Coil packing machines are integral to Industry 4.0 by automating and streamlining the end-of-line packaging process for coiled materials. They enhance efficiency, ensure consistent quality, reduce waste and labor costs, and integrate with smart factory systems through IoT and data analytics, contributing significantly to overall smart manufacturing.

In today’s rapidly evolving manufacturing landscape, the principles of Industry 4.0 and smart manufacturing are no longer futuristic concepts but essential strategies for maintaining competitiveness and efficiency. For industries dealing with coiled materials – from steel and aluminum to wires and cables – the ability to efficiently and reliably pack and prepare these products for shipment is paramount. Coil packing machines, once considered standalone equipment, are now emerging as critical components in the interconnected ecosystem of Industry 4.0. Understanding their role within this paradigm shift is crucial for manufacturers looking to optimize their operations and embrace the future of manufacturing.

The Foundational Importance of Coil Packing

| Before exploring the Industry 4.0 integration, it’s vital to recognize the inherent importance of effective coil packing itself. Coiled goods, by their nature, are susceptible to damage throughout the supply chain. Inadequate packing can lead to a cascade of problems, impacting product quality, safety, and ultimately, the bottom line. | Issue | Consequence | Impact |

|---|---|---|---|

| Physical Damage | Scratches, dents, deformation during handling and transit | Unusable material, costly rework, customer dissatisfaction | |

| Corrosion | Exposure to moisture and environmental elements | Material degradation, rejections, financial losses | |

| Safety Hazards | Unsecured coils shifting during transport | Worker injury, damage to cargo and equipment, legal liabilities | |

| Inefficient Handling | Manual packing processes are slow and inconsistent | Bottlenecks, increased labor costs, reduced throughput |

Proper coil packing directly mitigates these risks. It ensures that valuable materials are protected from physical damage and environmental factors, arrive at their destination in optimal condition, and are handled safely throughout their journey. This foundational benefit is amplified when coil packing machines are integrated into the smart manufacturing framework of Industry 4.0.

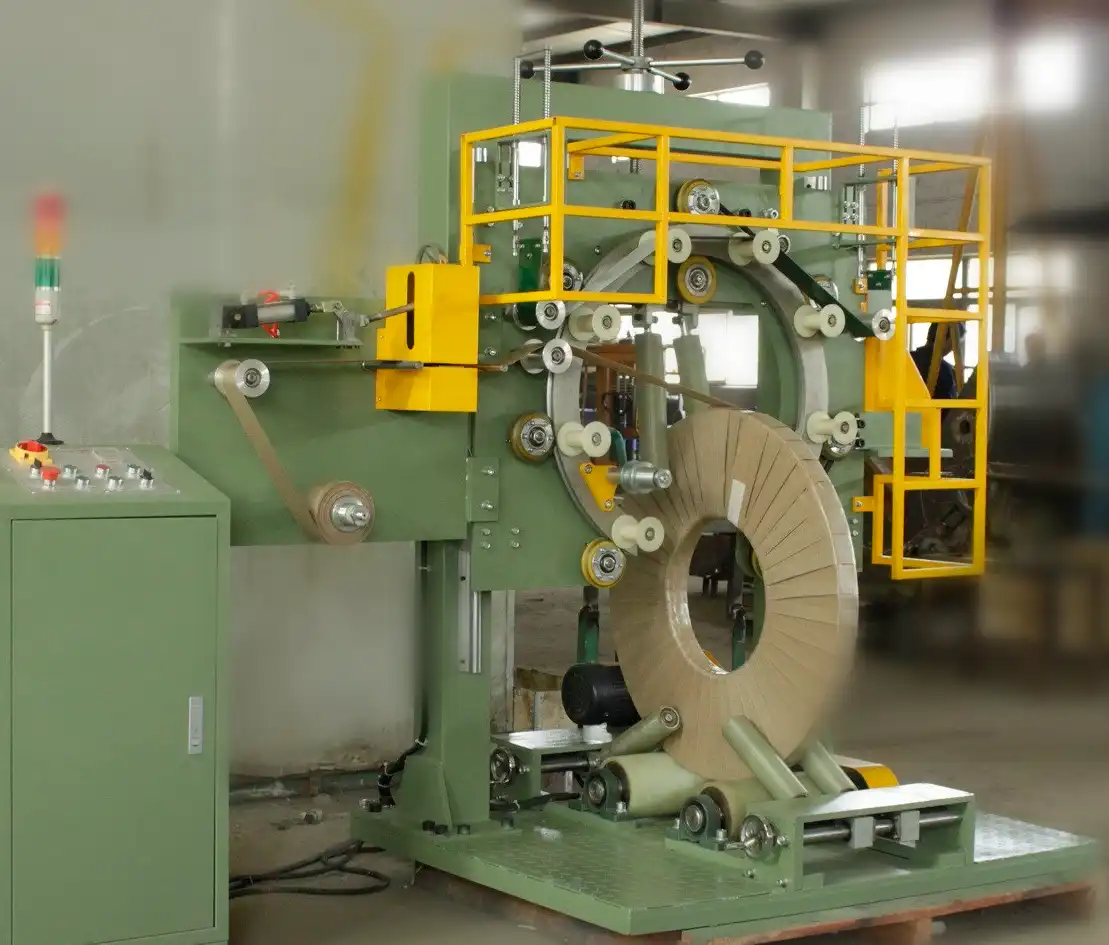

Coil Packing Machines: More Than Just Wrapping

Modern coil packing machines are sophisticated systems far beyond simple wrapping devices. They represent an automation evolution designed to optimize every stage of the end-of-line packaging process. A comprehensive system typically comprises several interconnected components, each playing a crucial role:

- Wrapping Machines: These machines apply protective layers of film, paper, or other materials around the coil. This barrier shields against abrasion, moisture, dust, and other potential contaminants. Advanced wrappers offer adjustable tension and overlap control for tailored protection.

- Strapping Machines: Strapping machines secure the wrapped coil using steel or plastic straps. This ensures the wrapping remains tight, the coil is stable, and it can withstand the rigors of transportation and handling. Automated strapping provides consistent tension and placement, crucial for load stability.

- Labeling Systems: Integrating labeling systems directly into the packing line ensures accurate and immediate identification of each coil. Labels can include product codes, batch numbers, customer-specific information, and even RFID tags for real-time tracking. This streamlines inventory management and traceability.

- Material Handling Equipment: Efficient material handling is integral to a high-throughput coil packing system. Conveyors, lifts, turntables, and robotic arms seamlessly move coils through each stage of the process, minimizing manual intervention and optimizing flow.

By combining these components into an integrated and automated system, manufacturers move far beyond basic packaging and create a streamlined, data-rich process ready for Industry 4.0 integration.Unlocking Industry 4.0 Benefits with Automated Coil Packing

The true power of coil packing machines is unleashed when they are incorporated into the broader context of Industry 4.0. This integration leverages advanced technologies to transform coil packing from a necessary task into a strategic asset, driving significant improvements across manufacturing operations.

| Benefit | Description | Industry 4.0 Enabler |

|---|---|---|

| Enhanced Efficiency | Automated systems operate at significantly higher speeds than manual packing, boosting throughput. | Automation, Robotics |

| Consistent Quality | Machines ensure uniform wrapping, strapping, and labeling, eliminating human variability and errors. | Sensors, Programmable Logic Controllers (PLCs) |

| Reduced Labor Costs | Automation minimizes manual labor requirements, freeing up personnel for higher-value tasks. | Automation, Robotics |

| Improved Safety | Automated systems handle heavy coils, reducing the risk of worker injuries associated with manual handling. | Robotics, Automation, Safety Sensors |

| Data-Driven Optimization | Modern machines generate data on performance, material usage, and potential issues, enabling process refinement. | IoT Sensors, Cloud Computing, Data Analytics, Machine Learning |

| Predictive Maintenance | Real-time data monitoring allows for proactive maintenance, minimizing downtime and extending equipment life. | IoT Sensors, Machine Learning, Predictive Analytics |

| Sustainable Practices | Optimized material usage and energy-efficient equipment contribute to environmental responsibility. | Smart Sensors, Energy Management Systems, Sustainable Materials |

| Seamless Integration | Coil packing systems can be integrated with WMS and ERP for real-time inventory and order management. | Industrial IoT, Cloud Platforms, API Integrations |

Industry 4.0 Technologies in Action:

- IoT Sensors for Real-time Monitoring: Integrating IoT sensors into coil packing machines provides a wealth of real-time data. Sensors can monitor wrapping tension, strap tightness, cycle times, energy consumption, and equipment vibration. This data is transmitted to a central system for analysis and visualization, providing operators and managers with immediate insights into system performance.

- Machine Learning for Process Optimization: The data generated by IoT sensors becomes invaluable when coupled with machine learning algorithms. These algorithms can analyze vast datasets to identify patterns, optimize machine settings for different coil types, predict potential maintenance needs before failures occur, and even automatically adjust packing parameters based on real-time conditions. This leads to continuous improvement and increased Overall Equipment Effectiveness (OEE).

- Robotics for Enhanced Flexibility and Automation: Collaborative robots (cobots) and industrial robots are increasingly being integrated into coil packing lines. Cobots can work alongside human operators, assisting with tasks like coil feeding or quality inspection. Industrial robots can handle heavier lifting and repetitive tasks with speed and precision. This robotic integration enhances flexibility, allowing for quicker changeovers and adaptation to varying coil sizes and packing requirements.

- Digital Twin Technology for Simulation and Training: Creating a digital twin of the coil packing system allows manufacturers to simulate process changes and optimize equipment layout in a virtual environment before implementing them in the physical world. This minimizes disruption and allows for risk-free experimentation. Digital twins also provide a powerful tool for operator training, allowing personnel to become proficient in system operation and troubleshooting in a safe, virtual setting.

Sustainability and the Smart Coil Packing System

Industry 4.0 also emphasizes sustainability, and coil packing machines are contributing to greener manufacturing practices. Modern systems are designed to:

- Optimize Material Usage: Precision controls and automated processes minimize waste of wrapping and strapping materials.

- Utilize Recyclable Materials: Manufacturers are increasingly opting for eco-friendly packaging materials like recyclable plastics and paper-based wraps, readily compatible with modern coil packing equipment.

- Improve Energy Efficiency: Newer machines incorporate energy-efficient motors and optimized pneumatic systems, reducing energy consumption and the associated carbon footprint.

- Facilitate Sustainable Logistics: By ensuring compact and secure packing, coil packing machines contribute to optimized loading and transportation, reducing fuel consumption and emissions across the supply chain.

The Future is Integrated and Intelligent

The evolution of coil packing machines within Industry 4.0 is ongoing and dynamic. Looking ahead, we can anticipate even greater integration and intelligence:

- Artificial Intelligence (AI) Driven Automation: AI will play an increasingly significant role in optimizing coil packing processes autonomously. AI-powered systems will be capable of self-adjusting to variations in coil dimensions, material properties, and environmental conditions, ensuring peak performance without manual intervention.

- 5G Connectivity for Enhanced Data Flow: The wider deployment of 5G networks will enable faster and more reliable data transmission from coil packing machines. This will facilitate real-time monitoring, remote diagnostics, and seamless communication with other smart factory systems.

- Augmented Reality (AR) for Maintenance and Operation: AR technology will empower maintenance personnel and operators with real-time, on-demand information. AR overlays can provide step-by-step maintenance instructions, equipment diagnostics, and operational guidance directly in the user’s field of view, streamlining maintenance and reducing downtime.

- Advanced Sustainable Materials: Continued innovation in sustainable packaging materials will further drive the development of coil packing systems capable of handling and processing these new eco-friendly options efficiently.

Conclusion: Coil Packing Machines – Cornerstones of Smart Manufacturing

Coil packing machines are no longer isolated pieces of equipment but are evolving into intelligent, interconnected components within the Industry 4.0 paradigm. By automating processes, ensuring quality, reducing waste, and integrating seamlessly with smart factory systems, they play a vital role in enhancing efficiency, sustainability, and competitiveness for manufacturers dealing with coiled materials. As Industry 4.0 continues to advance, coil packing machines will remain at the forefront, driving innovation and enabling manufacturers to meet the evolving demands of a smart, connected, and efficient future. Embracing these advanced systems is not just an operational upgrade; it’s a strategic investment in the future of manufacturing.