How Did an Aerospace Company Achieve Zero Defects with Upenders?

Striving for perfection, aerospace manufacturers face immense pressure to eliminate defects. The slightest imperfection can lead to catastrophic failures. Discover how one aerospace company revolutionized its quality control, achieving the coveted Zero Defects standard by integrating specialized handling equipment – upenders – into their advanced manufacturing processes.

This aerospace company achieved Zero Defects by strategically integrating precision upenders into their production line. These machines minimized handling-induced damage to sensitive components and ensured consistent part orientation for automated processes. This physical control, combined with data-driven Zero-Defect Manufacturing (ZDM) strategies like real-time monitoring and predictive analytics, created a holistic system that virtually eliminated defects from source to final assembly, addressing both physical and process-related error sources.

This innovative blend of robust physical handling and intelligent digital oversight marks a significant leap in quality management. Let’s delve deeper into how this synergy works and why it’s becoming essential for high-stakes aerospace manufacturing.

The Zero-Defect Imperative in Aerospace Manufacturing

In the demanding world of aerospace, there’s no room for error. The pursuit of Zero-Defect Manufacturing (ZDM) isn’t just a quality goal; it’s a fundamental requirement for safety, reliability, and mission success. Components must withstand extreme conditions, making defect prevention paramount from the earliest stages.

Zero-Defect Manufacturing (ZDM) is critically important in the aerospace sector because component failures can have catastrophic consequences, impacting safety and mission viability. ZDM represents a holistic quality philosophy focused on preventing defects throughout the entire value chain, rather than just detecting them post-production. It integrates advanced process controls, rigorous standards (like AS9145), data analytics (Big Data, AI), and meticulous physical handling techniques. The goal is to ensure every component conforms precisely to specifications, minimizing waste, reducing costs associated with rework or recalls (Price of Nonconformance), and guaranteeing the extreme reliability demanded by aircraft and spacecraft systems. This proactive approach builds quality into the design and manufacturing process itself.

Bridging Physical Handling and Digital Oversight

The journey towards Zero Defects in manufacturing has been an evolution. Early quality efforts focused primarily on inspection after production, identifying and removing faulty items. This progressed to Statistical Quality Control (SQC), using sampling to monitor processes. Total Quality Management (TQM) broadened the scope to include continuous improvement and employee involvement. Methodologies like Six Sigma introduced rigorous data-driven approaches to minimize process variation.

Zero-Defect Manufacturing builds upon these foundations but integrates modern digital capabilities and emphasizes prevention above all else. Philip Crosby, working on the Pershing missile program, formalized early ZDM principles: quality means conformance to requirements, prevention is key, the standard is Zero Defects, and quality is measured financially (Price of Nonconformance). While initially rooted in aerospace, these ideas heavily influenced automotive standards like APQP (Advanced Product Quality Planning) and its Core Tools (FMEA, SPC, MSA, PPAP). Aerospace later formalized its own standard, AS9145, adapting these concepts.

However, a significant portion of defects, especially in aerospace where components can be large, complex, and surprisingly delicate, arise not just from process variation but from physical handling. Scratches, dents, micro-cracks from improper lifting, or misalignment during transfer can compromise component integrity. This is where specialized equipment like upenders becomes crucial.

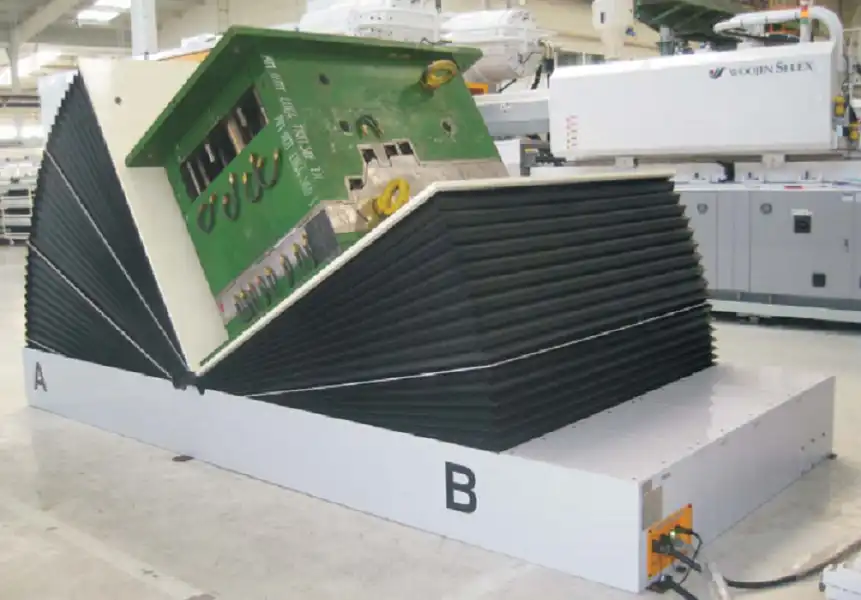

Upenders, also known as mold flippers or tilters, are designed to safely and precisely rotate, tilt, or invert heavy or unwieldy objects. In aerospace, they handle critical items like:

- Large molds for composite structures

- Engine casings and components

- Fuselage sections or tooling

- Satellite chassis or assemblies

By automating and controlling the movement of these parts, upenders directly address physical handling risks. They ensure smooth, controlled motion, minimizing shock loads and preventing accidental impacts. They position parts accurately for subsequent operations like machining, non-destructive testing (NDT), or assembly, contributing significantly to process control – a cornerstone of ZDM. This meticulous physical control forms the essential groundwork upon which digital ZDM strategies can build.

| Handling Risk Factor | Manual Handling Consequence | Upender Handling Mitigation | ZDM Principle Supported |

|---|---|---|---|

| Component Weight/Size | Strain, drops, collisions, slow speed | Controlled lift & rotation, secure clamping | Defect Prevention |

| Component Fragility | Scratches, dents, stress concentration | Smooth motion profile, precise positioning | Conformance to Req. |

| Positioning Accuracy | Misalignment, rework, process errors | Repeatable positioning, integration with guides | Process Control |

| Operator Safety | Injury risk leading to errors/delays | Remote operation, removes personnel from hazard | (Indirect) Efficiency |

| Handling Consistency | Variable methods, potential for errors | Standardized, automated sequences | Reducing Variation |

Upenders: The Unsung Heroes of Precision Handling

While data analytics and AI often steal the spotlight in modern manufacturing discussions, the physical manipulation of components remains a critical factor, especially in achieving Zero Defects. Upenders play a pivotal, often underestimated, role in ensuring this physical integrity throughout the production lifecycle.

Upenders directly contribute to Zero Defects in aerospace by providing precise, controlled, and automated manipulation of large, heavy, or sensitive components. They eliminate the risks associated with manual lifting and turning, preventing physical damage like scratches, dents, or stress fractures. Furthermore, they ensure consistent and accurate positioning for subsequent high-precision manufacturing steps like machining, automated inspection, and assembly, thereby reducing process variability and supporting overall quality control.

How Upenders Integrate into the ZDM Workflow

Upenders are not just standalone machines; they are integral components within a sophisticated ZDM ecosystem. Their integration is multifaceted, impacting various stages of aerospace manufacturing:

- Material Receiving and Preparation: Large raw material blocks, forgings, or castings often need to be repositioned for initial inspection or machining setup. Upenders handle these heavy items safely, preventing damage before value-added processes even begin.

- Tooling and Mold Handling: Aerospace manufacturing relies heavily on complex and expensive tooling, jigs, and molds (especially for composites). Upenders allow for safe rotation and positioning of these tools for maintenance, cleaning, preparation, or placement into production machinery (like autoclaves or presses). Damage to tooling directly impacts part quality. A dedicated mold upender ensures these critical assets are handled with care.

- In-Process Handling: Between manufacturing stages (e.g., moving an engine casing from a milling center to an NDT station), components often need reorientation. Upenders provide this reliably and repeatably, far exceeding the consistency of manual or crane-based methods. This is vital for automated cells where robotic arms or inspection systems expect parts in a precise location and orientation.

- Automated Inspection: Achieving 100% quality control often involves advanced inspection techniques like CMM (Coordinate Measuring Machines), laser scanning, or automated optical inspection (AOI). Upenders can present complex parts to these systems at optimal angles, ensuring all critical features are accessible and accurately measured without risky manual repositioning.

- Assembly Operations: Large assemblies, like fuselage sections or wing structures, may need to be rotated or tilted for access during joining or component installation. Upenders facilitate this, improving ergonomic access for technicians and ensuring correct alignment.

- Data Integration Potential: Modern upenders can be equipped with sensors monitoring parameters like load, tilt angle, rotation speed, and cycle time. This data, though perhaps simpler than machine tool sensor data, can be fed into Manufacturing Execution Systems (MES) or data analytics platforms. It can verify process completion, detect anomalies (e.g., unexpected load indicating a fixture issue), and contribute to the overall digital twin or process model, enriching the data available for ZDM analysis.

By minimizing the variability and risk inherent in manual handling, upenders establish a stable physical baseline. They ensure that defects are not introduced through simple mishandling, allowing the more sophisticated data-driven ZDM tools (like predictive analytics and AI inspection) to focus on detecting and preventing subtler process-related defects. This synergy is key to achieving near-perfect quality levels in high-tolerance aerospace production.

Synergizing Upenders with Big Data and AI for 100% Quality Control

Facing the challenge of eliminating every potential flaw? Relying solely on precise physical handling, even with advanced upenders, isn’t enough. True Zero Defects requires digital intelligence to oversee and optimize the entire process. Combining the physical control of upenders with the predictive power of Big Data and AI creates a formidable quality assurance system.

Achieving near 100% quality control in aerospace hinges on synergizing the physical damage prevention offered by upenders with the process insights derived from Big Data and AI. Upenders ensure components aren’t compromised during handling, while advanced analytics monitor production parameters in real-time, predict potential deviations or equipment failures, and enable proactive adjustments, addressing defects before they even occur.

Data-Driven Enhancements to Physical Processes

The integration of Big Data analytics transforms manufacturing from a reactive to a proactive paradigm, perfectly complementing the defect prevention role of upenders. Here’s how they work together within a ZDM framework:

-

Real-Time Monitoring and Process Control: Sensors on production machinery (CNC machines, composite layup machines, etc.) and potentially on handling equipment like upenders generate vast amounts of data (Volume, Velocity, Variety). Big Data platforms collect, integrate (from MES, ERP, sensors), and analyze this data.

- Synergy: While upenders ensure parts arrive undamaged and correctly positioned, real-time analytics monitor the subsequent value-added process (e.g., machining). Algorithms detect subtle deviations in parameters (temperature, vibration, cutting forces) that might indicate a drift towards a defect, even if the part was handled perfectly. Corrective actions can be triggered automatically or flagged for operators. Statistical Process Control (SPC) evolves into Continuous Process Control (CPC) powered by this real-time data.

-

Predictive Maintenance: Analyzing historical and real-time sensor data from both production equipment and potentially the upenders themselves allows AI/ML models to predict potential failures before they happen. This could range from predicting tool wear on a CNC machine to forecasting hydraulic system issues in an upender.

- Synergy: Upenders ensure consistent loading and operation, providing a more stable baseline for predictive maintenance algorithms focused on the primary manufacturing equipment. Preventing unexpected downtime (estimated 35-45% reduction) in either handling or production equipment is crucial for maintaining process stability and quality. Predictive maintenance reduces costs by 20-30%.

-

AI-Driven Quality Inspections: Automated inspection systems using computer vision and AI can analyze images or sensor data far faster and often more reliably than humans, detecting microscopic flaws or complex geometric deviations. Companies using AI quality control see 25-40% fewer manufacturing errors.

- Synergy: Upenders position parts optimally and repeatably for these AI inspection systems, ensuring consistent imaging conditions and maximizing the effectiveness of the defect detection algorithms. A part slightly tilted or rotated incorrectly by manual handling could fool an AI system or require complex recalibration.

-

Root Cause Analysis and Optimization: When defects do occur (despite best efforts), Big Data analytics can rapidly correlate data from multiple sources (handling logs, machine parameters, environmental sensors, inspection results) to pinpoint the root cause far quicker than traditional methods. Diagnostic analytics uncover why defects happened. Prescriptive analytics can then suggest optimal parameter adjustments.

- Synergy: Data indicating proper handling by an upender helps eliminate handling as a root cause, allowing analysis to focus more quickly on the actual production process parameters or material issues.

Table: ZDM Technologies and Their Contribution

| Technology | Contribution to ZDM | Example Metric Improved |

|---|---|---|

| Upenders / Tilters | Prevents physical handling damage, ensures consistency | Reduction in handling-related scrap/rework (%) |

| Big Data Analytics | Real-time process monitoring, root cause analysis | Defect Rate Reduction (up to 50%) |

| AI Vision Systems | Automated, high-accuracy defect detection | Inspection Accuracy & Speed; Error Reduction (25-40%) |

| Predictive Maintenance | Prevents equipment failure & related quality deviations | Reduced Downtime (35-45%), Maintenance Costs (-20-30%) |

| Digital Twins | Process simulation, optimization, what-if analysis | Time-to-Quality, Process Yield (%) |

Success stories abound: the automotive industry reduced defects by 40% using AI inspections; aerospace enhanced component reliability via predictive analytics; electronics cut defect rates by 35% with real-time monitoring. While these often highlight the digital aspects, the underlying assumption is that basic physical handling is already robust – a role perfectly filled by technologies like upenders.

Overcoming Challenges and Future Trends in ZDM with Precision Handling

Implementing a comprehensive ZDM strategy that integrates precision handling equipment like upenders with advanced digital technologies is powerful, but not without hurdles. Understanding these challenges and anticipating future trends is key for successful adoption and continuous improvement in aerospace manufacturing.

Key challenges involve the cost and complexity of integrating advanced upenders and data systems, especially with legacy infrastructure, ensuring high-quality data capture from both handling and production processes, bridging skill gaps for operating and maintaining these integrated systems, and addressing data security concerns. Future trends point towards smarter, interconnected handling equipment leveraging AI and edge computing for real-time adaptive control, deeper digital twin integration encompassing physical handling dynamics, and enhanced traceability using technologies like blockchain to track components meticulously throughout their lifecycle, including every handling step. Addressing these requires strategic planning, investment, and a commitment to a data-driven culture.

Integrating sophisticated equipment like automated upenders into existing factory floors can be complex. Compatibility with legacy control systems, MES, and ERP platforms requires careful planning and potentially middleware solutions. Ensuring seamless data flow using standards like OPC-UA or MQTT is crucial. The initial investment in both the physical handling equipment and the supporting digital infrastructure (sensors, networks, software) can be significant, requiring clear justification based on the expected reduction in the Price of Nonconformance (scrap, rework, warranty costs).

Data quality remains paramount. Data from sensors on upenders or related processes must be accurate, consistent, and properly contextualized to be useful for analytics. This requires robust data governance policies, cleaning processes, and validation checks. Furthermore, operating and maintaining these integrated systems requires a workforce skilled in both mechanical/electrical systems and data analysis. Training programs and fostering collaboration between IT and Operations Technology (OT) teams are essential to bridge potential skill gaps and overcome resistance to change. Finally, as systems become more connected, cybersecurity becomes critical. Protecting sensitive process data and ensuring the operational integrity of automated handling equipment against cyber threats requires robust security measures, adherence to standards (like ISO 27001, NIST), and ongoing vigilance.

Looking ahead, several trends promise to further enhance ZDM:

- Smarter Upenders: Future upenders will likely incorporate more sophisticated onboard sensors and processing (edge computing). This could enable real-time adjustments to handling profiles based on component characteristics or feedback from downstream processes, managed by AI/ML algorithms.

- Enhanced Digital Twins: Digital twins will become more comprehensive, accurately simulating not just the machining or assembly process, but also the physical dynamics of handling operations, allowing for virtual testing and optimization of handling strategies.

- Blockchain for Traceability: Blockchain technology can provide an immutable record of a component’s entire lifecycle, including every handling step, inspection result, and processing parameter, enhancing quality assurance and simplifying root cause analysis.

- Advanced Robotics and Automation: Collaborative robots (cobots) may work alongside upenders for complex positioning or light assembly tasks directly on the handling equipment, further reducing manual intervention in defect-prone areas.

By proactively addressing the challenges and embracing these technological advancements, aerospace manufacturers can continue to push the boundaries of quality, making Zero Defects an increasingly achievable reality.

Conclusion

Achieving Zero Defects in the high-stakes world of aerospace manufacturing demands a multi-faceted approach that extends beyond traditional quality control methods. It requires a seamless integration of robust physical processes and sophisticated digital intelligence. This exploration reveals how aerospace companies are leveraging specialized handling equipment, specifically upenders, as a critical component in their ZDM strategy. By minimizing handling-induced damage and ensuring process consistency, upenders provide the stable physical foundation necessary for advanced data-driven techniques like Big Data analytics, AI-powered inspections, and predictive maintenance to function effectively. The synergy between precise physical control and intelligent digital oversight allows for proactive defect prevention, moving significantly closer to the goal of 100% quality control. As technology evolves, the integration of smarter handling systems within connected, data-rich environments will continue to define the future of quality in Aerospace manufacturing.