We are providing following aluminum profile spiral stretch packing solution for customer need.

http://www.fhopepack.com/Horizontal_wrapping_machine.html

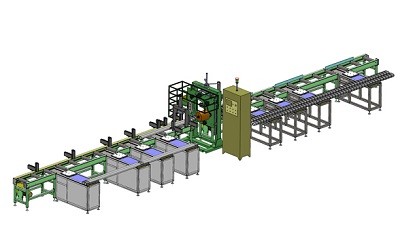

1. 1 x complete packing line for wrapping and packing mill-finish and surface treated

aluminium profiles with lengths 2000-8000mm.

2. 1 x complete aluminum packing line for wrapping and packing mill-finish and surface treated

aluminium profiles with lengths 2000-14000m.

3. Features:-

a. Profile envelope 350mm wide x 200mm high.

b. Weight of profiles max. 15 kg/m.

c. Capable of managing at least 35 tons of profiles per day (over the 2 lines).

d. For simplicity, assume 60% is spiral wrapped and all is packed as

commercial bundle (wood base board and outer strapping). Assume the

remaining is masterpack (no spiral wrap but with cardboard outer box on

wood base board or wood crate, paper layers/interleaving and outer

strapping).

e. Batching table (8/14m profiles) in-feed side and transfer to roller in-feed.

End strapping to hold profiles together before spiral wrapping assumed to

be made by hand on batching table.

f. Spiral wrap machine on each aluminum packing line. For paper or plastic rolls. Auto centering

on in-feed side.

2) Aluminum wrapping machine

An aluminum profile spiral stretch wrapper is a specialized machine used to wrap cardboard boxes or containers with plastic film to protect the contents and seal the packaging. Some key features and benefits of these stretch wrappers include:

- Uses aluminum profiles: The profiles that guide and control the plastic film are made of aluminum. This provides strength, durability and flexibility for efficient wrapping.

- Spiral design: The profiles are shaped into a spiral to effectively wrap containers of different sizes and shapes. The spiral can expand and contract as needed for each package.

- Applies tension: The profiles apply tension to the plastic film as it wraps around the package. This secures the wrap tightly for a snug, protectsive seal.

- Seals edges: heating elements or tape dispensers can be used to seam and seal the edges of the plastic wrap for a completely enclosed package.

- Adjustable speed: Adjustable speed controls allow for optimal wrapping of different package typesat the proper tension and speed. Slower speeds are better for more delicate items.

- Accommodates various sizes: Spiral stretch wrappers can handle a wide range of container heights, widths and depths for maximum flexibility. They are ideal for pallets, cartons, cases and more.

- Prevents damage: By sealing cardboard boxes and containers in plastic film, these stretch wrappers help protect the contents from damage, moisture, contamination and environmental exposure during storage and shipping.

- Easy loading: An open designand adjustable height controlsmake these stretch wrappers simple to load different types and sizes of packages for efficient wrapping. Manual, semi-automatic or fully automatic models are available.

- Safety features: Many stretch wrappers include safety switches, overload protection and emergency stop buttonsto prevent injuries and damage. Proper guarding also helps keep operator hands away from moving parts.

That covers the key highlights about aluminum profile spiral stretch wrappers and how they work to wrap and pack different containers for protection and secure sealing during storage and transportation.