Preventing rust and corrosion can make or break your metal coil packaging systems. Rust not only compromises the integrity of your coils but also leads to costly delays and product loss. Tackling this issue head-on ensures your packaging remains efficient and your products stay protected.

Rust and corrosion are significant threats to metal coil packaging systems. Effective prevention strategies are essential to maintain the quality and longevity of your coils, ensuring smooth operations and cost savings.

Keeping your coils free from rust and corrosion is crucial for maintaining the efficiency and reliability of your packaging systems. Understanding the underlying causes and implementing the right solutions can make a substantial difference in your production processes.

1. What causes rust and corrosion in metal coil packaging systems?

Rust and corrosion in metal coil packaging systems arise from various environmental and operational factors. These processes degrade the metal over time, leading to weaker coils and compromised packaging integrity.

Understanding the Root Causes

Rust and corrosion are primarily caused by exposure to moisture, oxygen, and contaminants. In packaging environments, factors such as humidity levels, temperature fluctuations, and the presence of corrosive agents play a significant role in the deterioration of metal coils. Additionally, improper storage and handling practices can exacerbate these issues, leading to accelerated metal degradation.

| Factor | Impact on Metal Coils | Mitigation Strategy |

|---|---|---|

| Moisture Exposure | Promotes oxidation, leading to rust formation | Implement moisture-resistant packaging materials |

| Oxygen Levels | Accelerates the oxidation process | Use inert gas environments or protective coatings |

| Contaminants | Chemical agents can react with metal surfaces, causing corrosion | Regular cleaning and use of anti-corrosion agents |

| Temperature Fluctuations | Causes expansion and contraction, potentially cracking protective layers | Maintain stable storage conditions |

| Improper Storage | Increased contact with environmental factors, leading to rust | Use climate-controlled storage facilities |

By addressing these factors through improved packaging systems, such as using anti-corrosion coatings and ensuring proper storage conditions, you can significantly reduce the risk of rust and corrosion. Investing in high-quality Coil packaging machines equipped with advanced rust prevention technologies further enhances the protection of your metal coils, ensuring their longevity and performance in the supply chain.

2. How can we effectively prevent rust and corrosion?

Every year, businesses face losses due to metal corrosion affecting their packaging systems. This not only impacts product quality but also incurs additional costs for repairs and replacements. Without effective strategies, managing rust becomes a daunting challenge.

Effective rust prevention involves a combination of proper packaging systems, anti-corrosion coatings, and regular maintenance. By implementing these measures, businesses can protect their metal assets and ensure longevity.

Understanding the Basics of Rust Prevention

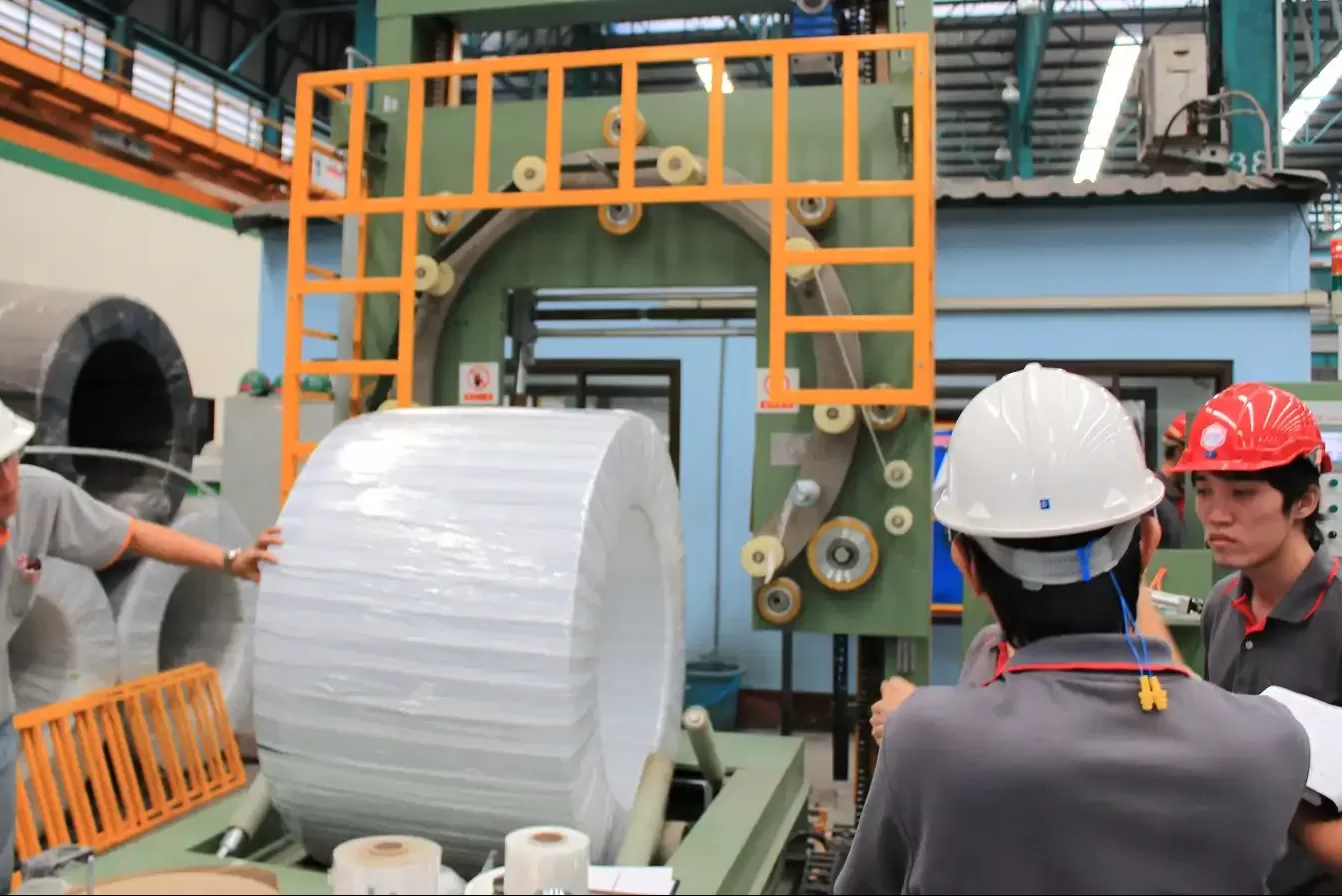

Preventing rust on metal coils requires a comprehensive approach. The first step is selecting the right packaging system that minimizes exposure to moisture and corrosive elements. Coil wrapping machines and pallet inverters play a crucial role in securing coils effectively. Additionally, applying anti-corrosion coatings creates a protective barrier against environmental factors.

Regular maintenance is essential to identify and address potential rust issues early. This includes inspecting coils for signs of corrosion and ensuring that coatings remain intact. Investing in high-quality materials and equipment can significantly reduce the risk of rust formation.

| Method | Description | Benefits |

|---|---|---|

| Packaging Systems | Use of advanced coil wrapping machines and pallet inverters to secure coils | Reduces moisture exposure, ensures stability |

| Anti-Corrosion Coating | Application of protective coatings on metal surfaces | Creates a barrier against moisture and chemicals |

| Regular Maintenance | Routine inspections and touch-ups of protective measures | Early detection of rust, extends lifespan of coils |

By integrating these methods, businesses can effectively combat metal corrosion. Choosing the right packaging system not only protects the coils but also enhances operational efficiency. Anti-corrosion coatings provide long-lasting protection, reducing the need for frequent maintenance. Moreover, regular inspections help in maintaining the integrity of the protective measures, ensuring sustained rust prevention.

3. What are the long-term benefits of preventing rust and corrosion?

Managing rust proactively can lead to significant long-term advantages for businesses. It ensures that packaging systems remain functional and efficient, reducing downtime and maintenance costs. Moreover, protecting metal coils extends their usability, contributing to overall operational sustainability.

Preventing rust and corrosion extends the lifespan of metal coils, reduces maintenance costs, and enhances operational efficiency. These benefits lead to improved productivity and cost savings over time.

Advantages of Sustained Metal Protection

Investing in rust prevention yields multiple benefits that enhance both the financial and operational aspects of a business. Firstly, extending the lifespan of metal coils means fewer replacements and lower material costs. This directly impacts the bottom line by reducing expenses associated with new purchases and waste disposal.

Operational efficiency is another major benefit. When coils are protected from corrosion, they perform better and require less frequent maintenance. This ensures that production schedules remain uninterrupted, leading to higher output and reliability. Additionally, well-maintained coils contribute to the overall quality of the products, meeting industry standards and customer expectations.

| Benefit | Impact | Example |

|---|---|---|

| Extended Lifespan | Reduces the need for frequent coil replacements | Lower material costs over time |

| Reduced Maintenance Costs | Decreases expenses related to repairs and upkeep | Savings on labor and materials |

| Enhanced Operational Efficiency | Maintains smooth production without interruptions | Increased production output |

| Improved Product Quality | Ensures consistency and reliability of products | Higher customer satisfaction |

Furthermore, rust prevention supports environmental sustainability. By prolonging the life of metal coils, businesses can minimize their environmental footprint through reduced waste and resource consumption. This aligns with corporate social responsibility goals and can enhance a company’s reputation in the market.

In my experience, implementing robust rust prevention strategies not only safeguarded our equipment but also fostered a culture of proactive maintenance. This approach led to significant improvements in both efficiency and cost management.

Conclusion

By understanding the causes and implementing effective prevention techniques, businesses can significantly extend the lifespan of metal coil systems. This not only ensures operational continuity but also provides economic and environmental benefits.