Price Analytics of Automatic Tyre Packing Systems: A Comprehensive Report

-

Executive Summary

The automation of tyre packing processes represents a critical strategic investment for manufacturers and distributors aiming to enhance operational efficiency, reduce costs, and improve workplace safety. This report provides a comprehensive analysis of automatic tyre packing systems, with a particular focus on price analytics, control system architectures, and the offerings of prominent suppliers such as SHJLPACK and FHOPEPACK.

Key findings indicate that while the initial investment in automated tyre packing systems can be substantial, the potential for a significant Return on Investment (ROI) is considerable. This ROI is primarily driven by direct labor cost reductions, increased throughput, minimized material wastage, and enhanced safety leading to fewer compensation claims.1 System costs exhibit wide variability, influenced by factors such as the level of automation, throughput capacity, range of tyre sizes handled, and the degree of customization required.2

A crucial aspect of the investment decision is the adoption of a Total Cost of Ownership (TCO) approach, which considers all lifecycle costs beyond the initial purchase price, including installation, training, operation, maintenance, and eventual disposal.3 This holistic view is essential for accurate financial assessment and comparison between different systems and suppliers.

The sophistication of control systems, typically categorized by ISA-95 Levels 1, 2, and 3, plays a pivotal role in the system’s intelligence, data acquisition capabilities, and integration potential with broader Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms.4 Higher-level control systems, while adding to the initial cost, unlock strategic value through data-driven operational intelligence, enabling advanced analytics, Overall Equipment Effectiveness (OEE) monitoring, and predictive maintenance (PdM).

Suppliers like SHJLPACK and FHOPEPACK offer a range of solutions, from standalone wrapping units to fully integrated packing lines. The selection process should involve a detailed needs assessment and a thorough evaluation of supplier offerings against specific operational requirements and long-term strategic goals. Ultimately, a well-chosen automated tyre packing system can deliver substantial competitive advantages and operational excellence.

-

The Landscape of Automatic Tyre Packing Systems

The tyre industry, characterized by high-volume production and the handling of bulky, relatively heavy products, has increasingly turned to automation to address modern manufacturing and logistical challenges. This section explores the evolution of this automation, the core components and technologies involved, and the operational benefits derived.

2.1. Evolution and Importance of Automation in Tyre Packaging

The transition from manual to automated tyre packing processes has been driven by a confluence of factors, including the relentless pursuit of increased efficiency, the need for consistent packaging quality, the imperative to enhance worker safety, and the challenge of labor availability and cost.5 Modern industrial operations, particularly in high-throughput sectors, rely on automation to achieve the speed, precision, and error-free efficiency that manual methods often cannot consistently deliver.6 Automation in packaging is not merely a cost-saving measure; it is a strategic enabler that ensures product integrity, enhances brand presentation through consistent packaging, and allows businesses to scale their operations effectively while safeguarding their workforce.6 In industries handling cumbersome items like coils or tyres, automation directly addresses issues like labor shortages and escalating wage costs, which were historically significant operational burdens.5

The progression of automation in tyre packaging extends beyond the simple replacement of manual labor. Initially, the focus was on automating repetitive and physically demanding tasks. However, as these systems have become more sophisticated, incorporating Programmable Logic Controllers (PLCs), advanced sensors, and networked communication capabilities4, they have evolved into rich sources of operational data. This data generation capability is a crucial development. When captured and analyzed, often through higher-level control systems, this data facilitates process optimization, enables predictive maintenance strategies, and supports more informed operational decision-making. This evolution marks a foundational step towards the realization of Smart Factory and Industry 4.0 principles, where interconnected systems and data analytics drive continuous improvement and operational intelligence.

2.2. Core Components, Workflow, and Key Technologies

A typical automatic tyre packing line is an integrated system comprising several key components, each performing a specific function in a synchronized workflow. Understanding these elements is crucial for appreciating the system’s capabilities and cost structure.

- Infeed Conveyor System: This is the entry point for tyres into the automated system. It is designed for durable and smooth transport, often utilizing belt, roller, or chain conveyors. Integrated sensors play a vital role in detecting tyre presence and ensuring accurate positioning for subsequent wrapping operations.4

- Orbital Wrapping Unit: This is the heart of the packaging process. It employs a rotating ring that carries a dispenser of stretch film (or other wrapping materials like VCI paper in analogous coil wrapping applications5). Key technological features include:

- Powered Pre-Stretch: This mechanism stretches the film before application, significantly reducing film consumption (often by up to 300%) while improving load containment and stability.4

- Adjustable Film Tension Control: Allows for precise control of the wrapping force, ensuring optimal tightness for different tyre sizes and types without causing distortion.

- Variable Overlap Control: Enables operators to program the degree of film overlap, enhancing protection and package integrity.

- Automatic Film Cut & Clamp: Streamlines the cycle by automatically managing the film at the start and end of each wrap, preparing the system for the next tyre.

- Automated Tapping Unit: After wrapping, this unit secures the tail end of the stretch film using adhesive tape. This prevents the film from unraveling during subsequent handling and storage, ensuring package integrity.4 These units typically feature automatic tape feeding and cutting mechanisms, adaptable to different tyre sizes.7

- Stacking Unit: Once wrapped and secured, tyres are transferred to a stacking unit. This component uses mechanisms such as pneumatic pushers, robotic arms, or lifting platforms to create neat, stable stacks of tyres.4 Programmable stack height allows flexibility for various storage or transport requirements, and stack centering logic ensures well-formed and safe stacks.

- Control System (PLC with HMI): The entire automated line is managed by a Programmable Logic Controller (PLC) coupled with a Human-Machine Interface (HMI), typically a touchscreen display. This system allows operators to select pre-programmed recipes for different tyre sizes/types, monitor the system’s status and diagnostics in real-time, and adjust operational parameters such as wrapping speed, film tension, and stack height.4

- Optional Add-ons: Depending on specific requirements, lines can be equipped with integrated labeling systems for product identification and traceability7, automatic weighing scales, or vision systems for quality inspection.4 While orbital stretch wrapping is common, shrink wrapping machinery presents an alternative method for unitizing products.8

The typical workflow sees tyres entering the line via the infeed conveyor. They are then automatically detected and positioned at the wrapping station. The orbital wrapper applies stretch film, after which the tapping unit secures the film. Finally, the wrapped tyre is moved to the stacking unit, where it is stacked according to pre-set parameters. The entire process is automated and synchronized by the central control system.4

The modular nature of these components—conveyor, wrapper, tapper, stacker—offers a degree of scalability in automation. While fully integrated lines represent a significant investment, a company could potentially phase in automation. For instance, an operation might begin with a standalone orbital wrapper operating semi-automatically9 and later integrate infeed/outfeed conveyors and an automated stacking unit. This phased approach can make the initial capital outlay more manageable and allow the organization to adapt to automation incrementally, impacting both the initial investment strategy and the timeline for realizing ROI. Consequently, an "automatic tyre packing system" should be understood not as a monolithic entity but as a spectrum of solutions with varying degrees of integration and automation.

2.3. Operational Benefits: Efficiency, Safety, and Quality

The implementation of automatic tyre packing systems yields a range of substantial operational benefits, contributing directly to improved productivity, reduced costs, and enhanced workplace conditions.

- Increased Throughput and Efficiency: Automated systems operate at significantly faster cycle times compared to manual methods. Packing speeds can range from 30-35 seconds per piece to over 90 tyres per hour, depending on the system’s design and the tyre’s characteristics.4 Studies on general packaging automation indicate that such systems can increase overall throughput by as much as 30% when compared to manual processes.10

- Labor Cost Reduction: One of the most immediate and quantifiable benefits is the reduction in direct labor costs. Automated lines require fewer operators to manage the packing process.1 According to reports from PMMI (The Association for Packaging and Processing Technologies), companies implementing packaging automation see an average reduction in labor costs of 20-30% within the first year of operation.10

- Improved Package Quality and Consistency: Automation ensures that each tyre is packaged uniformly, with consistent film application, tension, and securement. This leads to better protection of the tyres during handling and transit, and more stable stacks for storage and shipment.1 Automated systems can also reduce packaging error rates by up to 50% compared to manual handling.10

- Enhanced Worker Safety: Manual handling of tyres is physically demanding and carries ergonomic risks. Automation eliminates these tasks, creating a safer work environment and significantly reducing the likelihood of worker fatigue, strain injuries, and accidents.5 Companies with highly automated packaging lines have reported experiencing 15% fewer workplace injuries.10

- Reduced Film and Material Consumption: Technologies like powered pre-stretch in orbital wrappers can dramatically reduce the amount of stretch film consumed per tyre, often by up to 300%.4 Optimized material usage is a key design benefit of modern automated packaging machinery.11

- Optimized Floor Space Utilization: Integrated automated packing lines can often have a more compact footprint compared to the multiple manual workstations they replace. This frees up valuable floor space within the facility, which can be repurposed for other value-adding activities.1

Beyond the direct cost savings associated with fewer compensation claims10, the enhancement in worker safety yields important indirect benefits. A safer working environment can contribute positively to employee morale and reduce absenteeism. Furthermore, in competitive labor markets, offering less physically demanding and safer jobs can be a significant factor in attracting and retaining skilled personnel.5 These "softer" benefits, while sometimes harder to quantify in a simple ROI calculation, contribute to long-term operational stability, productivity, and overall cost control.

-

Dissecting Control System Architectures in Tyre Packing Automation

The intelligence and operational capabilities of automatic tyre packing systems are largely determined by their control system architectures. The ISA-95 standard for Enterprise-Control System Integration provides a widely accepted framework for understanding these architectures, typically depicted as a pyramid with multiple levels. For tyre packing automation, Levels 1, 2, and 3 are of primary relevance, governing everything from basic device operation to integration with plant-wide management systems.

3.1. Overview of Industrial Automation Levels (ISA-95 Framework)

The ISA-95 model defines a hierarchical structure for integrating control systems with enterprise systems, ranging from Level 0 (the physical process itself) up to Level 4 (business planning and logistics) and Level 5 (enterprise management, though often Level 4 and 5 are combined or viewed as enterprise-level functions beyond direct process control).12 This report focuses on:

- Level 1: Field Device Control and Data Acquisition

- Level 2: Supervisory Control, HMI, and Real-time Monitoring

- Level 3: Manufacturing Operations Management (MOM)

These levels represent increasing sophistication in control, monitoring, and data utilization, directly impacting the system’s capabilities and cost.

3.2. Level 1: Field Device Control and Data Acquisition

Level 1 forms the foundation of the automation pyramid, encompassing the physical devices that directly interact with the manufacturing process. This includes sensors (e.g., proximity sensors for tyre detection, encoders for positioning, safety light curtains), actuators (e.g., electric motors driving conveyors, the wrapping ring, tapping mechanisms, and stacking components), valves, and other field devices.12 Programmable Logic Controllers (PLCs) often execute basic control logic originating at this level or act as a bridge to Level 2 functionalities.

In the context of automatic tyre packing systems, Level 1 components are critical for the machine’s basic operation. Sensors ensure accurate tyre detection, feeding, and positioning.4 Motors provide the motive force for all mechanical movements, with inverters often used for precise speed control of elements like the wrapping ring and conveyors.7 Safety interlocks and emergency stop buttons are crucial Level 1 safety devices. The data generated by these devices—such as cycle counts, fault occurrences, or motor status—constitutes the raw input for higher-level monitoring and control systems.

The quality and comprehensiveness of Level 1 devices directly influence the overall reliability and data richness of the entire automated system. While investing in higher-quality sensors, more robust actuators, and more comprehensive instrumentation at Level 1 might increase the initial system cost, this investment can significantly enhance the effectiveness of Level 2 monitoring and Level 3 MES/OEE functionalities. For example, poor quality or insufficient sensors can lead to misfeeds, incorrect wrapping parameters, or even safety failures, thereby increasing downtime and rework. Conversely, a richer suite of sensors (e.g., monitoring motor current, vibration, or temperature in addition to basic presence/absence) can provide valuable data for predictive maintenance algorithms (a Level 2 or 3 function), reducing unexpected breakdowns and lowering long-term maintenance costs. Thus, the initial outlay for superior Level 1 components is an investment in future operational stability and data-driven optimization, ultimately contributing to a better Total Cost of Ownership (TCO).

3.3. Level 2: Supervisory Control, HMI, and Real-time Monitoring

Level 2 of the ISA-95 model is concerned with supervisory control and real-time process monitoring. This layer typically involves PLCs executing more complex control strategies and Human-Machine Interfaces (HMIs) that allow operators to interact with and oversee the machinery.12 While Distributed Control Systems (DCSs)13 are also Level 2 systems, they are more common in large-scale continuous process industries rather than standalone packaging lines, where PLCs are ubiquitous. The HMI, often a touchscreen panel, provides visualization of the packing process, allows for recipe management (e.g., selecting parameters for different tyre sizes), displays alarm annunciations, and facilitates operator inputs.14 Real-time data from Level 1 devices is processed at Level 2 for immediate operational adjustments and continuous monitoring.

In automatic tyre packing systems, operators rely heavily on the HMI to select appropriate packing recipes for various tyre types, initiate or halt the production line, adjust parameters such as film overlap or wrapping tension, and diagnose and troubleshoot issues based on alarm messages and system status displays.4 The PLC at this level executes the programmed sequence of operations for the entire packing cycle, coordinating the actions of the infeed, wrapping, tapping, and stacking units.

The design and intuitiveness of the HMI significantly impact operator efficiency, training time, and the potential for errors. A well-designed, user-friendly HMI6 can reduce the learning curve for new operators, enable quicker responses to system events or alarms, and minimize the likelihood of incorrect parameter settings, all of which directly affect system uptime and output quality. While the HMI’s ergonomic design and software usability are not always itemized as separate "price" components of the hardware, the development effort invested by the supplier in creating an effective HMI contributes to the system’s overall value and has a considerable bearing on its operational TCO.

3.4. Level 3: Manufacturing Operations Management (MOM) and MES Integration

Level 3 serves as the crucial bridge between the real-time automation on the plant floor (Levels 1 and 2) and the broader business and planning systems at the enterprise level (Level 4/5). This level encompasses Manufacturing Operations Management (MOM) functions, including detailed production scheduling, performance tracking (e.g., Overall Equipment Effectiveness – OEE), quality data management, maintenance workflow coordination, and, critically, data exchange with Manufacturing Execution Systems (MES)15 or Enterprise Resource Planning (ERP) systems.12 The terms MOM and MES are often used interchangeably, with MES being a key enabling technology for MOM.

For automatic tyre packing systems, Level 3 integration means that operational data—such as production counts, downtime incidents with reasons, material consumption rates, and quality parameters—can be automatically fed into MES or ERP systems.4 This provides real-time visibility into the packing operation’s status, facilitates more accurate inventory management, and enables comprehensive performance analysis. Such integration empowers management with the data needed for strategic decision-making, process optimization, and resource allocation. While the tyre packing system itself is not an MES, its ability to seamlessly connect and share data with an MES is a hallmark of Level 3 capability.15

The readiness for Level 3 integration, often facilitated by standard industrial communication protocols like EtherNet/IP or PROFINET4, is a significant differentiator in both the pricing and the future-proofing of an automated system. Systems lacking robust Level 3 connectivity may effectively become "data silos," limiting their contribution to broader operational intelligence and plant-wide optimization initiatives. The cost and complexity of retrofitting such integration capabilities later can be substantially higher than specifying them upfront. If an organization has an existing MES or plans to implement one, selecting a tyre packing system that cannot easily integrate16 could create an information bottleneck, diminishing the potential synergistic benefits of plant-wide data management. Therefore, the price evaluation of a packing system should account for the value and potential cost savings derived from this level of integration.

3.5. Implications for System Intelligence, Data Analytics, and Connectivity

The progression through these control system levels directly correlates with an increase in the "intelligence" and data-driven capabilities of the automated tyre packing system. Level 1 provides the fundamental sensing and actuation. Level 2 enables real-time supervisory control and local monitoring via the HMI. Level 3, however, unlocks the potential for broader data analytics, such as OEE calculation, trend analysis of machine performance, and correlation of packing parameters with quality outcomes, by connecting the machine to MES/ERP and other plant-wide information systems.17 This connectivity is vital for making informed, data-driven decisions, implementing effective predictive maintenance programs, and achieving continuous process optimization.4

The choice of control system level, therefore, is a key consideration in price analytics. A system with primarily Level 1 and basic Level 2 capabilities will have a lower initial cost. However, a system designed with robust Level 2 features and, critically, Level 3 integration capabilities, will command a higher price but offers significantly greater potential for long-term savings, efficiency gains, and strategic value within a connected, data-driven manufacturing environment. This "smartness" is a direct function of the control architecture’s sophistication.

The following table summarizes the key aspects of ISA-95 automation levels as they apply to tyre packing systems:

Table: ISA-95 Automation Levels in Tyre Packing Systems

Level Key Functions Typical Technologies in Tyre Packing Impact on Price & Capability Level 1 Sense & Actuate; Basic Device Control Tyre presence/position sensors, conveyor motors, wrapper drive motors, tapping actuators, safety switches, basic interlocks, variable frequency drives (VFDs). Forms the base cost of the automated components; essential for any automated operation. Quality of components impacts reliability. Level 2 Supervise & Control; Operator Interface Programmable Logic Controller (PLC), Human-Machine Interface (HMI) touchscreen, recipe management software, alarm system, real-time status display, basic fault diagnostics. Standard on most fully automatic systems. Adds to PLC/HMI hardware and programming cost. Crucial for operational usability, efficiency, and basic troubleshooting. Level 3 Manage Operations & Integrate with Enterprise Ethernet/IP or PROFINET communication interfaces, data logging capabilities, connectivity to Manufacturing Execution Systems (MES) / Enterprise Resource Planning (ERP), OEE data point collection, remote monitoring capabilities. Higher initial system cost due to advanced hardware, software, and integration engineering. Enables advanced analytics, plant-wide visibility, predictive maintenance inputs, and strategic operational management. Future-proofs the investment. -

Comprehensive Price Analytics for Automatic Tyre Packing Systems

Determining the price of an automatic tyre packing system involves more than looking at a single figure. A multitude of factors contribute to the final cost, and a thorough financial evaluation requires an understanding of these drivers, indicative price ranges, the Total Cost of Ownership (TCO), and the potential Return on Investment (ROI).

4.1. Key Factors Influencing System Costs

The investment required for an automatic tyre packing system is highly variable, contingent upon a range of technical and operational specifications. Key influencing factors include:

- Throughput/Speed: Systems designed for higher packing rates (measured in tyres per hour or seconds per tyre) necessitate more robust mechanical components, faster PLCs, and potentially more sophisticated material handling systems, all of which contribute to increased cost.4

- Tyre Size Range (OD, Width, Weight): Machinery capable of handling a broader spectrum of tyre outer diameters (OD), widths, and weights requires more robust construction, larger frames, and more powerful actuators to manage the variability and physical loads.7

- Level of Automation: The extent of automation is a primary cost driver. Fully automatic lines that integrate infeed, wrapping, tapping, stacking, and potentially palletizing and labeling, are significantly more expensive than semi-automatic systems or standalone wrapping units.2

- Included Modules/Functions: Each additional automated function—such as automatic film tapping, integrated stacking units, automatic labeling systems, pallet dispensers, or extensive conveying systems—adds to the overall system complexity and cost.4

- Control System Sophistication: Systems equipped with advanced PLCs, larger and more capable HMIs, and network connectivity for MES/ERP integration (indicative of Level 3 capabilities) will have a higher price point than those with basic, standalone control systems.1

- Customization: Tailoring a system to fit specific plant layouts, integrate seamlessly with existing upstream or downstream equipment, or accommodate unique tyre characteristics or packaging requirements involves additional engineering design and manufacturing effort, thereby increasing costs.5

- Supplier Reputation, Origin, and Support: Established brands with a strong reputation for quality, reliability, and comprehensive after-sales support (including warranties and service networks) may command higher prices. Additionally, the geographical origin of the machinery can influence cost due to differences in manufacturing expenses, material costs, and shipping.18

- Material Handling Integration: The complexity of integrating the tyre packing system with upstream processes (e.g., tyre building and curing lines) and downstream systems (e.g., automated warehousing, Automated Guided Vehicles – AGVs) adds to the engineering scope and cost.4

- Installation, Commissioning, and Training: These essential services, which ensure the system is correctly set up, functions as intended, and that personnel are proficient in its operation and maintenance, represent significant costs that are often separate from the core machine price.19

- Spare Parts and Maintenance Contracts: The availability and cost of critical spare parts, as well as the option for ongoing maintenance and service contracts, influence the long-term financial commitment and operational continuity.20

A less obvious but critical cost factor is the desired level of "future-proofing." Opting for a system with limited upgradability, restricted connectivity options, or a control system that cannot easily adapt to new technologies (such as AI-driven quality assurance or advanced MES functionalities) to save on initial capital expenditure can lead to significantly higher expenses in the future.21 If production needs evolve, new tyre types are introduced, or broader smart factory initiatives are pursued, a cheaper, less adaptable system21 might rapidly become obsolete or necessitate costly custom modifications to remain viable. In such scenarios, the initial "savings" can quickly erode, making the lower upfront price a false economy when viewed through the lens of long-term operational needs and technological advancements.

4.2. Indicative Pricing Ranges and Tiers

While precise pricing necessitates detailed specifications and direct supplier quotations, it is possible to establish general tiers for automatic tyre packing systems based on their complexity and level of automation. These ranges draw analogies from similar automated packaging machinery, such as coil wrappers, and available market data for tyre-specific equipment.

- Basic/Standalone Orbital Wrappers (Often Semi-Automatic): These units typically focus on the core wrapping function with manual loading and unloading. Prices can range broadly from approximately $6,000 to $35,000.9 Some tyre-specific orbital wrappers listed on online marketplaces fall within a $5,500 to $6,450 range, likely representing simpler configurations.22 For context, manual coil wrappers can be under $10,000, while semi-automatic coil wrappers span $10,000 to $70,000.2 At the most basic end, a handheld strapping tool for tyres might cost around $77523, representing minimal automation.

- Automatic Tyre Wrapping Machines (Standalone, including wrapping and tapping): These systems offer a higher degree of automation for the core packaging tasks. Indicative pricing is likely in the $15,000 to $70,000 range, depending on features, capacity, and build quality. An "Automatic Tyre Packing Machine and Tire Stretch Wrapping Machine" listed by FHOPEPACK on Alibaba was priced at $45,98024, suggesting a more complete standalone unit. Fully automatic standalone coil wrappers, as an analogy, can range from $50,000 to $150,000.2

- Integrated Automatic Tyre Packing Lines (Incorporating wrapping, tapping, stacking, and basic conveying): These more comprehensive systems could range from $75,000 to $200,000 or more. Drawing parallels, fully automatic integrated coil packing lines can cost between $150,000 and $500,000+.2 Specialized tyre machinery, like hydraulic tyre doublers/triplers for used tyre processing (a different technology but indicative of specialized equipment costs), are in the $7,300 to $8,500 range.25

- Highly Customized/High-Speed/Robotic Lines: For operations requiring very high throughput, extensive customization, robotic handling for tasks like palletizing, or integration with AGVs, costs can readily exceed $200,000 and potentially reach $500,000 or more. General pricing for complex coil packing lines can range from "tens of thousands of dollars…to several hundred thousand dollars or more".21

It is crucial to emphasize that these are indicative ranges. Final pricing is heavily dependent on the specific configuration, chosen options, supplier, and scope of services included.

A noteworthy consideration when evaluating prices, particularly those from broad online marketplaces22, is that the "sticker price" may not encompass all essential elements. Crucial aspects such as robust control systems featuring PLCs from reputable international brands, comprehensive safety features meeting recognized standards (e.g., CE compliance), professional installation and commissioning services, thorough operator and maintenance training, and reliable long-term support are often standard inclusions from established industrial automation suppliers like SHJLPACK and FHOPEPACK.7 These elements might be optional extras or entirely absent in lower-priced listings. This potential discrepancy can make direct price comparisons misleading if not carefully contextualized within a comprehensive TCO framework, as a lower upfront cost might conceal significant future expenses related to reliability, safety compliance, integration challenges, and inadequate support.

4.3. Total Cost of Ownership (TCO) Deep Dive

The Total Cost of Ownership (TCO) provides a comprehensive financial estimate of all direct and indirect costs associated with acquiring, operating, maintaining, and disposing of an automatic tyre packing system over its entire lifecycle.26 Adopting a TCO perspective is paramount for making informed investment decisions that look beyond the initial purchase price. The components of TCO for such systems typically include:

- Initial Investment Costs:

- Installation and Commissioning Costs:

- Site Preparation: Any necessary modifications to the facility.

- Mechanical and Electrical Installation: Labor and materials for setting up the machinery.21

- System Integration: Connecting the packing line with existing upstream/downstream equipment or control systems.

- Testing and Validation: Ensuring the system performs to specified parameters.

- Training Costs:

- Operator Training: Educating staff on correct and efficient operation.26

- Maintenance Staff Training: Equipping technical personnel with the skills to maintain and troubleshoot the system.

- Operational Costs (Ongoing):

- Maintenance and Repair Costs (Ongoing):

- Preventative Maintenance: Scheduled servicing, including labor and parts.1

- Spare Parts Inventory: Cost of holding critical spares on-site.

- Unscheduled Repairs: Costs associated with unexpected breakdowns, including labor and expedited parts.

- Service Contracts: Optional agreements with the supplier for ongoing support and maintenance.

- Software and Licensing Costs (Ongoing/Periodic):

- Fees for PLCs, HMIs, and any integrated data management, analytics, or MES interface software.1

- Potential costs for software updates or upgrades.

- Downtime Costs (Indirect):

- Lost Production: Value of output lost due to planned downtime (e.g., changeovers, scheduled maintenance) or unplanned downtime (e.g., breakdowns, material shortages).27

- Impact on Delivery Schedules: Potential penalties or loss of customer goodwill.

- Upgrade and Modification Costs (Potential):

- Costs to adapt the system if production needs change significantly (e.g., new tyre sizes, increased throughput requirements).20

- End-of-Life Management Costs:

- Decommissioning: Costs to safely remove the system.

- Disposal or Recycling: Expenses related to environmentally responsible disposal or recycling of components.26

- Potential trade-in value (which would offset costs).

It is important to recognize that TCO is not a static figure calculated only at the time of purchase. It is a dynamic metric influenced by operational discipline and strategic choices made throughout the system’s lifespan. For instance, comprehensive operator training19 can significantly reduce user errors that might lead to downtime or damage. Similarly, the proactive implementation of predictive maintenance strategies (discussed further in Section 6) can lower unscheduled repair costs and extend the operational life of the machinery, thereby favorably impacting the overall TCO.28 The narrative example in 18, where a lack of training and a service plan led to escalating costs, vividly illustrates how post-purchase decisions directly shape the actual TCO. Thus, TCO is not just an estimate but an outcome that can be actively managed and optimized through diligent operational practices.

4.4. Return on Investment (ROI) Framework and Analysis

Return on Investment (ROI) is a key performance indicator used to evaluate the profitability and financial viability of investing in an automatic tyre packing system. It quantifies the financial benefits gained from the automation relative to the total cost of the investment.1 A robust ROI analysis is essential for justifying capital expenditure.

Key Quantifiable Benefits for ROI Calculation:

- Labor Savings: This is often the most significant contributor to ROI. It includes reduced operator headcount, elimination of manual handling tasks, and associated savings in wages, benefits, and overtime.1

- Increased Throughput & Productivity: Automated systems pack more tyres per shift or day, leading to increased production capacity. This can translate to higher sales if market demand exists, or the ability to meet demand surges without additional labor costs.1

- Material Cost Reduction: Optimized use of consumables like stretch film (through mechanisms like powered pre-stretch), adhesive tape, and labels, along with reduced waste, contributes to direct cost savings.1

- Improved Quality & Reduced Damage/Rework: Consistent and secure packaging minimizes product damage during internal handling, storage, and transit. This leads to fewer customer returns, reduced rework costs, and less scrap.1 Reports suggest that returns due to defects can inflate operational costs by up to 20%27, highlighting the potential savings from improved packaging quality.

- Enhanced Safety & Reduced Injury-Related Costs: Automation reduces physical strain and the risk of workplace injuries, leading to lower workers’ compensation claims, fewer lost workdays, and associated administrative costs.1

- Space Optimization Savings: The potentially smaller footprint of an integrated automated line compared to multiple manual packing stations can free up valuable floor space. This space can be used for other productive purposes or reduce the need for facility expansion.1

ROI Calculation Formulas:

A common approach to ROI analysis involves calculating the Payback Period and the ROI Percentage:

- Annual Net Benefit Calculation:

- Annual Savings = Sum of all quantifiable annual benefits (labor, material, quality, safety, etc.)

- Annual Operating Costs of New System = Energy, consumables, maintenance for the automated system.

- Annual Net Benefit = Annual Savings – Annual Operating Costs of New System.

- Payback Period (in years):

- Payback Period = Total Investment Cost / Annual Net Benefit.1 This indicates the time it takes for the cumulative net benefits to recoup the initial investment.

- Return on Investment (ROI Percentage):

- ROI (%) = (Annual Net Benefit / Total Investment Cost) x 100.1 This expresses the annual return as a percentage of the initial investment.

For a more precise financial assessment, especially for long-term investments, calculating the Net Present Value (NPV) is recommended. NPV accounts for the time value of money by discounting future cash flows back to their present value, providing a clearer picture of the investment’s worth compared to other opportunities.1

ROI calculations are often most sensitive to the assumptions made about labor savings and throughput increases. Given that actual labor reductions can vary based on how tasks are reorganized within the plant, and throughput gains depend on the overall line balance (not just the new machine’s capacity), presenting a single ROI figure can be potentially misleading. A sensitivity analysis, which examines how the ROI changes under different scenarios (e.g., conservative versus optimistic projections for labor reduction, or varying production volumes), provides a more robust and realistic financial picture for decision-makers.1 This approach also helps identify the key performance drivers that the investment’s success hinges upon. Labor costs1 and productivity gains29 are consistently cited as primary motivators for automation, making their accurate estimation critical.

The following tables provide frameworks for understanding cost drivers, TCO components, and ROI calculation:

Table: Key Factors Influencing Automatic Tyre Packing System Prices

Factor Impact on Price (Low, Medium, High) Notes Max Tyre OD Handled Medium to High Larger capacity requires more robust, larger machine components. Max Tyre Width Handled Medium Affects wrapper ring size and conveyor width. Max Tyre Weight Capacity Medium to High Influences structural integrity, motor power, and handling mechanisms. Throughput (Tyres/Hour) High Higher speeds demand faster PLCs, more powerful motors, and optimized mechanical design. Wrapping Automation Level Medium to High Auto film attach/cut, pre-stretch systems add cost. Tapping Automation Medium Integrated automatic tapping units increase complexity. Stacking Automation High Automated stacking (mechanical/robotic) is a significant cost component. Labelling System Integration Medium Cost varies with complexity (print & apply, data integration). Control System Level (ISA-95) Medium (L2) to High (L3) Basic PLC/HMI (L2) is standard; MES/ERP integration (L3) adds significant cost and capability. Custom Engineering Required Medium to High Modifications for specific layouts or non-standard tyres increase engineering and manufacturing time. Safety Standards Compliance (e.g., CE, UL) Medium Higher compliance levels may require more sophisticated guarding and control systems. Installation & Commissioning Included Medium Supplier-led installation is a significant service cost. Training Services Included Low to Medium Comprehensive training adds to the overall package price. Warranty and Support Package Low to Medium Extended warranties or premium support plans increase cost. Table: Illustrative Total Cost of Ownership (TCO) Components for an Automatic Tyre Packing System (5-Year Horizon)

Cost Category Estimated % of Initial Price or Annual Cost Range Notes Upfront Costs Machine Purchase Price 100% (Baseline) Core equipment cost. Shipping, Taxes, Insurance 5-15% of Purchase Price Variable based on origin and destination. Installation & Commissioning 10-25% of Purchase Price Can be higher for complex integrations.21 Initial Operator & Maintenance Training 2-5% of Purchase Price Essential for proper operation and upkeep.26 Initial Spare Parts Package 3-7% of Purchase Price Recommended critical spares. Annual Operating Costs Energy Consumption $500 – $5,000+ / year Depends on machine size, utilization, and energy rates.19 Consumables (Film, Tape, Labels) $2,000 – $20,000+ / year Highly dependent on production volume and material choices. Pre-stretch significantly reduces film cost.1 Labor (Operation & Supervision) Variable Reduced compared to manual, but not zero. Depends on automation level. Scheduled Maintenance (Parts & Labor) 2-5% of Purchase Price / year Following manufacturer’s recommendations.1 Unscheduled Repair Provision 1-3% of Purchase Price / year Budget for unexpected breakdowns, higher in early years if "teething" issues, or later years with wear. Software Licenses/Updates (if applicable) $0 – $2,000+ / year For specialized software or MES interfaces.1 Potential Future Costs (Lifecycle) Major Overhauls / Upgrades Variable May be needed after 5-10 years or if production needs change.20 End-of-Life Disposal/Trade-in Value ($500 – $2,000) or (negative cost) Cost of decommissioning and disposal, potentially offset by scrap or trade-in value.26 Table: Return on Investment (ROI) Calculation Framework for Tyre Packing Automation

Item Calculation / Description Example Data Source / Notes A. TOTAL INVESTMENT COSTS Machine Purchase Price Quoted Price From supplier.21 Installation & Commissioning Service Cost From supplier or third-party integrator. Training Costs Service Cost From supplier. Initial Spare Parts Cost of Package Recommended by supplier. Subtotal: Total Investment (A) Sum of above B. ANNUAL SAVINGS Labor Reduction (No. of Operators Reduced x Annual Wage & Benefits per Operator) Internal HR/Payroll data.1 Material Savings (Film, Tape) (Old Annual Cost – New Annual Cost) Based on reduced consumption (e.g., pre-stretch benefits) and volume.1 Reduced Product Damage/Rework (Estimated Annual Cost of Damage/Rework with Manual System x % Reduction) Internal quality/logistics data; industry benchmarks.27 Reduced Injury Claims & Lost Time (Estimated Annual Cost of Injuries with Manual System x % Reduction) Internal safety/HR data; insurance premiums.1 Space Savings (if applicable) (Sq. Footage Saved x Annual Cost per Sq. Foot) If freed space is repurposed or avoids expansion.1 Subtotal: Total Annual Savings (B) Sum of above C. ANNUAL INCREASED REVENUE (Optional) Value of Increased Throughput (Additional Units Produced x Profit per Unit) Only if increased output leads to actual additional sales. Subtotal: Total Annual Increased Revenue (C) D. ANNUAL OPERATING COSTS (New System) Energy Consumption Estimated Annual Cost Machine specifications and utility rates.19 Consumables (Film, Tape, Labels) Estimated Annual Cost Based on projected usage with new system.1 Maintenance (Scheduled & Unscheduled Provision) Estimated Annual Cost Supplier estimates, industry averages.1 Subtotal: Total Annual Operating Costs (D) Sum of above E. ANNUAL NET BENEFIT (B + C) – D PAYBACK PERIOD (Years) A / E Time to recoup initial investment.1 ROI (%) (E / A) * 100 Annual return as a percentage of investment.1 NET PRESENT VALUE (NPV) Calculated using discount rate over system lifespan For more advanced financial analysis, accounts for time value of money.16 -

Supplier Spotlight: SHJLPACK and FHOPEPACK

SHJLPACK and FHOPEPACK are recognized names in the field of automated packing machinery, offering a variety of solutions suitable for coiled products, long-shaped items, and, pertinently, tyres.30 This section provides an overview of their tyre packing solutions based on available information, focusing on machine models, features, control systems, and indicative pricing where possible.

5.1. SHJLPACK: Automatic Tyre Packing Solutions

SHJLPACK offers a range of automatic tyre packing machines tailored to different categories of tyres, including those for trucks, passenger cars, bicycles, and various industrial vehicles.31 Their product lineup is designed to accommodate diverse operational needs, from standalone units to fully integrated packing lines.

Overview of Relevant Machine Models:

The company’s offerings include several series and specific models:

- GS Series: Typically vertical tyre packing machines.

- GD Series: Often "U" type ring tyre packing machines.

- GW Series: Generally horizontal tyre packing machines.31 Specific systems highlighted include the "Automatic tyre packing line," a general "Automatic tyre packing machine," a "Horizontal tyre wrapping machine," "Tyre wrapping machine GS200," "Vertical tyre packing machine GD300," and "Tyre wrapping machine GS300".31 These systems are versatile, capable of operating as standalone units for simpler packaging tasks or being integrated with other equipment to form comprehensive automatic packing lines.31

Features:

SHJLPACK machines are designed for the outside packaging of tyres, utilizing materials such as stretch film or knit belt for protection.31 Advanced features can include integrated logo tapping and label printing capabilities.32 The design and manufacturing process considers specific tyre characteristics, dimensions, weight, preferred loading/unloading methods, and overall packing requirements.31

Control System Capabilities:

While specific details for tyre lines are not extensively enumerated in all provided materials, the descriptions of their automatic coil packing lines (a comparable technology)32 and the term "Automatic tyre packing line" suggest PLC control with HMI interfaces are standard.31 The "Automatic tyre packing line" is described as delivering integrated and intelligent performance, implying a sophisticated level of automation and control.31

Pricing Information:

Direct pricing for SHJLPACK’s complete automatic tyre packing lines is not readily available from the research and typically requires direct consultation with the supplier for customized quotes. However, some indicative price points can be inferred from analogous machinery or listings:

- For coil wrappers (which share some technological similarities), SHJLPACK/FHOPEPACK context suggests vertical coil packing machines might be in the $3,250 – $4,290 range for simpler models. Semi-automatic coil wrappers could be $10,000-$70,000, while fully automatic standalone coil wrappers might range from $50,000-$150,000, and fully integrated lines from $150,000-$500,000+.2

- An Alibaba listing for an "automatic coil wrapping machine for tyre" (models H600L/H1000L), which could be from SHJLPACK or a similar manufacturer, shows prices from $5,500 to $6,450, depending on the order quantity.22 These likely represent simpler orbital wrapping units rather than complete lines.

5.2. FHOPEPACK: Automatic Tyre Packing Solutions

FHOPEPACK is another key player specializing in a wide array of automatic packing solutions, with notable expertise in systems for copper coils30 and other industrial products, including tyres.33

Overview of Relevant Machine Models:

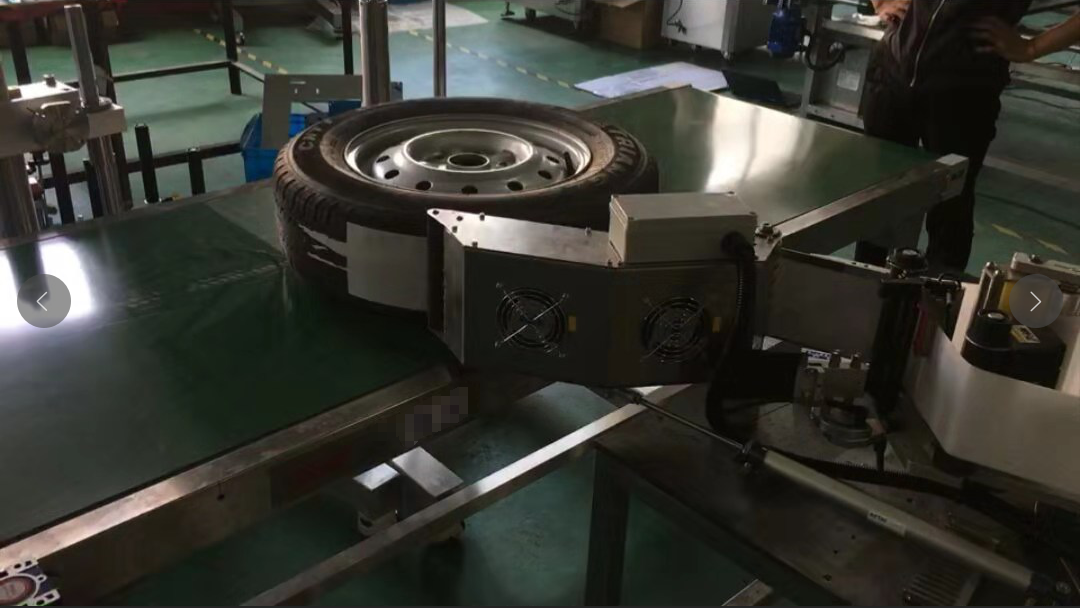

FHOPEPACK’s offerings include comprehensive "automatic tire packing lines" that can be customized to client needs.21 Detailed descriptions of an "auto tire wrapping machine with tapping and stacking" are available4, showcasing a fully integrated approach.

Features:

Their tyre packing systems typically incorporate orbital wrapping technology, automated tapping units for film securement, and integrated stacking mechanisms.4 Key features often include PLC control with user-friendly HMI touchscreens, sensor-based automation for tyre detection and positioning, powered pre-stretch for film economy, adjustable operational parameters (speed, tension, overlap), comprehensive safety features, and the capability for MES/ERP integration.4 These systems are designed to handle a variety of tyre sizes; one example specifies capabilities for tyres with an OD of 600-1000mm, width of 150-300mm, and weight of 5-100kg.7

Control System Capabilities:

FHOPEPACK systems prominently feature PLC-based control with HMI touchscreens. Significantly, their documentation explicitly mentions the capability for integration with plant-level MES/ERP systems using standard industrial protocols such as EtherNet/IP or PROFINET.4 They also offer software solutions for data transmission and label creation, indicating a focus on data management and traceability.7

Pricing Information:

Similar to SHJLPACK, precise pricing for FHOPEPACK’s tailored tyre packing lines requires direct engagement. However, some data points offer an indication:

- An Alibaba listing featuring the FHOPEPACK brand for an "Automatic Tyre Packing Machine and Tire Stretch Wrapping Machine" shows a price of $45,980.24 This suggests a more complete system than a basic wrapper.

- General pricing for FHOPEPACK coil packing lines (analogous complex systems) is stated to range from "tens of thousands of dollars…to several hundred thousand dollars or more," depending on complexity and automation.21

- FHOPEPACK emphasizes customized solutions and directs inquiries for detailed pricing to their sales team.21

5.3. Comparative Analysis (Based on Available Data)

Both SHJLPACK and FHOPEPACK offer comprehensive and automated solutions for tyre packaging, generally encompassing orbital wrapping, film tapping, and automated stacking. Both suppliers emphasize PLC control and HMI interfaces for system operation and management. FHOPEPACK’s available documentation more explicitly details advanced features like MES/ERP integration protocols4, though SHJLPACK’s description of an "Automatic tyre packing line" also implies a high level of integration and intelligence.31

Customization to meet specific client needs is a core offering from both manufacturers.5 Pricing for both appears to fall into broad and overlapping ranges, highly contingent on the final system configuration and the extent of automation and integration. The listings found on platforms like Alibaba likely represent more entry-level or less complex configurations from these suppliers or their affiliates/partners.

Potential differentiating factors, not always fully apparent from generalized product descriptions, could include specific patented technologies, the breadth and depth of their model range tailored to very specific tyre niches, the robustness and accessibility of their local after-sales support infrastructure, and the specific design and usability of their software and HMI interfaces. Based on the provided research, FHOPEPACK’s documentation (e.g.4) offers more granular detail on advanced features like powered pre-stretch mechanisms and specific control system integration protocols.

Ultimately, the selection between these, or other, capable suppliers will necessitate a thorough needs assessment by the prospective buyer. This assessment should cover specific technical requirements (e.g., throughput targets for a particular mix of tyre SKUs), the desired level of data integration with existing plant systems (like MES or WMS), data logging and traceability needs, the availability and quality of after-sales service in the client’s operational region, and, finally, a detailed, customized quotation that reflects the complete solution package. Relying solely on generic product brochures or list prices for basic units is insufficient for making a strategic capital investment of this nature. A direct and detailed engagement with suppliers to compare their proposed solutions against clearly defined user requirements is indispensable.

Table: Feature Overview of SHJLPACK and FHOPEPACK Tyre Packing Systems (Illustrative)

Feature Category SHJLPACK FHOPEPACK Core Machine Types Offered Vertical (GS), "U" type ring (GD), Horizontal (GW) tyre packing machines; Standalone units and integrated automatic packing lines.31 Automatic tyre packing lines; Auto tyre wrapping machines with integrated tapping and stacking units.4 Key Technologies Offered Orbital wrapping (stretch film, knit belt), logo tapping, label printing integration.31 Orbital wrapping (stretch film), powered pre-stretch, automated tapping, automated stacking (pneumatic/robotic/lift), labeling integration.4 Control System Basics PLC controlled with HMI (inferred for tyre lines, explicit for similar coil lines32). "Intelligent performance" for lines.31 PLC controlled with HMI touchscreen as standard.4 Advanced Control & Integration "Automatic tyre packing line" implies integration capabilities.31 Coil lines offer PLC control.5 Explicit MES/ERP integration via EtherNet/IP, PROFINET. Software for data transmission and label making.4 IoT-enabled systems mentioned for FHOPEPACK.34 Customization Focus Machines designed based on specific tyre characteristics, specs, weight, handling methods, and packing requirements.5 Offers customized coil packing lines; tyre lines can be customized to meet specific customer requirements and space constraints.21 Indicative Price Points (Snippets) Basic tyre wrappers (Alibaba, potentially related): $5.5k-$6.5k.22 Analogous coil lines: $10k to $500k+ depending on automation.2 Automatic Tyre Packing Machine (Alibaba, FHOPEPACK branded): $45,980.24 Analogous coil lines: "tens of thousands to several hundred thousand dollars or more".21 Note: This table provides an illustrative overview based on available data. Detailed and current specifications and pricing must be obtained directly from the suppliers.

-

Maximizing Value and Performance from Automated Systems

Investing in an automatic tyre packing system is a significant step. However, to truly maximize the value and performance derived from this investment, organizations should look beyond the initial installation and consider ongoing operational excellence strategies. Two powerful tools in this endeavor are Overall Equipment Effectiveness (OEE) monitoring and Predictive Maintenance (PdM).

6.1. The Role of Overall Equipment Effectiveness (OEE) in Packaging Lines

Overall Equipment Effectiveness (OEE) is a cornerstone metric for measuring manufacturing productivity. It provides a comprehensive view of how effectively a piece of equipment—or an entire production line, such as a tyre packing line—is utilized relative to its full potential during scheduled operating times. OEE combines three critical factors: Availability, Performance, and Quality.17

OEE Calculation:

The OEE score is calculated as the product of these three factors:

OEE = Availability x Performance x Quality17

Where:

- Availability: Measures the percentage of scheduled time that the equipment is actually available to operate. It accounts for all downtime, both planned (e.g., changeovers, scheduled maintenance) and unplanned (e.g., breakdowns, material shortages).

- Availability = Run Time / Planned Production Time

- Performance: Assesses the speed at which the equipment runs as a percentage of its designed or ideal speed. It accounts for losses due to running slower than optimal, including minor stops and reduced speed operation.

- Performance = (Ideal Cycle Time × Total Count) / Run Time (or Actual Bags/Tyres Per Minute / Planned Bags/Tyres Per Minute)

- Quality: Represents the percentage of good units produced out of the total units started. It accounts for products that are rejected, require rework, or do not meet quality standards on the first pass.

- Quality = Good Count / Total Count

Benefits in Packaging Operations:

In a packaging environment like a tyre packing line, OEE monitoring is invaluable. It helps to systematically identify and quantify losses related to equipment downtime, speed inefficiencies, and packaging defects. By pinpointing the root causes of these losses, OEE data empowers managers to implement targeted improvements, leading to tangible benefits such as reduced waste (of materials and time), lower operating costs, and maximized production efficiency.35 An increase in the OEE score directly translates to more efficient production and indicates a reduction in underlying inefficiencies.36

Cost of OEE Software/Systems:

The cost of implementing OEE monitoring can vary. Some OEE software solutions are offered on a subscription basis, potentially around $159 per month per machine (e.g., Evocon37). More comprehensive, IoT-based OEE system implementations, which might include sensors, gateways, data processing infrastructure, and advanced analytics, can range from $150,000 to $600,000 or more.35 Many modern CMMS (Computerized Maintenance Management Systems) and MES platforms also include OEE tracking modules as part of their functionality.37 Expected outcomes from OEE software implementation can include a 20-30% improvement in OEE and a 10-30% reduction in manufacturing costs.35

Implementing OEE monitoring effectively is not merely about tracking a numerical score; it is fundamentally about fostering a culture of continuous improvement within the organization. The data and insights derived from OEE analysis (often a Level 3 system function) should serve as catalysts for actionable changes in operational procedures, maintenance practices, material supply, and even operator training to realize the full spectrum of its benefits.38 The investment in OEE software or systems is, therefore, an investment in the capability to drive these ongoing improvements. Simply installing the software without a corresponding organizational commitment to analyze the data and act upon the insights will likely yield limited returns. The true value of OEE lies in the tangible improvements it facilitates, not just in the data it presents.

6.2. Leveraging Predictive Maintenance (PdM) for Uptime and Cost Reduction

Predictive Maintenance (PdM) represents a proactive approach to equipment upkeep. It utilizes real-time data collected from sensors embedded in machinery, combined with advanced analytics and machine learning algorithms, to predict potential equipment failures before they actually occur.28 This allows maintenance activities to be scheduled precisely when needed, optimizing resource allocation and minimizing disruptions, rather than relying on reactive maintenance (fixing equipment only after it breaks down) or purely time-based preventative maintenance schedules.

Benefits of Predictive Maintenance:

The advantages of implementing a PdM strategy are substantial:

- Reduced Unplanned Downtime: Industry reports suggest PdM can reduce unplanned downtime by up to 75%.28

- Lower Maintenance Costs: By addressing issues proactively and avoiding catastrophic failures, overall maintenance costs can be cut by up to 30%.28 This also avoids the over-servicing (e.g., replacing parts that are still good) and missed signs of degradation that can occur with rigid, time-based preventive maintenance schedules.39

- Extended Equipment Lifespan: Early detection and correction of wear and tear can extend the operational life of machinery by 20-40%.28

- Improved Energy Efficiency: Equipment operating at its peak performance, free from developing faults, tends to consume less energy.28

- Optimized Resource Allocation: Maintenance resources (personnel, spare parts) are deployed more efficiently.

Case studies demonstrate significant ROI from PdM; for example, an automotive supplier avoided major breakdowns, saving over $500,000 annually in repair costs and downtime losses.28

Cost of Predictive Maintenance Systems:

The cost of implementing PdM can vary widely depending on the scope and sophistication:

- Sensors: Individual sensors (e.g., vibration, temperature, acoustic) can range from around $100 to over $1,000 each, depending on type and precision.40

- CMMS Software: Often used to manage PdM workflows, CMMS software can start from around $400 per user per year.40 Some PdM-capable CMMS software like Fiix starts at $45/month, while others like Fracttal start at $229/month.41

- Data Analytics Tools/Platforms: Software for collecting, processing, and analyzing sensor data can start from around $200, with more advanced platforms (e.g., Senseye PdM) having higher costs, potentially starting from $2,000 for certain packages.41

- Implementation & Expertise: Initial setup, integration, and the need for skilled maintenance engineers or data analysts to interpret data and manage the program can range from thousands to tens of thousands of dollars, plus ongoing salary costs for experts (e.g., a maintenance engineer’s salary around $86,000 per year).40

The effectiveness of a PdM program for a tyre packing line is heavily reliant on the quality and scope of the Level 1 (sensors) and Level 2 (data processing, HMI for alerts) systems within the packing machinery itself. Furthermore, PdM often integrates with Level 3 systems like MES or CMMS for generating work orders and tracking maintenance history.39 This interdependency means that the decision to implement an advanced PdM strategy should influence the selection criteria for the tyre packing system. Preference should be given to machines that are "PdM-ready"—equipped with a comprehensive suite of relevant sensors and robust data connectivity options. Choosing a lower-cost packing machine with minimal sensing capabilities or limited data output could make the effective implementation of PdM more difficult and costly in the long run, thereby diminishing the potential TCO benefits that a proactive maintenance strategy can deliver. This creates a synergistic relationship where the machine’s inherent capabilities directly support and enhance the chosen maintenance strategy.

Table: OEE Calculation and Key Performance Indicators for Packaging Lines

OEE Component Formula Key Data Inputs from Tyre Packing Line Typical Improvement Levers Availability Run Time / Planned Production Time Planned Production Time (Shift length – breaks), Actual Run Time (Planned Production Time – Stop Time), Downtime Logs (coded by reason: e.g., breakdown, changeover, material shortage, no operator). Reduce changeover times through SMED techniques, minimize breakdowns via effective preventative/predictive maintenance, ensure timely material supply, optimize operator scheduling. Performance (Ideal Cycle Time × Total Count) / Run Time Ideal Cycle Time per Tyre (theoretical fastest time), Total Tyres Processed (including rejects), Actual Run Time. Alternatively: Actual Tyres per Minute / Target Tyres per Minute. Optimize machine settings for specific tyre types, ensure consistent material quality (film, tape), provide thorough operator training on efficient operation, address minor stoppages quickly, maintain equipment to designed speed capabilities. Quality Good Count / Total Count Total Tyres Processed, Number of Rejected Tyres (due to packaging defects like poor wrap, loose tape, incorrect label), Number of Tyres Requiring Rework (e.g., re-wrapping). Improve film/tape application mechanisms, ensure correct recipe selection for tyre type, calibrate sensors accurately, maintain consistent material quality, implement quality checks at source, operator training on quality standards. Overall OEE Availability × Performance × Quality Combines all losses to show the percentage of planned production time that is truly productive. Holistic improvement efforts targeting all three components. Data-driven problem solving to address the largest sources of loss first. Fostering a continuous improvement culture. Table: Cost Components of a Predictive Maintenance Program for Tyre Packing Machinery

Cost Category Initial Cost Range (Illustrative) Ongoing Cost Range (Annual/Subscription) Key Considerations Sensors (Vibration, Thermal, Acoustic etc.) $500 – $10,000+ Minimal (replacement as needed) Number of critical failure points to monitor on the packing line, type and precision of sensors required for specific components (motors, bearings, gearboxes), environmental conditions. Data Acquisition Hardware (DAQs, Gateways) $1,000 – $15,000+ Minimal Number of sensors, data transmission requirements (wired/wireless), compatibility with existing network infrastructure. PdM Software Platform (Cloud or On-Premise) $0 (for basic CMMS) – $50,000+ $500 – $20,000+ / year Features needed (data analytics, machine learning, dashboards, alert management, CMMS integration). Scalability, vendor support, ease of use. Some CMMS include basic PdM modules.41 Specialized platforms vary widely.41 Integration Costs (Machine, CMMS, ERP) $2,000 – $20,000+ Minimal Complexity of integrating sensor data with the PdM platform and linking PdM alerts/work orders to CMMS or ERP systems. Requires IT and automation expertise. Training for Maintenance & Operations Staff $1,000 – $10,000 $500 – $2,000 / year (refreshers) Training on using the PdM software, understanding sensor data, and implementing new maintenance procedures based on predictions. Data Analysis Expertise (Internal/External) $0 – $20,000+ (initial setup) $0 – $86,000+ / year (if dedicated role) Cost of hiring or contracting data scientists/reliability engineers if in-house expertise is lacking.40 Some software platforms offer built-in analytics, reducing this need. Network Infrastructure Upgrades $0 – $5,000+ Minimal Ensuring sufficient network bandwidth and connectivity for sensor data transmission, especially for wireless sensors or cloud-based platforms. - Availability: Measures the percentage of scheduled time that the equipment is actually available to operate. It accounts for all downtime, both planned (e.g., changeovers, scheduled maintenance) and unplanned (e.g., breakdowns, material shortages).

-

Market Dynamics and Future Outlook for Tyre Packaging Automation

The landscape of tyre manufacturing and logistics is continuously evolving, influenced by broader industrial trends, technological advancements, and shifting market demands. These dynamics directly impact the requirements and future development of automatic tyre packing systems.

7.1. Key Market Trends (2025 and Beyond)

Several interconnected trends are shaping the future of tyre packaging automation:

- Sustainability: There is a growing and pressing demand for environmentally responsible solutions across the manufacturing sector. In tyre packaging, this translates to the use of eco-friendly packaging materials (such as recyclable or biodegradable films), the design of energy-efficient machinery, and overall waste reduction strategies.42 Innovations include recyclable plastic edge protectors for coils (analogous to tyre handling needs)43, and even reusable Intermediate Bulk Containers (IBCs) for tyre transport, as offered by companies like Goodpack.44 The tyre industry itself is seeing a push towards sustainable tyre production and circular economy models, such as those championed by reTyre.45

- Smart Features & Connectivity (Industry 4.0): The integration of sensors, Artificial Intelligence (AI), and the Internet of Things (IoT) into packaging machinery is accelerating. This enables real-time monitoring of machine performance, predictive maintenance capabilities, and advanced data analytics for process optimization.34 The emergence of "smart tyres" themselves—tyres embedded with sensors for monitoring pressure, temperature, and tread wear—is a significant parallel trend.42

- Advanced Automation, Robotics, and AI in Manufacturing & Logistics: The adoption of sophisticated automation, including robotics and AI, continues to expand beyond core manufacturing into packaging and logistics. This is aimed at streamlining entire production flows, enhancing quality control stringency, and optimizing logistical operations.42 AI is already being applied in tyre design, optimizing production scheduling, and improving demand forecasting accuracy within the tyre industry.46

- Customization and Personalization: Market demand is increasing for packaging systems that can flexibly handle a diverse range of tyre types, sizes, and specific customer packaging requirements. This necessitates machinery with greater adaptability and easier changeover capabilities.5

- E-commerce Growth and Last-Mile Delivery: The ongoing expansion of e-commerce is a significant driver for efficient and robust packaging solutions, particularly for products like tyres that are increasingly sold online. This trend also fuels demand for specialized tyres, such as EV-ready commercial tyres designed for the rigors of last-mile delivery fleets.47

- Heightened Focus on Safety and Compliance: Regulatory bodies continue to introduce stricter safety and compliance standards for machinery and packaged goods. This influences the design of automated systems, requiring advanced safety guarding, interlocks, and adherence to international standards.42

- Productivity as a Paramount Goal: For high-volume manufacturers, akin to Consumer Packaged Goods (CPG) companies, boosting productivity remains a top priority, often followed by concerns around cost management and the implementation of further automation.29

- Growth in the Material Handling Equipment Market: The broader market for material handling equipment is experiencing robust growth, largely driven by the expansion of e-commerce, the push for automation to reduce labor costs and improve operational efficiency, and investments in smart logistics infrastructure.48

The rise of "smart tyres"42 is likely to create a corresponding demand for "smart packaging" solutions. This implies that future tyre packing lines may need to incorporate capabilities to interact with data embedded in the tyres themselves, for example, by reading RFID tags or unique identifiers. This information could then be integrated into the packaging labels or data logs associated with the packaged unit. Such a development would significantly enhance traceability and inventory management throughout the entire supply chain, moving beyond tracking tyre types to managing individual tyre identities. This, in turn, suggests a need for more sophisticated sensor integration (e.g., RFID readers) and advanced data handling capabilities (requiring robust Level 2 and Level 3 control systems) in future generations of tyre packing lines, potentially influencing their price, feature set, and overall value proposition.

7.2. The Impact of Robotics and AI on Future Systems

The integration of robotics and Artificial Intelligence is poised to further revolutionize automatic tyre packing systems, pushing the boundaries of efficiency, flexibility, and intelligence.

- Robotics: The use of industrial robots is expected to become more prevalent for a variety of tasks within the tyre packing workflow. This includes highly precise tyre handling, automated palletizing of wrapped and stacked tyres, and potentially more complex wrapping or insertion tasks that require intricate manipulation.34 Robotic coil handling systems are already established in the metals industry49, demonstrating the feasibility and benefits of robotic automation for heavy or awkwardly shaped items.

- Artificial Intelligence (AI): AI algorithms will increasingly be embedded into packing systems for several advanced functions:

- AI-Powered Quality Control: Vision systems enhanced with AI can perform more sophisticated inspections, accurately detecting subtle packaging defects, verifying label placement and readability, and ensuring overall package integrity.42

- Predictive Maintenance: AI is a core enabler of advanced PdM, analyzing sensor data to predict failures with greater accuracy and lead time.42

- Process Optimization: AI can dynamically optimize machine parameters (e.g., film tension, wrapping speed, conveyor synchronization) in real-time based on the specific tyre being processed and feedback from sensors, maximizing efficiency and minimizing material waste.46 In tyre manufacturing itself, AI is already used to automatically adjust machine parameters during critical processes like compound mixing.46

- Intelligent Scheduling and Logistics: AI can contribute to optimizing the scheduling of packing operations and integrating them more seamlessly with broader production and logistics planning.34

- Digital Twins: The concept of creating virtual replicas (digital twins) of physical packing lines is gaining traction. These models allow manufacturers to simulate different operational scenarios, optimize line layouts and workflows, predict maintenance needs without disrupting physical production, and test new configurations or software updates in a virtual environment before deployment.42

As AI and robotics become more deeply integrated into tyre packing lines, the nature of the human workforce interacting with these systems will inevitably transform. While the requirement for manual laborers directly involved in packing tasks may decrease, the demand for technicians and engineers skilled in robotics programming, PLC configuration, data analysis, and AI system maintenance will concurrently increase.12 This evolution in skill requirements has significant implications for training costs (a component of TCO) and the overall labor strategy of companies investing in these advanced automation solutions.42 The "labor savings" traditionally associated with automation might be partially offset by the higher compensation levels for these specialized technical roles, or by the need for substantial investment in upskilling the existing workforce. This is a critical long-term consideration for both TCO calculations and strategic workforce planning in the era of smart manufacturing.

-

Strategic Recommendations for System Selection and Implementation

Selecting and implementing an automatic tyre packing system is a multifaceted process that requires careful planning and consideration of various technical, operational, and financial factors. To ensure a successful investment that delivers optimal value, the following strategic recommendations are proposed:

- Conduct a Thorough Needs Assessment: Before engaging with suppliers, clearly define the objectives for automation. This includes establishing target throughput rates, desired levels of labor reduction, specific improvements in packaging quality, the full range of tyre types and sizes to be handled (both current and anticipated), and any plans for future expansion or changes in production volume.6

- Prioritize Total Cost of Ownership (TCO) over Initial Price: While the upfront purchase price is a significant factor, a comprehensive evaluation must consider all lifecycle costs, including installation, training, energy consumption, consumables, maintenance, potential downtime, and end-of-life disposal. A system with a lower initial price might have higher long-term operating costs, making it less economical over its lifespan.21

- Evaluate Control System Capabilities and Future Readiness: Choose a system with an appropriate control architecture (ISA-95 Levels 1, 2, and potentially 3) that meets current operational needs and provides the necessary data integration and analytics capabilities for future requirements, such as MES/ERP connectivity, OEE monitoring, or predictive maintenance.4 Consider the system’s capacity for upgrades and integration with emerging technologies.

- Engage with Multiple Suppliers for Detailed, Customized Quotes: Obtain comprehensive proposals from reputable and experienced suppliers, such as SHJLPACK and FHOPEPACK, as well as other relevant vendors. Compare these proposals not just on price but also on detailed technical specifications, the quality of components, the scope of included services (installation, training), warranty terms, and the availability and responsiveness of after-sales support.50

- Consider Modularity, Scalability, and Flexibility: Assess whether the proposed system offers modular components that allow for phased implementation or future expansion. The ability to scale the system to meet growing demand or adapt to new tyre products or packaging requirements can significantly enhance its long-term value.51

- Plan for Seamless Integration: If the tyre packing line needs to connect with existing upstream (e.g., tyre manufacturing) or downstream (e.g., palletizing, warehousing) processes, or with plant-level information systems (MES, ERP, WMS), ensure that the chosen system has proven integration capabilities and utilizes standard communication protocols.4

- Invest in Comprehensive Operator and Maintenance Training: Proper training for both operators and maintenance personnel is crucial for ensuring efficient system operation, minimizing errors, reducing downtime, and maximizing the equipment’s lifespan and performance. This should be factored into the initial project budget and planning.26

- Implement OEE Monitoring and Explore Predictive Maintenance (PdM): Utilize OEE as a tool to continuously monitor and improve the performance of the packing line. Explore the feasibility and potential ROI of implementing a PdM program to optimize uptime and reduce maintenance costs.28 The chosen system should ideally support data collection for these initiatives.

- Factor in Sustainability Goals: Evaluate the energy efficiency of the proposed machinery and its compatibility with sustainable or recyclable packaging materials. This aligns with growing corporate social responsibility mandates and can also lead to operational cost savings.42

- Perform Sensitivity Analysis for ROI Calculations: Given that ROI projections are based on assumptions (e.g., labor savings, throughput gains), conduct a sensitivity analysis to understand how the ROI might change if these key assumptions vary. This provides a more robust financial picture for decision-making.1

By adhering to these strategic considerations, organizations can navigate the complexities of selecting and implementing an automatic tyre packing system more effectively, leading to an investment that meets immediate operational needs while also supporting long-term strategic objectives.

-

Conclusion