The Role of Edge Protectors in Steel Coil Packaging

Are you battling frustrating damage and costly claims for your valuable steel coils during transit? Impacts, abrasions, and pressure can compromise product integrity before it even reaches the customer. Poor physical protection during handling and shipping is a critical vulnerability. Edge protectors offer a vital, often underestimated, defense to safeguard quality and minimize losses.

Edge protectors are crucial in steel coil packaging as they shield vulnerable edges and corners from physical damage during handling, storage, and transportation. They absorb impacts, prevent crushing, distribute strapping pressure evenly, and maintain load stability. Made typically from sturdy cardboard, plastic, or metal, these components ensure coils arrive in usable condition, reducing costly material waste and returns.

Ensuring your steel coils arrive in perfect condition requires a multi-layered defense strategy. While corrosion prevention is key, protecting against physical trauma is equally vital. Let’s delve into how specialized components like edge protectors play a foundational role in this complex packaging puzzle.

The Critical Need for Physical Protection in Steel Coil Packaging

Transporting heavy, bulky steel coils presents significant challenges. Every lift, stack, strap, and mile traveled exposes them to forces that can cause deformation, dents, or edge damage. Such physical imperfections can render entire sections of a coil unusable, directly impacting downstream manufacturing processes and costing businesses substantial amounts in scrap, rework, and customer dissatisfaction. Robust physical protection is non-negotiable for maintaining coil quality throughout the supply chain.

Physical damage is a major threat to steel coil quality during their journey from mill to end-user. Handling operations involving cranes and forklifts, the pressures exerted by strapping during transit, and potential impacts or shifting within transport units (trucks, railcars, ships) can all cause significant harm. This damage often manifests as crushed edges, dents on the outer wrap or body, and deformation of the coil’s shape, particularly the eye or inner diameter. Edge protectors are specifically designed to reinforce the most vulnerable areas – the edges and corners – providing a buffer that absorbs shocks and spreads applied forces. Without this targeted protection, the high weight and momentum of coils make them exceptionally susceptible to irreparable physical harm from even routine logistics activities, compromising their structural integrity and surface finish essential for subsequent processing like slitting, stamping, or coating.

Safeguarding Coil Integrity Against Mechanical Stress

The sheer weight and shape of steel coils make them uniquely susceptible to certain types of physical damage. Understanding these stresses highlights the necessity of specialized protective measures like edge protectors.

Common Types of Physical Damage

- Edge Damage: The outer and inner edges are the most exposed points during lifting, setting down, and strapping. Impacts can crush, bend, or deform these edges, making the coil difficult or impossible to process through machinery designed for precise width materials.

- Dents and Surface Abrasions: Contact with other objects, rough handling, or internal shifting can cause dents on the coil body. Friction during transit can lead to abrasions on the surface wrap or the coil itself, compromising surface finish, which is critical for painted or coated products.

- Telescoping: This occurs when layers of the coil slip sideways relative to each other, usually due to improper strapping or securing during transit. This can cause buckling and damage to the coil’s structure.

- Deformation (e.g., Eye Damage): The inner diameter (eye) is vulnerable, particularly when handled by hooks or if coils are stacked improperly or shift. Damage here can prevent proper mounting on processing equipment.

Mechanical Functions of Edge Protectors

Edge protectors serve several critical functions to counteract these damage types:

- Impact Absorption: Made from sturdy materials like compressed cardboard or plastic, edge protectors act as a buffer zone, absorbing the energy from minor impacts and preventing it from directly affecting the sensitive coil edge.

- Pressure Distribution: Strapping, whether steel or polyester, exerts significant tension to secure the coil. Without edge protectors, this tension is concentrated on a narrow line along the edge, potentially crushing or deforming it. Edge protectors distribute this pressure over a wider area, protecting the coil structure underneath.

- Abrasion Prevention: By covering the sharp edges, they prevent friction between the coil edge and other packaging materials or the transport unit, reducing the risk of abrasions.

- Shape Retention: Particularly for the outer edges, protectors help maintain the coil’s round shape, preventing the edge from "spreading" under its own weight or external pressure.

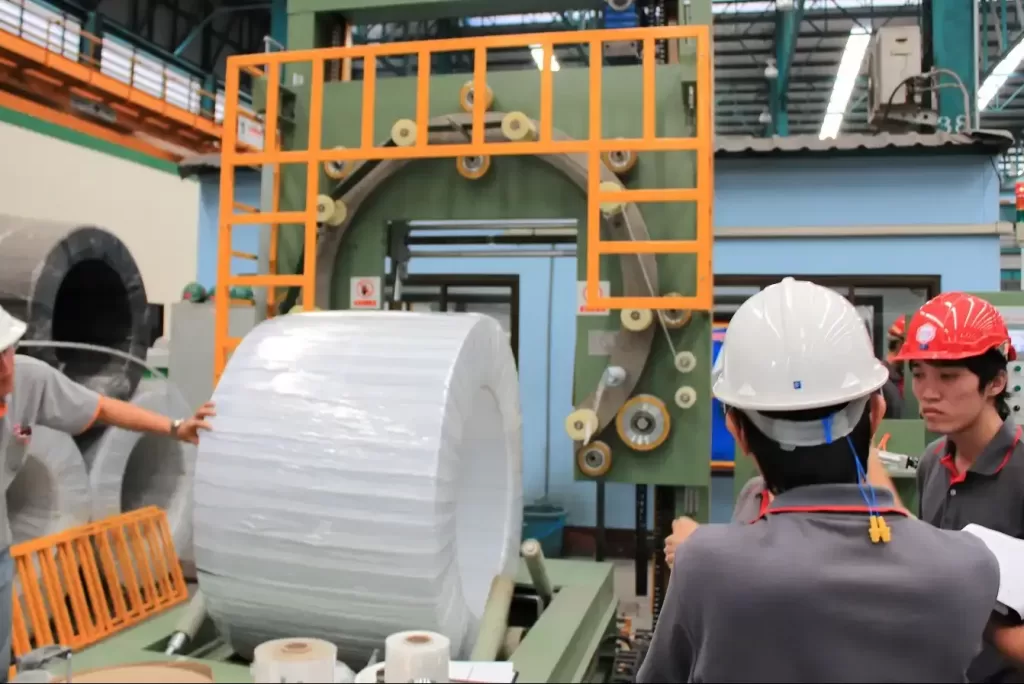

Edge protectors are typically applied to the outer circumference edges and often to the inner diameter edges (eye) before the coil is fully wrapped and strapped. Their rigidity helps the entire package maintain its form and integrity throughout transit.

| Edge Protector Material | Typical Composition | Key Benefits | Common Applications | Durability | Cost-Effectiveness |

|---|---|---|---|---|---|

| Recycled Cardboard | Compressed paperboard | Eco-friendly, cost-effective, good impact cushion | Standard duty, inner edge, domestic transport | Moderate | High |

| Plastic (e.g., HDPE) | High-density polyethylene | Moisture resistant, durable, reusable, rigid | Heavy duty, export, outdoor storage, outer edge | High | Moderate |

| Steel | Galvanized or painted steel | Maximum strength, ultimate impact/crush resistance | Extremely heavy coils, specialized transport | Very High | Low |

The material choice for edge protectors depends on the coil weight, the expected transit conditions (especially for export), and whether moisture resistance is needed. Combining edge protectors with high-strength films and proper strapping techniques forms a robust barrier against the physical stresses inherent in steel coil logistics.

Understanding Edge Protectors: The Unsung Heroes

In the complex world of industrial logistics, where protecting large, heavy cargo is paramount, certain simple components perform vital roles without much fanfare. Among these, edge protectors stand out as essential, albeit often overlooked, guardians of product integrity.

Edge protectors are humble yet critical packaging materials designed to safeguard the vulnerable corners and edges of goods during storage and transportation. They act as rigid buffers, preventing damage from impacts, abrasions, and the pressure exerted by strapping. Commonly made from recycled cardboard, plastic, or metal, these protectors are integral to maintaining the physical integrity of products like steel coils, ensuring they reach their destination in usable condition.

What are Edge Protectors and Why Do They Matter?

Edge protectors, also known by names such as corner protectors, edge guards, or angle boards, are specifically engineered components used within packaging systems. Their primary function is to provide a protective barrier along the vulnerable edges and corners of items, which are often the first points of contact for damaging forces during handling and transit.

While simple in concept, their impact on reducing product damage is significant. For heavy industrial goods like steel coils, the edges are particularly susceptible to crushing and deformation. Unlike a simple wrap, which provides surface protection, edge protectors add structural reinforcement precisely where it’s needed most.

Their importance extends beyond just preventing visible damage. Deformed edges on a steel coil can cause major issues in manufacturing processes, leading to machine downtime, material jams, and increased scrap rates. By preserving the precise dimensions and integrity of the coil edges, edge protectors ensure compatibility with automated processing equipment and maintain the efficiency of downstream operations.

Materials used for edge protectors are chosen for their rigidity, strength, and cost-effectiveness. Recycled cardboard is a popular and environmentally friendly choice for many applications. For heavier duty needs or exposure to moisture, plastic or even steel protectors are utilized. The angle design allows them to fit snugly along edges, providing continuous protection.

Proper application involves placing them directly onto the edges before the final wrapping and strapping stages. They are often secured in place by the outer wrap and held firmly by the tension of the strapping, becoming an integrated part of the coil’s protective shell. Their unassuming presence significantly contributes to delivering products in pristine condition, safeguarding both the product quality and the supplier’s reputation.

Protecting Against Physical Trauma: How Edge Protectors Work in Steel Coil Packaging

Ignoring the physical stresses your steel coils endure during logistics is a recipe for costly damage. Impacts from forklifts, pressure from stacking, and the unforgiving tension of strapping can all deform delicate edges. This physical trauma compromises quality and usability. Edge protectors are the engineered solution specifically designed to absorb these forces and preserve structural integrity where coils are most vulnerable.

Edge protectors function by creating a rigid buffer zone along the perimeter of steel coils, which are highly susceptible to damage at these points. They absorb and dissipate impact energy, preventing concentrated forces from crushing or bending the metal edges. Additionally, they spread the tension of strapping materials over a wider surface area, preventing indentation and deformation caused by high pressure. This targeted reinforcement ensures that the crucial outer and inner edges maintain their shape and integrity throughout the supply chain.

The Mechanics of Edge Protection

Edge protectors operate through simple yet effective mechanical principles to mitigate the forces that threaten coil integrity. Their placement and material properties are key to their performance.

Force Management Mechanisms

- Energy Dissipation: When an impact occurs directly on an edge protected by an edge protector, the protector absorbs a portion of the kinetic energy. The material crushes or deforms slightly, dissipating the force before it reaches the underlying steel edge. This cushioning effect is vital for preventing dents and crushing.

- Load Bearing and Spreading: Edge protectors act as miniature load-bearing beams along the edge. When strapping is applied with high tension, the edge protector distributes this linear force across its entire width, converting a high-pressure line into a lower-pressure band. This prevents the strapping from biting into the coil edge. Similarly, when coils are stacked or subjected to external pressure, the edge protectors help to bear some of the load and distribute it more evenly along the perimeter.

- Structural Reinforcement: By providing a rigid outer layer, edge protectors add stiffness to the vulnerable edges. This helps the coil maintain its intended shape, particularly preventing the outer wraps from "slumping" or becoming deformed at the edges.

Placement and Application

Correct application of edge protectors is crucial for maximizing their effectiveness.

- Outer Diameter (OD) Edges: Protectors are typically placed along the entire circumference of both outer edges of the coil. This is essential for protecting against stacking pressure, side impacts, and strapping tension.

- Inner Diameter (ID) Edges (Eye): Protectors are often fitted around the inside diameter (the "eye") of the coil. This area is vulnerable during handling, especially when lifting with hooks, and also during storage or transit if pressure is applied to the face of the coil.

- Securing: Edge protectors are held in place by the overall packaging system. The initial wrap (like stretch film) helps to keep them positioned, and the final strapping provides the tension that locks them firmly against the coil edge.

Comparison of Edge Protector Materials

The choice of material impacts the protector’s strength, durability, cost, and resistance to environmental factors.

| Feature | Recycled Cardboard Protectors | Plastic Protectors (e.g., HDPE) | Steel Protectors |

|---|---|---|---|

| Strength | Moderate; increases with thickness/density | High; maintains shape under significant load | Very High; resists severe crushing |

| Impact Resist. | Good; provides cushioning | Excellent; resilient, absorbs hard impacts | Highest; protects against sharp blows |

| Moisture Resist | Low (unless coated/laminated) | High | High (if coated/galvanized) |

| Durability/Use | Single use typical | Multi-use possible | Highly durable, multi-use |

| Cost | Lowest | Moderate | Highest |

| Env. Impact | Often recyclable/biodegradable | Recyclable | Recyclable (heavy) |

| Application | Standard coils, less harsh environments | Heavy coils, export, outdoor/marine transit | Heaviest coils, extreme conditions |

Implementing the right type and correctly applying edge protectors significantly enhances the physical protection of steel coils, complementing corrosion prevention measures like VCI packaging to ensure coils arrive ready for their intended application.

Integrating Edge Protectors into Comprehensive Steel Coil Packaging Systems

Protecting steel coils isn’t a one-size-fits-all task. A truly effective strategy combines multiple elements to create a layered defense against both environmental and physical threats. Edge protectors are a vital layer in this comprehensive system, working in concert with other materials and methods to ensure coils arrive in optimal condition, safeguarding product quality throughout the entire supply chain, from manufacturing plant to end-use.

Edge protectors are a vital component within a comprehensive steel coil packaging system, complementing other protective measures like VCI paper and film. They provide targeted physical reinforcement against impacts and strapping pressure at vulnerable edges, while VCI materials combat corrosion. Together, these elements, alongside durable wraps, sturdy pallets, secure strapping, and potentially desiccants, form a multi-layered defense that ensures steel coils are protected from physical damage and environmental degradation during storage, handling, and transit, crucial for maintaining their usability and value.

Effective steel coil packaging systems are designed to address the multitude of risks coils face during their journey. These risks include not only the physical impacts and pressures discussed but also environmental factors like moisture, humidity, temperature fluctuations, and corrosive atmospheres. A well-designed system integrates solutions for both.

The layers of a typical comprehensive steel coil packaging system often include:

- Corrosion Prevention: This is often the first internal layer. For steel coils, this commonly involves VCI (Vapor Corrosion Inhibitor) materials. VCI paper might be used inside the eye (ID) or interleaved between wraps, while VCI film (polyethylene) can form an outer wrap around the circumference. Desiccants may also be added to absorb moisture. These materials create a protective microenvironment to prevent rust and oxidation.

- Surface Protection: A primary wrap, often made from high-strength polyethylene film (PE) or woven fabric, is applied tightly around the coil. This layer protects the surface from abrasions, dust, and initial contact with moisture. Stretch film is popular for its conforming and containment properties.

- Edge and Corner Reinforcement: This is where edge protectors play their specific role. Applied to the OD and sometimes ID edges, they provide the targeted physical buffer against impacts and strapping pressure.

- Securing and Unitization: Strapping (steel or heavy-duty polyester) is applied around the coil to prevent telescoping and secure the coil to a pallet or skid. Edge protectors are essential underneath strapping to prevent crushing. Palletization lifts the coil off the ground, facilitating handling and protecting against floor contact moisture.

- Void Filling and Bracing: For transport within containers, trucks, or railcars, dunnage bags or other bracing materials are used to fill empty spaces and prevent the secured coils from shifting during transit, a major cause of damage, particularly during sea voyages.

- Outer Barrier (for Export): For international shipping, especially by sea, an additional robust outer wrap or container liner might be used to provide enhanced protection against moisture and the harsh marine environment.

The successful implementation of these layers depends on proper application techniques, often facilitated by automated coil packaging lines. These machines ensure consistent wrapping tension, accurate edge protector placement, and secure strapping, reducing manual error and improving overall packaging reliability. Investing in such a system is not just about individual components; it’s about creating a cohesive protective strategy that safeguards the quality of the steel coil from the moment it’s finished to the moment it’s unpacked by the customer. This integrated approach minimizes product degradation, reduces costly claims and rework, and upholds the manufacturer’s commitment to delivering high-quality material.

Conclusion

Maintaining the quality of steel coils through every stage of handling, storage, and transit is paramount for manufacturers and their customers. While corrosion prevention using technologies like VCI is critical, physical protection against impacts, crushing, and strapping pressure is equally vital. Edge protectors serve as indispensable components in a comprehensive coil packaging line, providing targeted reinforcement to the vulnerable edges and corners of coils. By absorbing impacts, distributing strapping tension, and aiding load stability, edge protectors significantly reduce the risk of physical damage, ensuring coils arrive in usable condition. Integrating edge protectors effectively alongside VCI materials, durable wraps, secure strapping, and proper handling techniques creates a multi-layered defense that safeguards product integrity, minimizes costly losses, and enhances customer satisfaction in the demanding world of steel logistics.