1. What Are the Best Practices for Maintaining Plastic Pipe Bagging Equipment?

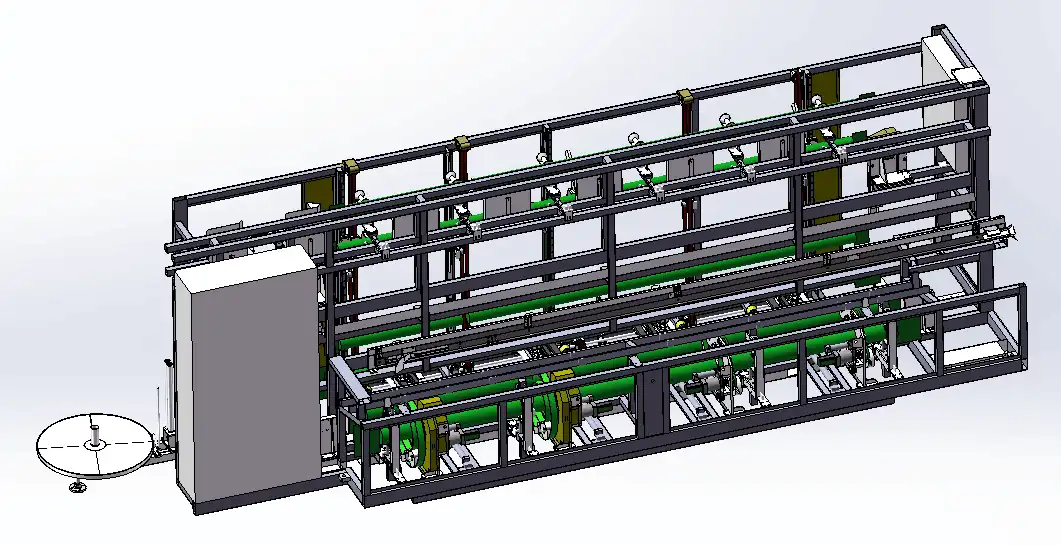

Maintaining plastic pipe bagging equipment is critical for smooth operations. Regular maintenance ensures efficiency, reduces downtime, and extends the equipment’s lifespan, ultimately optimizing productivity and cost-effectiveness in plastic pipe manufacturing.

The best practices for maintaining plastic pipe bagging equipment include regular inspections, lubrication, cleaning, and timely parts replacement. Detailed maintenance schedules, operator training, and adherence to safety protocols are crucial for preventing breakdowns and ensuring consistent bagging quality. These practices reduce downtime, extend equipment life, and enhance operational efficiency.

To ensure your bagging equipment operates efficiently, it’s crucial to delve into specific maintenance practices. These will keep your equipment running smoothly and minimize disruptions to your production schedule.

2. Developing a Comprehensive Maintenance Schedule

A well-structured maintenance schedule is the foundation of effective equipment care. It outlines tasks, frequency, and responsibilities, ensuring that every aspect of the bagging machine receives attention.

Developing a maintenance schedule for plastic pipe bagging equipment involves defining daily, weekly, monthly, and annual tasks. These include cleaning, lubrication, inspection of components, and calibration. A clear schedule prevents oversights, ensures consistent maintenance, and maximizes equipment uptime.

Crafting an Effective Maintenance Schedule

Creating a maintenance schedule involves several steps:

- Identify Critical Components: Determine which parts of the equipment are most prone to wear or failure.

- Define Tasks: Specify the tasks needed for each component, such as cleaning, lubrication, or inspection.

- Set Frequency: Establish how often each task should be performed (daily, weekly, monthly, annually).

- Assign Responsibilities: Clearly assign tasks to specific personnel.

- Document the Schedule: Create a written or digital schedule that is easily accessible.

Essential Elements of a Maintenance Schedule

A comprehensive maintenance schedule incorporates the following elements:

- Daily Checks:

- Visual inspection for any signs of damage or wear

- Cleaning of accessible parts

- Checking for loose connections

- Weekly Tasks:

- Lubrication of moving parts

- Inspection of belts and chains

- Cleaning of sensors and control panels

- Monthly Activities:

- Detailed inspection of all components

- Calibration of sensors and settings

- Checking and tightening fasteners

- Annual Overhaul:

- Complete disassembly and cleaning

- Replacement of worn parts

- Detailed calibration and testing

Benefits of a Scheduled Approach

Adhering to a maintenance schedule yields many benefits:

- Reduced Downtime: Prevents unexpected breakdowns, minimizing production disruptions.

- Extended Equipment Life: Regular care prolongs the lifespan of the equipment.

- Consistent Bagging Quality: Ensures the machine operates at peak performance, producing high-quality bags.

- Improved Safety: Identifies and addresses potential safety hazards.

By prioritizing a well-structured maintenance schedule, plastic pipe manufacturers can optimize their bagging operations and maintain a competitive edge.

3. Implementing Regular Inspection Procedures

Regular inspections are vital for spotting potential problems early. Trained personnel should conduct thorough examinations of all critical machine components.

Regular inspection procedures for plastic pipe bagging equipment involve checking belts, sensors, motors, and sealing mechanisms for wear, damage, or misalignment. Identifying and addressing minor issues proactively prevents them from escalating into major problems, ensuring consistent operation and minimizing downtime.

Focus Areas for Inspections

Effective inspection procedures should focus on the following:

- Belts and Chains: Check for wear, cracks, or looseness.

- Sensors: Verify proper functioning and alignment.

- Motors: Listen for unusual noises and check for overheating.

- Sealing Mechanisms: Ensure proper alignment and temperature control.

- Electrical Connections: Inspect for loose or frayed wires.

- Pneumatic Systems: Check for leaks and proper pressure levels.

Tools and Techniques

Equipping inspection personnel with the right tools and techniques is essential:

| Tool/Technique | Description | Benefit |

|---|---|---|

| Visual Inspection | Thoroughly examine components for visible signs of wear or damage. | Identifies obvious issues and potential problems. |

| Vibration Analysis | Measures the vibration levels of motors and bearings. | Detects imbalances and early signs of wear. |

| Thermal Imaging | Uses infrared cameras to detect temperature anomalies. | Identifies overheating components, which can indicate friction or electrical faults. |

| Ultrasonic Testing | Detects leaks in pneumatic or hydraulic systems. | Pinpoints leaks that can reduce efficiency. |

| Measurement Tools | Calipers, micrometers, and gauges. | Ensures parts meet specified dimensions and tolerances. |

Documentation and Follow-Up

Proper documentation of inspection findings is essential for tracking trends and planning maintenance activities:

- Record Findings: Document all inspection results, including any issues identified.

- Track Trends: Monitor inspection data over time to identify recurring problems or patterns.

- Schedule Repairs: Promptly schedule repairs for any identified issues.

- Follow-Up: Verify that repairs have been completed correctly and effectively.

Regular inspection procedures are a proactive approach that enhances the reliability and longevity of plastic pipe bagging equipment.

4. Lubrication: Reducing Friction and Wear

Lubrication is necessary for the longevity of your [PVC pipe packaging machines]. Moving parts like bearings, rollers, and chains must be adequately lubricated to reduce friction and minimize wear.

Proper lubrication of plastic pipe bagging equipment involves applying the correct type and amount of lubricant to all moving parts. Regular lubrication minimizes friction, reduces wear, and prevents overheating. Adhering to the manufacturer’s lubrication schedule and using high-quality lubricants are essential for optimal performance.

Selecting the Right Lubricants

Choosing the appropriate lubricants is crucial for effective maintenance:

- Manufacturer Recommendations: Always follow the manufacturer’s guidelines for lubricant types.

- Temperature Considerations: Select lubricants that perform well within the equipment’s operating temperature range.

- Compatibility: Ensure lubricants are compatible with the materials used in the equipment.

- Specialized Lubricants: Consider using specialized lubricants for specific applications, such as food-grade lubricants for equipment used in food processing.

Establishing a Lubrication Schedule

Create a lubrication schedule as part of your maintenance routine to ensure nothing is missed:

- Identify Lubrication Points: Determine all points on the equipment that require lubrication.

- Define Frequency: Establish how often each point should be lubricated.

- Assign Responsibilities: Clearly assign lubrication tasks to specific personnel.

- Document the Schedule: Create a written or digital schedule that is easily accessible.

Avoiding Common Lubrication Mistakes

To ensure effective lubrication, avoid these common mistakes:

| Mistake | Consequence | Solution |

|---|---|---|

| Inadequate Lubrication | Increased wear, overheating, and premature part failure | Adhere to the lubrication schedule and use the correct amount of lubricant. |

| Over-Lubrication | Attracting dust and contaminants, causing wear | Use the recommended amount of lubricant and clean excess lubricant. |

| Using the Wrong Lubricant | Reduced effectiveness and potential damage to components | Always use the type of lubricant recommended by the manufacturer. |

5. Cleaning: Maintaining Hygiene and Performance

Cleaning your Plastic pipe bagging equipment is essential for both hygiene and machine performance. Debris, dust, and packaging material residue can clog moving parts and cause malfunctions.

The benefits of keeping your equipment clean include:

- Hygiene: By implementing a regular cleaning routine using the recommended cleaning products to maintain operational efficiency.

- Improved Machine Performance: Keep machines clean by debris, dust, and packaging material residue to clog moving parts and cause malfunctions.

- Machine life: keeping your machine clean will greatly extend its life.

Effective cleaning is vital for maintaining both hygiene and machine performance.

Regular cleaning of plastic pipe bagging equipment involves removing debris, dust, and material residue from all accessible parts. Using the recommended cleaning agents and following a consistent cleaning schedule ensures optimal performance and prevents malfunctions. Cleanliness also promotes a hygienic environment, essential for certain applications.

6. Steps To Extend the Life of Your Equipment

Regular care and preventive measures keep your packaging machinery running smoothly for years to come.

The life and effeciency of your plastic pipe bagging equipment depends on several factors, from creating a solid maintenance schedule to regular inspections and prioritizing saftey. It is extremely important to follow these steps to have machines operating for many years.

Extending the lifespan of plastic pipe bagging equipment involves implementing comprehensive maintenance practices. This includes regular lubrication, cleaning, timely parts replacement, and adherence to safety protocols. Proper training of operators and ongoing monitoring of equipment performance are also crucial for maximizing the equipment’s operational life.

Conclusion

By prioritizing comprehensive training, hands-on practice, continuous education, and rigorous safety protocols, manufacturers can cultivate a skilled and safe workforce that drives operational excellence and maximizes the return on their machinery investments.