video of the steel coil covering in packing line

Precision and Protection: A Look at Automated Steel Coil Covering in the Modern Packing Line

Content:

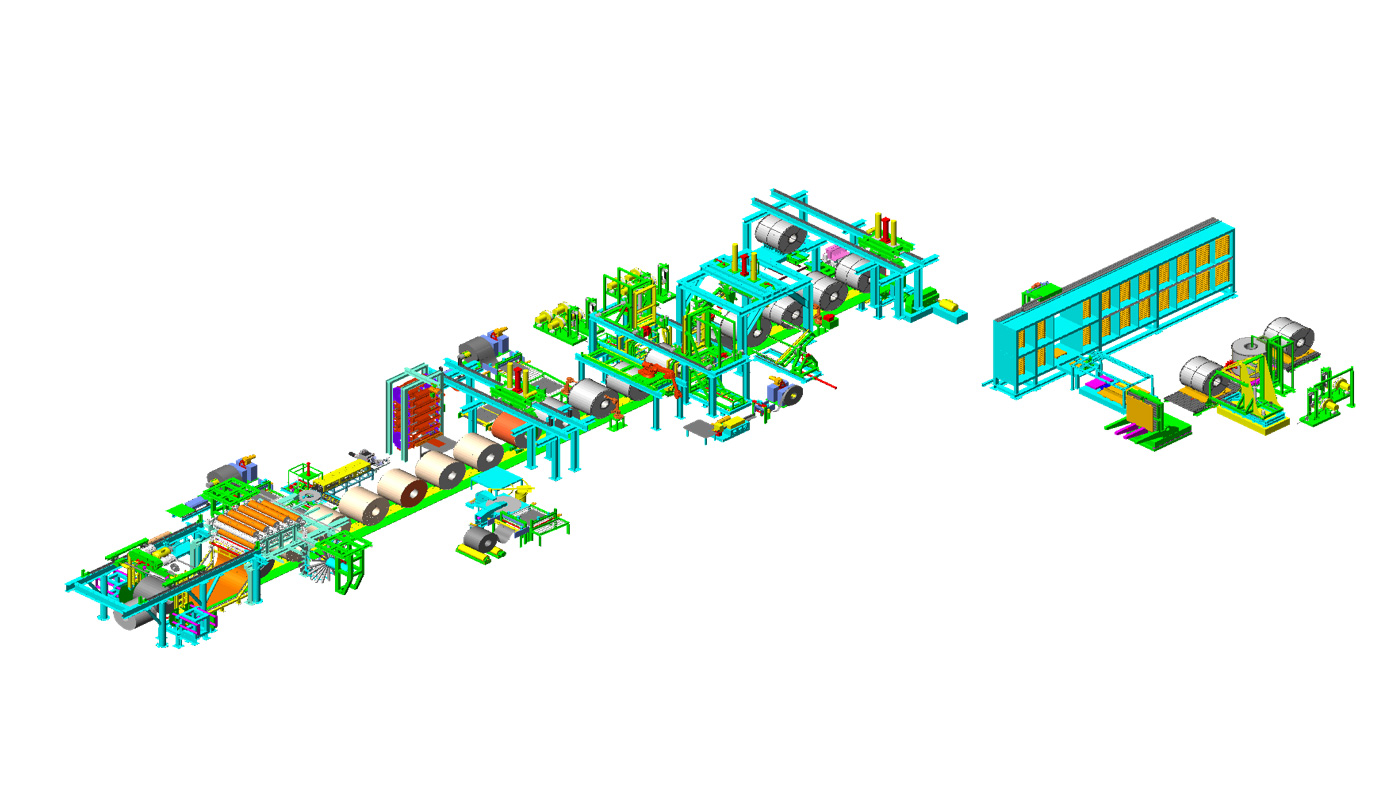

As fabricators at the forefront of steel coil packing technology, we understand that the journey of a steel coil doesn’t end when it comes off the mill. Its protection during transit and storage is paramount to preserving its quality and value. One of the critical stages in ensuring this protection is the steel coil covering process, specifically utilizing paper or specialized protective sheets. This isn’t just about wrapping; it’s a symphony of automated precision designed for efficiency, reliability, and material integrity. Today, we pull back the curtain on how our advanced automated systems achieve this, focusing on the seamless integration of coil handling and precision paper application.

The entire sequence is engineered to minimize manual intervention, reduce the risk of damage, and optimize throughput. Let’s break down the key components and processes involved in this sophisticated operation, which often forms an integral part of a larger steel coil packing line.

Automated Coil Handling – The Coil Car’s Crucial Role

The process begins with the safe and efficient delivery of the steel coil to the covering station. This is typically accomplished by an automatic coil car (often referred to as a coil transfer car or saddle car). These robust, PLC-controlled vehicles are the unsung heroes of the initial stage.

- Precision Alignment: The coil car is designed to receive the coil – whether from an upender, a turnstile, or directly from a conveyor system – and transport it with exacting precision. Sensors guide the car, ensuring the coil is perfectly centered and aligned as it approaches the covering station. This accuracy is vital for the subsequent automated paper application to be effective.

- Gentle Handling: We understand the delicate nature of finished steel surfaces. Our coil cars are equipped with V-shaped saddles or flat beds, often lined with protective materials like polyurethane, to prevent any scratching or deformation of the coil during transit. The movement is smooth and controlled, avoiding jarring stops or starts.

- Safety Interlocks: Safety is always a primary design consideration. The coil car system is integrated with the overall packing line’s safety interlocks. Light curtains, emergency stops, and area scanners ensure that the car operates safely within its designated zone, protecting both personnel and equipment.

- Programmable Logic: The coil car’s operation is seamlessly integrated into the packing line’s central control system. This allows for programmable transfer sequences, automatic queuing if necessary, and communication with upstream and downstream equipment, ensuring a continuous and optimized flow.

Once the coil car has securely and accurately positioned the coil at the covering station, the automated paper application sequence is initiated.

Automatic Paper/Sheet Feeding, Cutting, and Adhesiving – The Art of Protective Wrapping

This is where the true ingenuity of the steel coil covering machine comes into play. The goal is to apply a protective layer of paper (often VCI paper for corrosion inhibition, kraft paper, or other specialized barrier materials) around the outer diameter and, in some configurations, the eye of the coil.

- Automated Material Dispensing: Large rolls of the chosen protective paper are mounted on an automated unwind stand. This system ensures consistent tension and smooth feeding of the material. Sensors monitor the roll diameter, alerting operators when a change is required, minimizing downtime.

- Precision Feeding & Measurement: As the coil is rotated (either by driven rollers on the station or by the coil car itself in some designs), the paper is drawn into the application zone. Sophisticated sensors and encoders measure the exact length of paper required based on the coil’s diameter and the desired overlap. This eliminates material wastage and ensures complete coverage.

- Accurate Cutting Mechanism: Once the precise length of paper is dispensed, a high-speed, automated cutting mechanism (often a rotary shear or a guillotine-style cutter) makes a clean and accurate cut. The durability and sharpness of the blade are critical for consistent performance, especially with tougher protective materials.

- Automated Adhesiving: Applying the paper securely is key to its protective function. Our systems utilize automated adhesive application. This can take several forms:

- Hot-Melt Glue Systems: These are common for their fast setting times and strong bond. Precisely controlled nozzles apply beads or a spray pattern of hot-melt adhesive to the trailing edge of the paper sheet or directly onto the previous wrap layer just before the new layer is applied. The temperature and quantity of adhesive are meticulously regulated.

- Tape Application: In some systems, an automated taping unit applies adhesive tape to secure the paper’s edge. This is often seen for specific types of protective materials or customer requirements.

- Controlled Application & Wiping: As the paper is fed and cut, synchronized rollers or a pressure arm system ensures the paper is applied snugly and smoothly to the coil’s surface. This eliminates air pockets and ensures the adhesive makes proper contact. For full-width covering, the paper is often guided to wrap around the coil’s circumference. In some specialized machines, particularly for eye wrapping, intricate mechanisms guide the paper through the coil’s center.

- Tail Tucking/Sealing: The final step is to secure the trailing edge of the paper. This might involve a final press by a roller, an additional spot of adhesive, or a tucking mechanism to ensure the wrap doesn’t unravel.

This automated process of feeding, cutting, and adhesiving happens rapidly and consistently, coil after coil. The PLC control system manages all parameters, from paper length and adhesive application patterns to the rotational speed of the coil, ensuring a repeatable, high-quality wrap every time.

Integration into the Steel Coil Packing Line

The automated steel coil covering station is rarely a standalone unit. It’s a vital module within a comprehensive steel coil packing line. Downstream, the covered coil might proceed to:

- Strapping stations: Where steel or PET straps are applied circumferentially and/or radially.

- Stretch wrapping stations: For an additional layer of plastic film protection.

- Stacking and palletizing units: For preparing coils for shipment.

The beauty of modern fabrication is the seamless integration of these diverse processes. Data from one station informs the next, and the entire line operates as a cohesive unit, driven by intelligent automation.

By investing in robust and intelligent automated covering solutions, steel producers and processors can significantly enhance their operational efficiency, reduce labor costs, improve worker safety, and, most importantly, deliver a product that arrives at its destination in pristine condition. We, as fabricators, take immense pride in engineering these sophisticated solutions that play such a critical role in the global steel industry.

Resources and Further Information

To witness these automated steel coil covering machines in action, we recommend searching for videos and information from leading manufacturers in the coil packing industry.

Recommended Search Terms for Videos and Information:

- "Automatic steel coil paper covering machine video"

- "Steel coil wrapping line with paper applicator"

- "Coil packaging line paper wrapping"

- "FHOPEPACK steel coil covering" (If you are interested in a specific manufacturer mentioned previously)

- "Automatic coil car for steel plant"

- "VCI paper application machine for steel coils"

Where to Look:

- YouTube and Vimeo: Many manufacturers showcase their equipment through video demonstrations on these platforms.

- Manufacturer Websites: Companies specializing in coil packing machinery often have video galleries or detailed product pages with embedded videos and technical specifications. (e.g., Search for FHOPEPACK, Pesmel, Signode, Fromm, or other industrial packaging solution providers).

- Industrial Trade Show Archives: Websites of major steel and manufacturing trade shows sometimes feature exhibitor videos or technology highlights.

Example of how to footnote a specific (hypothetical) resource in Markdown if you find one:

Let’s say you find a relevant video from a manufacturer named "FHOPEPACK":

"…the paper is drawn into the application zone.1"

And then at the bottom of your document:

Or for a product page:

"…forms an integral part of a larger steel coil packing line.2"

By using such specific search terms on video hosting sites and manufacturer websites, you should be able to find visual demonstrations that align with the processes described above. These visual aids are invaluable for understanding the intricacies and efficiency of modern steel coil covering technology.

Automatic coil car for coil handling to the covering station.

Automatic paper/sheet feeding, cutting and adhesiving.

That can be a part of the steel coil packing line .

Video and more steel coil packing line

-

FHOPEPACK. (Date of Video if available). Automatic Steel Coil Paper Covering Line in Action. [https://www.fhopepack.com/Automatic-Coil-Packing-Line/]

-

Manufacturer Name. Product Page for Model XYZ Steel Coil Covering Machine. [https://www.shjlpack.com]