How can you diagnose and identify the root causes of uneven wrapping?

Uneven wrapping can disrupt your production flow and lead to costly defects. Identifying the root causes quickly is essential to maintaining high wrapping quality and minimizing downtime.

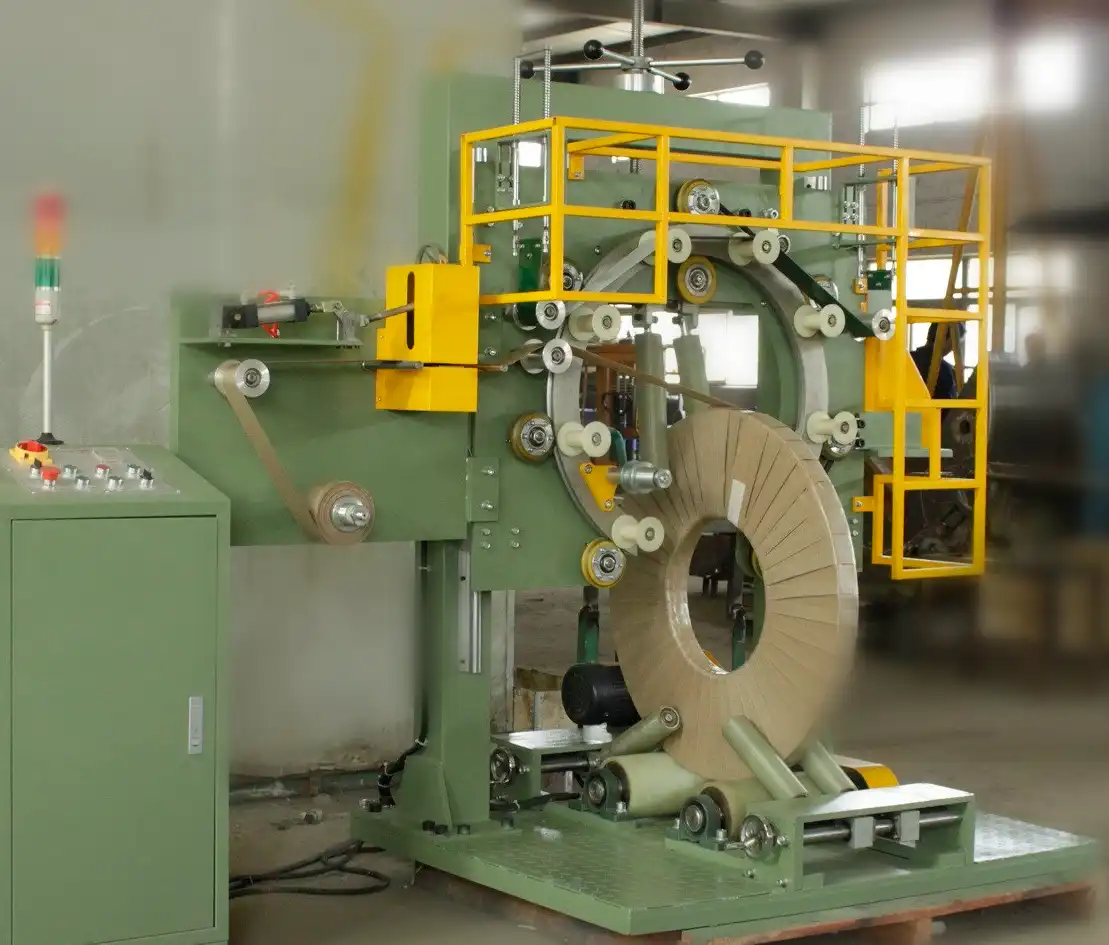

Diagnosing uneven wrapping involves a systematic approach to troubleshoot coil packing machines effectively.

Understanding the Causes of Uneven Wrapping

To effectively diagnose uneven wrapping in coil packing machines, it’s important to understand the common causes. These issues can stem from mechanical, electrical, or operational factors. Here’s a detailed look:

| Cause | Description | Impact |

|---|---|---|

| Tension Control Issues | Inconsistent tension settings can lead to loose or overly tight wraps. | Wrapping quality varies |

| Machine Calibration | Improper calibration of the machine’s sensors and actuators affects wrapping. | Increased packing defects |

| Material Inconsistencies | Variations in coil size or material can disrupt the wrapping process. | Uneven wraps and potential damage |

| Wear and Tear | Regular use can cause parts to wear out, affecting machine performance. | Maintenance needs and downtime |

| Software Glitches | Errors in the machine’s control software can lead to irregular wrapping patterns. | Unpredictable wrapping quality |

By analyzing each potential cause, you can pinpoint the specific issue affecting your coil packing machines and take appropriate corrective actions.

What solutions can be implemented to prevent uneven wrapping in coil packing machines?

Preventing uneven wrapping ensures consistent packaging quality and reduces operational costs. Implementing effective solutions is key to achieving smooth and reliable coil packing processes.

Implementing solutions such as regular maintenance, precise calibration, and advanced tension control can prevent uneven wrapping in coil packing machines.

Effective Strategies to Ensure Even Wrapping

Preventing uneven wrapping involves a combination of proactive maintenance, accurate machine settings, and quality materials. Here are some strategies to consider:

| Solution | Implementation | Benefits |

|---|---|---|

| Regular Machine Maintenance | Schedule routine checks and servicing of moving parts and sensors. | Reduces wear-related issues |

| Precise Calibration | Calibrate sensors and actuators regularly to maintain accurate settings. | Ensures consistent wrapping tension |

| Advanced Tension Control Systems | Upgrade to tension control systems that automatically adjust tension levels. | Minimizes human error and variability |

| High-Quality Materials | Use uniform coil materials to prevent inconsistencies during wrapping. | Enhances overall wrapping quality |

| Staff Training | Train operators on best practices for machine setup and troubleshooting. | Improves operational efficiency |

Implementing these solutions can significantly enhance wrapping quality and operational reliability. For instance, adopting advanced tension control systems allows for automatic adjustments, reducing the risk of human error and ensuring uniform wraps. Additionally, regular maintenance not only prolongs the lifespan of your coil packing machines but also prevents unexpected breakdowns that can disrupt your production schedule.

Investing in high-quality materials and comprehensive staff training further supports the consistency and efficiency of your wrapping processes. By focusing on these areas, you can achieve a higher level of precision and minimize packing defects, ultimately leading to better product quality and customer satisfaction. For more information on advanced coil packing machines, visit our website.

Conclusion

Effective troubleshooting of uneven wrapping in coil packing machines involves understanding the root causes, utilizing proper diagnostic techniques, and implementing targeted solutions. By addressing these factors, manufacturers can enhance wrapping consistency, reduce material waste, and ensure the smooth operation of their packing machinery.