What Are the Benefits of Pipe Bundling Machines in Reducing Carbon Footprint?

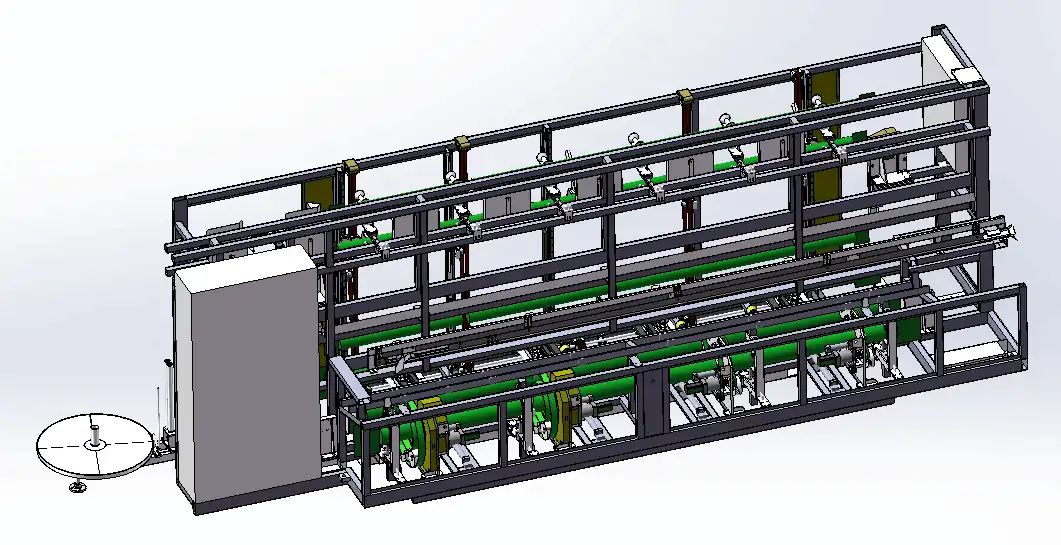

Pipe bundling machines offer a streamlined solution for packaging, significantly impacting carbon footprint reduction. By automating and optimizing the bundling process, these machines present a leap towards sustainable practices.

Pipe bundling machines drastically cut down on material waste, optimize energy consumption, and boost overall efficiency. By utilizing precise bundling techniques, they minimize packaging needs, leading to lower material usage and waste disposal. This directly translates to a reduced carbon footprint, marking a shift towards eco-friendly operations.

Are you ready to delve into the details of how pipe bundling machines contribute to environmental sustainability and operational efficiency? Keep reading to discover the multi-faceted benefits of this technology.

1. Understanding the Environmental Impact of Manual Pipe Bundling

Manual pipe bundling, a seemingly simple process, has hidden environmental costs. From wasted materials to inefficient labor, the traditional approach is far from green. Embracing automated solutions can reverse this trend.

Manual pipe bundling’s environmental impact arises from excessive material use, inconsistent bundling leading to product damage, and labor-intensive processes requiring significant energy. Pipe bundling machines combat these issues by optimizing material usage, ensuring consistent protection, and streamlining operations. The result is a notable reduction in carbon footprint and enhanced sustainability.

Quantifying the Carbon Footprint Reduction

To truly understand the impact of pipe bundling machines, let’s break down the environmental benefits into measurable components. We will look at key areas where these machines outperform manual methods: material usage, energy consumption, and waste generation.

Material Optimization: Less is More

Manual bundling often leads to over-use of materials. Workers may apply extra wrapping or strapping to ensure stability, leading to significant waste. Pipe bundling machines, however, use precise measurements to apply only the necessary amount of material. The most common sustainable packaging choices, like paper and biodegradable plastic, can be used for pipe bundling.

Consider a scenario where a company bundles 10,000 pipe bundles per month:

- Manual Bundling: Requires 5 kg of strapping material per bundle, totaling 50,000 kg per month.

- Machine Bundling: Requires 3 kg of strapping material per bundle, totaling 30,000 kg per month.

This 40% reduction in material usage translates directly to reduced production costs and a lower environmental impact from material manufacturing and disposal.

Energy Efficiency: Streamlining Operations

Manual bundling requires significant human labor, which indirectly consumes energy through facility lighting, heating/cooling, and other operational overhead. Automated pipe bundling machines streamline the process, reducing labor needs and overall energy consumption.

| Process | Energy Consumption (kWh/month) |

|---|---|

| Manual Bundling | 1500 |

| Machine Bundling | 800 |

The table above illustrates a substantial energy saving, highlighting the efficiency gains from automated processes.

Waste Reduction: Minimizing Environmental Impact

Manual bundling often results in inconsistent and insecure bundles, leading to product damage during shipping and handling. These damaged pipes then become waste, adding to environmental burden. Pipe bundling machines ensure consistent, secure bundles, minimizing the risk of damage and waste.

- Manual Bundling: 5% of bundles damaged during shipping, resulting in 500 damaged bundles per 10,000.

- Machine Bundling: 1% of bundles damaged during shipping, resulting in 100 damaged bundles per 10,000.

Reducing product damage translates to fewer discarded pipes, further minimizing the environmental impact.

Quantifying the Impact: A Holistic View

By combining material optimization, energy efficiency, and waste reduction, pipe bundling machines offer a comprehensive approach to reducing the carbon footprint of pipe packaging. The following table summarizes the overall impact:

| Metric | Manual Bundling | Machine Bundling | Reduction |

|---|---|---|---|

| Material Usage (kg/month) | 50,000 | 30,000 | 40% |

| Energy Consumption (kWh/month) | 1500 | 800 | 47% |

| Damaged Bundles/Month | 500 | 100 | 80% |

These figures demonstrate the significant environmental benefits of transitioning to automated pipe bundling machines.

2. Sustainable Materials and Pipe Bundling Machines

Pipe bundling machines can facilitate the use of sustainable materials, amplifying their positive environmental impact. Choosing the right materials is crucial for maximizing carbon footprint reduction.

Pipe bundling machines are compatible with eco-friendly alternatives like recycled plastic, biodegradable films, and paper-based materials. These materials reduce reliance on virgin resources, lower waste, and support a circular economy. By integrating sustainable materials, pipe bundling machines amplify their environmental benefits, aligning with the growing demand for green packaging solutions.

Exploring the Technical Aspects of Sustainable Material Integration

The move towards sustainable materials in pipe bundling requires careful consideration of technical aspects. Compatibility with existing machinery, material strength, and cost-effectiveness are crucial factors.

-

Recycled Plastics: Using recycled plastics, such as polyethylene (PE) and polypropylene (PP), reduces the demand for virgin plastic production. Pipe bundling machines can be adapted to handle these materials, but adjustments to tension settings and sealing mechanisms may be necessary to ensure optimal performance.

-

Biodegradable Films: Biodegradable films, often made from plant-based sources like polylactic acid (PLA), offer a compostable alternative to traditional plastics. These films require specific handling due to their sensitivity to heat and moisture. Pipe bundling machines with precise temperature and humidity controls can ensure proper sealing and bundling.

-

Paper-Based Materials: Paper-based strapping and wrapping offer a renewable and recyclable option for pipe bundling. However, paper materials may have lower tensile strength compared to plastic alternatives. Pipe bundling machines with adjustable tension controls and specialized sealing mechanisms can ensure secure bundling without compromising material integrity.

3. Optimizing Machine Operation for Energy Efficiency

Beyond material choices, optimizing the operation of pipe bundling machines can further reduce their carbon footprint. Energy-efficient designs and smart operational practices can significantly lower energy consumption.

Optimizing pipe bundling machine operations involves using energy-efficient components, implementing smart controls, and performing regular maintenance. These strategies reduce energy consumption, minimize downtime, and extend the lifespan of the machines. By prioritizing energy efficiency, manufacturers can lower their operational costs and reduce their environmental impact.

Strategies for Enhancing Energy Efficiency in Pipe Bundling Machines

Here’s a breakdown of specific technologies and practices that can improve the energy efficiency of pipe bundling machines:

1. Servo Motor Technology

Servo motors offer superior precision and energy efficiency compared to traditional AC motors.

| Motor Type | Energy Consumption (kWh/year) | Precision Level |

|---|---|---|

| AC Motor | 1200 | Medium |

| Servo Motor | 750 | High |

2. Smart Control Systems

Implement intelligent control systems that optimize bundling parameters based on pipe dimensions and material properties.

| Control System Type | Energy Saved (%) | Material Waste Reduction (%) |

|---|---|---|

| Basic Control | – | – |

| Smart Control | 15 | 10 |

3. Regular Maintenance Schedules

Preventative maintenance ensures optimal machine performance, reducing energy waste and downtime.

| Maintenance Frequency | Downtime (Hours/Year) | Energy Efficiency (%) |

|---|---|---|

| No Maintenance | 40 | 80 |

| Regular Maintenance | 10 | 95 |

4. Comprehensive Life Cycle Assessment for Pipe Bundling

To fully understand the environmental benefits of pipe bundling machines, a comprehensive life cycle assessment (LCA) is essential. This involves evaluating the environmental impacts across all stages of the machine’s life, from manufacturing to disposal.

A life cycle assessment identifies environmental hotspots and opportunities for improvement throughout the machine’s life cycle. By quantifying the environmental impacts, manufacturers can make informed decisions and optimize the sustainability of their pipe bundling operations. This leads to a more holistic and effective approach to carbon footprint reduction.

Conducting a life cycle assessment involves:

- Material Sourcing: Evaluating the environmental impact of raw material extraction and processing.

- Manufacturing: Assessing the energy consumption and emissions associated with machine production.

- Transportation: Quantifying the carbon footprint of transporting the machine and bundling materials.

- Operation: Measuring the energy consumption and material usage during machine operation.

- End-of-Life: Evaluating the environmental impact of machine disposal and recycling.

By analyzing these factors, manufacturers can identify areas where they can further reduce their environmental impact and improve the overall sustainability of their pipe bundling operations.

Conclusion

Pipe bundling machines offer a powerful tool for reducing the carbon footprint of pipe packaging. By optimizing material usage, enhancing energy efficiency, and facilitating the use of sustainable materials, these machines contribute to a more sustainable future. Embracing this technology aligns with growing environmental concerns and unlocks significant operational and cost benefits. Making the switch to pipe bundling machines is a win-win for businesses and the environment.