The Role of Coil Cradles in Maintaining Coil Shape During Transport

Steel coils, vital to countless industries, are notoriously challenging to transport. Imagine a massive roll of steel, weighing tons, shifting precariously on a truck bed. The threat of damage to the coil and danger to everyone on the road is real. But what if there was a simple, yet crucial device that could mitigate these risks, ensuring coils arrive at their destination in perfect condition?

Coil cradles, also known as coil racks, are specialized frames designed to securely hold and stabilize steel coils during transportation. They prevent coils from rolling, shifting, and deforming, thus maintaining their shape and quality while ensuring safety on the road. This article delves into the essential role of coil cradles in preserving coil integrity during transit.

Let’s explore how these seemingly simple devices are indispensable for safe and efficient coil transport.

Enhancing Coil Integrity: The Core Function of Coil Cradles

Have you ever witnessed the aftermath of improperly secured cargo? For steel coils, the consequences can be severe – deformed shapes, damaged edges, and compromised material integrity. This not only leads to material waste but also potential safety hazards during unloading and further processing.

Coil cradles are engineered to combat these issues head-on. Their primary function is to provide a stable and supportive base for steel coils, preventing them from losing their shape during the rigors of transportation. By cradling the coil, these racks distribute weight evenly and minimize stress points that could lead to deformation. Utilizing coil cradles is a proactive measure to safeguard the quality and usability of steel coils, right from the moment they leave the manufacturing facility until they reach their final destination.

To fully appreciate the impact of coil cradles, it’s essential to understand the technical aspects that contribute to their effectiveness. Let’s break down the key features and design considerations.

Technical Deep Dive: How Coil Cradles Work

Coil cradles are not just simple frames; they are meticulously designed pieces of equipment that leverage engineering principles to ensure optimal coil protection. Several factors contribute to their ability to maintain coil shape:

- Material and Construction: Typically constructed from heavy-gauge steel, coil cradles are built to withstand immense weight and pressure. Welded joints and robust frame structures ensure durability and prevent structural failure during transit.

- Cradle Design: The curved or V-shaped design of the cradle conforms to the coil’s shape, providing maximum contact and support. This design minimizes pressure points and evenly distributes the coil’s weight across the cradle.

- Spindle or Arm Integration: Many coil cradles incorporate spindles or arms that extend upwards along the coil’s edges. These act as barriers, preventing lateral movement and further securing the coil within the cradle.

- Base Stability: A wide and stable base is crucial for preventing tipping and ensuring the entire cradle remains stable on the trailer bed. Some designs include features for bolting or securing the cradle to the trailer for enhanced stability.

To illustrate the impact of these features, consider the following comparison:

| Feature | Coil Cradle | Traditional Blocking (Wood) |

|---|---|---|

| Support | Contoured cradle, even weight distribution | Point contact, uneven pressure |

| Stability | Spindles/arms, secure frame | Limited lateral support, prone to shifting |

| Durability | Heavy-gauge steel, long lifespan | Wood can compress, split, wear out quickly |

| Coil Shape Maintenance | Excellent, minimizes deformation | Less effective, higher risk of damage |

| Safety | Engineered design, secure coil containment | Reliant on proper placement, less secure |

This table highlights the clear advantages of using engineered coil cradles over traditional methods. The precise design and robust construction translate directly to better coil shape maintenance and enhanced safety.

Minimizing Damage: Protecting Coils from Transit Trauma

Steel coils are susceptible to various forms of damage during transportation. Bumps, vibrations, sudden stops, and even regular road conditions can contribute to coil deformation, edge damage, and surface scratches. Such damage not only affects the coil’s aesthetic appearance but can also compromise its structural integrity and functionality.

Coil cradles act as a protective barrier, significantly reducing the risk of transit-induced damage. By securely holding the coil and preventing movement, they minimize friction, impact, and stress that could lead to deformation or surface damage. This protective function is crucial for maintaining the coil’s quality and reducing material waste and rework.

Beyond the general protective benefits, coil cradles offer specific advantages in preventing common types of coil damage. Let’s explore these in detail.

Targeted Protection: Addressing Specific Damage Risks

Coil cradles are designed to address the most prevalent threats to coil integrity during transport. Here’s how they provide targeted protection:

- Preventing Coil Rolling and Shifting: The primary risk during transport is coil movement. Cradles, with their contoured design and spindle options, effectively immobilize coils, preventing them from rolling off the trailer or shifting and colliding with each other.

- Reducing Edge Damage: Coil edges are particularly vulnerable. Cradles lift the coil off the direct trailer bed surface and prevent coils from rubbing against each other or trailer walls, minimizing edge crimping and damage.

- Minimizing Deformation from Strapping Pressure: Over-tightening straps directly on coils can cause deformation. Cradles distribute strapping pressure across the cradle frame, preventing direct pressure on the coil itself and reducing deformation risk.

- Absorbing Vibrations and Impacts: While not suspension systems, the solid construction of coil cradles provides a degree of dampening against road vibrations and minor impacts, further protecting the coil from subtle but cumulative damage.

By addressing these specific damage risks, coil cradles provide comprehensive protection, ensuring coils arrive at their destination in optimal condition. This reduces material waste, minimizes processing delays due to damaged materials, and ultimately contributes to cost savings and improved efficiency.

Safety First: Coil Cradles and Transportation Security

Transporting steel coils is inherently risky. The sheer weight and awkward shape of coils pose significant safety challenges. Improperly secured coils can shift, roll, or even fall off trailers, causing catastrophic accidents, injuries, and fatalities. Safety is paramount in coil transportation, and coil cradles play a vital role in enhancing security.

Coil cradles are designed with safety as a core principle. By providing a secure and stable containment system for steel coils, they drastically reduce the risk of load shifting and accidents during transit. This not only protects drivers and other motorists but also ensures compliance with safety regulations and reduces liability risks.

Let’s examine the specific safety advantages offered by coil cradles and how they contribute to safer coil transport operations.

Safety Advantages: Ensuring Secure Coil Transport

Coil cradles contribute to transportation safety in several critical ways:

- Enhanced Load Stability: By cradling the coil and preventing movement, coil cradles significantly improve load stability. This reduces the risk of the trailer becoming unbalanced, especially during turns or sudden maneuvers.

- Reduced Risk of Coil Roll-Off: The spindle or arm features in many cradles act as physical barriers, preventing coils from rolling off the sides of the trailer, even in emergency braking situations.

- Clear Load Securement Points: Coil cradles provide designated and robust points for securing straps or chains. This ensures proper tie-down procedures can be followed, maximizing the effectiveness of load securement.

- Improved Driver Confidence: Knowing that coils are securely cradled and stabilized provides drivers with greater confidence and reduces stress associated with hauling heavy and potentially hazardous loads.

The safety benefits of coil cradles extend beyond preventing accidents. They also contribute to a safer working environment for loading and unloading personnel and reduce the risk of damage to handling equipment. Investing in coil cradles is an investment in safety and responsible material handling practices.

Versatility and Efficiency: Expanding the Role of Coil Cradles

While primarily designed for transport, coil cradles offer versatility that extends beyond over-the-road hauling. They can be effectively used in various material handling scenarios, contributing to improved efficiency and organization throughout the coil lifecycle.

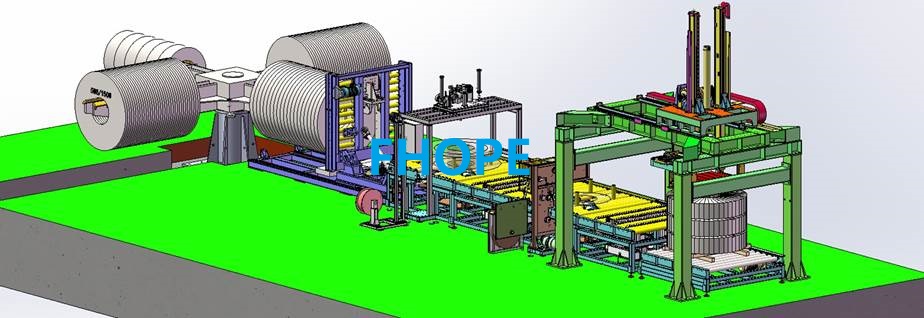

Coil cradles are not limited to transportation; they can also be used for in-plant material handling, temporary storage, and even as part of automated handling systems. Their robust design and coil-securing capabilities make them adaptable to diverse operational needs, maximizing their value and contributing to streamlined workflows.

Beyond transportation, coil cradles prove their worth in various applications:

- In-Plant Material Handling: Coil cradles can be used with forklifts or cranes to move coils safely and efficiently within manufacturing facilities, warehouses, and storage yards.

- Temporary Storage: Cradles provide a stable and organized storage solution, preventing coils from rolling and maximizing space utilization, especially in temporary storage areas.

- Integration with Automated Systems: Coil cradles can be designed for seamless integration with automated coil handling systems, facilitating robotic loading, unloading, and transfer processes.

- Coil Unpacking and Processing: In some applications, coils can even be processed directly from the cradle, eliminating the need for additional handling steps and improving workflow efficiency.

Coil cradles represent a versatile material handling solution that extends beyond transportation. Their adaptability and robust design make them valuable assets in optimizing coil handling processes throughout the supply chain. Their use contributes to improved safety, efficiency, and overall operational effectiveness in any industry dealing with steel coils.

Conclusion

In conclusion, coil cradles are indispensable tools for maintaining coil shape during transport. Their engineered design directly addresses the challenges of handling heavy, cylindrical loads, ensuring both product integrity and transportation safety. By investing in coil cradles, businesses prioritize quality, efficiency, and, most importantly, the safety of everyone involved in the material handling process. For businesses seeking reliable coil packing line solutions, coil cradles are not just accessories; they are essential components of a responsible and effective material handling strategy.