Understanding Automated Packing for Cold-Rolled Galvanized Steel Coils

Automating the packaging process for cold-rolled galvanized steel coils presents unique challenges and requires a coordinated system involving material handling, protective wrapping, and secure strapping. An effective automated packing line ensures product integrity during transport and storage, enhances operational efficiency, and improves worker safety.

The packing process typically involves several stages, combining robust machinery with various protective materials. Key steps include careful coil handling, wrapping the coil with materials like VCI paper or stretch film, applying protective coverings, and finally, strapping the coil securely. Explore detailed configurations of steel coil automatic packing systems for more insights.

Key Stages in Automated Cold-Rolled Coil Packaging

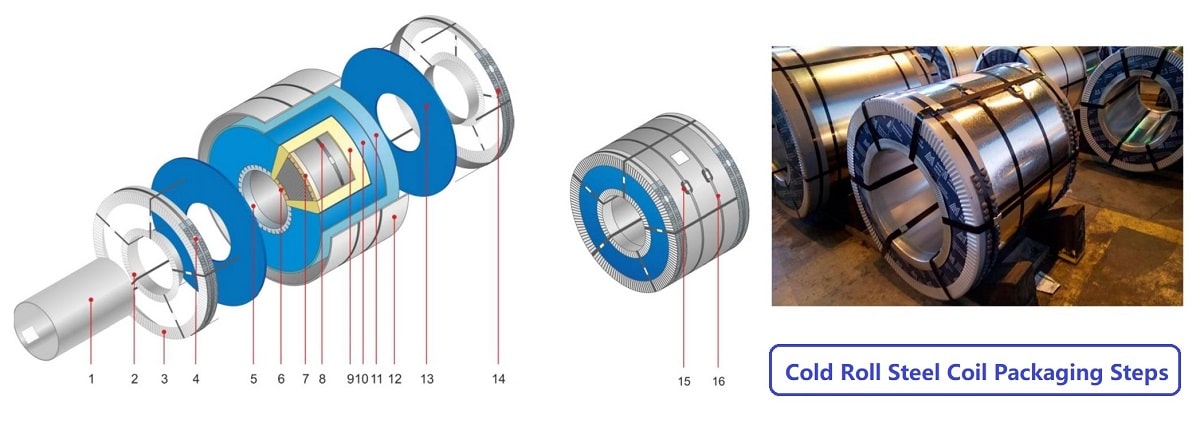

The following steps represent a comprehensive automated packaging sequence, often tailored for sea-worthy transport standards observed by many manufacturers:

Coil Handling and Preparation:

- Coils, often weighing several tons, are transported using automated systems like coil cars, turnstiles, or conveyors.

- Robust gripper mechanisms, lifters, or vacuum systems position the coils accurately and securely for subsequent steps.

Inner Diameter (ID) Protection:

- Application of protectors (e.g., cardboard or steel rings) to the inner diameter (ID) hole prevents damage during handling and transit.

- Specialized applicators ensure protectors are correctly placed.

Outer Diameter (OD) Protection:

- Steel or cardboard edge protectors are applied to the outer diameter (OD) edges to guard against impacts and deformation.

- These protectors may be secured with initial light strapping.

Protective Wrapping:

- The coil is wrapped circumferentially with protective materials. Common choices include:

- VCI Paper/Film: Volatile Corrosion Inhibitor (VCI) materials release compounds that form a protective layer on the metal surface, preventing rust and corrosion, crucial for galvanized steel.

- Stretch Film: Provides a tight, moisture-resistant barrier and helps unitize the package.

- Automated wrapping machines ensure consistent tension and overlap for optimal protection.

- The coil is wrapped circumferentially with protective materials. Common choices include:

Covering Application:

- Additional layers may be applied over the primary wrap for enhanced durability and protection:

- Cardboard/Paper: Kraft paper or cardboard sheets add abrasion resistance. Paper rolling machines synchronize with coil rotation for even application, often bonded with adhesive.

- Steel Sheet: A metallic outer layer provides maximum physical protection against punctures and impacts during rough handling.

- Side Covers: Protective discs or sheets are applied to the coil faces (sides).

- Additional layers may be applied over the primary wrap for enhanced durability and protection:

Strapping:

- High-tensile steel or polyester straps secure the entire package. Automated strapping heads perform two main types of strapping:

- Circumferential (OD) Strapping: Bands are applied around the coil's outer diameter, securing the wrapping and covering materials. The strapping head adjusts its position for accurate placement.

- Radial (Eye-Through) Strapping: Straps pass through the coil's inner diameter and around the outside, preventing the coil from unwinding or telescoping.

- Strapping systems use controlled tension mechanisms and reliable sealing methods (e.g., friction weld or mechanical seals) to ensure straps remain tight.

- High-tensile steel or polyester straps secure the entire package. Automated strapping heads perform two main types of strapping:

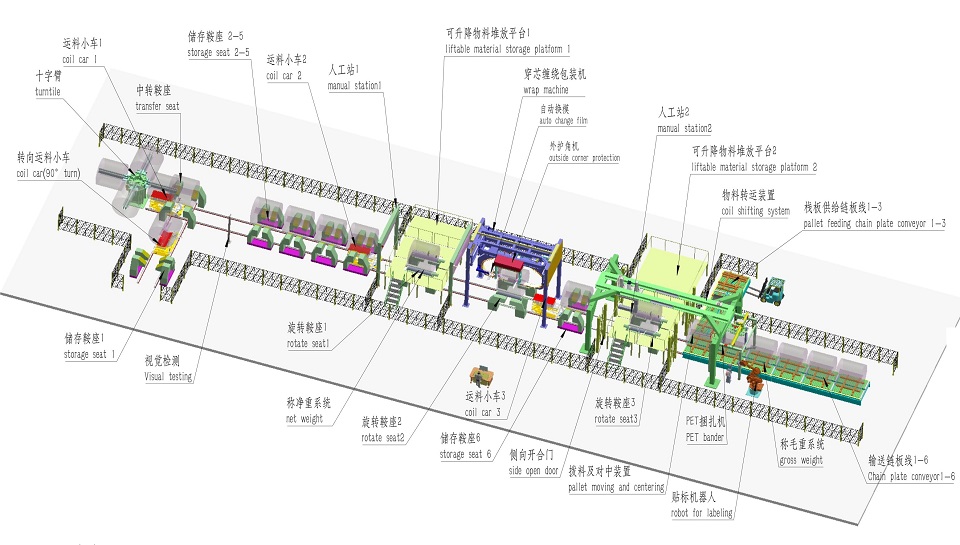

Essential Equipment Components

A typical automated cold-rolled coil packing line integrates several key pieces of machinery:

- Coil Handling Equipment: Coil cars, upenders/downenders, turnstiles, conveyors, and lifting devices.

- Wrapping Machines: Orbital stretch wrappers designed for heavy coils, capable of applying stretch film, VCI film, or paper.

- Strapping Machines: Automated systems with adjustable heads for both radial and circumferential strapping.

- Radial Strapping:

- Circumferential Strapping:

- Radial Strapping:

- Applicators: Automated units for placing ID/OD protectors and side covers.

System Considerations

Designing an effective automated packing line requires careful consideration of:

- Coil Specifications: Range of coil weights, widths, and diameters.

- Packaging Materials: Types of VCI, film, paper, protectors, and strapping required based on protection needs and destination (e.g., domestic vs. export).

- Throughput: Required packing speed (coils per hour) to match production rates.

- Integration: Seamless communication and material flow between different stations (handling, wrapping, strapping).

- Safety: Implementation of safety guards, sensors, and emergency stops.

Conclusion

Automated packing lines for cold-rolled galvanized steel coils are sophisticated systems crucial for protecting valuable products. By integrating robust handling, precise wrapping, effective covering, and secure strapping technologies, manufacturers can ensure their coils arrive at their destination in optimal condition, while simultaneously improving operational efficiency and workplace safety. The specific configuration and steps involved can be tailored to meet diverse production needs and transportation requirements.