Optimizing Slit Coil Handling and Packaging: A Comprehensive Guide from Production to Delivery

Executive Summary

The handling and packaging of slit coils—narrow strips of metal cut from larger master coils—present a critical set of challenges and opportunities for manufacturers across diverse sectors such as automotive, construction, and electronics. These materials, whether steel, copper, or aluminum, are valuable and often feature sensitive surfaces requiring meticulous care to prevent damage that can lead to significant financial and operational losses. This report provides an in-depth analysis of the problems inherent in slit coil handling and packaging, from initial production through to final delivery, and offers comprehensive solutions focusing on optimized handling equipment, advanced packaging materials and techniques, and the strategic implementation of automation.

Key findings indicate that common damage types such as edge damage, surface scratches, telescoping, and corrosion are frequently interlinked and can be exacerbated by inconsistencies in upstream processes or downstream handling choices. The true cost of such damage extends beyond material loss to include operational disruptions, rework, customer dissatisfaction, and safety hazards.

Optimized handling relies on a systematic approach, incorporating specialized equipment like coil cars, turnstiles, precision down-enders, and advanced lifting devices (C-hooks, grabs, tongs) designed for gentle yet efficient movement. Best practices emphasize minimizing coil movements, maintaining equipment cleanliness, and employing material-specific handling protocols, particularly for surface-sensitive aluminum and corrosion-prone copper. Adherence to stringent safety standards and the use of appropriate Personal Protective Equipment (PPE) are paramount.

Advanced packaging materials, including various forms of Volatile Corrosion Inhibitor (VCI) products, physical protection like stretch films and edge guards, and appropriate strapping (increasingly PET over steel for many applications due to safety and TCO benefits), are crucial. Sustainability is a growing driver, favoring recyclable and recycled-content materials.

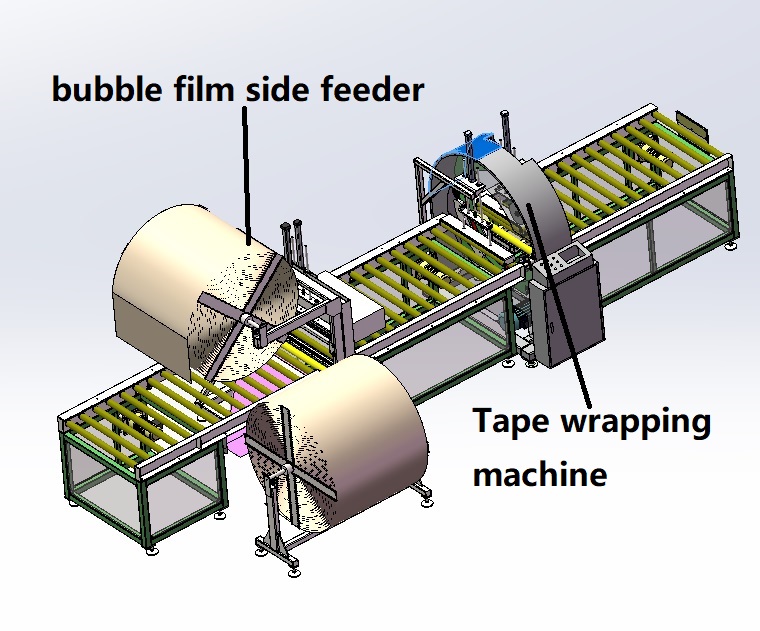

Automation, ranging from semi-automated standalone machines to fully integrated packaging lines connected with MES/ERP systems, offers substantial benefits. These include reduced labor costs, increased throughput, consistent packaging quality, minimized material waste, and enhanced safety. The report details the components and workflow of automated lines, highlighting the role of PLCs, HMIs, robotics, and data integration.

Justifying investment in automation requires a thorough Total Cost of Ownership (TCO) analysis and ROI calculation, considering quantifiable benefits like labor and material savings, and less tangible, yet critical, advantages such as improved quality and safety. Tools like Overall Equipment Effectiveness (OEE) monitoring and Predictive Maintenance (PdM) are vital for maximizing the performance and lifespan of automated systems.

Future trends point towards increased adoption of smart technologies like AI, IoT, and Digital Twins for predictive and adaptive packaging operations, alongside a continued push for greener solutions. Strategic implementation involves comprehensive assessment, careful technology selection, phased adoption where appropriate, robust workforce training, and a commitment to continuous improvement driven by data analytics. This holistic approach is essential for transforming slit coil handling and packaging into a source of competitive advantage.

Section 1: The Critical Nature of Slit Coil Handling and Packaging

The journey of a metal coil from its initial slitting to its final application is fraught with potential pitfalls. Slit coils, by their very nature, are more susceptible to damage than their master coil counterparts due to increased exposed surface area, more edges, and often lighter gauges. Understanding the specific properties of these materials and the common types of damage they can incur is fundamental to developing effective handling and packaging strategies. The economic and operational consequences of failing to do so can be severe, impacting not only direct costs but also customer satisfaction and overall business competitiveness.

1.1. Understanding Slit Coils: Properties, Value, and Sensitivities

Slit coils are narrower strips of metal, precisely cut from wider master coils, and are produced to meet the specific width and thickness requirements of downstream manufacturing processes.1 These coils are foundational materials for a vast array of products across numerous industries, including automotive components, construction materials (like roofing and cladding), electronics (such as connectors and casings), and appliance manufacturing.2 The value embedded in slit coils is significant, not only due to the base material cost, which can account for up to 70% of total manufacturing costs 1, but also due to the precision slitting process itself.

Material-specific considerations are paramount:

- Steel Slit Coils: Steel is used in a multitude of grades, including high-strength low-alloy (HSLA), dual-phase (DP), and martensitic steels, each presenting distinct processing and handling challenges due to variations in yield strength, tensile strength, and formability.1 Steel coils are highly susceptible to oxidation (rust) if exposed to moisture and atmospheric contaminants without adequate protective measures.3

- Copper Slit Coils: Copper is prized for its exceptional electrical and thermal conductivity, making it indispensable in electrical wiring, power distribution, transformers, and electronics.2 However, copper is prone to oxidation, tarnishing, and staining, and its surface finish is often a critical quality parameter.4 Given its relatively high market value, preventing any form of damage, including corrosion and physical deformation, during packaging and transit is economically vital.4

- Aluminum Slit Coils: Aluminum offers benefits such as light weight, high malleability, and excellent inherent corrosion resistance.1 However, it is a soft metal, making it highly susceptible to surface damage like scratches, gouges, dents, and water stains if not handled with extreme care.5 Aluminum coils are produced in a wide range of thicknesses, from as thin as 0.2 mm up to 8 mm 1, with thinner gauges being particularly delicate.

Many slit coils, irrespective of the base metal, undergo surface treatments or are manufactured with critical surface finishes. These can include polished surfaces, pre-painted or coated layers (e.g., galvanized, aluminized), Class A automotive finishes requiring flawless appearance, or specialized surfaces like those on lithographic aluminum.6 Such coils demand exceptionally careful handling and the use of non-abrasive packaging materials. Often, protective films made of paper, vinyl, or PVC are applied during or immediately after the slitting process to shield these sensitive surfaces.7

The inherent diversity in material properties, gauges, widths, and surface finishes means that a universal approach to slit coil handling and packaging is often inadequate. Solutions must be adaptable and tailored to the specific characteristics of the coil to prevent damage and preserve its value. This necessity for customization is a driving force behind the development of more sophisticated and flexible handling equipment and packaging lines.

1.2. Common Problems and Damage Types in Slit Coil Handling and Packaging

Slit coils are vulnerable to a range of damage types throughout the handling, storage, packaging, and transportation processes. These issues can compromise the material’s integrity, usability, and aesthetic quality, leading to significant losses.

Physical Damage:

- Edge Damage: This includes dents, bends, nicks, and tears along the slit edges of the coil. It is a prevalent issue often resulting from rough handling, impacts during loading and unloading (e.g., with forklift tines or against other objects), or the use of inadequate edge protection materials during packaging and transit.5 Damaged edges are particularly problematic as they can affect the coil’s effective width, lead to issues in downstream processing equipment (e.g., jamming in presses or roll formers), and may necessitate re-slitting the coil to a narrower width, thereby generating scrap and reducing yield.5

- Surface Damage: Scratches, gouges, abrasions, and scuff marks on the coil surface can occur due to contact with contaminated or worn handling equipment (e.g., rollers, guides, C-hooks), abrasive packaging materials, unsecured strapping, or friction between coil laps during movement.5 For materials with critical or cosmetic surface finishes, even minor scratches can render the coil unusable for its intended application.5

- Kinks, Dents, and Unsightly Bends: These deformations can arise if coils are moved too roughly, dropped, or are not properly supported during lifting and transport.8 Such damage can affect the flatness and formability of the material.

- Telescoping (Dish or Clock-Springing): This defect is characterized by the sideways shifting or axial displacement of inner coil wraps relative to the outer wraps, causing the coil to resemble an extended telescope.3 It is often caused by insufficient or uneven winding tension during the recoiling process after slitting, improper handling techniques (especially sudden starts/stops or swinging during crane movements), inadequate lateral support during transit, or vibration.3 Telescoped coils can be difficult to unwind smoothly, may lead to coil collapse, and can cause significant disruptions in automated processing lines.3

- Coil Breaks, Banding Marks, and Reel Breaks: These are indentations, creases, or localized deformations on the coil surface. Banding marks result from the over-tightening of circumferential or eye straps, or the use of inappropriate strapping material or incorrect strap positioning.3 Reel breaks can occur during winding or unwinding if the coil conforms to irregularities on the mandrel surface, such as the edges of segmented leaves, particularly if the mandrel is worn or if there’s insufficient cushioning.5 These breaks can "print through" multiple layers of the coil, damaging a considerable amount of material.5

- Physical Distortion (Ovality, Out-of-Roundness, Flat Spots): Coils can lose their cylindrical shape due to improper stacking (e.g., stacking too high, leading to excessive weight on bottom coils), uneven weight distribution during storage or transport, or significant impacts.3 Stacking coils more than three high, for instance, is often discouraged as it can deform the bottom coils, rendering them scrap.5 Ovality or flat spots can cause problems with coil payoff and processing in subsequent manufacturing stages.

Corrosion and Environmental Damage:

- Rust and Water Stains (Primarily Steel): Exposure to moisture is a primary cause of rust on steel coils. This can occur due to inadequate moisture barrier packaging, condensation forming on the coil surface due to temperature fluctuations (e.g., moving a cold coil into a warm, humid environment), or direct contact with water during storage or transit.3 Water trapped between coil laps can lead to "white rust" or water stains, which can be difficult to remove and may compromise surface quality.8

- Oxidation and Tarnish (Non-Ferrous Metals): Copper and its alloys are susceptible to tarnishing and oxidation, while aluminum can also exhibit surface changes if not properly protected from atmospheric conditions or incompatible materials.4

- Saltwater Corrosion: Coils transported by sea are at high risk of corrosion from saltwater spray or humid, salty air, necessitating packaging with enhanced moisture and corrosion-inhibiting barriers.6

Handling-Induced Issues:

- Spring-Back (Uncontrolled Uncoiling): Coiled metal, especially high-strength materials or those with significant internal stresses, has a natural tendency to unwind or "spring back" if not adequately restrained by banding.9 This poses a significant safety hazard to personnel and can lead to rapid, uncontrolled uncoiling if bands are removed improperly or prematurely. The risk increases with material thickness, width, and reduced coil inner diameter.9

- Damage from Lifting Equipment: Improper use of C-hooks (e.g., contacting coil edges or ID), forklift tines (gouging coil sides or ID), or worn/unsuitable mandrel surfaces can directly damage the coil.5

Packaging Failures:

- Broken or Inadequate Skids/Pallets: If the skids or pallets used are not robust enough for the coil weight or are already damaged, they can fail during handling or transit, leading to coil damage.8

- Insecure Strapping: Insufficiently tensioned or improperly sealed straps can allow coils or coil stacks to shift, leading to damage or safety hazards.

- Protective Film Issues: Protective PVC films, if left on coils exposed to UV radiation or moisture for extended periods, can break down, leaving adhesive residues or failing to provide protection.8

Many of these damage types are not isolated incidents but are often interlinked. For example, insufficient winding tension during recoiling (an upstream process) can directly contribute to telescoping during subsequent handling or transit.3 Similarly, improper stacking practices in the warehouse (a downstream choice) can lead to physical distortion of coils.5 This interconnectedness underscores the necessity of a holistic, end-to-end quality control philosophy that considers the entire lifecycle of the slit coil, from its creation to its final use. Packaging solutions, therefore, cannot be viewed in isolation but must be integrated into a broader strategy of careful handling and process control.

Table 1: Common Slit Coil Damage Types: Causes, Consequences, and Prevention

| Damage Type | Description | Common Causes (Categorized) | Primary Consequences | Key Prevention Strategies (Equipment, Materials, Process Control) |

|---|---|---|---|---|

| Edge Damage | Dents, bends, tears on coil edges 3 | Handling: Rough handling, impacts with equipment/environment. Packaging: Inadequate edge protectors. Transit: Shifting, impacts. | Material loss (re-slitting), processing issues, customer rejection. | Proper lifting devices, cushioned handling equipment, robust edge protectors (plastic/paperboard) 10, secure transit packaging. |

| Surface Damage | Scratches, gouges, abrasions, stains 3 | Handling: Contact with worn/dirty equipment, improper lifting. Packaging: Abrasive materials, loose debris. Environment: Contaminants. | Reduced aesthetic/functional quality, rejection for critical surfaces, corrosion initiation. | Clean/cushioned handling surfaces (polyurethane, felt) 7, non-abrasive packaging (VCI paper/film, PE film) 6, protective interleaving, controlled environments. |

| Telescoping | Sideways shifting of coil layers 3 | Winding: Insufficient/uneven tension. Handling: Sudden crane movements, improper support. Transit: Vibration, inadequate lateral restraint. | Coil collapse, unwinding difficulties, processing jams, material damage. | Optimized winding tension control 11, smooth handling protocols, proper coil orientation and support during transit, tight wrapping. |

| Coil Breaks / Banding Marks | Indentations/creases from strapping or mandrels 5 | Strapping: Over-tensioning, wrong strap type/placement. Winding: Pressure from mandrel segments. | Localized deformation, stress points, print-through damage, reduced material yield. | Correct strapping material (steel/PET) and tension 12, cushioned mandrel sleeves 5, proper banding tools and techniques. |

| Physical Distortion | Ovality, flat spots, out-of-roundness 3 | Storage: Improper stacking (too high, uneven). Handling: Impacts, incorrect support. | Processing issues, fitment problems in final application. | Adherence to stacking limits, stable/level storage surfaces, careful handling, robust pallets/skids. |

| Corrosion (Rust, Tarnish, Oxidation) | Chemical degradation of metal surface 6 | Environment: Moisture, humidity, temperature fluctuations, contaminants (salt). Packaging: Insufficient barrier properties, breached packaging. | Reduced strength/integrity, poor appearance, material failure, costly removal or scrap. | VCI packaging (papers, films, emitters) 13, moisture barrier wraps (PE film) 6, desiccants, controlled storage environments, proper sealing of packages. |

| Spring-Back | Uncontrolled unwinding of coil 9 | Material Properties: High yield strength, internal stresses. Handling: Premature or incorrect band removal. | Severe safety hazard to personnel, rapid coil unspooling, material damage. | Adherence to strict banding protocols, sufficient number/strength of bands, controlled de-banding procedures, use of decoiling equipment with hold-downs. |

1.3. The Cost of Inefficiency and Damage: Financial and Operational Impacts

The repercussions of inefficient handling and packaging, leading to damaged slit coils, extend far beyond the simple cost of the spoiled material. These issues trigger a cascade of direct and indirect costs that can significantly erode profitability and operational efficiency.

Direct Costs:

- Material Waste: The most obvious cost is the value of the slit coil material that must be scrapped due to irreparable damage. This can involve entire coils or significant portions if re-slitting to remove damaged sections is necessary.5

- Rework Costs: Damaged coils may require additional processing, such as re-slitting to remove edge damage, re-flattening, cleaning to remove surface contaminants or light corrosion, or re-packaging if the initial packaging failed.5 These activities consume labor, machine time, and resources.

- Replacement Costs: If coils are damaged beyond salvage or rework, they must be replaced, incurring the full cost of new material and processing.

- Damage Claims and Returns: Customers receiving damaged or out-of-specification slit coils will likely reject the shipment, leading to damage claims, return logistics costs, and administrative overhead to process these claims.14 Studies indicate that improper packaging can elevate the risk of coil damage by as much as 40% 15, and returns due to various defects can increase overall operational costs by up to 20%.14

Indirect Costs:

- Lost Production Time and Downtime: Dealing with damaged coils—inspecting, sorting, reworking, or awaiting replacements—disrupts production schedules and leads to unplanned downtime for both the supplier and potentially the customer.16

- Increased Labor Costs: Additional labor is expended on manual inspection of suspect coils, sorting damaged from usable material, performing rework, and handling returns and claims processing.17

- Reputational Damage and Loss of Customer Trust: Consistently delivering damaged products severely impacts a supplier’s reputation. Customer dissatisfaction is a major concern, as evidenced by findings that 73% of customers would not repurchase from a company if they received a damaged product.18 This can lead to loss of future business and market share.

- Increased Inspection Costs: If damage rates are high, companies may need to implement more intensive (and costly) inspection procedures for both incoming master coils and outgoing slit coils to mitigate risks.5

- Voided Warranties: Improper storage or handling that leads to environmental damage, such as water staining or corrosion on coils with protective films, can void material or coating warranties.8

- Safety-Related Costs: Mishandling damaged or improperly secured coils increases the risk of workplace accidents and injuries, leading to medical expenses, workers’ compensation claims, and potential regulatory fines.14

- Administrative Overheads: Managing complaints, processing returns, arranging replacement shipments, and dealing with insurance claims all add to administrative burdens and costs.

The cumulative financial and operational impact of these factors underscores that the "cost of damage" is not merely the scrap value of the metal. It encompasses a wide spectrum of operational inefficiencies, wasted resources, administrative burdens, and, crucially, potential erosion of customer relationships and market standing. Consequently, investments in robust handling equipment, appropriate packaging materials, optimized processes, and thorough personnel training are not merely expenses but strategic measures to prevent these cascading negative outcomes. Proactive spending on preventative measures is highly leveraged, as it can yield disproportionately large savings by avoiding the multifaceted costs associated with damaged goods.

Section 2: Optimizing Slit Coil Handling from Production to Packaging

Effective slit coil handling is a critical intermediate stage between the slitting operation and final packaging. The primary objectives are to move coils efficiently, maintain their physical integrity, and ensure operator safety. This requires a systematic approach involving specialized equipment, adherence to best practices (particularly for sensitive materials), and robust safety protocols.

2.1. Essential Handling Equipment: A Systematic Approach

A range of specialized equipment is employed to manage slit coils from the exit of the slitter through various intermediate steps to the packaging line. The selection and integration of this equipment are pivotal in preventing damage and maximizing operational flow.

Initial Coil Transfer & Orientation:

- Coil Cars: These are fundamental for transporting coils, particularly from the slitter’s recoiler to a turnstile or directly to the packaging line infeed. Coil cars are designed to handle significant weights and come in various configurations: entry-end cars for feeding master coils to slitters, exit-end cars for receiving slit mults, and even propane-powered versions for transferring large master coils within a facility.19 Key features often include robust welded steel frames, hydraulic hold-down mechanisms (especially important for securing narrow or unstable coils), and various control options such as pendant or remote controls.20

- Turnstiles: Typically featuring two to four arms, turnstiles act as a buffer or accumulation station, receiving sets of slit coils (mults) from the coil car or directly from the slitter’s exit.19 They allow for the sequential feeding of individual coils to the packaging line. Coils can be loaded onto or removed from turnstile arms using C-hooks, other coil cars, or down-enders. Design features may include U-shaped arms to facilitate C-hook access, hydraulic pushers for coil movement, and precision positioning latches.20

- Down-enders (De-stackers/Tilters): These machines are crucial for reorienting coils. Most commonly, they take coils from an eye-horizontal position (as they sit on a turnstile arm) and rotate them 90 degrees to an eye-vertical (eye-to-sky) position for subsequent strapping, wrapping, and stacking on pallets.21 Conversely, upenders may be used at the end of a packaging line to tip a fully packaged stack of eye-vertical coils back to eye-horizontal if required for specific shipping methods, particularly for wide coils.22

- Pick & Place Down-enders: These are automated units that individually pick slit mults from the turnstile arm, rotate them, and place them onto a conveyor. They are generally preferred for high-productivity lines and for handling sensitive materials because they minimize the risk of coil ID marking or telescoping that can be caused by push-off mechanisms found in simpler systems.19 Advanced pick & place down-enders can be programmed to recognize the width of each coil and the sequence of coils on the turnstile arm. They can also incorporate features like a "Double Pick" routine for very narrow mults (to prevent them from sticking together) and magnetic or vacuum stabilization systems for thin or delicate materials.20

- Fixed Position Down-enders: These are often simpler and may be better suited for heavy-gauge coils. In such systems, a pusher arm on the turnstile typically slides the coil onto the downender’s receiving arm.22

Advanced Lifting Devices:

The choice of lifting device is critical for both safety and damage prevention.

- C-Hooks: These are simple, robust, and widely used devices for lifting coils by their inner diameter (ID).23 They are effective when coils need to be stacked closely together end-to-end or when access to the coil ID is restricted to one side. C-hooks require no external power. To protect the coil surface, the contact areas of C-hooks should be lined with protective materials like polyurethane or heavy felt.7 Optional features include urethane bumpers on the C-hook body, low-headroom designs for tight spaces, and motorized rotation capabilities.23

- ID Lifters (Expanding Mandrel Type): These devices are inserted into the coil ID and then expand mechanically or hydraulically to grip the inner surface securely.6 They are often used with jib cranes in manual or semi-automated coil stacking operations.22

- OD Lifters (Tongs/Grabs): These grip the coil around its outer diameter.6 Their use requires careful consideration to avoid damaging the outer wraps or surface of the coil.

- Telescoping Coil Grabs (Motorized): These are often the preferred solution for handling coils with their axis horizontal. Their telescoping legs can adjust to handle a wide range of coil diameters and widths while maintaining a relatively low headroom profile.23 A key advantage is that they engage the coil from both sides, offering enhanced safety and stability. They are well-suited for automated crane applications and use in areas with limited space. Common features include motorized rotation around the vertical axis, hold-down arms to secure un-banded coils, and integrated digital weighing systems.23

- Parallelogram Coil Lifters: Also used for coils with a horizontal axis, these lifters employ a parallel linkage mechanism.23 This design is advantageous in facilities with narrow aisles between coil storage racks because the outer width of the lifter remains consistent. However, they generally require more vertical headroom to operate compared to telescoping grabs. Options can include powered rotation and retractable feet for precise positioning.23

- Vertical Axis Coil Tongs: These are designed for lifting coils that are already in an "eye-to-the-sky" (axis vertical) position, particularly when the underside of the coil is not accessible for other types of lifters.23 They are heavy-duty units, custom-configured for the specific range of coil sizes to be handled. Versions include single-rim grip (gripping one side between ID and OD, suitable for heavy gauge coils) or double-rim grip (gripping both sides, more secure for delicate or thinner gauge strip and more tolerant of ID/OD variations). Automatically activated tongs can enable virtually "hands-free" operation.23

Conveying and Transfer Systems:

Once coils are oriented and lifted, they need to be moved efficiently between processing stations.

- Conveyors (Roller, Belt, Chain): These are the workhorses for transporting individual coils or stacks through the various stages of a packaging line—for example, from a down-ender to a strapping station, then to a wrapping machine, and finally to a stacking area.21 The number and length of conveyors are often dictated by plant layout, space availability, and budget. More conveyor sections can provide valuable buffer storage, allowing different parts of the line to operate somewhat independently and freeing up upstream equipment like turnstiles more quickly.22

- Shuttle Cars: These are used to transfer coils or completed skidded stacks between different conveyor lines or to and from offline processes or storage areas.22

- Sortation Tables: In operations where a single master coil is slit into mults for multiple customer orders or different final widths, sortation tables are essential. These typically powered turntables can have multiple (e.g., 4, 6, 8, or 12) positions, allowing operators or automated systems to sort and stack coils onto the correct skid for each order.19 Features often include smooth hydraulic or gear-driven rotation, precision center bearings for stability, automatic indexing to any selected position (often via the shortest route), and mechanical latching for consistent positioning accuracy.22

The Role of Automated Guided Vehicles (AGVs) in Coil Transport:

AGVs are increasingly being adopted for material handling in demanding industrial environments, including metal coil processing.

- Applications: AGVs can transport raw materials such as master coils or slit coils from receiving areas to storage, or from storage to production lines (like slitters or packaging lines).24 Specialized "heavy burden carrier" AGVs are designed specifically for very heavy loads like large coils and plates in steel manufacturing.25 They can also be used to transfer slit mults from the slitter exit to turnstiles at the start of a packaging line.22

- Navigation: AGVs navigate using various technologies, including magnetic tape or wires embedded in the floor, laser guidance (using reflectors), optical guidance (following painted lines or markers), inertial navigation (using gyroscopes and accelerometers), or GPS for outdoor applications.25

- Benefits: AGVs offer the potential for 24/7 operation without operator fatigue, leading to reduced labor costs and increased efficiency.24 They can enhance workplace safety by reducing manual handling and forklift traffic in congested areas. Their programmable nature offers flexibility to adapt to changing production layouts or needs. Real-time monitoring and data collection capabilities can integrate with plant management systems. AGVs can also contribute to space optimization and, being typically electric-powered, may offer environmental benefits over fossil-fueled vehicles.22

The careful selection and seamless integration of these diverse handling equipment components are fundamental to achieving a "gentle handling" philosophy.26 This means that equipment design must prioritize the preservation of coil integrity at every touchpoint.5 Features like cushioned surfaces on C-hooks and coil cars 5, soft start/stop capabilities in drive systems 27, non-contact centering mechanisms 26, and precise, controlled movements in automated systems are not just refinements but essential elements in preventing the costly damage detailed previously.

Furthermore, the adoption of automated handling systems, such as pick & place down-enders, AGVs, and automatic cranes for stacking 19, provides a significant dual advantage. These systems directly reduce the need for manual labor, leading to cost savings. Simultaneously, and perhaps more importantly in terms of overall cost reduction, they minimize the opportunities for human error-induced damage. Given that such damage itself carries substantial financial penalties (material loss, rework, customer claims), this synergistic benefit of reduced labor and reduced damage risk presents a powerful economic justification for investing in automation within the coil handling process.

2.2. Best Practices for Damage-Free Handling (focus on aluminum and surface-sensitive coils)

Preventing damage during handling, especially for delicate materials like aluminum or coils with critical surface finishes, requires a combination of appropriate equipment, meticulous operator practices, and suitable environmental controls. The overarching principle is to minimize the number of times a coil is handled and to ensure each touchpoint is as gentle as possible.28

General Principles and Initial Checks:

- Minimize Handling: Every movement introduces a risk of damage; therefore, streamline workflows to reduce unnecessary handling.29

- Inspect Incoming Material: Upon receipt, all coils should be inspected for any pre-existing damage or signs of wetness. Any issues should be documented on the shipper’s paperwork and reported to the supplier immediately.28 This is crucial for accountability and claim processing.

Equipment Cleanliness and Condition:

The condition of handling and processing equipment is paramount.

- Contact Surfaces: All surfaces that come into contact with coils (e.g., rollers, guides, support arms) must be kept clean, smooth, and free from debris or damage that could be transferred to the coil surface.28

- Rollers: Bridle rolls, pass-line rolls, pinch rolls, and tension rolls should be regularly inspected for wear. Covering these rollers with softer, high-traction materials like rubber, polyurethane, or specialized plastics can prevent scratches and improve grip, reducing slippage that can mar surfaces.5

- Mandrels: Expanding mandrels used for uncoiling or recoiling can cause "reel breaks" or ID damage if their segmented leaves have sharp edges or if the mandrel is excessively worn. Using protective rubber or polyurethane sleeves (often called "boots") on the mandrel can cushion these edges, distribute pressure more evenly, and significantly reduce or eliminate this type of damage.5

- Lifting Devices: The contact surfaces of C-hooks, coil car cradles, and other lifting attachments should be cushioned with materials like UHMW (ultra-high molecular weight) plastic, polyurethane, or heavy felt to prevent direct metal-to-metal contact and absorb impacts.7

Specific Handling Techniques:

- Vertical Coils (Eye-to-the-Side Orientation):

- Ensure coils are securely banded before any movement.28

- Never place coils directly on concrete floors; always use appropriate dunnage, coil padding, or cushioning material underneath to protect the bottom edge and surface.28

- Secure coils from rolling using chocks, braces, or dedicated storage racks.28

- Stacking of eye-to-the-side coils is generally not recommended due to the risk of deformation and edge damage.28

- Horizontal Coils (Eye-to-Sky Orientation, typically on Skids):

- These are commonly moved using forklift trucks. Always inspect the condition of the skid before lifting; never attempt to lift a coil on a broken or unstable skid.28

- Ensure the forklift tines are of adequate length to fully support the load and are positioned correctly to avoid contacting and damaging the coil material (especially sidewall damage).28

- When lifting individual cuts or coils from a skid, appropriate equipment such as slings, vacuum grabs, or specialized ID/OD lifters should be used, always adhering to load capacity limits and safety procedures.28

- Uncoiler Operations:

- Hold-Down Rolls (Snubber Rolls): These are essential for preventing the outer lap of a coil from loosening or "clock-springing" during setup, which can cause surface damage or safety hazards. This is especially critical for heavy-gauge materials. If the hold-down roll is driven, its surface speed must precisely match the uncoiler’s line speed to prevent scratching. Some processors coat these rolls with polyurethane for added protection, though this may require more effort to keep clean.7

- In-Line Processing Equipment:

- Feed Rolls: Should be made from non-stick materials to maintain cleanliness. If driven, their speed must synchronize with the line speed. When used as strip support (e.g., at crop shears), they must adequately support the material to prevent contact with sharp edges like the bottom knife.7

- Slitter Heads: To avoid scratching the material during slitting, it’s crucial to regularly check the knife/arbor runout (for wobbling) and ensure proper alignment of male/female stripper rings.7

- Cascade Rolls: These rolls guide the strip into looping pits and must adequately support the material to prevent it from kinking or bending under its own weight.7

- Tension Stands: These units are critical for ensuring tightly wound recoiled coils but also represent a high potential for surface damage if not correctly designed and maintained. Various designs exist (pad-type, roll/pad combination, bridal roll, roll-only). Maintaining relatively constant tension throughout the recoiling operation is key to preventing tension scratching. Any axial movement or slipping of the strip must be controlled.7

- Recoiler Drum: Using interchangeable recoiler drums with close-tolerance segment openings and smooth surface finishes can significantly reduce the risk of ID damage on the recoiled coil.7

- Over-Arm Separators/Supports on Recoilers: Excessive down-pressure from the over-arm support can cause damage. The unit should be properly counterbalanced, and its geometry designed so that any banding grooves on the support do not mark the coil surface.7

Aluminum Coil Specific Best Practices 30:

- Cleanliness: Ensure aluminum coils are clean and free of dirt or debris before packaging, as trapped particles can cause abrasions during transit.

- Secure Wrapping: Wrap coils tightly with stretch film to secure them and protect against dust, moisture, and other environmental factors.

- Palletization: Place wrapped coils on sturdy, defect-free pallets, ensuring even weight distribution.

- Corner Protection: Use corner protectors on the palletized load to prevent damage to coil edges during handling and transit.

- Sealing and Labeling: Secure the entire package with appropriate packaging tape and clearly label it with destination information, weight, dimensions, and product type.

Storage Practices (Interlinked with Handling to/from Storage):

- Environment: Store coils in a heated, humidity-controlled environment to prevent condensation, which can lead to water stains on aluminum or rust on steel.28 If metal is brought in cold, it must be allowed to warm to the ambient temperature of the storage area before unwrapping or moving to a more humid zone to prevent condensation.28

- Original Packaging: If feasible, keep coils in their original protective packaging until they are needed for processing.28

- Re-Banding: If coils stored eye-to-the-side are partially used or need to be moved, ensure they are tightly re-banded to prevent wrap-to-wrap movement (which can cause scratching) and for safety.28

- Racking Systems: Utilize industrial storage racking systems for skidded coils to avoid stacking them directly on top of each other, which reduces the risk of crushing and edge damage.28

- Floor Pads: For coils stored directly on the floor (though less ideal), use protective floor pads made of polyurethane or similar cushioning material to isolate them from moisture, debris, and impact.7

A common thread through these best practices is the importance of preventative maintenance and regular condition monitoring of all handling and processing equipment. Worn rollers 5, excessive mandrel wear 5, or the development of sharp corners on carrier surfaces 7 are all equipment-related issues that can directly lead to coil damage. This implies that robust maintenance schedules and equipment audits are just as critical as operator diligence in a comprehensive damage prevention strategy. The condition of the equipment dictates the quality of the handling.

2.3. Safety Standards and Personnel Protective Equipment (PPE) in Coil Handling

Handling heavy and potentially sharp-edged metal coils inherently involves risks. Adherence to established safety standards and the consistent use of appropriate Personal Protective Equipment (PPE) are non-negotiable for protecting personnel from injury.

General Risks:

Metal coils, due to their weight and form, present several hazards:

- Crushing Injuries: From falling coils or shifting loads.

- Cuts and Lacerations: From sharp metal edges or broken/snapped strapping bands.

- Impact Injuries: From moving equipment or uncontrolled coil movement.

- Hazards from Spring-Back: High-strength or improperly secured coils can unwind rapidly and unexpectedly.8

Compliance with occupational safety regulations, such as those from OSHA in the United States, often mandates specific protective equipment and safe operating procedures when handling heavy materials like metal coils.31

Mandatory Personal Protective Equipment (PPE) 31:

A comprehensive PPE program for coil handling operations should include:

- Hard Hat (ANSI Z89.1 Certified or equivalent): Essential for protecting the head from falling objects (e.g., debris from overhead cranes, stacked coils) or impacts from sudden coil movements or breaking straps.

- Steel-Toe Boots (ASTM F2413-18 Standard or equivalent): Crucial for shielding feet from crushing injuries if a coil shifts, rolls, or falls. Slip-resistant soles are also important for preventing falls on potentially oily or wet floors common in metal processing facilities.

- High-Visibility Vest (ANSI Class 2 or 3 or equivalent): Ensures that workers are easily visible to operators of forklifts, cranes, and other mobile equipment, especially in busy or low-light environments.

- Heavy-Duty Cut-Resistant Gloves (ANSI Cut Level A5 or Higher, or equivalent EN standards): Protect hands from sharp coil edges, burrs, and the potential for cuts when handling strapping material. Kevlar-reinforced or similar high-performance gloves are often recommended, particularly when handling uncoiled sheets or individual slit mults.

- Safety Glasses or Face Shield (ANSI Z87.1 Certified or equivalent): Essential for protecting eyes from flying debris, metal shavings, or fragments from snapping coil bands. A full face shield provides additional protection and is often recommended when cutting coil bands under tension.

- Hearing Protection (Meeting OSHA 85 dB+ exposure standards or local equivalents): Necessary in environments with high noise levels from machinery such as slitters, presses, or general plant operations. Options include earplugs or earmuffs, depending on the noise level and duration of exposure.

- Back Support Belt (For Manual Handling): While mechanical handling should always be prioritized, if smaller coils or components must be manually lifted or adjusted, a back support belt can help reduce lower back strain and the risk of long-term musculoskeletal injuries.

Safe Operating Procedures 28:

Beyond PPE, safe operations depend on well-defined and consistently enforced procedures:

- Equipment Inspection: All safety gear and handling equipment (cranes, forklifts, lifters, slings) must be inspected before each use to ensure they are in good condition and functioning correctly.

- Prioritize Mechanical Lifting: Manual lifting of coils should be avoided whenever possible. Cranes, forklifts with appropriate attachments (e.g., coil rams, C-hooks), and other mechanical aids should be the primary means of movement.

- Secure Coils: Coils must be properly secured with strapping, chocking, or bracing before and during movement to prevent shifting or rolling.8 The outer wraps of coils should be secured with tape or banding when being moved.

- Correct Tools: Only use handling tools and lifting attachments (e.g., coil lifters, C-hooks, spreader beams) that are specifically designed for coils and are rated for the weight and size of the coil being handled.

- Comprehensive Worker Training: All personnel involved in coil handling must receive thorough training on safe operating procedures, Lockout/Tagout (LOTO) protocols, proper coil storage techniques, emergency stop locations, and the specific hazards associated with their tasks.32

- Spring-Back Hazard Management 9: This is a critical safety concern.

- Personnel must be aware that the risk of spring-back increases with higher material yield strength, greater material thickness and width, and smaller coil inner diameters.

- Workers should never stand directly in line with the potential unwinding direction of the coil during handling or band removal.

- Before handling or transporting any coil, verify that the required minimum number of straps (as often specified on coil labels or internal standards) are present and secure. Missing or damaged bands must be replaced before the coil is moved.

- Prior to unpacking or removing any bands, the coil must be positioned securely, ideally with the coil tail tucked underneath at approximately the 7 o’clock position (when viewed from the end). "This Way Up" labels on packaging should be observed. If a coil is not in a safe position, it must be readjusted using suitable equipment like a mandrel or positioning rolls.

- Never remove banding from a coil that is suspended from an overhead crane or forklift. The coil must be stably supported on the ground, on a pallet, or in a decoiling machine.

- When de-banding, bore bands (through the eye) should generally be removed before circumferential bands, as bore bands may have less capacity to restrain the coil’s stored energy.

- Circumferential bands should only be removed when the coil is safely resting in the correct position on a decoiling installation or other secure fixture.

- If bands are removed manually, the outermost straps should be cut last. This should be done from a position that does not place the operator directly in line with the potential path of the unwinding tail end. Appropriate long-handled band cutters or shears designed for this purpose must be used.

- If a coil is partially decoiled, safety banding must be restored to the remaining portion, respecting the original number, position, and type of bands. The number of bands may need to be increased as the coil diameter decreases.

- Materials prone to significant spring-back should be clearly indicated on the coil or its packaging.

- Controlled Equipment Operation: Crane movements should be smooth, with controlled acceleration and deceleration, and defined lift zones to prevent swinging loads.3 Forklift operators must be trained, and their attachments regularly inspected for stability and integrity.3

- Clear Safety Zones: Designate and maintain clear zones around machinery and coil handling areas to prevent unauthorized access and ensure safe operating distances.32

- Machine Guarding and Emergency Stops: All automated and semi-automated equipment must have adequate machine guarding to prevent access to moving parts, along with clearly marked and easily accessible emergency stop buttons.32

- No Adjustments During Operation: Operators should never attempt to make adjustments to machinery while it is running.32

The adoption of automation in coil handling and packaging significantly contributes to enhanced safety by reducing the need for manual handling, thereby minimizing ergonomic risks, worker fatigue, strain injuries, and the likelihood of accidents associated with direct human-coil interaction.21

Effective safety in coil handling is not achieved through a single measure but through a multi-layered approach. This combines engineered controls (e.g., robust machine guarding 33, automation to remove operators from hazardous tasks), administrative controls (e.g., comprehensive safe work procedures 9, rigorous training programs 31), and the consistent use of appropriate PPE.31 Relying solely on PPE is insufficient; a hierarchical approach to safety, where engineering out hazards is prioritized, is crucial for creating a genuinely safe working environment. These elements are interconnected and mutually reinforcing, forming the foundation of a mature safety culture in coil processing operations.

Table 2: Key Slit Coil Handling Equipment: Functionality and Considerations

| Equipment Type | Primary Function | Key Operational Features/Technology | Typical Capacity Range | Damage Prevention Aspects | Safety Considerations |

|---|---|---|---|---|---|

| Coil Car | Transfers coils from slitter to turnstile/packaging line 22 | Rail-mounted or free-ranging; powered (electric, propane); hydraulic hold-downs; pendant/remote control 22 | Up to 100,000 lbs (45+ tons) or more 20 | Smooth transfer, cushioned cradles/supports, hold-downs for narrow coils 7 | Secure coil on car, clear travel path, operator training. |

| Turnstile | Buffers and stages slit coil sets for sequential feeding 22 | 2-4 arms; U-shaped arms for C-hook access; hydraulic pushers; positioning latches 20 | 8,000-100,000 lbs (3.6-45+ tons) 20 | Smooth rotation, secure coil holding on arms. | Proper loading/unloading procedures, pinch point awareness. |

| Pick & Place Down-ender | Orients coils from eye-horizontal to eye-vertical; transfers to conveyor 22 | Automated pick-up, 90-degree rotation, placement; programmable for coil width/sequence; magnetic/vacuum stabilization 20 | Varies by model, tailored to coil sizes. | Minimizes ID marking/telescoping (no push-off); gentle handling for sensitive materials.20 | Guarding of moving parts, interlocks, clear zones. |

| C-Hook | Lifts coils by ID 23 | Single alloy steel plate construction; optional urethane bumpers, motorized rotation 23 | Varies widely based on design (e.g., up to 20+ tons). | Protective padding (urethane/felt) on contact surfaces 7; curved saddle. | Correct sizing for coil ID/width, balanced load, operator training. |

| Telescoping Coil Grab | Lifts horizontal axis coils, engaging both sides 23 | Motorized telescoping legs; optional rotation, hold-down arms, weighing systems 23 | Wide range, custom designed. | Secure grip on both sides, coil protection features available.23 | Ensures proper engagement, load balancing, interlocks for automated systems. |

| Vertical Axis Coil Tongs | Lifts eye-to-sky coils by ID/OD grip 23 | Single or double-rim grip; automatic activation options 23 | Custom designed for coil range. | Double-rim grip for delicate/thin gauge; avoids underside contact.23 | Secure grip before lifting, clear lift path, operator training. |

| AGV (Automated Guided Vehicle) | Transports coils within facility 24 | Laser, magnetic, optical navigation; battery-powered; heavy burden carrier types 25 | Up to 50+ tons for heavy-duty types 34 | Smooth, programmed movement reduces impacts; specialized coil cradles. | Collision avoidance sensors, defined pathways, integration with traffic management. |

| Sortation Table | Sorts and allows stacking of coils by order/width 22 | Powered rotation (4-12 positions); auto-indexing; mechanical latching 22 | Stack weights up to 15 tons 26 | Smooth, precise positioning for stacking. | Guarding of rotating table, load stability on skids. |

Section 3: Advanced Packaging Materials and Techniques for Slit Coil Protection

The choice of packaging materials and the techniques used to apply them are fundamental to protecting slit coils from a multitude of threats, including corrosion, physical damage during handling and transit, and environmental factors. Modern packaging solutions increasingly emphasize not only robust protection but also efficiency in application and sustainability.

3.1. Preventing Corrosion: The Role of VCI (Volatile Corrosion Inhibitor) Technology

Corrosion is a primary concern for most metal coils, particularly steel, but also for non-ferrous metals like copper and aluminum which can tarnish or oxidize. Volatile Corrosion Inhibitor (VCI) technology offers a clean and effective method for preventing such degradation.

Mechanism of VCI Protection:

VCI packaging products contain chemical compounds that slowly vaporize (volatilize) within an enclosed package. These VCI molecules migrate through the air within the package and then condense on all exposed metal surfaces, including hard-to-reach crevices and recessed areas.13 This forms a very thin, often monomolecular, invisible layer that disrupts the electrochemical reactions responsible for corrosion (e.g., rust on steel, tarnish on copper).35 The key is that the VCI passivates the electron flow between anodic and cathodic areas on the metal surface, effectively making the metal unreactive to corrosive agents like moisture and oxygen.35

Types of VCI Products and Their Applications:

A wide array of VCI products are available, tailored to different application needs:

- VCI Paper: Kraft paper impregnated or coated with VCI compounds. It is commonly used for wrapping individual parts, interleaving between layers of metal, or lining boxes and containers.6 For heavy-duty applications, such as wrapping large coils or protecting items during export shipment, reinforced VCI papers are available. These may feature polyethylene (PE) coatings for moisture resistance, or internal scrim reinforcement (e.g., tri-directional polyester scrim) for enhanced tear strength and puncture resistance. Examples include Daubert Cromwell’s Steelwrap MPI (heavyweight kraft laminated with reinforcement and poly to another VCI kraft layer, for steel coils) and UW94MPI Woven (kraft poly laminated to woven poly fabric for multi-metal protection).36

- VCI Film (Polyethylene): Low-density polyethylene (LDPE) film that has VCI compounds incorporated directly into the polymer matrix. VCI films are available in various forms, including flat sheeting, tubing (for creating custom-length bags), J-sheeting, C-fold sheeting, pre-made flat bags, gusseted bags (for bulky items), and zipper bags for reclosable protection.13 These films are often transparent, allowing for easy inspection of the packaged coil or part without compromising the protective VCI atmosphere.13 Some VCI films are co-extruded to create multi-layer structures, potentially offering enhanced barrier properties or incorporating other additives like UV inhibitors or anti-static (ESD) agents.13 Specialized VCI films like ZERUST® ICT®504-LM are designed with lower water vapor transmission rates for improved moisture limiting, beneficial for long-term storage or international shipments.13

- VCI Stretch Film: This is a stretchable LLDPE film containing VCIs, used for unitizing pallet loads or banding large metal parts, providing both load stability and corrosion protection simultaneously.6

- VCI Shrink Film: Typically a multi-layer LDPE film with VCIs, designed to be draped over a coil or pallet load and then heated, causing it to shrink tightly and conform to the shape of the product. This provides a secure, form-fitting, and weather-resistant protective layer.6

- VCI Emitters, Diffusers, and Packs: These are devices (capsules, pouches, foams, cups) containing concentrated VCI compounds (often powders or impregnated materials) that are placed inside an enclosed space (e.g., an electrical cabinet, a large export crate, or within the eye of a coil) to release VCI vapors and protect the contents.37 They are useful when direct contact with VCI paper or film is impractical or when supplementary VCI protection is needed for larger volumes.

- VCI Bubble Bags/Wrap: Combine the cushioning properties of bubble wrap with VCI protection, ideal for delicate, precision-finished metal parts that are susceptible to both physical damage and corrosion.38

- VCI Foam Sheeting: Lightweight, resilient closed-cell foam sheeting impregnated with VCIs, offering both cushioning and corrosion protection. It is resistant to moisture and dust [^6 (ICT®570 VCI Foam Sheeting)].

- VCI Steel Wrap (Woven Films): These are heavy-duty packaging materials, often made from woven polyethylene or polypropylene fabrics coated or laminated with VCI-impregnated layers. They are specifically designed for the demanding requirements of the steel industry, offering superior strength, tear resistance, and puncture resistance for wrapping large steel coils, wire, and other heavy metal products [^19 (VCI Steel Wrap), ^49 (UW94MPI Woven)]. Some offer self-healing properties.38

- VCI Wire Strip: A specialized product designed for the internal corrosion protection of tubes, pipes, or conduits. The strip is placed inside the hollow structure, which is then capped or sealed. The VCI vapors saturate the enclosed space, protecting the internal surfaces.38

- VCI Cardboard: Corrugated cardboard that has a VCI coating applied to its inner surface. This allows for the creation of VCI-protective boxes without the need for separate VCI liners or bags, potentially reducing packing time and labor.35

Key Considerations for VCI Application:

- Metal Specificity: VCI formulations are often optimized for specific types of metals. Some are designed primarily for ferrous metals (iron and steel), others for non-ferrous metals (like aluminum, copper, brass, bronze), and multi-metal VCIs are available to protect assemblies containing a mix of different metals.6 For example, ZERUST® offers ICT®510-C for non-ferrous metals and ICT®520-CB1 Anti-Tarnish Film specifically for silver, copper, brass, and tin.13 It is crucial to select a VCI product compatible with all metals being packaged.

- Sealing: The effectiveness of VCI packaging relies heavily on creating a well-sealed or enclosed environment. This allows the VCI vapors to reach an effective concentration and prevents their premature escape, ensuring the protective layer forms and is maintained on the metal surfaces.35

- Duration of Protection: Most VCI products offer protection for extended periods, typically up to 24 months, and some even longer, depending on the specific product, the quality of the seal, and the storage/shipping conditions.13

- Cleanliness: VCI protection is most effective when applied to clean, dry metal surfaces. Oils, greases, or other contaminants can interfere with the VCI action.

- Benefits: The primary benefit is the prevention of corrosion, which in turn extends product lifespan, reduces costs associated with damage, replacements, and rework.35 VCI packaging eliminates the need for traditional, often messy and labor-intensive, rust preventative oils, greases, or coatings. This means metal parts are clean and ready for use immediately upon removal from the VCI packaging, without requiring degreasing or cleaning steps.35 This also contributes to a safer working environment by reducing exposure to hazardous materials.35 Many modern VCI products are also designed with sustainability in mind, being nitrite-free and recyclable. Some companies, like ZERUST®, offer recycling programs for their VCI films (e.g., ZeCycle Recycling Program) and utilize post-consumer recycled (PCR) content in their products.39

The synergy between the VCI layer and the outer packaging is critical. While VCI provides chemical protection, the outer layers (like stretch wrap or shrouds) provide the physical barrier against moisture ingress and mechanical damage, and crucially, maintain the sealed environment necessary for the VCI to function effectively.35 A breach in this outer layer can compromise the VCI’s ability to maintain the protective atmosphere, potentially leading to corrosion despite the presence of VCI material. Furthermore, the choice of VCI must be carefully aligned with the specific metal type, the anticipated storage duration, and the environmental conditions of transit (e.g., maritime shipping often requires VCI products with enhanced moisture barrier properties and potentially desiccants in conjunction 6). Using an incompatible VCI or one not robust enough for the conditions can lead to ineffective protection or, in rare cases, adverse reactions with the metal surface.

Table 3: Comparison of VCI Product Types for Slit Coil Protection

| VCI Product Type | Form | Metal Compatibility | Primary Application Method | Key Advantages | Considerations/Limitations |

|---|---|---|---|---|---|

| VCI Paper (Plain) 38 | Kraft paper saturated/coated with VCI | Ferrous, Non-Ferrous, Multi-Metal (depends on formulation) | Wrapping, Interleaving, Lining | Cost-effective, breathable, easy to use, recyclable. | Lower tear strength, limited moisture barrier unless coated/laminated. |

| VCI Paper (Reinforced) 36 | Kraft paper with PE coating and/or scrim reinforcement | Ferrous, Multi-Metal | Wrapping heavy coils, interleaving, pallet liners | High strength, tear/puncture resistant, moisture barrier. | Higher cost than plain paper, less flexible. |

| VCI Film (Stretch) 6 | Stretchable LLDPE film with VCI | Ferrous, Non-Ferrous, Multi-Metal | Wrapping coils/pallets (orbital or turntable wrappers) | Provides load stability and corrosion protection simultaneously, transparent. | Requires proper stretch application for effectiveness. |

| VCI Film (Shrink) 13 | LDPE film with VCI | Ferrous, Non-Ferrous, Multi-Metal | Draping and heat-shrinking around coils/equipment | Tight, conforming fit, good moisture barrier, transparent. | Requires heat source for shrinking, can be energy-intensive. |

| VCI Bags (Flat, Gusseted, Zipper) 13 | Pre-formed PE bags with VCI | Ferrous, Non-Ferrous, Multi-Metal | Enclosing individual coils or parts | Convenient, easy to seal (heat seal, zipper), good for various sizes. | Seal integrity is crucial, may require custom sizes for large coils. |

| VCI Emitters/Diffusers 37 | Capsules, pouches, foam containing VCI powder/material | Ferrous, Non-Ferrous, Multi-Metal | Placing inside enclosed spaces (coil eye, crates, cabinets) | Protects hard-to-reach areas, supplements protection in large volumes. | Effectiveness depends on enclosure volume and seal quality. |

| VCI Woven Fabric/Steel Wrap 38 | Woven PE/PP fabric with VCI coating/lamination | Ferrous, Multi-Metal | Wrapping large, heavy coils, export shipments | Maximum strength, tear/puncture resistant, durable for rough handling. | Higher cost, may be less conformable than film. |

| VCI Cardboard 35 | Corrugated board with VCI coating | Ferrous, Multi-Metal | Forming protective boxes or structural components | Provides physical protection and VCI, reduces need for separate liners. | Bulkier than film/paper, seal of box is important. |

3.2. Physical Protection: Wrapping, Cushioning, and Edge Guards

Beyond corrosion, slit coils require robust physical protection against impacts, abrasions, and distortions during handling, storage, and transit.

Primary Wrapping Materials:

- Stretch Film (LLDPE – Linear Low-Density Polyethylene): This is one ofthe most widely used materials for wrapping coils and palletized loads. Applied using orbital wrappers (for through-the-eye wrapping of coils) or turntable stretch wrappers (for pallet loads), it provides a tight, containing layer that protects against dust, moisture, and minor abrasions, and helps to unitize the load.6 Modern wrappers often feature powered pre-stretch mechanisms that can significantly reduce film consumption while improving load containment.40 Stretch film can also be formulated with VCI additives for combined physical and corrosion protection.41

- Shrink Film (LDPE – Low-Density Polyethylene): This film is typically draped loosely over the coil or pallet load and then passed through a heat tunnel or exposed to a heat gun, causing it to shrink tightly around the contents.6 It provides a very secure and often weather-resistant covering. VCI-impregnated shrink films are also available.

- Paperboard and Corrugated Protection: These materials offer an economical way to provide physical buffering and structural support. They can be used as interleaving sheets between coil laps (less common for tightly wound slit coils but possible), as side protectors (mantle protection), or as protection for the inner (eye) and outer diameters of coils [^18 (Lamishield), ^11]. VCI-coated cardboard can combine physical and corrosion protection.35

- Scrim-Reinforced Papers and Woven Fabrics: For particularly demanding applications or when wrapping coils with sharp edges, papers or plastic fabrics reinforced with a strong scrim (a mesh of synthetic fibers) offer superior tear and puncture resistance.36 These can be polyethylene-coated for moisture resistance or asphalt-laminated for a very robust barrier, and can also incorporate VCI.

- Plastic Sheeting/Bags: Simple PE sheets or bags can be used as liners within crates, as shrouds to cover palletized coils, or as a basic wrap for dust and moisture protection.6

Cushioning Materials 6:

To absorb shocks and vibrations, and to protect sensitive surfaces from direct contact with harder packaging elements:

- Bubble Wrap: Consisting of entrapped air bubbles within PE film, bubble wrap provides lightweight cushioning against impacts and can prevent scratching. VCI-infused bubble wrap is available for combined protection.38

- Foam Sheeting/Rolls (Polyethylene or Polyurethane): Closed-cell PE foam or open-cell PU foam offers excellent shock absorption and surface protection. It can be used to line crates, wrap parts, or as interleaving material.

Edge Protection:

The edges of slit coils are particularly vulnerable to damage.3 Dedicated edge protectors are essential:

- Plastic Edge Protectors: Often made from PE or PP, these can be rigid or semi-flexible and are designed to fit over the coil edges. Some are designed to be recyclable (e.g., Lamiflex offers recyclable PE edge protection).41

- Paperboard Edge Protectors: Made from laminated, heavy-duty paperboard, these provide good impact resistance and are often an economical and sustainable option. Greif’s Protect-A-Coil, for example, is made from 100% recycled paperboard and is customizable to fit various coil circumferences.10

- Automated Application: Modern automated packaging lines can incorporate systems for the automatic placement of edge protectors onto coils before final wrapping or strapping.6

Coil Eye (ID) and Circumference (OD) Protection:

Specific protectors made from materials like hardboard, molded pulp, or specialized plastics can be inserted into the coil eye or placed around the circumference to prevent deformation and damage, particularly for coils handled or stored eye-vertical.42

The packaging industry is experiencing a significant shift towards sustainability. This is driven by increasing environmental awareness, stricter regulations (such as Extended Producer Responsibility – EPR schemes), and growing customer demand for eco-friendly solutions.18 This trend is evident in the increased availability and use of recyclable packaging materials like Lamiflex’s PE edge protectors 41 and Greif’s 100% recycled paperboard Protect-A-Coil.10 Furthermore, the use of materials with post-consumer recycled (PCR) content, such as in some PET strapping 43 and VCI films 39, is gaining traction. This focus on sustainability is not merely an environmental consideration; it can also lead to tangible economic benefits by reducing waste disposal costs, potentially mitigating EPR fees 18, and enhancing brand image.

3.3. Strapping Solutions: Securing Coil Integrity

Strapping is essential for maintaining the integrity of individual slit coils (preventing unwinding/spring-back) and for unitizing multiple coils on a pallet or skid for safe and efficient handling and transport.9 The choice of strapping material and application technique is critical.

Purpose of Strapping:

- Secures individual coils to prevent unwinding (especially important for spring-back prone materials).9

- Bundles multiple slit coils together.

- Unitizes coils or coil stacks on pallets/skids, preventing shifting during transit.44

- Minimizes damage from impact and vibration by keeping the load compact.44

Materials: Steel Strapping vs. PET (Polyester) Strapping

A key decision in coil packaging is the choice between traditional steel strapping and modern PET strapping.

- Steel Strapping:

- Properties: Steel offers the highest tensile strength and rigidity with minimal elongation (typically <1%) before yielding.43 It generally maintains applied tension well over time, provided it’s not stressed beyond its elastic limit.45

- Applications: Historically favored for very heavy-duty loads, items with sharp edges that might cut softer straps, applications in hot environments, or products that cannot tolerate any elongation (e.g., tightly wound, high-density steel coils, bricks, heavy machinery).44

- Drawbacks: Susceptible to rust if not specially treated, which can stain the product.43 It is heavy, which adds to shipping weight and handling difficulty. Its sharp edges pose a significant safety hazard to operators during application and removal (risk of cuts) and can also damage the product being strapped if not protected.43 When cut under tension, steel strapping recoils with considerable force, creating a serious risk of injury.43 The total cost of ownership (TCO) can be higher due to potential injury costs, higher freight, and often more expensive and cumbersome manual or pneumatic tooling.43 Recyclability can be more complex than PET, and its production is energy-intensive.43

- PET (Polyester) Strapping:

- Properties: PET strapping offers high tensile strength, often approaching that of steel (some sources claim up to 80% of steel’s strength, or specific values like 9500N for PET vs. 12000N for steel).46 Its key advantages lie in its excellent shock absorption capabilities and its property of elongation with good recovery. PET can elongate significantly more than steel (e.g., up to 12% 46) but can recover a large portion of this elongation (approx. 70% 47) when stress is relieved. This allows it to maintain tension on packages that might settle, shrink, or experience dynamic forces during transit.47 PET is rust-proof, UV-resistant (making it suitable for outdoor exposure), and generally safer to handle due to its lack of sharp edges and the fact that it does not recoil dangerously when cut.43

- Applications: Increasingly used as a viable and often superior alternative to steel for a wide range of medium to heavy loads, including lumber, pavers, compressed bales, palletized goods, and many types of metal coils.43 It is particularly well-suited for products that are sensitive to pressure or loads that might shift or settle.44

- Advantages: Typically offers a lower cost per foot/meter than steel.43 Its lighter weight reduces shipping costs and makes handling easier.44 Tools for PET strapping are often lighter, more ergonomic, and frequently battery-powered, improving operator comfort and efficiency.43 PET is readily recyclable and is often made with post-consumer recycled (PCR) content, contributing to sustainability goals.43 The overall TCO for PET is often lower when safety, freight, tooling, and material costs are considered.43 For example, one source suggests a 50% cost saving compared to steel due to the weight-to-length ratio (6 meters of PET can equal the weight of 1 meter of steel of similar size).48

Strapping Techniques and Tension Control:

- Application Types: For slit coils, strapping is typically applied radially (circumferentially around the OD) and/or axially (through the eye or ID).6 The number and placement of straps depend on coil size, weight, material, and transport mode.

- Tensioning: Achieving the correct strap tension is critical. Over-tensioning can damage the coil (e.g., cause edge crushing, deformation, or marking) or even break the strap itself, especially with softer materials like aluminum.12 Under-tensioning will result in a loose, unstable load that can shift during transit, leading to damage or safety issues.12 A common guideline is to tension straps to 30-50% of their rated breaking strength, though this can vary based on the application and material properties.12

- Jointing/Sealing: The method used to join the ends of the strap (e.g., metal seals for steel strapping, friction welds or seals for PET strapping) must create a strong, reliable joint capable of holding the applied tension.12

- Automated Strapping Machines: These machines, whether semi-automatic or fully automatic, significantly improve the consistency of tensioning and sealing, increase strapping speed, and reduce operator fatigue compared to manual tools.6 They are integral components of automated packaging lines.

Polypropylene (PP) Straps:

While available, PP straps are generally used for light to medium-duty bundling and palletizing. They have higher elongation and lower tension retention (more "dead stretch" and greater tension decay over time) compared to PET.44 Consequently, PP strapping is not typically robust enough for securing heavy slit coils.

The industry trend indicates a significant shift from steel to PET strapping for many applications. This is driven not solely by a direct comparison of ultimate tensile strength, but by a more holistic evaluation of performance characteristics, safety benefits, total cost of ownership, and sustainability. While steel remains the choice for the most extreme loads or conditions where zero elongation is permissible, PET’s ability to absorb shocks and maintain tension on dynamic or settling loads due to its elongation and recovery properties (its "working range" 47) often makes it a more effective solution in real-world transit conditions. The considerable advantages in safety, cost, and environmental impact further strengthen the case for PET in a growing number of slit coil packaging scenarios.

Table 4: Technical and Economic Comparison of Steel vs. PET Strapping for Slit Coils

| Feature | Steel Strapping | PET (Polyester) Strapping |

|---|---|---|

| Tensile Strength | Very High (e.g., up to 12000N) 46 | High (e.g., up to 9500N, ~80% of steel) 46 |

| Elongation (%) | Minimal (<1%) 46 | Moderate (e.g., up to 12%) 46 |

| Elongation Recovery (%) | ~100% (below yield point) 47 | Good (~70%) 47 |

| Shock Absorption | Low (rigid, brittle) 43 | Excellent (absorbs impact) 43 |

| Weight | Heavy 43 | Lightweight 43 |

| Safety (Edges) | Sharp, can damage product/injure personnel 43 | Smoother edges, safer to handle 43 |

| Safety (Recoil when cut) | Dangerous, high recoil 43 | Minimal to no dangerous recoil 43 |

| Rust Resistance | Prone to rust (can stain product) 43 | 100% Rust-Free 43 |

| Tooling | Manual, often heavy/costly pneumatic tools 43 | Lighter, ergonomic, often battery-powered tools 43 |

| Material Cost (per unit length) | Generally higher 43 | Often lower (e.g., 20-50% less) 43 |

| Total Cost of Ownership (TCO) | Higher (due to injuries, freight, tooling, potential damage) 43 | Lower (long-term savings) 43 |

| Recyclability/Sustainability | Limited recyclability, energy-intensive production 43 | Recyclable, often contains Post-Consumer Recycled (PCR) content 43 |

| Typical Applications for Slit Coils | Extremely heavy coils, sharp-edged coils, high-temperature environments, zero-elongation needs.44 | Medium to heavy coils, loads prone to settling, general purpose where safety and TCO are key.43 |

3.4. Palletizing and Skidding Strategies

A stable base is crucial for the safe and efficient handling, storage, and transportation of slit coils, particularly when they are moved using forklifts or pallet jacks, or when stacked.6

Materials for Pallets/Skids 6:

- Wood Pallets/Skids: These are the most commonly used option due to their cost-effectiveness and availability. However, it is essential that wooden pallets are sturdy, in good condition, and appropriately sized for the load. Damaged or weak skids can lead to load instability and product damage.8

- Plastic Pallets: While generally more expensive upfront, plastic pallets offer several advantages over wood. They are more durable, resistant to moisture and weather, easier to clean (making them more hygienic for certain applications), and maintain consistent dimensions.

Palletizing Process:

Slit coils are typically stacked in an eye-vertical ("eye-to-the-sky") orientation on skids or pallets.49

- Spacers: To improve stability within a stack and prevent damage from coil-on-coil contact, spacers (often wooden blocks or specialized dunnage) can be automatically or manually placed between individual coils in a multi-layered stack.22 This allows multiple slit coils to be packaged together on a single pallet without damaging each other and facilitates easier un-packaging and handling at the destination.22

- Securing to Pallet: Once stacked, the entire unit load (coils and pallet) must be secured. This is commonly achieved by:

- Strapping: Applying circumferential straps around the entire stack and pallet.

- Stretch Film Wrapping and Roping: Encasing the entire skidded stack in stretch film, often with additional "roping" (concentrated bands of stretch film) applied at key points for extra stability.22

Automated packaging lines frequently incorporate automatic pallet dispensers that feed pallets into the line as needed, and coil-to-pallet placement systems. These placement systems can utilize robotics or dedicated automatic stackers to accurately position the coils onto the pallets according to pre-programmed patterns.6

3.5. Sustainable Packaging Innovations for Metal Coils

The metal coil industry, like many others, is increasingly focusing on sustainable packaging solutions to reduce environmental impact, meet regulatory demands, and satisfy customer expectations.

Key trends and innovations include:

- Emphasis on Recyclable Materials: There is a clear shift towards using packaging components that are easily recyclable. Examples include:

- Use of Recycled Content: Incorporating post-consumer recycled (PCR) materials into packaging is a significant step. This is seen in:

- Reusable Packaging Systems: While less common for one-way shipment of slit coils, the concept of reusable containers is gaining traction in some logistics chains. Goodpack, for instance, offers reusable Intermediate Bulk Containers (IBCs) like the MB5 for the rubber and tyre industry, which are stackable, space-saving, operate on a pay-per-use model, and can feature real-time tracking.50 The principles could be adapted for closed-loop coil transport.

- VCI Product Sustainability: Modern VCI products are often designed to be more environmentally friendly (e.g., nitrite-free). Furthermore, initiatives like ZERUST®’s ZeCycle Recycling Program allow for the collection and recycling of used VCI films, turning them back into raw materials for new VCI products, thus promoting a circular economy.39

- Optimized Material Usage through Automation: Automated packaging lines enable precise application of materials like stretch film (through powered pre-stretch) and strapping (through consistent tensioning), which significantly reduces overall material consumption and waste compared to manual methods.17