How Did a Food Plant Meet FDA Standards Using Sanitary Upenders?

Struggling to meet stringent FDA hygiene standards in your food plant? Manual handling and tipping of heavy containers can introduce contamination risks, leading to costly compliance failures. Implementing specialized equipment designed for sanitation is crucial, but finding the right solution that satisfies both operational needs and regulatory demands can be challenging.

A food plant successfully met FDA standards by integrating sanitary upenders into their process. These machines, built with hygienic design principles like stainless steel construction, smooth surfaces, and sealed components, minimize contamination risks during material handling. They allow for controlled, automated tipping and rotation of bins or containers, reducing manual contact and ensuring compliance with FDA’s stringent requirements for cleanability, material safety, and prevention of product adulteration.

This approach not only ensured compliance but also improved operational efficiency and worker safety. Read on to discover the specific design features, regulatory considerations, and practical benefits that made sanitary upenders the key to unlocking FDA approval for this facility.

Understanding Sanitary Upenders and Their Role in FDA Compliance

Navigating the complex web of FDA regulations is a paramount concern for food processing plants. Ensuring every piece of equipment meets strict hygiene standards is non-negotiable. Sanitary upenders emerge as critical assets in this demanding environment, specifically engineered to handle materials hygienically while adhering to rigorous regulatory requirements, safeguarding both product integrity and consumer health.

Sanitary upenders are specialized material handling machines designed to invert, tilt, or rotate containers (like bins, drums, or vats) in food processing environments while adhering to stringent hygiene standards. Their role in FDA compliance is crucial because they minimize direct manual handling of large containers, reducing contamination risks. Built with FDA-compliant materials (e.g., specific grades of stainless steel), smooth, crevice-free surfaces, and sealed mechanisms, they are easily cleanable and prevent bacterial harborage, directly addressing FDA regulations concerning equipment design, construction, and maintenance (§ 416.3, § 416.4) to prevent product adulteration.

Key Sanitary Design Features Mandated by FDA for Upenders

Meeting FDA standards necessitates meticulous attention to equipment design. Sanitary upenders are not merely functional; they are engineered ecosystems of compliance. Every component, material, and construction detail is scrutinized against FDA guidelines to ensure they actively contribute to a hygienic processing environment.

H3: Material Selection and FDA Compliance

The FDA mandates that materials used in food processing equipment must be durable, compatible with products and cleaning agents, non-toxic, non-absorbent, and corrosion-resistant (Ref: § 416.2(g)(1), § 416.3(a), 21 CFR 117.40). Stainless steel, particularly AISI 300 Series (like 304 or 316L), is the preferred material for sanitary upenders due to its inherent properties.

- Durability: Stainless steel withstands the physical stresses of lifting and rotating heavy loads and resists wear from cleaning cycles.

- Corrosion Resistance: Its passive chromium oxide layer protects against corrosive food products (acids, salts) and aggressive cleaning chemicals (caustics, acids, sanitizers). 316L offers enhanced resistance, especially against chlorides.

- Non-Reactivity/Non-Toxicity: It does not leach harmful substances into food products or react chemically to alter taste or composition.

- Imperviousness: Stainless steel is non-porous and non-absorbent, preventing the harboring of bacteria within the material itself.

Other materials, like FDA-compliant polymers (e.g., UHMW-PE, PTFE) or specialized alloys, might be used for specific components (e.g., bearings, seals, contact pads) but must meet the same stringent FDA criteria. Documentation tracing material certifications is vital for verification.

H3: Surface Finish, Texture, and Cleanability

FDA regulations emphasize that food contact surfaces must be smooth, free of imperfections, and easily cleanable (§ 416.3(a), 21 CFR 117.40). The surface finish of a sanitary upender is critical.

- Smoothness: Polished surfaces (e.g., a No. 4 finish or smoother) minimize adherence points for food debris and microorganisms. Rougher surfaces are harder to clean and sanitize effectively.

- Ra Value: Surface roughness average (Ra) is a quantifiable measure. While FDA doesn’t specify an exact Ra value, standards like 3-A often provide benchmarks (e.g., Ra < 0.8 µm for food contact surfaces) which are widely accepted as good practice for demonstrating cleanability.

- Crevice Elimination: Designs must avoid sharp internal angles, pits, cracks, and crevices where bacteria can proliferate. Welds should be continuous, smooth, and often ground flush.

| Surface Finish | Typical Ra (µm) | Characteristics | FDA Compliance Aspect |

|---|---|---|---|

| Mill Finish (No. 2B) | 0.3 – 0.8 | Smooth, reflective, standard | Generally acceptable, cleanable |

| No. 4 Finish | 0.3 – 0.6 | Brushed, uniform lines, common | Highly cleanable, standard |

| Electropolished | < 0.2 | Extremely smooth, mirror-like, enhanced Cr layer | Superior cleanability & corrosion |

H3: Construction Principles: Preventing Contamination Traps

Sanitary construction goes beyond materials and finish. The way an upender is built must prevent areas where contaminants can collect or enter the product zone.

- Sealed Components: Hollow frameworks, legs, or enclosures must be fully sealed to prevent ingress of moisture, pests, or debris. Penetrations for bolts or wiring should be minimized and sealed appropriately.

- Drainability: Surfaces should be sloped to drain completely, preventing pooling of liquids (water, product residue, cleaning solutions) which can harbor bacteria (Ref: § 416.2(e)(4), ASME BPE SD-3).

- No Ledges/Crevices: Design should minimize horizontal ledges where dust or debris can accumulate. Internal angles should be coved (rounded) with appropriate radii (e.g., 1/4 inch minimum per 3-A standards).

- Accessible Design: Equipment must be designed for easy access for inspection, cleaning, and maintenance. Components should be easily removable where necessary. Bearings and gearboxes must be sealed or located outside the food contact zone to prevent lubricant contamination.

By adhering to these material, surface, and construction principles, sanitary upenders become demonstrably compliant with FDA requirements, ensuring they contribute positively to the overall hygiene and safety of the food processing operation.

How Sanitary Upenders Directly Address FDA’s Sanitary Operations Requirements (§ 416.4)

FDA’s regulations under § 416.4 focus keenly on the operational aspects of sanitation within a food plant. This includes the cleaning and sanitizing of food-contact and non-food-contact surfaces, the safe use of chemicals, and the protection of products from adulteration during all stages of handling and processing. Sanitary upenders play a direct and vital role in fulfilling these operational mandates.

Sanitary upenders facilitate compliance with § 416.4 by enabling thorough cleaning and sanitation of both their own surfaces and associated containers. Their smooth, non-porous, crevice-free design allows for effective cleaning routines. By automating the tipping process, they minimize manual handling, reducing the risk of cross-contamination between raw and cooked products or allergenic materials, thus protecting the product from adulteration during handling as required by § 416.4(d).

Integrating Upenders into Compliant Workflows and SSOPs

Simply having sanitary equipment isn’t enough; it must be integrated effectively into the plant’s overall sanitation program, particularly the Sanitation Standard Operating Procedures (SSOPs). Sanitary upenders are designed to simplify this integration.

Their inherent cleanability means SSOPs can specify straightforward, validated cleaning methods (e.g., manual washing, CIP rinsing if applicable to associated components, specific chemical concentrations and contact times). The materials used are compatible with standard food-grade cleaners and sanitizers specified in § 416.4(c), ensuring effectiveness without damaging the equipment.

Operationally, using a sanitary upender helps maintain hygienic conditions as mandated by § 416.4(a) and (b). Controlled, automated tipping prevents spills and uncontrolled dispersal of powders or liquids, which could contaminate surrounding areas and equipment. This minimizes the frequency and complexity of cleaning required for non-food-contact surfaces in the vicinity.

Furthermore, the ability to fully invert containers ensures complete emptying, reducing product loss and residual material that could spoil or harbor microbes. This supports efficient batch changeovers and cleaning cycles. For processes requiring segregation (e.g., allergens), dedicated or thoroughly cleaned upenders ensure strict adherence to protocols preventing cross-contamination, a key aspect of protecting product from adulteration (§ 416.4(d)).

Integrating the upender’s use and cleaning protocols into the SSOPs provides documented evidence to FDA inspectors that the establishment is actively managing contamination risks associated with material handling. This includes specifying cleaning frequency, methods, chemicals used, and responsible personnel, demonstrating a systematic approach to maintaining sanitary conditions. The upender becomes not just a piece of machinery, but a documented control point within the plant’s food safety system.

Verifying Compliance: 3-A Standards and Beyond for Sanitary Upenders

Navigating FDA compliance often involves demonstrating adherence not just to the regulations themselves, but also to recognized industry standards that embody best practices. Failure to use properly designed and verified equipment poses a significant risk of regulatory action, product recalls, and reputational damage. How can a food plant confidently select and validate sanitary upenders?

While FDA sets the rules, voluntary standards like 3-A Sanitary Standards provide detailed design and fabrication criteria that, if met by an upender, offer strong evidence of compliance with FDA’s intent. Choosing upenders built to 3-A (or similar NSF/EHEDG principles) standards, backed by proper documentation like material certifications and cleaning validations, significantly simplifies the process of demonstrating hygienic design and operational safety to FDA inspectors.

Navigating Standards and Documentation for FDA Acceptance

While FDA regulations (like 21 CFR 117.40 and 9 CFR 416) outline the requirements for sanitary design, they don’t always prescribe the specific methods to achieve them. This is where established industry standards become invaluable tools for both manufacturers and food processors.

H3: The Role of 3-A Sanitary Standards and Similar Benchmarks

3-A Sanitary Standards, Inc. has a long history, particularly in the dairy industry, of developing detailed specifications for hygienic equipment design and fabrication. While not regulations themselves, they are widely recognized by regulatory bodies, including the FDA and USDA, as benchmarks for compliance. The Pasteurized Milk Ordinance (PMO), for instance, explicitly references 3-A standards. Equipment bearing the 3-A symbol has undergone third-party verification (TPV) against the relevant standard.

Even if a specific 3-A standard doesn’t exist for "upenders," the principles embedded within numerous 3-A standards (covering materials, surface finish, radii, weld quality, drainability, seal design, cleanability, etc.) are directly applicable. Manufacturers building sanitary upenders often design them "in the spirit of" or according to these established 3-A principles. Similarly, NSF International standards (often for food service but increasingly for processing) and EHEDG guidelines (prominent in Europe) offer comparable hygienic design criteria. Adhering to these established principles provides a robust framework for meeting FDA’s more general requirements.

H3: Material Certifications and Traceability

FDA requires assurance that materials contacting food are safe, durable, and suitable (§ 416.3). For sanitary upenders, this means manufacturers must provide documentation certifying the materials used, especially for food-contact surfaces.

- Mill Certificates: For stainless steel components, mill test reports (MTRs) confirm the specific alloy composition (e.g., 304, 316L) and compliance with standards like ASTM or ASME.

- FDA Compliance Statements: For plastics, elastomers (seals, gaskets), or coatings, documentation should state compliance with relevant FDA regulations (e.g., 21 CFR parts 170-199 for indirect food additives).

- Traceability: The ability to trace materials back to their source is crucial for quality control and potential investigations.

This documentation is essential during FDA or FSIS inspections to verify that the equipment construction aligns with regulatory mandates.

H3: Documentation for FSIS/FDA Review

Beyond material certificates, a comprehensive documentation package helps demonstrate compliance and facilitates validation and maintenance.

| Document Type | Purpose | Relevance to FDA/FSIS |

|---|---|---|

| Equipment Manual | Operation, installation, safety procedures, parts list | Verifies proper installation & use, aids inspection access |

| Cleaning Procedures | Detailed steps for effective cleaning and sanitation (CIP/COP) | Demonstrates adherence to § 416.4, SSOP validation |

| Material Certificates | Proof of material composition and compliance (see above) | Verifies compliance with § 416.3, material safety |

| Design Specifications | Drawings showing construction details, radii, welds, surface finishes | Supports claims of sanitary design, cleanability |

| 3-A/NSF Certification | (If applicable) Third-party verification of adherence to specific standards | Strong evidence of meeting hygienic design principles |

Having this documentation readily available shows inspectors that the plant has performed due diligence in selecting, installing, operating, and maintaining equipment designed to meet FDA’s stringent sanitary requirements.

Case Study Insights: Real-World FDA Compliance Through Sanitary Upenders

Theory and regulations are essential, but understanding how sanitary upenders perform in a real-world food processing environment provides invaluable insight. Many plants face challenges with manual handling, cleaning validation, and preventing cross-contamination – issues that can lead to FDA scrutiny. Implementing the right equipment can be transformative.

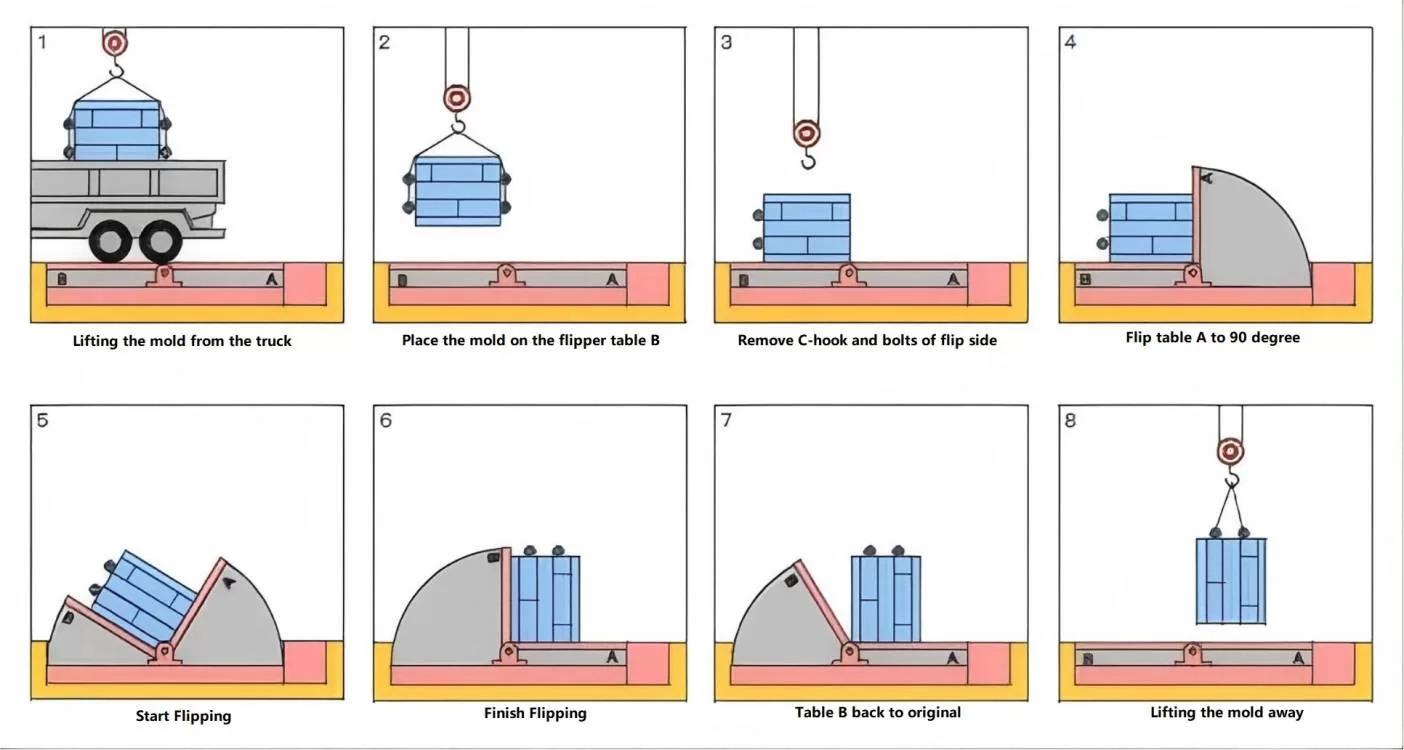

Consider a hypothetical plant processing bulk powdered ingredients. Previously, manual scooping and tipping of large bins led to dust generation (cross-contamination risk) and incomplete emptying, complicating cleaning and allergen control. By introducing stainless steel, washdown-duty sanitary upenders with sealed bearings and smooth finishes, the plant automated the transfer process. This contained dust, ensured near-complete bin emptying via controlled inversion, and dramatically simplified cleaning validation. During an FDA inspection, the documented procedures and easily verifiable cleanability of the upenders were key factors in demonstrating compliance with § 416.3 and § 416.4, satisfying inspectors.

The benefits extended beyond direct compliance. The automated process reduced manual lifting, improving worker ergonomics and safety. The controlled tipping minimized spills, reducing ingredient loss and cleaning time. For sensitive ingredients like allergens, the ability to thoroughly clean the upender between batches, verified through swab testing facilitated by the accessible design, provided robust support for the plant’s allergen control program. In another scenario, a meat processing facility used sanitary upenders to rotate large combo bins for cleaning. The upender’s ability to securely hold and invert the heavy bins allowed maintenance staff safe and complete access to all internal surfaces, ensuring effective sanitation and preventing bacterial harborage – a critical factor for FSIS compliance. The return on investment wasn’t just in avoiding fines or recalls, but also in operational efficiency, improved yield, and enhanced worker safety, all underpinned by equipment designed from the ground up with FDA standards in mind.

Conclusion

Meeting stringent FDA standards in food processing hinges on meticulous attention to sanitation at every stage, particularly in material handling. Sanitary upenders, designed and built according to rigorous hygienic principles, provide a critical solution. By utilizing FDA-compliant materials like stainless steel, incorporating smooth, crevice-free surfaces, ensuring easy cleanability, and enabling controlled, automated handling, they directly address key FDA requirements outlined in regulations such as 21 CFR 117.40 and 9 CFR Part 416. Their integration helps prevent product adulteration, facilitates effective sanitation protocols, and minimizes contamination risks. Investing in purpose-built sanitary Food processing equipment like a mold upender is not just about compliance; it’s a strategic move towards enhanced food safety, operational efficiency, and consumer confidence.