How to Do Automatic Steel Wire Rewinding and Strapping from Reel

Automating steel wire rewinding and strapping from reels streamlines production, enhancing efficiency and reducing labor costs. This process involves sophisticated machinery capable of precisely winding wire and securely strapping coils for storage and transportation. Understanding the process is crucial for optimizing industrial operations.

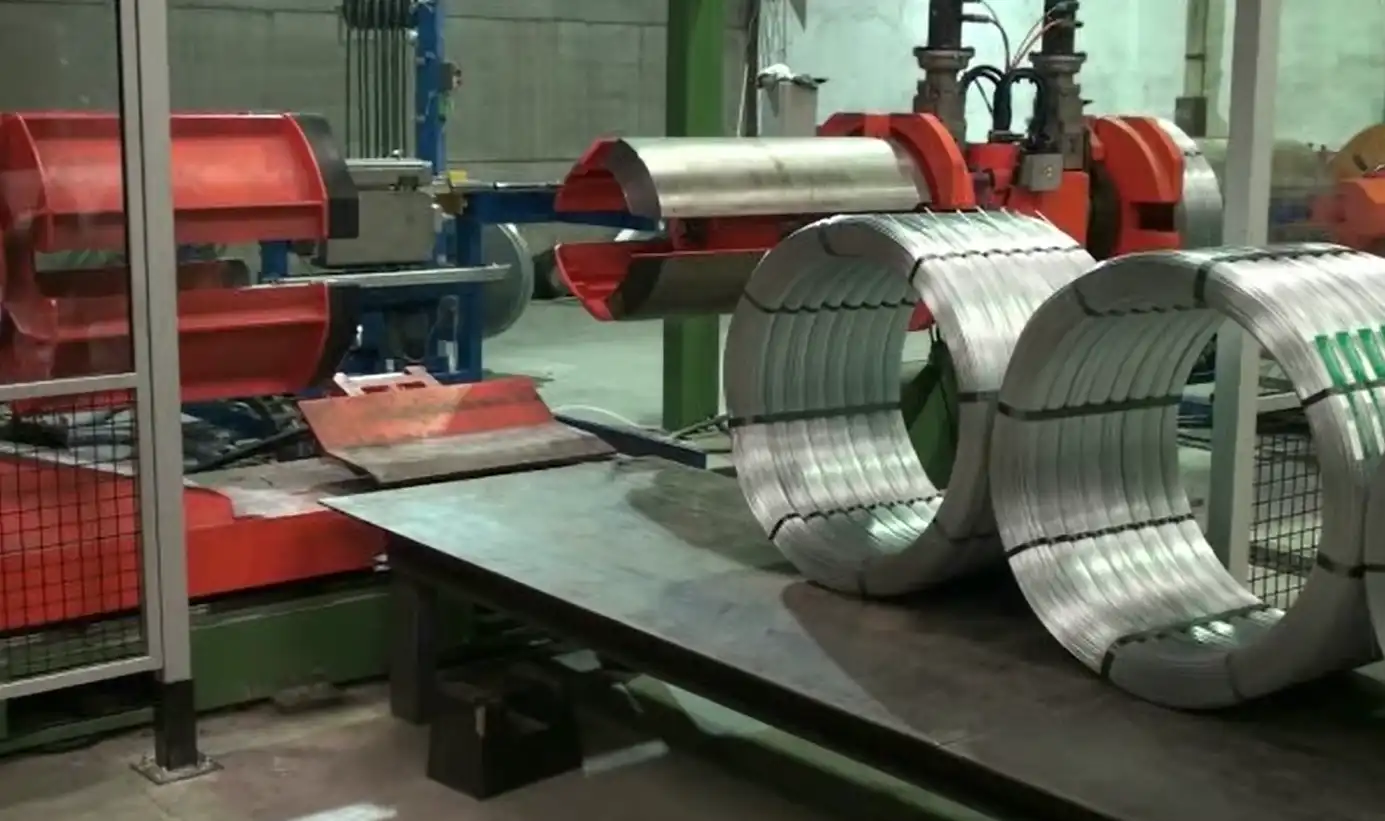

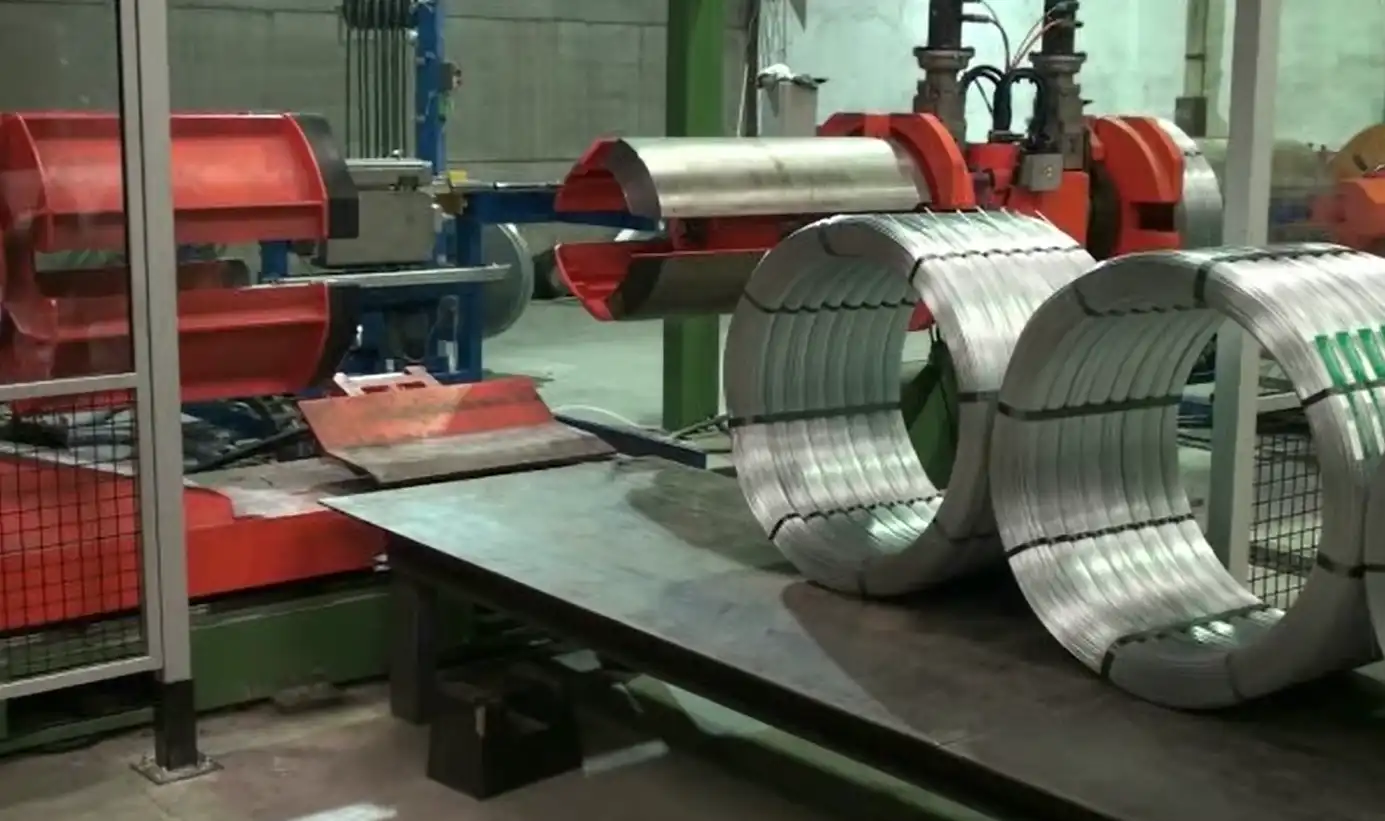

Automatic steel wire rewinding and strapping involves using specialized machines that unwind steel wire from a reel, precisely rewind it into a coil of a specific size and weight, and then securely strap the coil for handling and transport. This automation minimizes manual labor, increases speed, and ensures consistent quality in the finished product.

The world of industrial automation is constantly evolving, and the process of handling steel wire is no exception. Let’s delve into the specifics of automatic steel wire rewinding and strapping, exploring the key steps, equipment, and considerations involved. Prepare to discover how this innovative technology can transform your operations.

1. Understanding the Automatic Steel Wire Rewinding Process

The automatic steel wire rewinding process is a significant upgrade from manual methods, offering greater speed, precision, and consistency. Let’s explore the stages involved.

Automatic steel wire rewinding automates the process of transferring wire from one spool or reel to another, ensuring uniform tension and accurate coil dimensions. This process involves unwinding the wire, guiding it through tension control devices, winding it onto a new spool or reel, and then securing the finished coil.

The Benefits of Automatic Steel Wire Rewinding: A Critical Look

While the advantages of automation are clear, a nuanced understanding is vital for making informed decisions. Let’s break down the benefits and consider potential drawbacks.

Enhanced Efficiency

Automatic systems significantly reduce cycle times compared to manual winding. These machines operate continuously, minimizing downtime and increasing the number of coils produced per hour.

Improved Precision and Consistency

Automated systems offer unparalleled precision in coil diameter, winding tension, and layer placement. This level of control ensures consistent product quality, minimizing defects and waste.

Reduced Labor Costs

By automating the winding process, manufacturers can significantly reduce their reliance on manual labor. This leads to lower labor costs and frees up personnel for other tasks.

Enhanced Safety

Manual wire handling can be hazardous, exposing workers to potential injuries from sharp edges and heavy loads. Automation minimizes these risks, creating a safer working environment.

The Role of Pay-off Machine

The pay-off machine is an integral part of the wire coiler system. Its primary function is to supply wire to the rewinding machine at a consistent and controlled tension. A pay-off machine ensures smooth and efficient unwinding, preventing tangles and breaks.

Consider these benefits and potential challenges when implementing an automatic wire rewinding system. Proper planning and implementation can significantly enhance your wire handling operations.

| Benefit | Description |

|---|---|

| Increased Efficiency | Faster cycle times, continuous operation, and minimized downtime lead to higher production output. |

| Improved Precision | Precise coil diameter, winding tension, and layer placement result in consistent product quality. |

| Reduced Labor Costs | Automation reduces the need for manual labor, leading to significant cost savings. |

| Enhanced Safety | Automation minimizes the risks associated with manual wire handling, creating a safer work environment. |

2. The Importance of Strapping in Steel Wire Coiling

After rewinding, securing the coil is crucial for safe handling and transportation. Strapping plays a vital role in maintaining the integrity of the coil, preventing unraveling, and protecting the wire from damage.

Strapping is essential for securing steel wire coils after rewinding, preventing them from unraveling during handling and transport. Automatic strapping machines apply straps with consistent tension, ensuring the coils remain intact and protected. This process is vital for maintaining product integrity and minimizing potential damage.

Choosing the Right Strapping Material: A Technical Overview

Selecting the correct strapping material is critical for ensuring the coil’s stability. The choice depends on factors such as wire gauge, coil weight, and environmental conditions.

Several factors must be considered:

-

Steel Strapping: Provides the highest tensile strength, suitable for heavy coils and demanding applications.

-

Polyester Strapping: Offers a good balance of strength and flexibility, ideal for medium-weight coils and general-purpose applications.

-

Polypropylene Strapping: Is a lightweight and cost-effective option for light-duty applications and smaller coils.

The selection should be based on a thorough assessment of the coil’s characteristics and the expected handling and transportation conditions. Over-strapping can damage the wire.

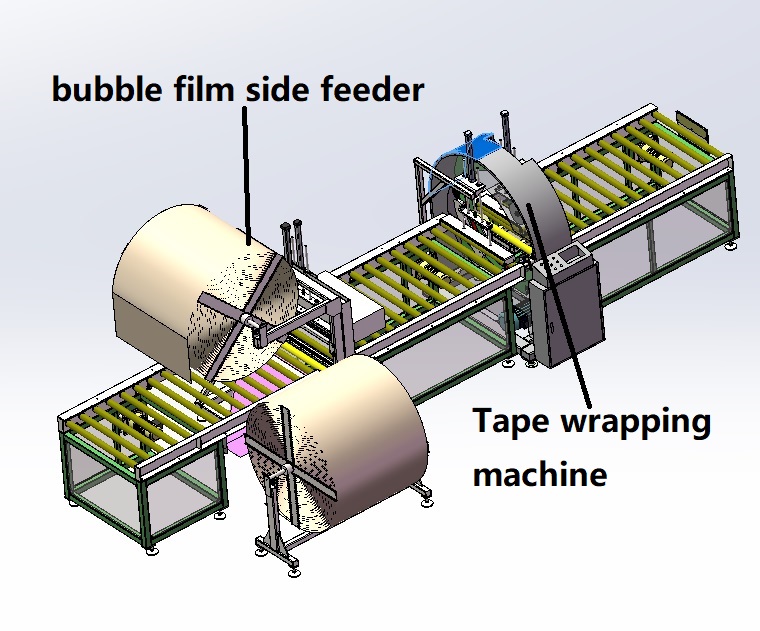

3. Integrating Rewinding and Strapping for Full Automation

Combining rewinding and strapping into a fully automated system maximizes efficiency and minimizes human intervention. This integration requires careful planning and coordination to ensure seamless operation.

Integrating rewinding and strapping creates a fully automated system where wire is unwound, rewound into a coil, and then automatically strapped for transport. This complete automation minimizes manual handling, reduces labor costs, and increases throughput, making the process highly efficient and consistent.

Troubleshooting Common Issues in Integrated Systems: A Practical Guide

Even with advanced technology, integrated systems can experience issues. A proactive approach to troubleshooting is essential for maintaining optimal performance.

| Issue | Possible Cause | Solution |

|---|---|---|

| Wire breaks during rewinding | Excessive tension, damaged wire, misaligned guides | Adjust tension settings, inspect wire for defects, realign guides |

| Strapping malfunctions | Incorrect strapping material, damaged strapping head, sensor issues | Verify strapping material, inspect and repair strapping head, check and calibrate sensors |

| Coil misalignment | Improper winding parameters, faulty sensors | Adjust winding parameters, calibrate sensors, inspect mechanical components |

Regular maintenance and proactive troubleshooting can significantly reduce downtime and ensure the smooth operation of your integrated system. It’s important to schedule routine inspections and address issues immediately to prevent bigger problems.

4. Safety Considerations for Automatic Wire Handling

Safety is paramount when operating automatic wire rewinding and strapping equipment. Always follow established safety procedures and wear appropriate personal protective equipment (PPE). Proper training is essential for all personnel involved in operating and maintaining the machinery.

Operating automatic wire handling equipment requires strict adherence to safety protocols. Proper training, the use of PPE, and regular equipment maintenance are crucial. Safety measures minimize risks and ensure a safe working environment for all personnel.

Ensuring the safety of personnel is a paramount concern when dealing with automatic wire handling systems. It’s critical to follow established protocols and implement measures to mitigate potential hazards.

The following are fundamental safety considerations:

-

Comprehensive Training: All operators and maintenance staff should undergo thorough training on the proper use of the equipment, emergency shutdown procedures, and potential hazards.

-

Personal Protective Equipment (PPE): Always use appropriate PPE, including safety glasses, gloves, and steel-toed shoes, to protect against potential injuries from sharp edges, moving parts, and heavy loads.

-

Emergency Stop Mechanisms: Ensure that emergency stop buttons are readily accessible and clearly marked. Regularly test these mechanisms to verify their functionality.

-

Regular Maintenance: Conduct routine inspections and maintenance to identify and address potential safety hazards, such as loose connections, worn components, or malfunctioning sensors.

-

Lockout/Tagout Procedures: Implement lockout/tagout procedures during maintenance and repairs to prevent accidental startup of the equipment.

Conclusion:

Automatic steel wire rewinding and strapping represent a significant advancement in industrial automation, streamlining production processes and improving efficiency. By understanding the key components, operational considerations, and safety requirements, businesses can leverage this technology to optimize their wire handling operations and achieve significant cost savings. Embracing automation is essential for staying competitive in today’s dynamic marketplace.