Enhancing Packaging Efficiency: A Deep Dive into the 3m Diameter Turntable Pallet Wrapping Machine

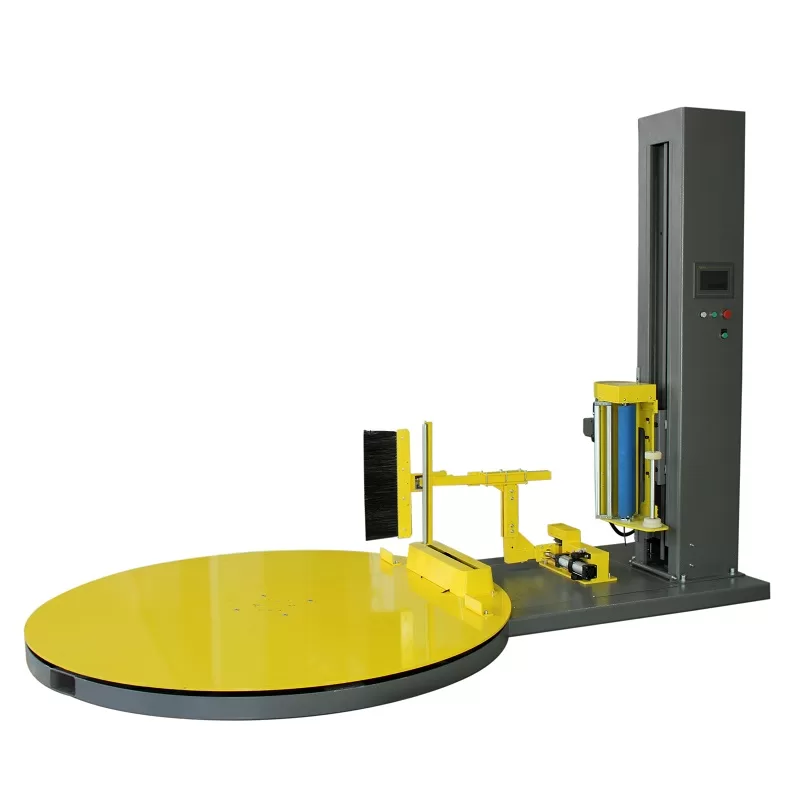

Handling oversized or unusually large pallet loads presents unique challenges in packaging and logistics. Ensuring these large items are securely wrapped for transit is crucial for preventing damage and maintaining supply chain integrity. The large diameter turntable pallet wrapping machine, specifically models featuring a 3-meter turntable, is engineered to address these challenges effectively. This specialized equipment offers robust construction and advanced features designed for heavy-duty applications.

Let's explore the key features, operational workflow, and benefits of incorporating a 3m diameter turntable stretch wrapper into your packaging operations.

Key Features and Capabilities

These machines are more than just scaled-up versions of standard wrappers; they incorporate specific designs for large-scale tasks:

1. Robust 3-Meter Turntable Design

The centerpiece is the heavy-duty, large-diameter turntable (3000mm). It's constructed to support substantial weight capacities and provide a stable, smooth rotating platform essential for wrapping large, potentially unstable, or uneven loads without compromising balance or safety.

2. Advanced Film Carriage System with Pre-Stretch

Equipped with a sophisticated film carriage system, these machines often feature powered pre-stretch capabilities. This technology stretches the film before application (commonly up to 250-300%), significantly reducing film consumption while simultaneously increasing load containment force and stability. The system ensures consistent film tension across the entire load.

3. Customizable Wrapping Programs

Modern large pallet wrappers offer programmable logic controllers (PLCs) with intuitive human-machine interfaces (HMIs). Operators can easily set and save various wrapping parameters, including:

- Turntable rotation speed

- Film carriage ascent/descent speed

- Number of top and bottom wraps

- Film tension settings

- Film overlap percentage

This flexibility allows tailoring the wrap cycle perfectly to different load types and stability requirements.

4. Intuitive Controls and Automation Potential

Designed for ease of use, these machines typically feature straightforward control panels. Many models offer options for integration into automated production lines, including features like remote start/stop capabilities and automatic film clamp-and-cut systems to minimize manual intervention and boost throughput.

5. Integrated Safety Mechanisms

Safety is paramount when dealing with large rotating machinery. Standard safety features include emergency stop buttons, safety bumpers on the film carriage, and often options for safety fencing or light curtains to protect personnel during operation.

Streamlined Operational Workflow

Operating a large diameter wrapper typically follows these steps:

- Load Placement: The oversized palletized load is placed centrally onto the 3m turntable using a forklift or other appropriate material handling equipment.

- Program Selection: The operator selects the pre-set wrapping program suitable for the load type via the HMI or manually adjusts parameters.

- Film Attachment: The stretch film is manually attached to the pallet base or load. (Some automated systems may handle this).

- Cycle Initiation: The operator starts the wrapping cycle via the control panel or remote signal.

- Automated Wrapping: The turntable rotates, and the film carriage moves vertically, applying the stretch film according to the selected program parameters (including pre-stretching, tension, and wrapping counts).

- Cycle Completion: Once the cycle is finished, the film is typically cut (manually or automatically), and the securely wrapped load is ready for removal from the turntable.

Core Benefits for Your Packaging Line

Investing in a 3m diameter turntable wrapper provides significant advantages:

- Superior Load Containment: Ensures large, heavy, or irregular loads are tightly secured, minimizing shifting and damage during handling and transport.

- Optimized Throughput: Automates the wrapping process for oversized goods, significantly speeding up packaging compared to manual methods.

- Material Cost Savings: Powered pre-stretch dramatically reduces the amount of stretch film needed per pallet, leading to substantial cost savings and reduced environmental impact.

- Enhanced Workplace Safety: Reduces the need for manual wrapping of large, potentially hazardous loads, decreasing risks of worker injury.

- Handling Versatility: Provides the capability to securely wrap a wide range of large products that standard machines cannot accommodate.

Ideal Applications for Large Diameter Wrapping

These machines are essential in industries dealing with bulky items, such as:

- Building materials (doors, windows, panels, insulation)

- Furniture manufacturing

- Large machinery components or assembled units

- Automotive parts (large body panels, etc.)

- Textile rolls

- Other oversized palletized goods

Maintaining Peak Performance

Like any industrial equipment, regular maintenance is key. This includes routine cleaning, lubrication of moving parts (turntable bearings, carriage chain/belt), sensor checks, and inspection of the film pre-stretch rollers and cutting mechanism to ensure consistent and reliable operation. Following the manufacturer's recommended maintenance schedule is crucial. For insights into general packaging best practices, resources from organizations like the Packaging Machinery Manufacturers Institute (PMMI) can offer valuable guidance.

Conclusion: A Strategic Investment for Oversized Load Packaging

The 3m diameter turntable pallet wrapping machine is a specialized solution designed for businesses that regularly handle oversized loads. By combining a large capacity turntable with advanced wrapping technology like powered pre-stretch and customizable programs, it delivers enhanced load security, improved operational efficiency, significant material savings, and a safer working environment. For companies looking to streamline the packaging of large-scale products, this equipment represents a valuable and strategic investment.