In a fast-paced industrial world, efficiency and precision are critical in maintaining competitive advantages. When dealing with bulky and sensitive materials like steel coils, choosing the right wrapping machine can make or break operational efficiency. Over the years, coil wrapping machines have become indispensable, offering solutions tailored to specific industry needs. But what are the types available, and how can businesses make informed decisions when selecting one?

The variety of coil wrapping machines can seem overwhelming at first. However, each type serves a specific purpose, making it crucial to understand their features and benefits. By diving deeper into these machines' capabilities, you can unlock operational efficiencies and achieve cost savings, ensuring your business stays ahead in the game.

Understanding the types of coil wrapping machines and their applications is the first step. From horizontal to vertical designs, fully automated systems, and semi-automated alternatives, the choice depends on your operational scale, material requirements, and long-term goals. Selecting the wrong one could lead to inefficiencies, but the right choice ensures smoother operations and better results.

[Claim]

Choosing the right coil wrapping machine requires a balance of operational needs, future scalability, and budget constraints. This article explores the key types of machines available and offers actionable insights to guide your decision-making process.

1. What Types of Coil Wrapping Machines Exist and Which Should You Consider?

1.1 Horizontal Coil Wrapping Machines

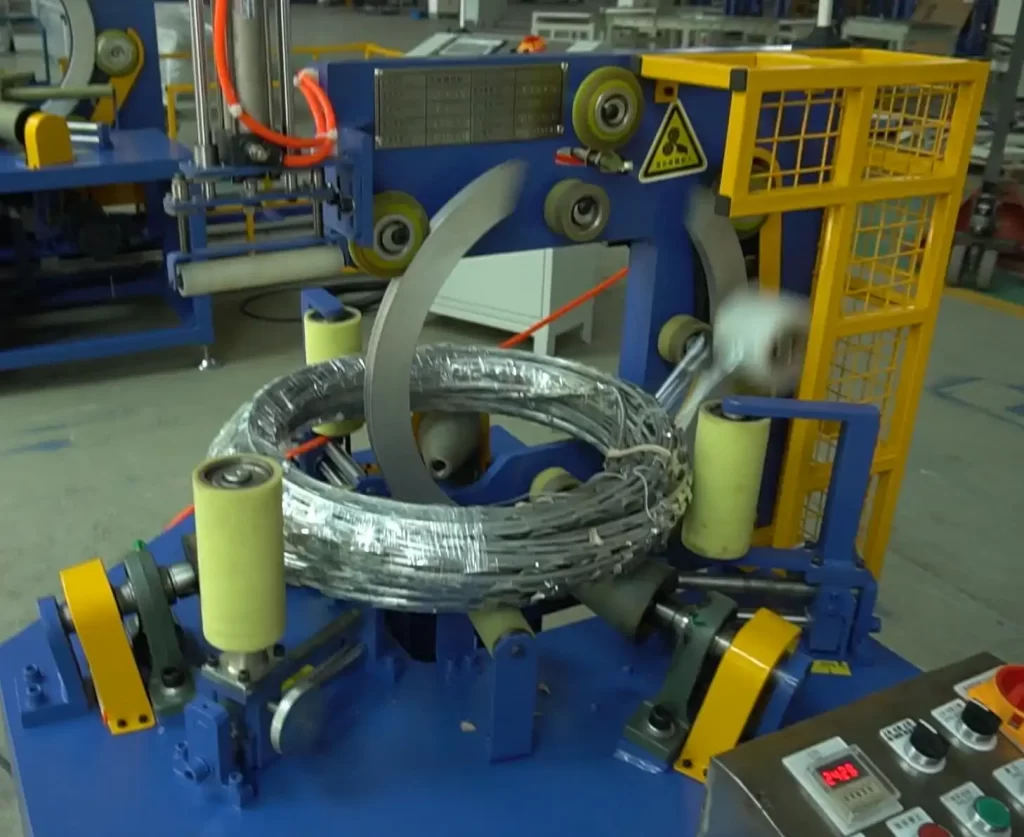

Horizontal coil wrapping machines are designed to handle coils laid flat, making them ideal for operations requiring stability and easy maneuvering. These machines work well for smaller coils or those needing extra support during the wrapping process. Their versatility and compact design allow them to be integrated seamlessly into existing production lines.

1.2 Vertical Coil Wrapping Machines

Vertical coil wrapping machines are perfect for handling larger or heavier coils that are stored upright. They often come equipped with high-tensile materials to ensure secure wrapping.

| Feature | Details |

|---|---|

| Maximum Coil Diameter | Up to 3 meters |

| Wrapping Speed | 30–60 coils per hour |

| Wrapping Materials | Stretch film, VCI film |

Vertical machines are especially favored for export packaging where securing large shipments is critical.

1.3 Fully Automated Systems

Fully automated coil wrapping systems are a game-changer for large-scale operations. Equipped with intelligent controls, these machines minimize human intervention, reducing labor costs while maximizing efficiency. With automated film adjustments and seamless integration with conveyors, they streamline the entire packaging process.

1.4 Semi-Automated Solutions for Cost-Conscious Operations

Semi-automated coil wrapping machines offer a budget-friendly alternative for medium-sized operations. They strike a balance between manual and automated processes, ensuring flexibility without excessive upfront investment.

| Advantages | Details |

|---|---|

| Lower Initial Costs | Ideal for SMEs |

| Customization | Adjustable settings |

| Durability | Long-lasting components |

While these machines require some manual input, their adaptability makes them a popular choice for businesses in growth phases.

1.5 Two Fact Statements

True: Horizontal coil wrapping machines are more compact and require less operational space than vertical models.

False: Fully automated systems require the same level of human supervision as semi-automated alternatives.

2. How Do Specific Features Impact Wrapping Machine Performance?

2.1 Intelligent Controls for Precision Wrapping

The integration of intelligent controls in modern coil wrapping machines revolutionizes performance. These systems ensure precision by adjusting film tension, overlap, and speed automatically, tailored to the specific coil dimensions. By reducing manual errors, businesses can achieve consistent wrapping results that meet industry standards.

2.2 Film Material Compatibility: What Works Best?

Coil wrapping machines offer flexibility in film usage, accommodating a variety of materials like stretch film, VCI film, and polyethylene. Choosing the right film type is critical for ensuring adequate protection.

| Film Type | Ideal For |

|---|---|

| Stretch Film | Domestic packaging |

| VCI Film | Corrosion-prone materials |

| Polyethylene Film | Heavy-duty applications |

The compatibility of the machine with diverse film types ensures versatility, especially for industries managing different packaging needs.

2.3 Customization Options for Industry-Specific Needs

One size does not fit all in coil wrapping. Customizable machines allow businesses to tweak features such as coil rotation speed, wrap count, and integration with other machinery. For example, industries dealing with delicate materials can opt for machines with soft-start mechanisms to prevent damage.

2.4 Dive Deeper: Automation vs. Manual Intervention

While fully automated systems ensure high throughput and uniformity, semi-automated machines provide flexibility for smaller-scale operations. Data reveals that automated systems improve packaging speed by 35–50% compared to manual alternatives.

| Aspect | Automated Systems | Manual Systems |

|---|---|---|

| Throughput | 50–80 coils per hour | 20–30 coils per hour |

| Labor Involvement | Minimal | Moderate |

| Initial Investment | High | Low |

The decision between automation and manual operation depends on business size, budget, and long-term goals.

2.5 Two Fact Statements

True: Machines with intelligent controls improve the consistency of wrapping across varied coil sizes.

False: Manual coil wrapping machines are faster than fully automated systems.

3. What Are the Most Critical Factors When Choosing a Coil Wrapping Machine?

3.1 Operational Scale and Throughput Needs

Understanding your production scale is the first step in selecting the right coil wrapping machine. High-volume operations demand fully automated systems to keep up with throughput requirements, while smaller setups can benefit from semi-automated solutions that offer more flexibility.

| Operational Scale | Recommended Solution |

|---|---|

| Large-Scale Production | Fully Automated Systems |

| Medium-Sized Businesses | Semi-Automated Machines |

| Small Businesses | Manual or Compact Systems |

3.2 Cost Analysis: Initial Investment vs. Long-Term Savings

Investing in a high-end coil wrapping machine may seem costly upfront, but the savings in labor, material wastage, and efficiency often justify the price. Businesses report a 20–30% reduction in packaging costs after transitioning to automated systems.

3.3 Dive Deeper: Maintenance and After-Sales Support

Maintenance is often an overlooked factor when choosing a coil wrapping machine. Machines with accessible components and minimal downtime requirements significantly lower operational disruptions.

Brands offering reliable after-sales support, such as training and regular servicing, add value to the investment. Data indicates that businesses with robust maintenance plans experience 15% fewer breakdowns over five years.

3.4 Conclusion

Selecting the right coil wrapping machine involves a careful analysis of operational needs, financial constraints, and long-term goals. Machines tailored to specific requirements not only optimize performance but also ensure sustainable growth.

3.5 Two Fact Statements

True: Businesses with automated coil wrapping systems reduce packaging costs by up to 30%.

False: Maintenance plans are unnecessary for fully automated systems due to their reliability.

4. How Do You Ensure Long-Term ROI with the Right Machine?

4.1 Assessing Durability and Build Quality

The longevity of a coil wrapping machine directly impacts its return on investment (ROI). Machines built with high-grade steel frames and durable components withstand wear and tear, especially in demanding environments. Investing in a robust machine ensures operational continuity and reduces repair costs over time.

| Durability Factors | Impact on ROI |

|---|---|

| High-Grade Materials | Longer Lifespan |

| Component Accessibility | Lower Maintenance Costs |

| Modular Design | Easier Upgrades |

4.2 Energy Efficiency: Why It Matters

Energy-efficient machines significantly lower operational costs. Advanced coil wrapping systems incorporate energy-saving features, such as automatic shut-off and low-energy motors, reducing electricity consumption by 20–40% annually.

| Feature | Energy Savings |

|---|---|

| Automatic Shut-Off | Up to 25% |

| Low-Energy Motors | Up to 40% |

4.3 Dive Deeper: Scalability and Future-Proofing

As industries evolve, so do their packaging requirements. Machines with scalable features, such as modular add-ons or software updates, allow businesses to adapt to future needs without incurring significant costs. For example, a machine capable of handling larger coil sizes or integrating with smart systems provides a competitive edge.

4.4 Conclusion

Ensuring long-term ROI requires a strategic approach to machine selection. By prioritizing durability, energy efficiency, and scalability, businesses can achieve cost-effective operations that align with future growth objectives.

4.5 Two Fact Statements

True: Energy-efficient coil wrapping machines reduce annual electricity costs by up to 40%.

False: Machines with scalable features require frequent replacements to remain competitive.

Conclusion

Investing in a coil wrapping machine is not just about meeting immediate packaging needs—it’s about ensuring long-term value and operational excellence. By understanding the different types of machines, evaluating critical features, and aligning them with your business objectives, you can make an informed decision that drives efficiency and sustainability.

[Claim] Choosing the right coil wrapping machine is an investment in your company’s future, providing the tools necessary to optimize operations and maintain a competitive edge in the industry.

Get Your Best Solution !