How to do Automatic Cable Coil Winding and Wrapping Online?

As a factory manager like Michael Chen, you carry the weight of the entire operation on your shoulders. The pressure to boost output, control costs, and maintain safety is relentless. You look at your packing line, and you see a major bottleneck. Your team is manually winding and then clumsily wrapping heavy cable coils. It’s slow, it’s dangerous, and the finished products are not consistently protected from the elements, leading to damage and customer complaints. You know you need to automate, but after dealing with unreliable suppliers in the past, you are rightfully cautious.

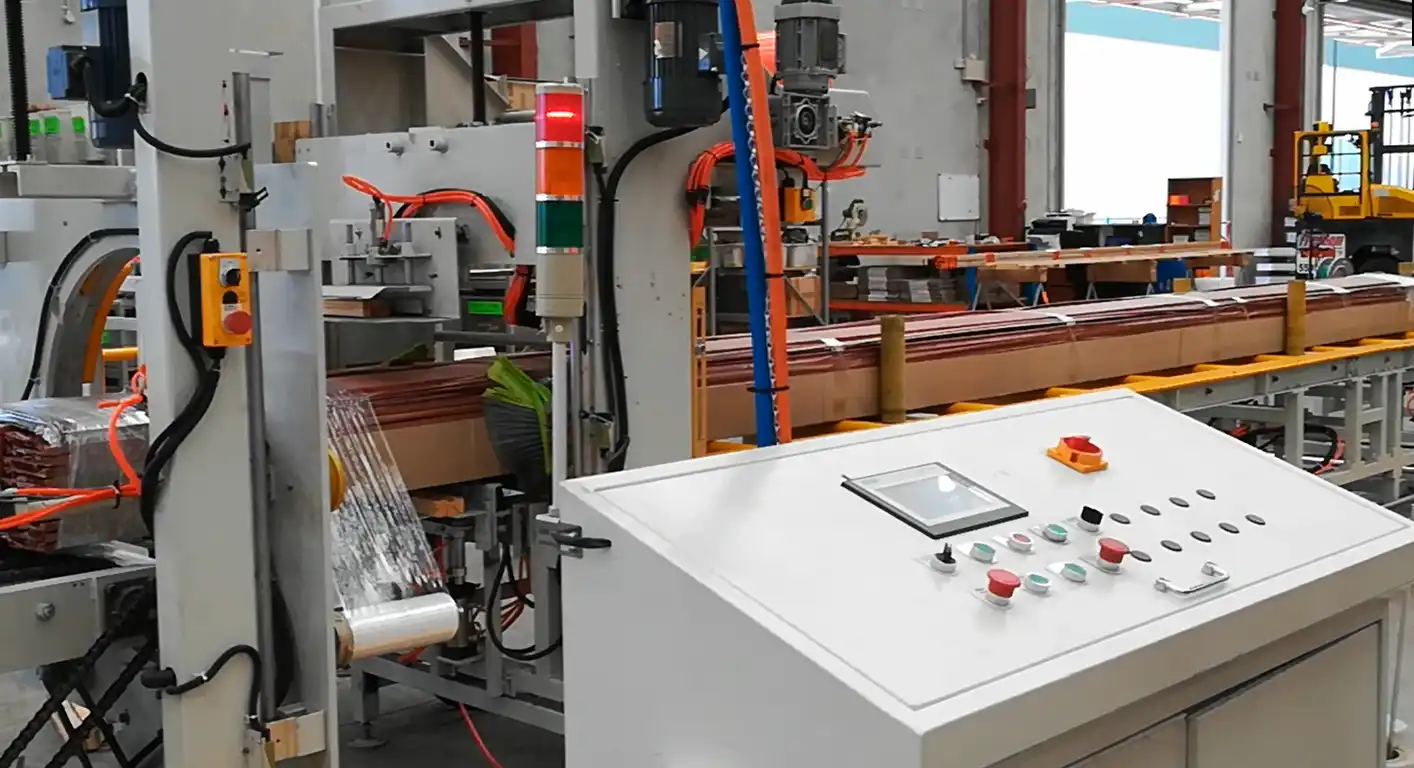

The solution is to install an integrated, fully automatic cable coil winding and wrapping line. This system automates the entire end-of-line process. A coiling machine first winds the cable or wire into a neat coil. Then, without any manual handling, the coil is transferred to an orbital wrapping station. This station automatically wraps the entire coil in layers of stretch film, completely sealing it from dust, moisture, and scratches before it is ejected for palletizing.

I’ve been in your shoes. I started my career as an engineer on the factory floor, wrestling with these same frustrations. When I built my own packing machine factory, I learned that solving these problems isn’t just about buying a machine; it’s about fundamentally re-engineering a process. It’s about finding a partner who understands the immense cost of downtime and the true value of a safely, securely packaged product. Let’s walk through how this technology works, step-by-step, and how it can directly solve the efficiency and product damage issues you’re facing right now.

What are the steps in an automated winding and wrapping process?

You see your crew struggling to wrap a heavy, awkward coil. They are trying to manually pass a roll of film around and through the center, a process that is slow, inconsistent, and physically demanding. You can see the potential for injury and inconsistent quality. You wonder how a machine can possibly replicate this complex motion efficiently and flawlessly every time.

An automated winding and wrapping line performs this task in a seamless, three-part sequence controlled by a central PLC. First, the coiling machine precisely winds the cable to a programmed length. Second, an automated transfer system moves the finished coil from the winder to the wrapper’s infeed conveyor. Third, the orbital wrapper passes a rotating ring carrying a roll of stretch film through the center of the coil, completely encasing it in a protective layer. The machine then automatically cuts and secures the film, and the finished, sealed coil is ejected.

Dive Deeper: A Look Inside the Integrated Line

Let’s break this down further. Understanding the mechanics helps you see how reliable and efficient this process really is. It’s a beautifully simple concept executed with robust engineering. I always loved watching these machines work when I was starting out because it’s a perfect blend of power and precision.

Step 1: The Precision Coiling Station

This is where the quality of the final product begins. A perfect wrap starts with a perfect coil.

- Controlled Infeed: The machine pulls the cable or wire from your source, but it does so through a tensioning system. This is critical. Consistent tension ensures the coil is dense and stable. Without it, you get loose, sloppy coils that are difficult to wrap and transport.

- HMI Control: Your operator uses a simple touch screen, the HMI, to tell the machine exactly what to do. They can enter the desired coil length, the wire diameter, and the target speed. The system can save hundreds of these "recipes," so switching between different product runs takes only seconds.

- Servo-Driven Traverse: As the coil is wound, a traverse arm moves back and forth, guiding the wire into neat, even layers. This is controlled by a highly accurate servo motor, which guarantees that every coil has the same shape and density. A perfectly cylindrical coil is much easier for the wrapping station to handle.

Step 2: The Hands-Free Transfer

This is the bridge between the two main processes and a major safety improvement. Once the coil is finished and the cable is automatically cut, the winding head retracts. Then, one of several transfer mechanisms takes over:

- A pusher arm might gently slide the coil onto the conveyor of the wrapper.

- A tilting mechanism could turn the coil and place it down.

- A robotic arm could pick up the coil and place it with high precision.

The key is that this step completely eliminates the need for a worker to lift and carry a heavy coil, which is where so many factory injuries occur.

Step 3: The Orbital Wrapping Station

This is where the magic happens. The coil sits on a set of powered rollers.

- The Ring: A large, vertical rotating ring is the heart of the machine. A dispenser holding a large roll of stretch film is mounted on this ring.

- The Motion: To start, the ring moves forward so the coil is in its center. Then, the ring begins to rotate. As it spins, it passes the stretch film through the eye of the coil, around the outside, and back through the eye. At the same time, the rollers on the bottom slowly turn the coil itself.

- The Result: This combined motion—the ring rotating vertically while the coil rotates horizontally—creates a cocoon of stretch film that completely covers the entire product. It’s fast, efficient, and provides total protection. The overlap of the film can be adjusted on the HMI to provide more or less coverage depending on your needs. When the wrap is complete, a clamp grabs the film, a hot wire cuts it, and a brush wipes it down to ensure a secure seal.

| Process Stage | Key Technology | Primary Benefit |

|---|---|---|

| Coiling | PLC Control, Servo Traverse, HMI | Creates precise, consistent, and dense coils every time. |

| Transfer | Automated Pushers or Robotics | Eliminates dangerous manual lifting and carrying. |

| Wrapping | Rotating Ring, Powered Rollers | Provides fast, complete, and secure product protection. |

| Control | Integrated PLC System | Ensures all three stages work together seamlessly as one machine. |

How does wrapping provide better product protection than strapping?

You’ve dealt with the frustration. A customer calls to complain that a shipment of steel wire arrived with surface rust. Or a coil of premium cable has scuffs and scratches on its outer layers from rubbing against other items during transit. Your current packing method, maybe just a few straps, isn’t enough. It’s costing you money in returns, rework, and, worst of all, customer trust.

Wrapping provides far superior product protection because it creates a complete environmental seal around the coil. Unlike strapping, which only secures the coil, stretch wrapping encases the product in a tight, multi-layered barrier of film. This barrier protects the coil from moisture, dust, dirt, and oil during storage and transportation. It also prevents surface scratches and edge damage, ensuring your product arrives at the customer in the exact same condition it left your factory.

Dive Deeper: The Functional Difference Between Securing and Protecting

When I was running my factory, I learned a valuable lesson: the cost of a customer complaint is always higher than the cost of getting the packaging right the first time. The choice between strapping and wrapping is a perfect example of this. They serve fundamentally different purposes.

Strapping: A Method of Unitizing

Strapping is a good solution for one thing: holding a coil together so it doesn’t unravel. It’s a method of "unitizing" or bundling.

- Limited Coverage: Straps are applied at two, three, or maybe four points. The vast majority of the product surface remains exposed.

- No Environmental Barrier: Dust from a warehouse, moisture from a humid container, or spray from a wet road can all directly contact the product. For metal products like steel wire, this can quickly lead to surface corrosion and rust.

- Potential for Damage: If a strap is applied with too much tension, it can cut into the edges of the coil, damaging the very product it’s supposed to protect.

Wrapping: A Method of Total Encapsulation

Orbital stretch wrapping takes a completely different approach. It aims to isolate the product from its environment.

- Complete Seal: The overlapping layers of stretch film create a cocoon. This protective skin is highly effective at keeping out contaminants. If you are producing high-value steel wire or cable where surface finish is critical, this is a non-negotiable benefit.

- Moisture and Dust Proof: This is the most significant advantage. By sealing the coil, you prevent the causes of corrosion and contamination. You can store wrapped coils for longer periods without fear of degradation. When shipping overseas or through areas with high humidity, this can be the difference between a happy customer and a rejected shipment.

- Abrasion Resistance: The multiple layers of film act as a protective buffer. During shipping, when pallets can shift and rub against each other, the film takes the abuse, not your product. This eliminates the scratches, scuffs, and dents that can happen with exposed coils.

- Stabilization: The tight film also adds to the stability of the coil itself, keeping the windings tight and secure, which complements the primary function of holding it together.

Let’s compare them directly:

| Feature | Strapping | Stretch Wrapping |

|---|---|---|

| Primary Function | Securing / Bundling | Protecting / Sealing |

| Surface Coverage | Minimal (5-10%) | Complete (100%) |

| Moisture Protection | None | Excellent |

| Dust/Dirt Protection | None | Excellent |

| Scratch/Abrasion Protection | None | Excellent |

| Risk of Product Damage | Moderate (edge damage from high tension) | Very Low |

| Ideal For | Low-value items where only bundling is needed. | High-value items needing environmental and surface protection. |

For a manager like you, Michael, who is responsible for the entire process from raw material to finished good, the choice is clear. Wrapping isn’t just a different packing method; it’s a commitment to delivering a higher quality product to your customers.

What safety hazards does an automatic wrapping line eliminate?

You see the safety posters on your factory walls, but you know that true safety is built into the process, not just talked about. Every time you see a worker wrestling with a heavy coil or manually handling packing materials, you see a risk. An injury means pain for your employee and a cascade of problems for you: lost productivity, increased insurance costs, and the struggle to find and train a replacement. You’re looking for a solution that doesn’t just make the work faster, but makes it fundamentally safer.

An automatic winding and wrapping line systematically eliminates the most significant safety hazards from your end-of-line packaging process. It removes the need for manual lifting and carrying of heavy coils, which is the leading cause of musculoskeletal injuries. It also eliminates the repetitive, awkward motions of hand-wrapping and the risks associated with manually handling packaging materials, creating a safer, more sustainable work environment for your team.

Dive Deeper: Engineering the Danger Out of the Job

One of the proudest moments for me as a factory owner was seeing a dramatic drop in a facility’s injury rate after we installed a new automated line. It’s a powerful feeling. You’re not just improving metrics; you’re protecting people. Let’s get specific about the risks an automated winder and wrapper removes.

Eradicating High-Risk Manual Handling

The most impactful safety improvement comes from taking the worker’s body out of the equation for heavy lifting.

- Lifting and Carrying: This is the big one. Manually moving a finished cable coil is a textbook recipe for back injuries, shoulder strains, and hernias. An automated line with an integrated transfer system handles 100% of this movement. The worker’s role changes from a physical laborer to a system supervisor.

- Awkward Postures: Think about how a person has to wrap a coil by hand. They have to bend over, reach through the center of the coil, and circle around it repeatedly. These awkward and unnatural movements, when performed all day, lead directly to chronic pain and repetitive strain injuries (RSIs). The orbital wrapper’s rotating ring does this work tirelessly and without any risk of strain.

Eliminating Secondary Hazards

Beyond the heavy lifting, there are other, more subtle risks that automation solves.

- Repetitive Strain: Even if the coils were light, the motion of manually wrapping is extremely repetitive. This can lead to conditions like carpal tunnel syndrome or tendonitis in the wrists and elbows. The machine takes on this repetitive burden.

- Trips and Falls: A manual wrapping station can become cluttered with rolls of film, tools, and finished coils waiting to be moved. This creates a messy and hazardous workspace. An automated line is a self-contained system with a clear, predictable footprint, reducing clutter and the associated trip hazards.

- Operator Fatigue: A tired worker is an unsafe worker. Manual packing is physically draining. As fatigue sets in, the risk of mistakes and accidents skyrockets. A machine doesn’t get tired. It performs with the same level of precision at the end of the shift as it did at the beginning, and the operator monitoring it is far less physically stressed.

Let’s categorize these safety wins:

| Hazard Type | Manual Wrapping Risk | How Automation Solves It |

|---|---|---|

| Acute Injury | Back injuries, strains, hernias from lifting heavy coils. | All lifting and carrying is performed by the machine. |

| Chronic Injury | Repetitive strain injuries (RSIs) from awkward wrapping motions. | The machine’s orbital ring performs all wrapping motions. |

| Workplace Hazard | Cluttered workspace, trip hazards from materials and tools. | The process is contained within the line, creating a cleaner, safer area. |

| Human Factor | Accidents caused by physical fatigue and distraction. | The machine handles the strenuous work, reducing operator fatigue and error. |

By automating, you are making a profound statement to your team that their health and safety are a top priority. This builds loyalty and creates a more stable, professional workforce, which is a massive, long-term asset for any factory.

How can you be sure an automated wrapping line is a worthwhile investment?

As an experienced manager, you are rightly skeptical. You’ve seen presentations for expensive equipment before, full of promises that didn’t materialize. You need to build a business case that is grounded in facts, not fantasy. You need to know that this isn’t just a cost, but a strategic investment with a clear and predictable return. And you need a partner who can help you make that case with honesty and expertise, not just a sales pitch.

You can be sure an automated wrapping line is a worthwhile investment by conducting a thorough ROI analysis that goes beyond just labor savings. A true partner will help you quantify the "hidden" costs you’re currently absorbing: the cost of product damaged by moisture and shipping, the cost of customer complaints and returns, and the opportunity cost of production bottlenecks. When you factor in these gains alongside the direct labor savings, the financial case becomes overwhelmingly strong.

Dive Deeper: My Insight on Calculating the True Return

This is where my journey from factory engineer to factory owner becomes so important. I’ve lived your challenges. I’ve had to justify these investments myself. The key is to change the way you think about the "return." It’s not just about subtracting the labor cost of a few workers. It’s about adding the new value you create.

Step 1: Calculate the "Hard" Savings (The Obvious ROI)

This is the easy part of the calculation, the numbers you can pull directly from your accounting.

- Direct Labor: How many employees are on your packing line per shift? What is their total cost (wages, taxes, benefits)? Let’s say 2 workers at $25/hour each for two shifts. That’s

2 * $25 * 16 hours = $800 per day. An automated line needs one supervisor, not two dedicated workers. You can reassign those valuable team members to other, higher-value tasks. - Material Savings: An automated wrapper uses a "pre-stretch" function, often stretching the film by 200-300%. This means 1 meter of film on the roll becomes 3-4 meters on the coil. This dramatically reduces your consumable film cost compared to inefficient hand wrapping.

Step 2: Calculate the "Soft" Savings (The Hidden ROI)

This is where a real expert partner helps you. These are the costs that are eating away at your profit margin right now.

- Cost of Product Damage: This is huge. What is your current rate of product rejection or customer complaints due to corrosion or shipping damage? 1%? 2%? Calculate the total value (materials, labor, shipping, administrative time) of those rejected goods over a year. An automatic wrapper can get that rate close to zero. This is pure profit added back to your bottom line.

- Cost of Low Throughput: Your manual wrapping station is a bottleneck. If the rest of your line can produce 40 coils an hour, but your packing team can only handle 20, you are losing the potential profit on 20 coils every hour. An automated line can easily match or exceed the speed of your production, unlocking that hidden capacity and allowing you to increase your total factory sales.

Let’s put this into a framework you can use:

| ROI Component | How to Calculate Your Annual Gain |

|---|---|

| Labor Savings | (Cost of Manual Labor) – (Cost of Automated Supervisor) |

| Material Savings | (Cost of Hand-Wrap Film) – (Cost of Machine Film with Pre-Stretch) |

| Damage Reduction | (Value of Annually Damaged/Rejected Goods) * (% Reduction) |

| Throughput Increase | (Additional Coils Shipped per Hour) (Profit per Coil) (Operating Hours) |

| Total Annual Gain | Sum of all the above savings and new profits |

When you lay out the numbers this way, the investment in automation stops looking like an expense. It becomes the most logical, data-driven decision you can make to improve safety, quality, and profitability. A supplier who only talks about the machine’s price isn’t a partner. A true partner, someone who has been in your position, will help you build this business case because they know their success is tied directly to yours.

Conclusion

Ultimately, an online automatic winding and wrapping machine solves your core challenges. It boosts speed, drastically improves safety, and delivers a perfectly protected product, building customer trust and enhancing your bottom line.