficiency, reducing labor costs, and ensuring that each coil is properly protected during storage and transportation, these machines can help to improve the overall productivity and profitability of the business.