Service Centers for Slitting Coil Production, Packing, and Warehouse Stacking: A Comprehensive Analysis

1. Introduction: Understanding Slitting Coil Service Centers

1.1 Defining Metal Service Centers and Their Specialization in Coil Slitting, Packing, and Warehouse Stacking

Metal service centers occupy a crucial position within the broader metals industry, functioning as vital intermediaries between large-scale metal producers, often referred to as mills, and the diverse array of end-users, which include manufacturers and fabricators.1 These centers procure substantial quantities of metal in bulk, typically in the form of coils, sheets, or plates, and then enhance their value by providing a range of processing services tailored to meet the specific requirements of their clientele. This value-added processing can encompass various techniques, with a significant segment of service centers specializing in coil slitting.2

Coil slitting is a precision-based process that involves taking wide, master coils of metal and cutting them lengthwise into multiple, narrower strips, commonly known as mults.3 This process allows manufacturers to obtain metal strips with precise widths that are ideally suited for their specific downstream manufacturing operations. Beyond simply altering the width, many service centers offer an array of related services to further refine the metal. These can include edge conditioning, which involves smoothing or shaping the edges of the slit strips to improve safety and handling.3 Leveling is another common service, aimed at correcting any inconsistencies in the flatness of the metal.4 Some facilities also provide blanking services, which entail cutting the metal into specific shapes or lengths as per the customer’s needs.3 The specialization of these service centers extends beyond the slitting process itself. They also manage the packing of the newly slit coils to ensure their safe transportation and storage, and they implement efficient warehouse stacking procedures to optimize inventory management.5 The emergence of metal service centers with a focus on these specialized processing capabilities indicates an an evolution within the industry to cater to the increasingly specific and demanding needs of modern manufacturing.

1.2 The Purpose and Role of These Service Centers in the Metal Supply Chain

Service centers specializing in coil slitting play a pivotal role in ensuring a consistent and reliable supply of processed metal to various industries.1 Unlike metal mills, which typically focus on large production runs of standard products, service centers maintain inventories of diverse steel grades and forms, readily available to meet the immediate needs of their customers.1 This readily available stock significantly reduces lead times for manufacturers who might otherwise face delays when ordering directly from mills. Furthermore, many service centers offer just-in-time (JIT) delivery services, ensuring that manufacturers receive the processed metal exactly when they need it for their production schedules.1 This is particularly crucial for businesses adopting lean manufacturing principles, where minimizing inventory is a key objective.

By providing essential processing services such as coil slitting, these centers enable manufacturers to concentrate on their core manufacturing operations.6 Instead of investing in expensive metal processing equipment and the associated labor, businesses can outsource these tasks to specialized service centers. This not only reduces their capital expenditure but also allows them to leverage the expertise of professionals who are highly skilled in metal processing techniques.7 Moreover, service centers often have lower minimum order quantity requirements compared to mills, making them an ideal source for small and medium-sized enterprises that may not require large volumes of metal.8 In many instances, these centers also offer valuable expertise in material selection, guiding customers to choose the most appropriate type of metal for their specific applications.7 The function of slitting coil service centers has become increasingly vital as manufacturing processes become more intricate and require highly customized metal inputs. Their presence in the supply chain acts as a critical facilitator, bridging the gap between the large-scale production of mills and the diverse, often highly specific, needs of end-users, ultimately contributing to a more efficient and responsive metalworking ecosystem.

2. Comprehensive Services Offered by Slitting Coil Service Centers

2.1 Coil Slitting Services

2.1.1 Range of Materials Handled

Service centers specializing in coil slitting demonstrate the capability to handle a broad spectrum of metallic materials, catering to the diverse needs of various industries.9 Among the most common materials processed are various grades of steel, including carbon steel, which forms the backbone of many manufacturing applications due to its strength and affordability.9 Stainless steel, prized for its resistance to corrosion and high temperatures, is also frequently handled, finding applications in industries ranging from appliance manufacturing to food processing.9 Aluminum, known for its lightweight properties and corrosion resistance, is another significant material processed by these centers, serving sectors like automotive and aerospace.10 Beyond these primary metals, some service centers also handle specialty metals such as copper, brass, and bronze, often required for specific electrical or aesthetic applications.10 The ability to process a wide array of steel types, including galvanized steel, coated steel like galvalume, and hot-rolled steel, further underscores the versatility of these facilities.9 It is also common for certain service centers to develop a specialization in particular materials, such as focusing primarily on stainless steel processing or becoming experts in the slitting of aluminum coils.3 This broad material handling capability positions these service centers as invaluable partners for manufacturers who utilize a variety of metals in their production processes, offering a convenient and consolidated point of sourcing and processing.

2.1.2 Achievable Slitting Specifications

The precision achievable in coil slitting by these specialized service centers is a key factor in their value proposition to manufacturers. While capabilities can vary between facilities, many centers offer narrow slitting capabilities, with some able to slit coils down to a width of just 0.5 inches.3 The range of material thicknesses that can be accommodated is also extensive, spanning from very thin gauges, such as 0.010 inches, suitable for delicate applications, to significantly thicker materials, reaching up to 0.260 inches and even 0.500 inches in some cases.3 Maintaining tight width tolerances is paramount in the slitting process, and many modern service centers can achieve impressive accuracy, with tolerances as low as +/- 0.005 inches being common, depending on the specific material, its thickness, and the sophistication of the slitting equipment employed.11 It is important to note that the achievable tolerances can sometimes be influenced by factors such as the material’s thickness and the desired final width of the slit strips.12 The high degree of precision offered by these slitting services enables manufacturers to obtain metal strips that are essentially ready for direct integration into automated production lines, thereby minimizing the need for secondary processing and reducing material waste. The variability in slitting specifications across different service centers highlights the importance of clear and detailed communication between the customer and the service provider to ensure that the final product meets the exact requirements of the intended application.

2.1.3 Additional Services like Edge Conditioning and Leveling

Beyond the core service of coil slitting, many service centers offer supplementary processes that further enhance the value of their offerings to manufacturers. Edge conditioning is a significant value-added service that involves the treatment of the edges of the slit metal strips.3 This can include deburring, which removes sharp or rough edges, smoothing to create a more refined finish, and even rounding the edges for safety or specific functional requirements.3 By providing a cleaner edge, edge conditioning not only improves the safety of handling the material but also facilitates easier and more efficient processing in subsequent manufacturing stages. Leveling is another crucial service that addresses the issue of material memory and ensures the flatness of the metal.4 Coiled metal often retains a curvature from being wound, and leveling processes work to correct this, resulting in a flat material that is essential for downstream operations such as stamping, laser cutting, or CNC machining.4 In addition to these services, some service centers extend their capabilities to include sheeting and blanking.3 Sheeting involves cutting the coils into flat sheets of predetermined lengths, while blanking entails cutting sheets of metal into specific shapes or sizes tailored to the customer’s exact specifications. These additional services further integrate the service center into the manufacturing supply chain, providing customers with semi-finished or even finished components, thereby reducing the amount of in-house processing that the manufacturer needs to undertake. The availability of these diverse services underscores the role of slitting coil service centers as comprehensive metal processing partners.

2.2 Packing and Material Handling

2.2.1 Common Packing Materials and Techniques for Metal Coils

The packing of metal coils after slitting is a critical step in ensuring that the material is protected from various forms of damage during subsequent handling and transportation.13 A range of packing materials and techniques are employed to safeguard the coils from potential threats such as moisture, which can lead to rust and corrosion, physical scratches or dents, and general wear and tear during transit.14 Common packing materials include stretch film, which provides a protective outer layer against dust and minor abrasions, and VCI (Volatile Corrosion Inhibitor) paper or film, which releases compounds that prevent corrosion, particularly important for long-term storage or shipment in humid environments.14 Sturdy cardboard or hardboard materials are often used to provide additional physical protection, especially to the sides of the coils.14 To secure the coil and prevent it from unwinding during handling, steel or PET (Polyethylene Terephthalate) straps are commonly applied around the circumference and sometimes through the eye of the coil.14 Edge protectors, typically made of cardboard, plastic, or metal, are frequently used to prevent damage to the vulnerable edges of the coil.14 For ease of handling and stacking within warehouses, the packed coils are often placed on pallets, which can be made of wood or more durable steel, especially for stackable configurations.13 When preparing coils for shipping, particularly in containers, proper securing techniques are essential. This can involve the use of cradles, which are specialized supports designed to hold the curved shape of the coil, bedding beams placed underneath to distribute the weight, and blocking or bracing materials to prevent any movement during transit.13 The specific combination of packing materials and techniques employed is often tailored to the type of metal, the anticipated shipping conditions, the duration of storage, and the specific requirements of the customer. This careful attention to packing ensures the integrity of the slit coils and minimizes the risk of damage that could lead to material loss or customer dissatisfaction.

2.2.2 Automated Packaging Lines and Equipment

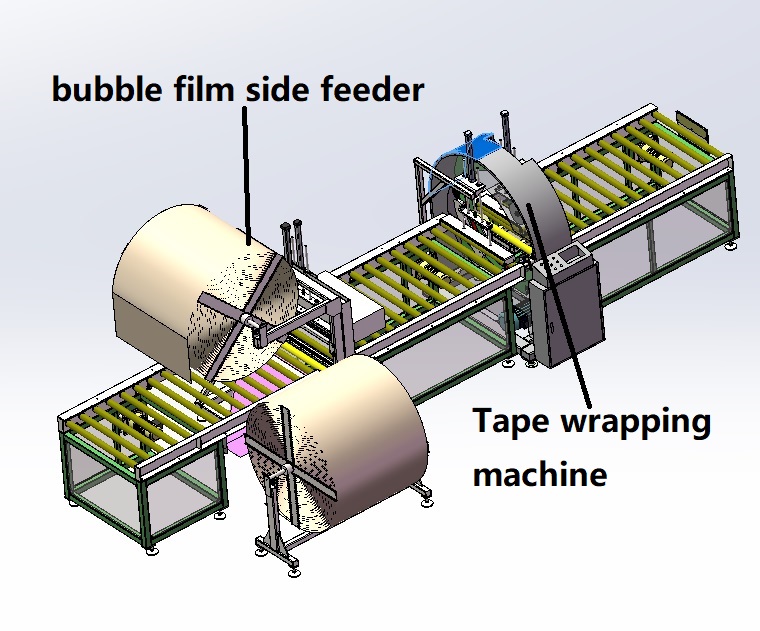

In order to enhance efficiency and ensure consistency in the packing process, many slitting coil service centers have invested in automated packaging lines and specialized equipment.5 These automated systems are designed to streamline the entire packaging operation, from the moment the slit coil exits the slitting line to its final preparation for shipment. Key pieces of equipment found in these automated lines include coil centering machines, which precisely position the coil for subsequent packaging steps, and various types of wrapping machines.14 Orbital wrappers are often used for eye-through wrapping, where the wrapping material is passed through the center of the coil, while rotary ring wrappers are commonly employed for wrapping palletized coils.15 Strapping machines, which can be either semi-automatic or fully automatic, apply and tension the steel or PET straps that secure the coil.14 Stacking machines are used to automatically lift and stack the wrapped and strapped coils onto pallets, often in pre-determined patterns to maximize stability and space utilization.5 Other equipment that may be integrated into these lines includes coil tilters and downenders, which change the orientation of the coil as needed for different processing or packaging steps, and palletizers, which automatically place coils onto pallets.15 Robotic label applicators are also increasingly being used to ensure accurate and efficient labeling of the packed coils.16 These automated systems can handle a wide range of coil sizes and weights, with some fully automated lines capable of processing up to 20 to 30 coils per hour for lighter materials, and handling coils weighing up to 35 tons in some cases.14 The implementation of automation in packaging not only significantly reduces the need for manual labor and the associated costs but also minimizes the potential for human error, leading to more consistent and reliable packaging quality and enhanced safety in the workplace.

2.2.3 Best Practices for Safe and Efficient Stacking of Metal Coils

The safe and efficient stacking of metal coils within a service center’s warehouse is paramount for preventing accidents, minimizing material damage, and optimizing the utilization of storage space.17 Several best practices are commonly implemented to achieve these objectives. Firstly, it is crucial to ensure that all coils are stacked on a level and stable surface, arranged in a straight and even manner, with heavier loads always placed on lower or middle shelves to maintain stability.18 Good housekeeping practices, such as keeping aisles and passageways clear of obstructions, are essential for safe movement of personnel and equipment.18 Proper lifting techniques should always be employed, and appropriate material handling equipment, such as cranes and forklifts with specialized coil attachments, should be used to move and stack the heavy coils.18 Coils should be stored on stable supports, either placed on their side (with the bore vertical, often referred to as "eye to the sky") or stored upright in specifically designed storage racks.19 The use of wooden or steel pallets is generally recommended for bulk storage, as they provide a stable base and facilitate handling.20 Vertical storage systems, utilizing racks, can be particularly effective in saving floor space and reducing the risk of product damage.20 While it might be tempting to double-stack coils to maximize space, this practice is generally discouraged due to the increased likelihood of damage from additional handling and the greater risk of accidents.21 For certain types of coils stored with the bore vertical, multiple stacking on pallets might be acceptable if proper precautions are taken to ensure the top cover of the lower coil can safely support the weight of the coil above.21 Maintaining appropriate environmental conditions within the warehouse is also vital, especially for metals like stainless steel and aluminum, which are susceptible to corrosion if exposed to excessive humidity or temperature fluctuations that can cause condensation.22 Regular inspections of storage areas, racking systems, and the coils themselves are necessary to identify any signs of damage or instability.22 By adhering to these best practices, service centers can create a safer working environment, protect the quality of their inventory, and ensure efficient warehouse operations.

3. Equipment and Technologies Utilized in Service Centers

3.1 Slitting Line Components and Technology

The core of a slitting coil service center lies in its slitting line, a sophisticated piece of machinery designed to transform wide master coils into narrower strips with precision and efficiency.23 A typical slitting line comprises several key components working in concert. The process begins with an uncoiler, which is responsible for securely holding the master coil and unwinding it as needed to feed the subsequent stages of the line.23 The metal strip then passes through the slitter itself, the heart of the operation. This unit is equipped with a set of rotary blades, often referred to as knives or cutters, which are precisely positioned to make longitudinal cuts along the length of the coil, dividing it into multiple narrower strips, or mults.23 Following the slitting process, the individual strips are rewound onto a recoiler, which maintains tension on the strips to ensure they are wound tightly and evenly into separate, narrower coils.23 Maintaining consistent tension throughout the slitting process is crucial for achieving high-quality results and preventing issues like wrinkling or misalignment of the strips. This is managed by a tension control system, which can employ various methods such as drag pads, rollers, or a combination of both.24 Additional components often found in a slitting line include entry guides to ensure the coil enters the slitter correctly, loop pits or tables that provide a buffer to manage variations in material flow and tension, separator units that keep the slit strips from tangling as they are recoiled, and scrap winders or ballers that collect the trimmed edges of the coil.24 Modern slitting lines are increasingly incorporating automation to enhance performance. Features like automatic loop control, which adjusts the speed of the uncoiler and recoiler to maintain optimal material flow, and automatic tension control, which ensures consistent tension on the strips, are becoming commonplace.25 Automatic tooling changeover systems and robotic tooling setup are also being adopted to minimize the time required for changing slitter knives and spacers when switching between different slitting patterns, thereby increasing overall efficiency.25 High-speed slitting lines can achieve impressive processing speeds, with some capable of reaching up to 400 meters per minute.26 The type of slitter blades used can vary depending on the material being processed and the desired outcome. High-speed steel razor slitters are particularly popular for their ability to produce clean and accurate slit edges, even on high-strength steels.27 Rotary shear slitters and slitting saws are other types of cutting tools used, each with its own advantages and limitations.27 The ongoing advancements in slitting line technology are focused on achieving greater precision, higher processing speeds, and improved operational efficiency through increased automation.

3.2 Packing Equipment

Following the slitting process, the narrower coils need to be securely packed for storage and transportation. Slitting coil service centers utilize a variety of specialized packing equipment to ensure this is done effectively and efficiently.14 Wrapping machines are essential for protecting the coils from environmental factors and physical damage. These can range from semi-automatic to fully automatic systems that apply stretch film, paper, or other wrapping materials around the circumference and sometimes through the eye of the coil.14 Different types of wrapping machines are available, including orbital wrappers, which rotate around the coil, and horizontal wrappers, which are suitable for coils lying on their side.15 Strapping machines are used to apply and tension straps, typically made of steel or PET, around the coils to keep them tightly wound and prevent unwinding during handling and transit.14 These machines can apply straps both radially (around the circumference) and axially (through the eye of the coil). Palletizers are used to automatically place the wrapped and strapped coils onto pallets for easier handling and storage.5 Some automated packing lines also include edge protector applicators, which automatically place protective materials on the edges of the coils to prevent damage.14 Other specialized equipment found in packing areas can include coil tilters and downenders, which change the orientation of the coils to facilitate different packaging operations.15 Weighing stations are often integrated into the packaging line to accurately determine the weight of the packed coils, and labeling machines, including robotic applicators, ensure that coils are properly identified with relevant information.16 The selection of specific packing equipment depends on factors such as the type and size of the coils being processed, the desired level of automation, and the specific packaging requirements of the customers.

3.3 Warehouse Management Systems and Equipment Used

Efficient inventory management and streamlined operations within a slitting coil service center’s warehouse are often facilitated by the use of sophisticated Warehouse Management Systems (WMS) and a variety of specialized equipment.28 These WMS software solutions are designed to manage the entire flow of inventory, from the moment a master coil is received until the slit coils are dispatched. Features commonly include real-time tracking of coil locations within the warehouse, optimization of storage space and retrieval processes, and seamless integration with other business systems such as Enterprise Resource Planning (ERP) platforms.28 Barcode scanning and Radio-Frequency Identification (RFID) technologies are often employed to ensure accurate and rapid data capture for inventory tracking.28 To handle the heavy weight and awkward shape of metal coils, service centers utilize specialized material handling equipment. Overhead cranes, including bridge cranes, gantry cranes, and jib cranes, are essential for lifting and moving coils, particularly for loading and unloading from delivery vehicles and for accessing coils stored at higher levels.29 Forklifts, equipped with specialized attachments such as coil rams (poles inserted into the eye of the coil) or coil clamps (large padded arms that grip the outside of the coil), are used for maneuvering coils within the warehouse and for loading onto processing lines or outbound transport.30 Coil cars, which are motorized platforms designed to carry coils, are also used for internal transport. Various types of racking systems are employed to store coils efficiently and safely.31 These include stackable coil pallets or skids, which allow for vertical stacking, coil cradles that provide stable support for individual coils, and heavy-duty structural steel racks, often with an I-beam construction, designed to hold multiple coils.31 In some of the more advanced facilities, Automated Storage and Retrieval Systems (ASRS) are utilized.32 These systems use automated cranes and robotics to store and retrieve coils from high-density storage areas, further enhancing efficiency and throughput. The integration of these WMS and specialized equipment demonstrates a commitment to operational efficiency, safety, and precise inventory control within the slitting coil service center industry.

4. Benefits of Outsourcing to Slitting Coil Service Centers

4.1 Cost Savings

Outsourcing coil slitting and related processes to specialized service centers can yield significant cost savings for manufacturing businesses.7 One of the primary advantages is the elimination of the need for substantial capital expenditure on expensive slitting lines, packing machinery, and warehouse material handling equipment.7 These specialized machines represent a considerable investment, and by outsourcing, manufacturers can avoid these upfront costs. Furthermore, service centers can achieve lower labor costs per unit of processed metal due to their economies of scale and specialized workforce.27 They have trained personnel who operate these machines efficiently, reducing the need for a manufacturer to hire and train their own specialized staff. Metal service centers often purchase raw materials in bulk directly from mills, allowing them to secure more competitive prices.8 These cost savings on raw materials can then be passed on to the customer. Additionally, the precision slitting offered by service centers helps in achieving minimized waste and scrap for the manufacturer.2 By providing metal strips of the exact required width, service centers reduce the amount of excess material that a manufacturer would otherwise need to handle and potentially scrap. Outsourcing can also help manufacturers reduce or eliminate the requirement for infrastructure for material storage and handling.33 Service centers often provide warehousing services, allowing manufacturers to order metal as needed without having to invest in extensive storage facilities. This conversion of fixed costs associated with equipment, labor, and infrastructure into variable costs per unit processed makes outsourcing a financially attractive option for many businesses.

4.2 Increased Efficiency and Productivity

Utilizing the services of specialized coil slitting centers can lead to notable gains in efficiency and productivity for manufacturers.9 These centers are inherently more efficient in performing slitting and related operations due to their specialized equipment and focused expertise.9 They are equipped with high-speed slitting lines and trained personnel who can process large volumes of metal quickly and accurately, resulting in faster turnaround times compared to in-house processing. By outsourcing these non-core but essential tasks, manufacturers can streamline their own production processes and concentrate their resources and efforts on their primary manufacturing activities.34 Receiving pre-processed metal in the exact dimensions required means that manufacturers can skip the initial processing stages and move directly to the next steps in their production line, saving valuable time and resources. Furthermore, many service centers offer just-in-time (JIT) delivery of processed materials, which can significantly improve a manufacturer’s production scheduling and reduce the need to maintain large in-house inventories of raw or semi-processed metal.1 This efficient supply of precisely processed material contributes to a smoother and more productive overall manufacturing operation.

4.3 Access to Specialized Equipment and Expertise

Slitting coil service centers possess specialized, often high-cost, equipment that may not be economically justifiable for every manufacturer to purchase and maintain in-house.7 This includes advanced slitting lines capable of handling a wide range of materials and achieving tight tolerances, as well as sophisticated packing and material handling equipment. Beyond the equipment, these service centers employ skilled technicians and operators who have developed specialized expertise in coil slitting, packing, and warehouse management.7 Their experience ensures that the processing is done correctly and efficiently, minimizing the risk of errors, material damage, or quality issues.23 Moreover, reputable service centers often stay abreast of the latest industry standards, best practices, and technological advancements in metal processing.7 By outsourcing, manufacturers can tap into this level of expertise and access cutting-edge technologies without having to make significant investments in either. This can lead to higher quality processed materials and more efficient production, ultimately benefiting the manufacturer’s bottom line.

4.4 Faster Turnaround Times and Improved Supply Chain Management

Engaging with slitting coil service centers can often result in faster turnaround times for processed metal compared to performing these operations internally, especially for large volumes or intricate slitting patterns.9 Service centers are structured and equipped to handle these specific tasks efficiently, allowing manufacturers to receive their processed materials more quickly. Furthermore, working with a service center can simplify the supply chain by reducing the number of vendors a manufacturer needs to manage.8 Instead of sourcing raw coils from a mill and then managing the slitting, packing, and potentially warehousing in-house or through multiple vendors, a manufacturer can consolidate these needs with a single service center. This streamlined approach can reduce logistical complexities and administrative overhead. Reliable service centers play a crucial role in ensuring a consistent and timely supply of precisely processed materials, which is essential for maintaining smooth production schedules and improving the overall reliability of the manufacturer’s supply chain.1 This improved supply chain management can lead to better responsiveness to customer demands and a more agile overall operation.

5. Key Factors for Businesses When Selecting a Service Center

5.1 Service Capabilities and Specialization

When selecting a service center for slitting coil production, packing, and warehouse stacking, businesses must first carefully evaluate the range of services offered and the center’s areas of specialization.35 It is crucial to determine if the service center provides all the specific services required, such as the desired slitting capabilities (including thickness and width ranges, and achievable tolerances), packing methods, and warehousing options.35 Businesses should also consider the center’s specialization in terms of material types; for instance, if a manufacturer primarily works with aluminum, they should look for a service center with expertise in aluminum slitting.36 Evaluating the service center’s capacity to handle the required volume of material and the specific sizes of coils is also essential.9 Choosing a service center whose capabilities and specializations align closely with the manufacturer’s specific needs ensures that the job will be done effectively and efficiently, minimizing the risk of quality issues or delays.

5.2 Quality Standards and Certifications

Quality control measures implemented by a service center are a paramount consideration when making a selection.7 Businesses should inquire about the specific procedures the center has in place to ensure the accuracy and consistency of their slitting, packing, and handling processes. Checking for relevant industry certifications, such as ISO 9001, which signifies a commitment to a robust quality management system, can provide assurance of the service center’s dedication to maintaining high standards.37 Furthermore, it is important to verify if the service center adheres to any other industry-specific standards or customer-specific quality requirements that may be pertinent to the manufacturer’s products or industry.7 Selecting a service center with strong quality standards and relevant certifications minimizes the risk of receiving substandard processed materials, which could lead to costly rework or product failures.

5.3 Experience and Reputation in the Industry

The experience and reputation of a slitting coil service center within the metal processing industry are valuable indicators of its reliability and the quality of its services.3 Businesses should consider the number of years the service center has been in operation and its track record of serving customers in similar industries.38 Seeking references or testimonials from other clients can provide valuable insights into the service center’s performance, reliability, and customer service.39 A service center with a strong reputation for on-time delivery, consistent quality, and responsive customer support is generally a safer choice, reducing the likelihood of encountering issues or delays in the processing of their metal coils.

5.4 Pricing Structure and Cost-Effectiveness

While quality and reliability are critical, the pricing structure and overall cost-effectiveness of a slitting coil service center are also important factors in the selection process.35 Businesses should obtain detailed quotes from multiple potential service centers to compare their pricing models and ensure they align with their budget.35 However, the decision should not be based solely on the lowest price. Manufacturers should evaluate the overall value proposition, considering factors such as the quality of the slitting and packing, the lead times offered, the potential for reducing material waste, and the reliability of the service.9 Inquiring about potential discounts for volume orders or long-term agreements may also be beneficial.40 The goal is to find a service center that offers a balance of competitive pricing and high-quality, reliable services that ultimately contribute to the manufacturer’s profitability and efficiency.

5.5 Proximity and Logistics, Especially for Los Angeles County

The geographical location of a slitting coil service center and its logistics capabilities are particularly important considerations, especially for businesses located in or around Los Angeles County.35 Proximity to the manufacturing facility can significantly impact shipping and delivery costs and lead times.7 For businesses in Los Angeles County, seeking service centers located within the area or those with well-established logistics networks in Southern California can lead to more timely and cost-effective delivery of processed coils.41 Evaluating the service center’s transportation options, including their ability to handle specific delivery requirements, is also crucial. Choosing a local or regionally accessible service center can streamline the supply chain and potentially improve responsiveness to urgent needs.

6. Operational Workflows and Quality Control Measures

6.1 Typical Operational Processes from Coil Intake to Dispatch

The operational workflow within a slitting coil service center typically begins with coil intake, where master coils of metal are received from the mill and subjected to an initial inspection to verify their condition and specifications.42 The next stage is slitting, the core process, which involves unwinding the master coil and feeding it through the slitting line. Here, rotary blades cut the coil into the specified narrower widths, and the resulting strips are then rewound onto separate spools or as multiple coils on the recoiler.23 Following slitting, the processed coils move to the packing area, where they are prepared for storage and shipment. This involves wrapping the coils with protective materials, applying straps to secure them, and often adding edge protection to prevent damage during handling.14 Once packed, the coils are moved to the warehouse stacking area, where they are stored safely and efficiently using appropriate material handling equipment and following established best practices to maximize space and prevent damage.17 Throughout these stages, inventory management systems are employed to track the location, quantity, and status of each coil within the facility.28 Finally, when an order is ready for shipment, the packed coils are retrieved from the warehouse, prepared for dispatch, and loaded onto trucks or other transport vehicles for delivery to the customer.7 Understanding this typical operational flow provides manufacturers with insight into the process and helps them anticipate lead times and potential points of contact within the service center.

6.2 Implemented Quality Control Procedures at Each Stage

Quality control is an integral part of the operations at every stage of a slitting coil service center. It often begins at coil intake, where incoming master coils are inspected for any visible damage, such as dents or excessive rust, and to ensure they match the ordered specifications.42 During the slitting process, various quality checks are performed. For instance, after the initial cuts, test strips might be taken and carefully examined to verify that the slit widths, material thickness, and edge quality are within the specified tolerances.43 Regular calibration and preventative maintenance of the slitting equipment are crucial for maintaining the precision and accuracy of the cuts.36 In the packing phase, quality control focuses on ensuring that the coils are properly wrapped, strapped, and protected according to the customer’s requirements and industry best practices.5 This includes checking the tightness of the straps and the correct application of any protective materials. Inventory management accuracy is maintained through regular cycle counts and audits, often facilitated by the WMS, to ensure that the physical inventory matches the system records.44 Finally, before dispatch, a final inspection is typically conducted to confirm that the correct coils are being shipped and that they are in good condition.7 These multi-stage quality control procedures are essential for ensuring that the final product meets the customer’s expectations and adheres to relevant industry standards, ultimately minimizing defects and the need for rework.

6.3 Importance of Certifications and Standards

The adherence to recognized certifications and industry standards plays a vital role in assuring the quality and reliability of services provided by slitting coil service centers.37 Certifications such as ISO 9001 demonstrate that a service center has implemented and maintains a comprehensive quality management system, ensuring that processes are consistently followed and continuously improved.37 Compliance with industry-specific standards, such as those set by ASTM International or EN standards, guarantees that the processed metal meets the required specifications for chemical composition, mechanical properties, and corrosion resistance, depending on the material and its intended application.37 Holding these certifications enhances the credibility of the service center, provides a framework for improving operational efficiency, and can even be a prerequisite for supplying to certain industries or clients with stringent quality requirements.45 By choosing a service center that prioritizes certifications and adheres to relevant standards, manufacturers can have greater confidence in the quality and consistency of the processed metal they receive.

7. Industry Landscape of Slitting Coil Service Centers

7.1 Overview of the Market Size and Growth Trends in the US

The steel service center market in the United States constitutes a significant segment of the overall steel supply chain, playing a crucial role in distributing and processing steel for a wide range of end-use industries.8 While specific market size figures can vary depending on the source and methodology, the industry generates billions of dollars in revenue annually, reflecting its importance to the US economy.46 The market has generally experienced growth in recent years, although factors such as economic cycles and fluctuations in raw material prices can influence its performance.47 Current trends within the industry indicate an increasing emphasis on automation and the adoption of advanced technologies in service center operations to enhance efficiency, precision, and overall productivity.36 There is also a growing demand for customized processing solutions to meet the increasingly specific needs of manufacturers. Furthermore, sustainability and waste reduction are becoming increasingly important considerations, driving the adoption of more efficient processing techniques and material utilization strategies.2 The integration of sophisticated warehouse management systems to optimize inventory control and material flow is another significant trend shaping the industry.28 These trends collectively suggest a dynamic and evolving industry that is adapting to the changing demands of the manufacturing sector and focusing on technological advancements to improve its value proposition.

7.2 Major Players in the Metal Service Center Industry

The metal service center industry in North America includes a mix of large, national corporations and numerous smaller, independent regional players.48 Among the major players are companies such as Reliance Steel & Aluminum Co., Ryerson Holding Corporation, Kloeckner Metals Corporation, Worthington Industries, and Russel Metals Inc.48 These large entities often operate a network of service centers across multiple locations and offer a comprehensive range of metal processing services, including coil slitting, along with extensive distribution networks.48 In addition to these industry giants, there are a significant number of smaller, often family-owned or privately held, service centers that cater to more localized markets or specialize in particular types of metals or processing services.49 This diverse landscape provides manufacturers with a range of options when selecting a service center, allowing them to choose a partner based on factors such as scale, geographic reach, specialization, and specific service offerings. The presence of both large and small players fosters competition and innovation within the industry.

7.3 Emerging Trends and Technological Advancements

The slitting coil service center industry is characterized by continuous innovation and the adoption of emerging trends and technological advancements aimed at improving efficiency, quality, and sustainability.36 One significant trend is the increased adoption of automation throughout the processing line, from coil handling and slitting to packing and warehousing.36 This includes the integration of Computer Numerical Control (CNC) systems in slitting lines for enhanced precision and the use of robotic systems for material handling and packaging. The incorporation of Artificial Intelligence (AI) and the Internet of Things (IoT) technologies is also emerging, enabling real-time monitoring and optimization of the slitting process, leading to improved accuracy and efficiency.36 Advancements in blade technology are resulting in the development of high-performance knives made from advanced materials like high-speed steel and carbide, offering superior durability and cutting accuracy.36 There is a growing demand for more customized packaging solutions and value-added services, such as the application of edge protection, oiling, and serialized labeling of slit coils.50 Sustainability is another key driver, with service centers increasingly focused on optimizing material utilization to reduce waste and minimize their environmental footprint.2 This includes investing in equipment that can achieve higher material yield rates. Finally, the adoption of sophisticated warehouse management systems (WMS) continues to grow, enabling better inventory control, real-time tracking of coils, and optimized material flow within the service center.28 These technological advancements and emerging trends are shaping the future of the slitting coil service center industry, leading to greater efficiency, higher quality, and more sustainable operations.

8. Service Centers in or Around Los Angeles County, California

8.1 Identification of Key Service Providers in the Region

Businesses in Los Angeles County seeking service centers for slitting coil production, packing, and warehouse stacking have several options in the local and surrounding areas.41 Pacific Toll Processing, located in Carson, California, is a prominent service center specializing in steel sheet and coil distribution and toll processing, equipped with advanced slitting and multi-blanking lines.51 Hansen Steel, based in Los Angeles, offers a range of coil processing services, including leveling, precision shearing, custom cuts, rolling, and forming for various metals such as stainless steel, carbon steel, and aluminum.52 Maksteel also has a facility in Los Angeles that provides steel slitting services.41 Additional service providers in the broader Southern California region include Reliance Metalcenter, which has a location in National City, near San Diego, offering a wide variety of metal products and processing services.53 Cal Steel, located in San Bernardino, provides steel services including leveling, forming, laser cutting, plasma cutting, slitting, and equalizing.54 Wieland Metal Services operates a facility in Ontario, CA, offering coil slitting for various metals and finishes.55 Paragon Steel, situated in Commerce, CA, provides metal processing services including slitting for both hot and cold rolled steel coils.55 Resources like ThomasNet and SteelServiceCenters.com also list other potential providers in the Southern California region.56 This selection of service centers indicates that businesses in Los Angeles County have access to a variety of options for their coil processing needs.

8.2 Specific Services and Capabilities Offered

The service centers located in and around Los Angeles County offer a diverse range of specific services and capabilities to meet the varying needs of their customers.41 Pacific Toll Processing in Carson stands out with its "State of the Art" automotive class-1 precision processing lines for both slitting and multi-blanking, indicating a focus on high-precision work for demanding applications.51 Hansen Steel in Los Angeles provides a comprehensive suite of coil processing services beyond just slitting, including leveling to ensure flatness, precision shearing for accurate cuts, custom cutting to specific dimensions, as well as rolling and forming capabilities.52 They handle a variety of common metals including stainless steel, carbon steel, and aluminum, and also process customer-provided coils.52 Maksteel focuses on steel slitting services at its Los Angeles location, catering to customers needing narrower strips for various applications.41 Reliance Metalcenter in National City offers next-day delivery on many stock and processed items and boasts a large inventory along with in-house processing expertise.53 Cal Steel in San Bernardino provides a wide array of metal services, including specialized slitting services with a focus on smooth and clean edges, as well as leveling and equalizing to enhance material quality.54 Wieland Metal Services in Ontario offers coil slitting with a broad range of width and gauge capabilities for materials like aluminum and steel, along with other finishing services like anodizing and painting.55 Paragon Steel in Commerce specializes in processing steel coils, including hot and cold rolled steel, and offers a full spectrum of fabrication services beyond slitting.55 This overview demonstrates that businesses in the Los Angeles County area have access to service centers with a wide array of specializations and processing capabilities, allowing them to find a suitable partner for their specific requirements.

9. Conclusion and Recommendations

Slitting coil service centers play an indispensable role in the modern metal supply chain, offering specialized processing, packing, and warehousing services that are crucial for manufacturers across various industries. These centers provide numerous benefits, including cost savings, increased efficiency, access to specialized equipment and expertise, and faster turnaround times, making them valuable partners for businesses that utilize slit metal coils in their production processes.

When selecting a service center, businesses should carefully consider factors such as the center’s service capabilities, quality standards and certifications, experience and reputation, pricing structure, and proximity, especially for those located in specific regions like Los Angeles County. A thorough evaluation of these factors will help ensure that manufacturers choose a service provider that can reliably meet their specific needs and contribute to their operational success.

The industry landscape of slitting coil service centers is dynamic, characterized by ongoing technological advancements, a focus on sustainability, and a mix of large national players and smaller regional specialists. Businesses should stay informed about these trends to leverage the latest innovations and optimize their sourcing strategies.

For companies in Los Angeles County, a number of service providers offer a range of capabilities in coil slitting and related services. It is recommended that businesses in this region conduct a detailed assessment of the local providers, such as Pacific Toll Processing, Hansen Steel, Maksteel, Reliance Metalcenter, Cal Steel, Wieland Metal Services, and Paragon Steel, to identify the best fit for their specific material processing requirements and logistical considerations.

Table: Key Service Providers in Los Angeles County and Surrounding Areas

| Company Name | Location (City) | Specializations | Contact Information |

|---|---|---|---|

| Pacific Toll Processing | Carson | Steel sheet and coil distribution, toll processing, slitting, multi-blanking | (310) 952-4992, https://pacifictoll.com/ |

| Hansen Steel | Los Angeles | Leveling, shearing, custom cuts, rolling, forming, stainless steel, carbon steel, aluminum | (323) 583-7100, https://www.hansensteel.com/ |

| Maksteel | Los Angeles | Steel slitting | (323) 569-1480, https://www.maksteel.com/steel-slitting/ |

| Reliance Metalcenter | National City | Wide variety of metal products, processing services, next-day delivery | (619) 263-2141, https://www.reliancemetalcentersd.com/ |

| Cal Steel | San Bernardino | Leveling, forming, laser cutting, plasma cutting, slitting, equalizing | (909) 877-6300, https://calsteel.com/ |

| Wieland Metal Services | Ontario | Coil slitting for aluminum & steel, anodizing, painting | (909) 986-9901, https://www.wielandmetalservices.com/ (Note: Website might redirect to parent company, verify specific location details) |

| Paragon Steel | Commerce | Steel processing, hot & cold rolled coils, fabricating, cutting, slitting | (323) 728-9161, https://www.paragonsteel.com/ |

This table provides a starting point for businesses in Los Angeles County to explore potential partners for their slitting coil processing needs. Further research and direct communication with these providers are recommended to determine the best fit based on specific requirements.

Works cited

-

What Is a Steel Service Center – Worthington Steel, accessed April 4, 2025, https://www.worthingtonsteel.com/flatrolledsteel/steel-expertise/dictionary-terms/steel-service-center ↩ ↩ ↩ ↩ ↩ ↩

-

www.meadmetals.com, accessed April 4, 2025, https://www.meadmetals.com/blog/what-value-add-services-does-a-metal-supplier-provide#:~:text=Slitting,-Slitting%20involves%20modifying&text=Metal%20service%20centers%20use%20custom,Reduce%20waste%2Fscrap ↩ ↩ ↩ ↩

-

Steel Coil Slitting Services & Steel Processing Capabilities – Scott Steel LLC, accessed April 4, 2025, https://www.scottsteelllc.com/capabilities/ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Coil Slitting Services – Harvard Steel, accessed April 4, 2025, https://www.harvardsteelsales.com/service/steel-coil-slitting ↩ ↩ ↩

-

Revolutionizing the Industrial Packaging Process with Steel & Metal Service Centers, accessed April 4, 2025, https://mvsips.com/revolutionizing-the-industrial-packaging-process-with-steel-metal-service-centers/ ↩ ↩ ↩ ↩ ↩

-

Top 4 Qualities of a Metal Service Center – Kloeckner Metals, accessed April 4, 2025, https://www.kloecknermetals.com/blog/4-things-look-metal-service-center/ ↩

-

What Value-Add Services Does a Metal Service Center Provide?, accessed April 4, 2025, https://www.meadmetals.com/blog/what-value-add-services-does-a-metal-supplier-provide ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Steel Service Centers: Products and Advantages – IQS Directory, accessed April 4, 2025, https://www.iqsdirectory.com/articles/steel-service-center.html ↩ ↩ ↩ ↩

-

Coil Slitting Advantages & Benefits – Alliance Steel, accessed April 4, 2025, https://www.alliancesteel.net/blog/2023/06/28/coil-slitting-advantages-and-benefits/ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Finding The Right Metals Service Center, accessed April 4, 2025, https://www.boydmetals.com/finding-the-right-metals-service-center/ ↩ ↩

-

Coil Slitting Services Capabilities – Alliance Steel, accessed April 4, 2025, https://www.alliancesteel.net/coil-slitting/ ↩

-

Coil conversion and slitting tolerances explained – EOXS, accessed April 4, 2025, https://eoxs.com/new_blog/coil-conversion-and-slitting-tolerances-explained/ ↩

-

TRANSPORT OF COILED MATERIALS IN CONTAINERS – Hapag-Lloyd, accessed April 4, 2025, https://www.hapag-lloyd.com/content/dam/website/downloads/local_info/%E9%92%A2%E5%8D%B7%E6%8D%86%E6%89%8E.pdf ↩ ↩ ↩

-

Coil packaging lines – Amova, accessed April 4, 2025, https://www.amova.eu/en/steel-industry/products/detail/coil-packaging-lines ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

What should you know for the precise steel coil packing and stacking? – FhopePack, accessed April 4, 2025, https://www.fhopepack.com/zh/what-should-you-know-for-the-precise-steel-coil-packing-and-stacking/ ↩ ↩ ↩ ↩

-

Coil Packing Lines – Signode, accessed April 4, 2025, https://www.signode.com/en-us/industries/metals/coil-packing-lines/ ↩ ↩

-

Safe Storage and Stacking in the Warehouse – LiftOne, accessed April 4, 2025, https://www.liftone.net/blog/safe-storage-and-stacking-in-the-warehouse/ ↩ ↩

-

Material Stacking Safety Tips to Prevent Hazards for Workers – Weeklysafety, accessed April 4, 2025, https://weeklysafety.com/blog/material-stacking ↩ ↩ ↩

-

Best Practices for Handling & Managing Steel Coils in CFS Construction – FrameCAD, accessed April 4, 2025, https://framecad.com/blog/best-practices-for-handling-and-managing-steel-coils-in-cfs-construction ↩

-

The Importance of Proper Sheet Metal Storage in the Warehouse, accessed April 4, 2025, https://calderamfg.com/resources/blog/the-importance-of-proper-sheet-metal-storage-in-the-warehouse/ ↩ ↩

-

STORAGE GUIDELINES FOR PRECOATED METAL – Lampre Srl, accessed April 4, 2025, https://www.lampre.com/wp-content/uploads/2024/12/Storage-Guidelines-A4-1.pdf ↩ ↩

-

How to Store Stainless Steel Coils to Prevent Damage, accessed April 4, 2025, https://mfysteel.com/proper-storage-stainless-steel-coils/ ↩ ↩

-

Metal Slitting | Coils & Sheet Steel | Service Steel, accessed April 4, 2025, https://www.servicesteel.org/services/metal-slitting ↩ ↩ ↩ ↩ ↩ ↩

-

Steel Processor Partnership Spotlight: Aluminum Slitting Services, accessed April 4, 2025, https://www.nationalmaterial.com/steel-processor-partnership-spotlight-aluminum-slitting-services/ ↩ ↩

-

What is Coil Slitting Line Machine, accessed April 4, 2025, https://www.technicmachines.com/what-is-coil-slitting-machine-line/ ↩ ↩

-

What Is Steel Coil Slitting Line, accessed April 4, 2025, https://lotosslitting.com/what-is-steel-coil-slitting-line/ ↩

-

Unrolling the Basics of Steel Slitting and Its Benefits – Mead Metals, accessed April 4, 2025, https://www.meadmetals.com/blog/unrolling-the-basics-of-steel-slitting-and-its-benefits ↩ ↩ ↩

-

Warehouse Management System for coil storage | Konecranes USA, accessed April 4, 2025, https://www.konecranes.com/en-us/industries/metals-production/the-strength-of-experience/warehouse-management-system-for-coil-storage ↩ ↩ ↩ ↩ ↩ ↩

-

Steel Crane Guide :Overview of Overhead Cranes in Steel Mills, accessed April 4, 2025, https://www.bettercrane.com/resouces/news/overhead-steel-crane-systems.html ↩

-

Forklift for Steel Coil – High Efficiency & Reliable Lifting – Alibaba.com, accessed April 4, 2025, https://www.alibaba.com/showroom/forklift-for-steel-coil.html ↩

-

Coil Storage Solutions – Warehouse Rack and Shelf, accessed April 4, 2025, https://rackandshelf.com/c/storage-products/warehouse-racks/coil-racks/ ↩ ↩

-

Coil Handling, Storage & Management – Carney Fabricating, accessed April 4, 2025, https://www.carneyfabricating.com/automated-coil-storage-and-retrieval-systems-asrs/ ↩

-

Structural Steel Service Centers, accessed April 4, 2025, https://www.aisc.org/globalassets/why-steel/service-center-brochure.pdf ↩

-

Steel Mills vs. Steel Service Centers – ECONSTEEL, accessed April 4, 2025, https://www.econsteel.com/blog/steel-mills-vs-steel-service-centers ↩

-

What To Look For In A Metal Service Center – Service Steel Warehouse, accessed April 4, 2025, https://www.servicesteel.org/resources/metal-service-centers ↩ ↩ ↩ ↩ ↩

-

Custom Metal Solutions: Optimizing Aluminum And Steel Coil Widths Through Slitting, accessed April 4, 2025, https://americandouglasmetals.com/2025/02/13/cost-efficiency-in-aluminum-extruding-streamlining-manufacturing-processes/ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Importance of Certification in Industrial Stainless Steel Products – Morning Ag Clips, accessed April 4, 2025, https://www.morningagclips.com/importance-of-certification-in-industrial-stainless-steel-products/ ↩ ↩ ↩ ↩

-

Columbus, Ohio Aluminum Coil Slitting Company – NKS, accessed April 4, 2025, https://nks.com/aluminum-coil-slitting-company-columbus-ohio/ ↩

-

Top 4 Qualities of a Metal Service Center – MFG Shop, accessed April 4, 2025, https://shop.machinemfg.com/top-4-qualities-of-a-metal-service-center/ ↩

-

How Metal Service Centers Add Value to Their Customers – KGS Steel Inc., accessed April 4, 2025, https://kgssteel.com/metal-service-centers-add-value-to-customers/ ↩

-

Steel Slitting, accessed April 4, 2025, https://www.maksteel.com/steel-slitting/ ↩ ↩ ↩ ↩ ↩

-

Guidelines for Proper Handling and Storage of Coiled Aluminum Strip, accessed April 4, 2025, https://unitedaluminum.com/guidelines-for-proper-handling-and-storage-of-coiled-aluminum-strip/ ↩ ↩

-

The Complete Guide to Aluminum Coil Slitting: Processes, Benefits, and Applications, accessed April 4, 2025, https://shop.machinemfg.com/the-complete-guide-to-aluminum-coil-slitting-processes-benefits-and-applications/ ↩

-

Coil Warehousing & Inventory Management – BDM Coil Coaters, accessed April 4, 2025, https://bdm-coilcoaters.com/inventory/ ↩

-

Why Certifications Matter in the Metals Industry – EOXS, accessed April 4, 2025, https://eoxs.com/new_blog/why-certifications-matter-in-the-metals-industry/ ↩

-

Steel Service Centers Market Size to Reach USD 1,001.6 Mn by, accessed April 4, 2025, https://dimensionmarketresearch.com/report/steel-service-centers-market/ ↩

-

State of the Steel Industry and Steel Service Centers Across the USA – Fabtech 2025, accessed April 4, 2025, https://www.fabtechexpo.com/news/state-of-the-steel-industry-and-steel-service-centers-across-the-usa ↩

-

2024 MCN Top 50 Service Centers – Metal Center News – Solutions for Profitable Distribution, accessed April 4, 2025, https://www.metalcenternews.com/editorial/current-issue/2024-mcn-top-50-service-centers/45544 ↩ ↩ ↩

-

Metal Service Centers – Vertical IQ, accessed April 4, 2025, https://verticaliq.com/product/metal-service-centers/ ↩

-

Steel Coil Slitting Service Market – PW Consulting Chemical & Energy Research Center, accessed April 4, 2025, https://pmarketresearch.com/chemi/seaweed-extracts-biostimulant-market/steel-coil-slitting-service-market ↩

-

PTP-Home – Pacific Toll Processing | (310) 952-4992, accessed April 4, 2025, https://pacifictoll.com/ ↩ ↩

-

Metal Coil Processing – Los Angeles, California | Hansen Steel | ECW Base Cart, accessed April 4, 2025, https://www.hansensteel.com/coil-processing.html ↩ ↩ ↩

-

Reliance Metalcenter – Metals Service Center, Steel Distributor, Steel Plate, Carbon Steel, accessed April 4, 2025, https://www.reliancemetalcentersd.com/ ↩ ↩

-

Metal Services – California Steel Services, accessed April 4, 2025, https://calsteel.com/steel-service-center ↩ ↩

-

Steel Coils Suppliers located in California – Southern – Thomasnet, accessed April 4, 2025, https://www.thomasnet.com/suppliers/southern-california/all-cities/steel-coils-16300600 ↩ ↩ ↩ ↩

-

Slitting & Rewinding Services Suppliers located in California – Southern – Thomasnet, accessed April 4, 2025, https://www.thomasnet.com/suppliers/southern-california/all-cities/slitting-rewinding-services-75944009 ↩