High-Efficiency Door Shrink Wrapping Systems: Design, Specifications, and Benefits

Packaging large, often bulky items like doors presents unique challenges for manufacturers and distributors. Ensuring protection against scratches, dust, moisture, and handling damage during transit and storage is paramount. Traditional methods can be labor-intensive and offer inconsistent results. Modern door shrink wrapping machines provide an automated, efficient, and high-quality solution, delivering a professional finish that enhances product presentation and protection. This article delves into the technical aspects, design considerations, operational benefits, and key specifications of these specialized packaging systems.

1. The Imperative for Specialized Door Packaging

Doors, whether interior or exterior, finished or unfinished, are susceptible to damage. Scratches, dents, moisture ingress (leading to warping), and dust accumulation can significantly diminish value and lead to costly returns or rework. Standard packaging methods like cardboard or simple plastic sheeting often fall short. Shrink wrapping offers distinct advantages:

- Superior Protection: A tightly shrunk film conforms to the door's shape, creating a robust barrier against environmental factors and handling mishaps.

- Enhanced Presentation: The clear, taut film provides a clean, professional look, allowing visual inspection without unwrapping.

- Tamper Evidence: A sealed shrink wrap layer immediately indicates if the package has been compromised.

- Unitization: Hardware or installation kits can often be securely bundled with the door under the wrap.

- Efficiency: Automated systems significantly reduce manual labor and increase packaging throughput compared to manual methods.

2. Technical Deep Dive: Door Shrink Wrapping Machine Anatomy

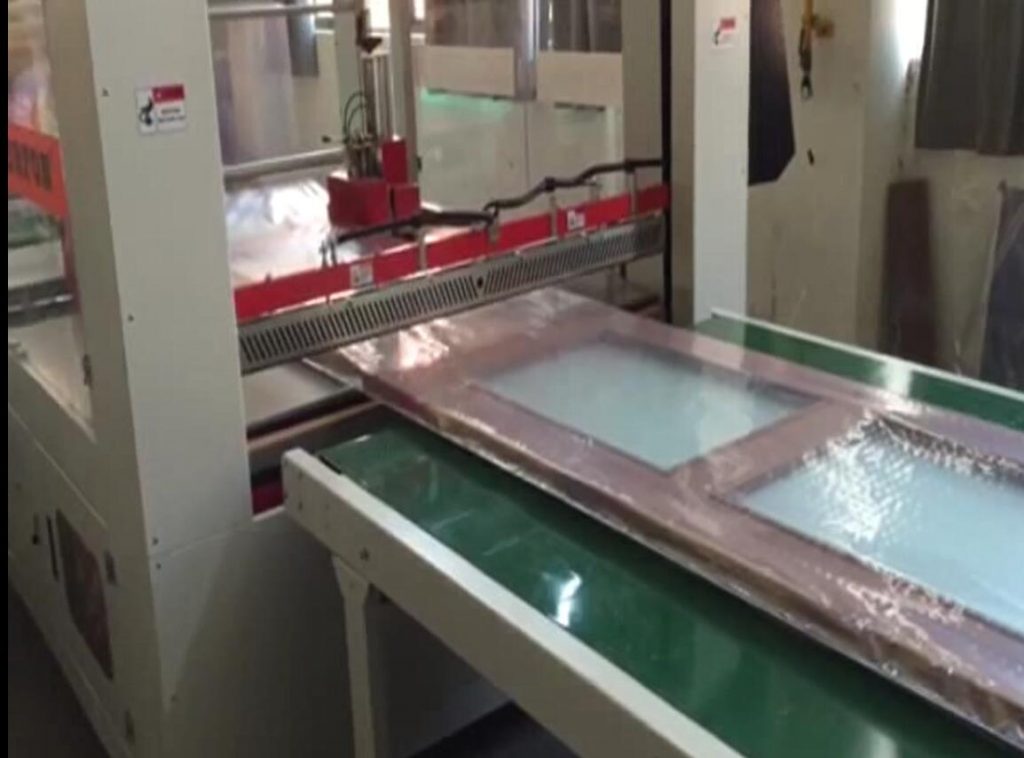

A typical high-performance door shrink wrapping machine integrates several key systems designed for robustness, adaptability, and continuous operation.

2.1 Design Philosophy

Modern systems emphasize modularity, ease of adjustment for varying door dimensions, and energy efficiency. Key design goals include minimizing film waste, ensuring consistent seal quality, and providing reliable, long-term operation in industrial environments.

2.2 Key Components and Functionality

- Infeed/Outfeed Conveyors: Automated conveyors transport doors into the sealing area and then through the shrink tunnel. Variable speed control is often included to match production line speeds.

- Film Delivery System: This holds large rolls of shrink film (often POF or PE). Advanced systems feature automatic film feeding and tension control. A crucial specification is the maximum film width capacity, often accommodating widths up to 1200mm or more to handle standard door sizes.

- Sealing System: This is critical for creating the bag around the door before shrinking. Common configurations include:

- L-Bar Sealer: Creates seals on two sides simultaneously. Suitable for moderate speeds.

- Side Sealers: Often used in higher-speed applications. These systems use continuously heated blades or wires to seal the sides of the film as the door passes through, followed by a cross-seal bar. The original post mentioned adjustable sealers:

- Three Sealers Adjustable: This likely refers to a side-sealing system where the side sealing mechanisms and the cross-seal bar can be adjusted to accommodate varying door widths and lengths efficiently. Two side sealers handle the length, and one cross-sealer finishes the bag.

- Long Sealer: Refers to the cross-seal capability, needing to span the maximum film width (e.g., 1200mm).

- Seal types can be impulse (heat applied only during the seal cycle) or constant heat, depending on the film type and speed requirements.

- Shrink Tunnel: After sealing, the loosely bagged door passes through a heated tunnel. Precise temperature control and optimized airflow patterns ensure the film shrinks uniformly around the door, creating a tight, protective layer without damaging the door surface. Key features include high-efficiency insulation, adjustable temperature zones, and variable airflow controls.

- Control System: Typically managed by a PLC (Programmable Logic Controller) with an HMI (Human-Machine Interface) touch screen. This allows operators to set parameters (temperature, conveyor speed, seal time), store recipes for different door sizes, and monitor system status and diagnostics. Sensors detect door position and manage the operational sequence.

2.3 Materials Compatibility

These machines are primarily designed to work with heat-shrinkable films:

- Polyolefin (POF): Known for its clarity, strength, and excellent shrinkage characteristics. It's FDA-approved for direct food contact (though less relevant for doors) and generally considered environmentally friendlier than PVC.

- Polyethylene (PE): Often used for heavier-duty applications requiring high puncture resistance. Available in various densities (LDPE, LLDPE).

- Film Thickness: The ability to handle a range of thicknesses, typically from 25 to 100 microns (µm), allows users to balance cost, clarity, and protection level based on the specific door type and distribution chain demands.

3. Performance Metrics & Typical Specifications

When evaluating a door shrink wrapping machine, consider these key technical parameters:

- Maximum Door Dimensions (L x W x H): Defines the largest door the machine can process. Crucial for compatibility. (e.g., 2500mm L x 1200mm W x 100mm H)

- Maximum Film Width: Must accommodate the widest door dimension plus necessary overlap. (e.g., 1200mm, as mentioned)

- Packing Speed: Measured in doors per minute or hour. Varies significantly based on machine type (L-bar vs. side seal), door size, and film type. (e.g., 3-10 doors/minute)

- Sealing System Type: L-Bar, Intermittent Side Seal, Continuous Motion Side Seal.

- Shrink Tunnel Aperture (W x H): Must be larger than the maximum door cross-section.

- Power Requirements: Voltage, Phase, Total Power Consumption (kW).

- Compressed Air Requirements: Pressure (bar/psi) and Consumption (L/min or CFM), if pneumatic components are used.

- Machine Dimensions (L x W x H): For installation planning and floor space allocation.

- Compatible Film Types: POF, PE.

- Film Thickness Range: (e.g., 25-100 µm)

(Note: Specific values vary significantly between models and manufacturers. The figures above are illustrative examples.)

4. Operational Considerations & User Experience

From a practical standpoint, operating and owning a door shrink wrapping machine involves several considerations:

- Ease of Use: Modern machines often feature intuitive HMI interfaces for quick setup, parameter adjustments, and recipe management for different door types/sizes. Quick changeovers are a key benefit.

- Maintenance: Routine maintenance includes cleaning sealing elements, checking conveyor belts, inspecting tunnel heating elements and airflow, and lubricating moving parts. Accessibility for maintenance is an important design factor.

- Safety: Machines should incorporate safety features like emergency stops, interlocked guarding on moving parts and heated areas, and clear warning labels, complying with relevant safety standards (e.g., CE marking in Europe).

- Integration: Consider how the machine fits into the overall production flow. Can it be synchronized with upstream manufacturing processes and downstream palletizing or loading operations?

- Observed Benefits: Users typically report significant reductions in packaging labor costs, increased throughput, drastically lower rates of transit damage, and positive feedback on the professional appearance of the packaged doors ("nice surface after shrinking").

5. Choosing the Right System

Selecting the appropriate door shrink wrapping system depends on production volume, the range of door sizes and types, budget constraints, and the level of automation required. Evaluating the manufacturer's reputation for reliability, technical support, and availability of spare parts is also crucial. While cost is a factor, the long-term value derived from efficiency gains, reduced product damage, and consistent quality should guide the investment decision. High-quality machines, even if sourced internationally (e.g., from reputable manufacturers in China), can offer excellent performance and value when properly specified and supported.

Conclusion

Automated door shrink wrapping machines represent a significant technological advancement over manual packaging methods. By leveraging sophisticated sealing systems, precisely controlled shrink tunnels, and robust designs, these systems deliver superior product protection, enhanced presentation, and substantial operational efficiencies. Understanding the underlying technology, key components, and performance specifications allows businesses to make informed decisions when investing in packaging solutions that safeguard their products and streamline their operations.

For further details on specific door packaging solutions:

Door Packing Machine Information

General Shrinking Machine Information

For inquiries, contact: info@fhopepack.com