Understanding Steel Wire Rod Coil Compressing and Strapping Machines

Steel wire rod coils are fundamental materials in numerous industries, but their handling, storage, and transportation require specialized processes to ensure efficiency and safety. A key piece of equipment in this process is the steel wire rod coil compressing and strapping machine, often integrated into an automatic coil packing line. This system optimizes the packaging workflow for wire manufacturers, construction suppliers, and logistics providers.

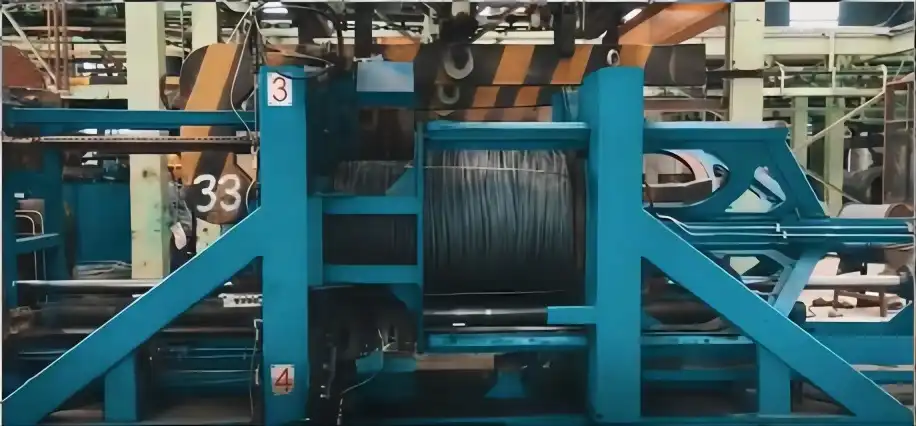

What is a Steel Wire Rod Coil Compressing and Strapping System?

This machinery is specifically designed to prepare steel wire rod coils for subsequent stages like storage or shipping. The core functions are:

- Compression: Reducing the overall volume of the wire coil.

- Strapping: Securely binding the compressed coil to maintain its shape and integrity.

These automated systems can often be directly linked to the end of a wire production line, enabling seamless automatic handling, stacking, and packaging of wire coils, sometimes utilizing wire baskets.

Key Components and Their Functions

An integrated automatic coil packing line typically comprises several key stations working in unison:

1. Coil Handling and Input

This stage involves receiving the wire rod coil from the production line or a staging area. Automated conveyors or transfer cars often handle this initial placement.

2. Compression Station

- Purpose: To compact the wire rod coil, making it denser and reducing its dimensions. This saves valuable space during storage and transportation.

- Mechanism: Typically utilizes powerful hydraulic power to apply controlled force, pressing the coil to a predetermined size.

3. Strapping Station

- Purpose: To apply durable straps around the compressed coil, preventing it from expanding or loosening. This secures the coil for safe handling and transit.

- Mechanism: The strapping machine automatically feeds, tensions, seals, and cuts strapping material (commonly PET or steel straps) around the coil circumference at one or multiple points.

steel wire reel rewinding and compacting line 4. Control System

Sophisticated PLC (Programmable Logic Controller) systems manage the sequencing, timing, and operation of the compression and strapping processes, ensuring consistent and reliable packaging.

5. Output and Stacking

Once compressed and strapped, the finished coil is typically moved via conveyor to a collection area, where it might be stacked automatically or prepared for forklift removal.

The Automated Packaging Process (Simplified)

- A steel wire rod coil enters the system.

- It moves into the compression station.

- Hydraulic pressure compacts the coil.

- The compressed coil transfers to the strapping station.

- Straps are automatically applied and secured.

- The finished, packaged coil exits the system.

Benefits of Automated Coil Compressing and Strapping

Implementing an automatic packaging solution for steel wire rod coils offers significant advantages:

- Enhanced Efficiency: Automates a labor-intensive process, increasing throughput and reducing packaging cycle times.

- Cost Reduction: Lowers labor costs associated with manual handling and packaging, and optimizes space utilization in warehouses and transport vehicles.

- Improved Safety: Minimizes manual lifting and handling of heavy coils, reducing the risk of workplace injuries.

- Product Protection: Ensures wire rod coils are securely packaged, protecting them from damage during handling and transit.

- Consistency: Delivers uniform, tightly bound packages every time, improving load stability and stackability.

Considerations for Implementation

When evaluating a steel wire rod coil compressing and strapping machine, businesses should consider:

- Coil Specifications: The range of coil diameters, widths, and weights the machine needs to handle.

- Throughput Needs: The required number of coils to be processed per hour or shift.

- Automation Level: The degree of integration desired with existing production lines.

- Strapping Material: Preference for PET or steel strapping based on coil properties and transport requirements.

- Space and Layout: The physical footprint of the machinery and its fit within the facility.

Conclusion

The steel wire rod coil compressing and strapping machine, especially when part of a fully automatic coil packing line, represents a critical investment for efficient and safe operations in the wire industry. By automating the compaction and securing of wire rod coils, these systems streamline workflows, cut operational costs, and ensure product integrity throughout the supply chain.

For further details on specific system configurations, explore solutions like the Automatic Coil Packing Line.