How Pallet Inverters Help You Meet Safety Standards in Your Warehouse

This block would typically auto-generate a Table of Contents in WordPress based on the headings below. Ensure your theme/plugins support this or manually create one if needed.

Introduction

Maintaining a safe working environment is paramount in any warehouse setting. Pallet inverters are essential tools that significantly contribute to achieving higher safety standards. By integrating pallet inverters into your material handling processes, you not only streamline operations but also markedly reduce the risk of workplace accidents and injuries related to manual lifting. This article delves into how pallet inverters assist in meeting critical safety regulations, minimizing physical strain on workers, and enhancing overall warehouse efficiency. Whether managing heavy loads, awkwardly shaped products, or operating in confined spaces, pallet inverters offer a reliable solution for boosting both safety and productivity.

1. The Critical Importance of Safety in Warehouse Operations

Warehouses are dynamic environments where heavy machinery, manual labor, and rapid workflows intersect, creating inherent safety risks. Industry data consistently highlights lifting-related injuries as one of the most frequent types of incidents, often stemming from the manual handling of heavy or unstable pallets. Furthermore, pallets can tip, shift unexpectedly, or collapse during movement or storage, leading to potentially hazardous situations. Adhering to stringent safety standards is not merely a regulatory obligation but a fundamental responsibility to protect your workforce and prevent accidents.

Pallet inverters directly address these risks by providing a mechanized method for handling palletized loads safely and efficiently, thereby reducing reliance on manual labor for strenuous tasks. These machines are engineered to support ergonomic lifting and turning protocols, effectively preventing the muscle strain, back injuries, and fatigue commonly associated with manual pallet manipulation.

2. Understanding How Pallet Inverters Function

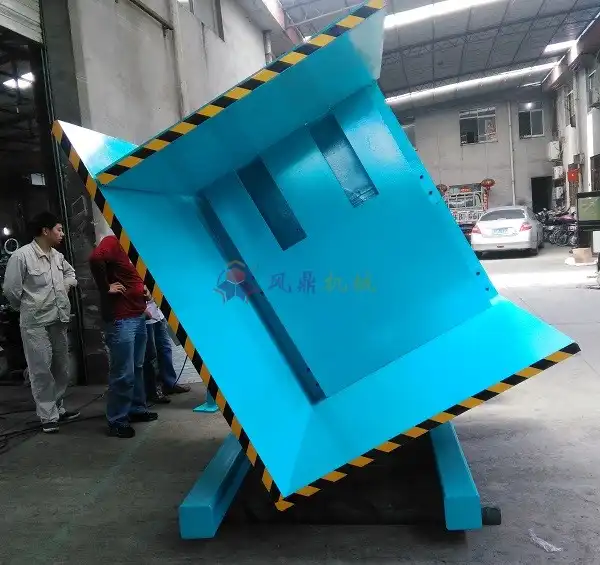

Grasping the operational mechanics of pallet inverters is key to appreciating their significant safety advantages. A pallet inverter is a specialized piece of equipment designed to securely clamp and rotate a loaded pallet, typically through 180 degrees. This rotation allows operators easy access to the bottom of the load, enabling tasks such as:

- Replacing damaged or unsuitable pallets (e.g., swapping wood for plastic hygiene pallets).

- Retrieving damaged goods from the bottom of a stack.

- Transferring loads between different pallet types or sizes.

- Straightening tilted or unstable loads.

The process generally involves:

- Loading the palletized goods into the inverter using a forklift or pallet jack.

- Securely clamping the load from the top and sides.

- Rotating the entire unit 180 degrees.

- Lowering the original pallet (now on top) for removal or replacement.

- Placing a new pallet (if required).

- Rotating the load back to its original orientation.

- Unclamping and removing the safely handled load.

This automated process minimizes manual intervention, ensuring a safer, more controlled transfer. By keeping workers away from potentially unstable loads and heavy lifting, pallet inverters help facilities comply with material handling safety guidelines focused on reducing hazardous manual tasks.

3. Meeting OSHA Standards with Pallet Inverters

A primary safety requirement for U.S. warehouses involves compliance with OSHA (Occupational Safety and Health Administration) standards. OSHA regulations strongly emphasize minimizing worker exposure to ergonomic risks, including heavy lifting, repetitive strain injuries (RSIs), and unsafe load handling practices. Pallet inverters directly align with these guidelines by significantly reducing, and often eliminating, the need for manual lifting during pallet exchange or load adjustment.

OSHA guidelines frequently recommend or require the use of mechanical assistance for handling heavy or awkward loads. Pallet inverters serve as an effective engineering control, providing a practical and efficient solution. They enable safe load transfers without requiring employees to manually lift, push, or pull heavy pallets, which can easily exceed safe lifting limits and lead to serious injury. Using pallet inverters demonstrates a proactive approach to workplace safety and OSHA compliance.

4. Reducing Manual Handling to Prevent Injuries

One of the most significant safety benefits of implementing pallet inverters is the substantial reduction in manual handling requirements. Manual handling encompasses any workplace activity requiring employees to lift, lower, carry, push, or pull items, and it remains a leading cause of musculoskeletal disorders (MSDs) and other workplace injuries.

Industry statistics consistently show that a large percentage of warehouse injuries (sometimes cited as high as 25% or more, though figures vary) result from improper lifting techniques or overexertion while moving heavy objects. Pallet inverters automate the most strenuous part of pallet exchange—the lifting and rotating—drastically cutting down these risks. This automation not only protects workers from acute injuries and chronic conditions like back pain but also ensures loads are handled smoothly, preventing product damage and the associated financial losses.

5. Improving Load Stability and Preventing Tip-Over Accidents

Unstable palletized loads present a serious safety hazard in warehouses. Instability can arise from uneven stacking, product settling, or damage to the pallet itself. When a load becomes unstable, the risk of tip-over accidents increases dramatically, endangering nearby personnel and potentially causing significant product loss.

Pallet inverters address this issue directly through their clamping mechanism, which securely holds the load from multiple sides during the entire rotation process. This containment prevents items from shifting or falling, significantly reducing the likelihood of a load collapse. Many modern inverters offer adjustable clamping pressure and accommodate various pallet dimensions, ensuring that diverse loads remain stable and secure during inversion. By enhancing load stability, pallet inverters also mitigate risks associated with moving or storing potentially precarious stacks.

6. Optimizing Material Flow and Reducing Forklift Hazards

While essential, forklift operations introduce significant safety risks within a warehouse, including collisions, tipovers, and struck-by incidents. Congested areas where forklifts frequently maneuver to adjust or exchange pallets can be particularly hazardous. Integrating pallet inverters at strategic points can help optimize material flow and reduce certain types of forklift movements.

Instead of requiring a forklift to carefully lift, balance, and potentially rotate a load manually (a complex and risky maneuver), the pallet inverter handles the inversion process safely within its designated footprint. This allows forklifts to simply deliver and retrieve loads from the inverter, potentially reducing complex maneuvering in tight spaces and minimizing the time forklifts spend stationary in high-traffic zones. This streamlined process contributes to a safer floor layout and reduces the probability of forklift-related accidents during these specific tasks.

7. Enhancing Ergonomics and Reducing Worker Fatigue

Ergonomics—designing the job to fit the worker—is crucial in physically demanding warehouse environments. Pallet inverters represent a significant ergonomic improvement by eliminating the need for workers to perform awkward postures like bending, twisting, and heavy lifting associated with manual pallet handling.

By automating these physically taxing processes, pallet inverters prevent immediate injuries and reduce the cumulative long-term wear and tear on workers' bodies, particularly the back, shoulders, and arms. This reduction in physical strain contributes to:

- Lower rates of MSDs.

- Reduced absenteeism due to injury.

- Improved worker morale and job satisfaction.

- Sustained productivity levels, as fatigue is lessened.

95 degree pallet tipper2 8. Ensuring Consistency and Precision in Load Handling

Manual handling introduces variability. Different workers may use slightly different techniques, and fatigue can lead to errors like uneven stacking, improper load distribution, or accidental dropping of goods. This inconsistency can compromise load integrity and product safety.

Pallet inverters provide consistency by handling every load using the same programmed, controlled motion. This mechanized precision ensures that loads are rotated smoothly and securely every time, regardless of the operator. Consistent handling helps:

- Maintain the integrity of the palletized unit.

- Prevent damage to sensitive or fragile goods.

- Reduce product loss attributed to human error during handling.

9. Lowering Costs Associated with Workplace Injuries

Workplace injuries impose substantial costs on businesses, extending beyond direct medical expenses. Indirect costs include lost productivity, administrative time for incident reporting, potential OSHA fines, increased workers' compensation insurance premiums, and negative impacts on employee morale. Organizations like the National Safety Council (NSC) report that workplace injuries, particularly MSDs, cost U.S. businesses billions of dollars annually.

Investing in safety equipment like pallet inverters can yield significant financial savings by directly reducing injury rates. Fewer manual lifting tasks translate to fewer MSDs and related incidents. This leads to:

- Lower workers' compensation claims and premiums.

- Reduced medical expenses.

- Less lost work time.

- A stronger overall safety record, enhancing company reputation.

In the long term, the investment in a pallet inverter often pays for itself through reduced injury-related costs and improved operational efficiency.

10. Selecting the Right Pallet Inverter for Your Warehouse Needs

Choosing the appropriate pallet inverter requires careful consideration of your specific operational requirements. Key factors include:

- Load Characteristics: Maximum weight, dimensions (height, width, length), and type of products handled (e.g., boxes, bags, drums, fragile items).

- Throughput Requirements: How many pallets need to be inverted per hour or shift? This influences the required cycle time and level of automation.

- Operational Environment: Available floor space, ceiling height, integration with existing conveyors or AGVs.

- Pallet Types: Compatibility with different pallet sizes and materials (wood, plastic, metal).

- Safety Features: Robust clamping systems, emergency stops, safety guarding or light curtains, user-friendly controls.

- Level of Automation: Options range from manual controls to fully automated systems integrated into production lines.

- Maintenance Needs: Consider ease of access for maintenance and availability of spare parts.

Consulting with experienced suppliers can help identify the model (e.g., free-standing, low-level, conveyor-fed) best suited to optimize safety and efficiency in your unique warehouse setting.

Conclusion: Pallet Inverters as a Critical Safety Tool in Modern Warehouses

In conclusion, pallet inverters are far more than just efficiency boosters; they are indispensable tools for enhancing warehouse safety standards. By automating risky manual handling tasks, preventing injuries, ensuring load stability, and protecting products, pallet inverters provide a comprehensive safety solution tailored to the demands of modern logistics and storage environments.

Their ability to help meet OSHA requirements, reduce significant workplace injury costs, and improve worker ergonomics makes them a strategic investment for any company committed to creating a safer, more productive, and compliant workplace. As warehouse operations continue to modernize and face increasing pressure for speed and safety, technologies like pallet inverters will remain critical for achieving operational excellence and safeguarding the well-being of the workforce. Investing in these systems is a forward-thinking decision that supports a future-ready, efficient, and fundamentally safer warehouse.