Automated Protective Film Application and Bagging Line for Aluminum Profiles

In modern aluminum extrusion and finishing operations, maintaining surface integrity from production to final installation is paramount. Scratches, abrasions, or contamination acquired during handling and transport can lead to costly rejects or rework. This video showcases an automated system designed to address these challenges: an integrated protective film applicator and potentially a bagging line specifically engineered for aluminum profiles. Such systems represent a significant step forward in efficiency, quality control, and operational cost reduction compared to manual methods.

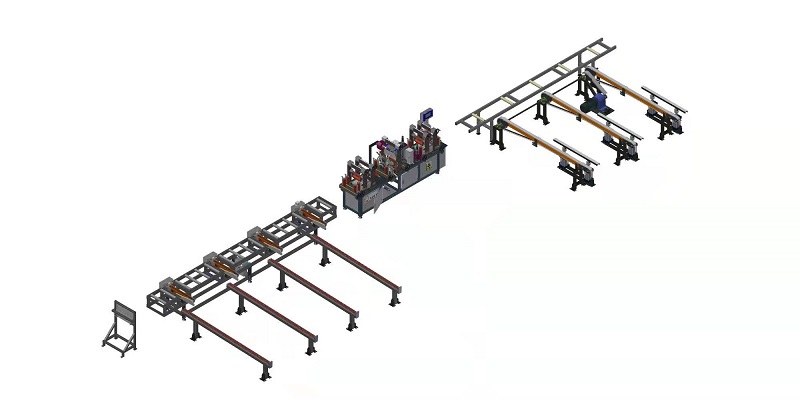

The process typically begins as aluminum profiles exit the extrusion line's cooling or handling section. As demonstrated, profiles move onto a transfer table conveyor, which efficiently reorients them, often by 90 degrees, for inline feeding into the subsequent processing stations.

1. System Overview: Streamlining Profile Protection

The core function of this automated line is to seamlessly apply protective adhesive film to aluminum profiles and, in many configurations, subsequently package them into bags for enhanced protection during shipping and storage.

- Infeed & Transfer: Profiles are received from upstream processes onto robust conveyor systems. Automated transfer mechanisms, like the 90-degree table shown, ensure correct orientation without manual intervention.

- Film Application: Profiles are indexed and fed individually into the automatic protective film applicator station.

- Bagging (Optional Integration): Following film application, the line can integrate an automatic bagging station where profiles are grouped or individually inserted into protective poly bags, which are then sealed.

- Outfeed: Protected profiles are conveyed to downstream processes like bundling, stacking, or dispatch.

2. Key Component Deep Dive: The Protective Film Applicator

The heart of the system is the automated film applicator, engineered for precision and reliability:

- Design & Structure: Built on a sturdy industrial frame, utilizing heavy-duty conveyors (belt or roller, depending on profile sensitivity) designed to handle various profile lengths and weights. Guide rollers ensure stable profile movement during application.

- Film Application Mechanism:

- Sensors: Optical or proximity sensors accurately detect the leading and trailing edges of each profile.

- Control System: A PLC (Programmable Logic Controller) calculates the required film length based on sensor input and pre-set parameters (allowing for over/underlap).

- Film Unwind & Cutting: Motorized unwind stands maintain consistent film tension. An automated cutter (pneumatic or servo-driven blade) precisely cuts the film to the calculated length.

- Application Rollers: A series of driven and pressure rollers (often rubber or PU coated) laminate the film smoothly onto the profile surfaces. Advanced systems can apply film to multiple faces simultaneously (e.g., 1, 2, 3, 4, or even 6 sides for complex shapes) using multiple applicator heads.

- Operator Interface: Typically features an HMI (Human-Machine Interface) touchscreen for setting parameters like profile dimensions, desired film overlap, application speed, and viewing system diagnostics.

3. Illustrative Technical Specifications

Automated profile protection lines can be configured for diverse requirements. Below are typical parameters; however, specifications vary based on the exact model and application needs.

- Machine Type: Automatic Protective Film Applicator (with optional Bagging Integration)

- Applicable Profiles: Aluminum Extrusions (Architectural, Industrial, Automotive, etc.)

- Profile Dimensions Handled:

- Width: Typically 20mm - 400mm (customizable)

- Height: Typically 10mm - 300mm (customizable)

- Length: Commonly 1000mm - 7000mm (or longer, specified by user)

- Applicable Film Types: PE, PVC, PET protective films with various adhesive types

- Film Thickness Range: 30 - 150 microns

- Film Application Speed: Up to ~20 meters per minute (profile dependent)

- Application Surfaces: 1 to 6 sides (model dependent)

- Control System: PLC with HMI Touchscreen

- Power Requirements: Typically 380V/415V, 50/60Hz, 3-Phase (installation specific)

- Compressed Air: 6-8 bar (if pneumatic components used)

- Compliance Potential: CE Standards, ISO 9001

Disclaimer: The parameters listed above are representative examples for this category of equipment. They do not necessarily match the specific machine shown in the video 100%. For precise specifications tailored to your operational needs, please contact us directly.

4. Operational Benefits and User Experience

Implementing an automated film application line delivers tangible advantages:

- Enhanced Throughput: Significantly faster than manual application, enabling continuous flow and higher production output.

- Consistent Quality: Guarantees uniform film tension, precise edge alignment, and bubble/wrinkle-free application, drastically reducing surface damage risk.

- Reduced Labor Costs: Frees up personnel from tedious and repetitive manual taping tasks, allowing reallocation to higher-value activities.

- Material Savings: Accurate length cutting minimizes film wastage compared to manual guesswork.

- Improved Safety: Reduces direct manual handling of long or heavy profiles and interaction with cutting tools.

- Process Integration: Can be seamlessly linked with extrusion saws, cooling tables, aging ovens, and downstream packaging systems like stackers or bundlers.

5. Key Applications for Aluminum Profile Protection

Protecting the surface finish is critical across various sectors utilizing aluminum extrusions:

- Architectural & Construction: Preserving the finish of window frames, door profiles, curtain wall systems, facades, and railings during transport and installation.

- Industrial & Engineering: Protecting structural elements, machine frames, heat sinks, conveyor components, and precision parts.

- Automotive & Transportation: Maintaining the appearance of trim parts, roof rails, running boards, and structural components.

- Furniture & Interior Design: Ensuring decorative profiles, cabinet frames, and display fixtures remain flawless.

- Solar Energy: Protecting frames for photovoltaic panels during manufacturing and installation.

6. Customization and Further Information

These automated lines are highly adaptable. Customizations can include handling unique profile geometries, specific film types, varying line speeds, and integration with existing plant control systems.

For more details on aluminum profile packaging solutions, visit: Fhopepack Aluminum Packaging Solutions

To discuss your specific profile protection requirements or inquire about the system shown, please contact us:

info@fhopepack.com