Streamlining Operations: An Overview of Automatic Hose Coiling and Packing Machines

Manual handling of hoses for coiling and packaging can be time-consuming, labor-intensive, and prone to inconsistencies. Automating this process offers significant advantages in efficiency, product protection, and operational safety. Automatic hose coiling and packing machines integrate these functions into a seamless workflow, crucial for manufacturers dealing with various types of flexible tubing.

Learn more about specific automatic coiling machine types

How Automatic Hose Coiling and Packing Machines Work

These integrated systems are engineered to manage the entire process from coiling to final wrapping. Typically, the operation involves several key stages:

- Hose Feeding: The hose is fed into the machine, often guided by sensors to ensure proper alignment and tension.

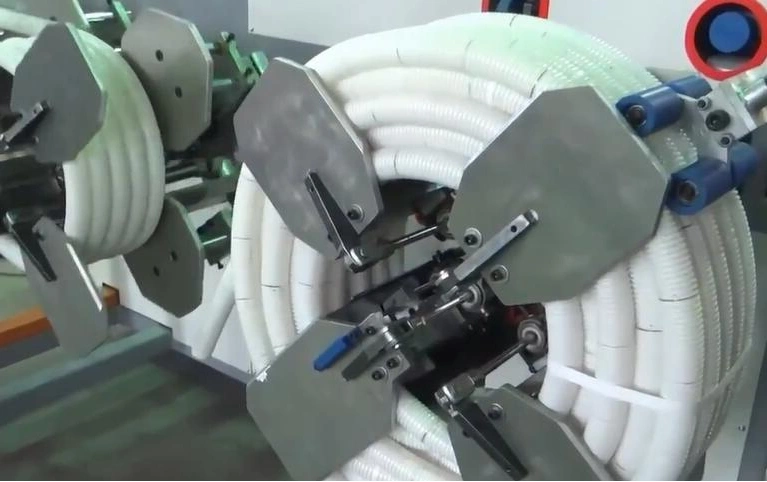

- Coiling: The machine precisely coils the hose to pre-set diameters and lengths. Advanced mechanisms ensure tight, uniform coils without kinks.

- Cutting (Optional): Some systems incorporate an automated cutting unit to segment hoses to desired lengths before or after coiling.

- Wrapping/Strapping: Once coiled, the hose is transferred to the packing station. Here, it's typically wrapped circumferentially with protective film (like PE or PVC stretch film) or secured with straps.

- Sealing/Ejection: The wrapping material is sealed, and the finished, packaged coil is ejected, ready for storage or shipment.

automatic pipe coiling machine, automatic hose coiling machine100

Control is typically managed via a Programmable Logic Controller (PLC) paired with a Human-Machine Interface (HMI), often a touch screen. This allows operators to easily set parameters like coil diameter, hose length, wrapping tension, and cycle speed, ensuring precise and repeatable results.

Important Note: The parameters listed below provide a general guideline. Specifications can vary significantly based on the model and configuration. For exact specifications matching specific equipment, please consult the manufacturer.

Key Features and Technical Specifications

While varying between models, typical features and specifications include:

- Machine Type: Integrated Coiling and Packing/Wrapping System

- Suitable Materials: Garden hoses, industrial hoses, hydraulic hoses, pneumatic tubing, flexible pipes (typically up to ~50 mm diameter, but varies)

- Coil Inner/Outer Diameter: Adjustable ranges (e.g., Inner Diameter: 150-400 mm, Outer Diameter: 300 mm to 600 mm)

- Hose Length Capacity: Programmable via PLC

- Coiling Speed: Variable, often adjustable (e.g., up to 25 coils per hour or higher depending on size/complexity)

- Wrapping Material: Compatible with PE film, PVC film, stretch wrap, paper wrap, or strapping materials

- Control System: PLC with HMI (Touch Screen Interface) for intuitive operation and parameter setting.

- Drive System: Servo motors or variable frequency drives for precise speed and tension control.

- Automated Systems: Includes features like automatic hose cutting, film clamping and cutting, and coil ejection.

- Power Requirements: Varies by region and machine size (e.g., 240V/480V, 50/60Hz, 3-Phase)

- Machine Dimensions (Approximate): Length: 4000mm; Width: 2500mm; Height: 2000mm (highly variable)

- Safety Features: Emergency stop buttons, safety interlocks, protective guarding, light curtains.

Applications and Benefits Across Industries

https://www.fhopepack.com/Automatic-Coiling-Machine/s deliver value in various sectors:

- Garden and Consumer Hose Production: Ensures neat, retail-ready packaging for garden hoses. Consistent coiling prevents tangles, enhances shelf appeal, and protects the product during distribution, improving customer satisfaction. Automation significantly increases throughput compared to manual methods.

- Industrial and Hydraulic Hose Manufacturing: Provides secure and protective packaging for robust industrial hoses. Proper coiling maintains hose integrity, crucial for high-pressure applications. Protective wrapping prevents contamination and abrasion during storage and transit.

- Firefighting Equipment: Critical for preparing fire hoses. Precise, kink-free coiling ensures rapid deployment in emergencies. Protective wrapping shields hoses from environmental factors like UV damage and abrasion, extending service life and ensuring reliability.

- Automotive and Aerospace: Used for packaging fluid transfer lines, wiring harnesses encased in conduit, and other flexible components. Automation ensures consistency required for quality control standards, protects sensitive components, and optimizes packaging for efficient logistics and storage within assembly operations.

Explore details on Automatic Hose Coiling & Packing Machine solutions

By automating the coiling and packing process, manufacturers can achieve higher production speeds, reduce labor costs, minimize material waste, improve worker safety, and deliver a consistently well-packaged product to their customers.