In-Depth Analysis of Steel Wire Coil Packaging Technology, Production Process, and Automation Requirements

I. Executive Summary

This report provides a comprehensive study of steel wire coil packaging technology, delving into different steel wire production methods and analyzing their corresponding automation packaging requirements. The packaging of steel wire coils is a critical step in ensuring that the product maintains its original quality and performance during storage, transportation, and delivery. Research indicates that effective packaging significantly reduces the risks associated with physical damage and environmental factors (such as corrosion), and its importance is self-evident, especially for high-value and surface-sensitive steel wire products1.

With the increasing demands for efficiency, cost control, and product quality in the modern steel industry, packaging automation has become an irreversible trend2. Automated packaging systems can not only improve the speed and consistency of packaging operations but also effectively reduce labor costs and human errors. This report will analyze in detail how various steel wire production characteristics, such as diameter, coating type, coil weight, coil diameter, and production line speed, directly influence the design, selection, and operational requirements of automated packaging equipment3.

A key conclusion points out that steel wire coil packaging is not an appendage at the end of the production process but an organic component closely linked to and mutually influencing the steel wire production process. The production process determines the final characteristics of the steel wire, which in turn dictates specific packaging needs; advanced automated packaging technology is the core driver to meet these needs, enhance overall operational efficiency, and improve market competitiveness. Therefore, a comprehensive understanding and strategic planning of steel wire production, packaging, and automation requirements are crucial for steel companies to optimize their value chain, ensure product quality, control operating costs, and meet customer expectations.

II. Overview of Steel Wire Coil Packaging in the Modern Steel Industry

A. Importance and Objectives of Steel Wire Coil Packaging

Steel wire coil packaging refers to a series of measures and operational processes undertaken after steel wire production is completed, aimed at protecting it from various adverse effects during subsequent storage, transportation, and delivery. Its fundamental importance lies in maintaining the integrity, quality, and commercial value of the steel wire product until it reaches the final user.

The primary objective of steel wire coil packaging is to provide adequate physical protection. During transportation and handling, steel coils may encounter collisions, impacts, and vibrations, all of which can lead to product damage1. Effective packaging can cushion external forces, preventing steel wire deformation, scratching, or breakage. Secondly, environmental protection is another core objective. Steel wire, especially cold-rolled or coated wire, is extremely sensitive to environmental factors. Humidity in the air, rain, and temperature fluctuations experienced during transportation (such as sea shipping through different climate zones) can cause condensation, leading to corrosion1. Packaging materials and methods need to effectively isolate these environmental factors to prevent steel wire from rusting or coating damage.

Furthermore, maintaining the market applicability and original performance of the steel wire is also a key purpose of packaging1. Packaging ensures that the steel wire remains in its good condition upon arrival at the customer, meeting usage requirements in terms of both appearance and mechanical properties. At the same time, proper packaging also contributes to the efficiency and safety of handling, storage, and transportation4. For example, winding steel wire onto suitable reels or ensuring stable bundling facilitates operations by equipment like forklifts and cranes and ensures stability during stacking and transportation. Especially for high-value products, such as steel wire with special coatings or precise dimensions, the importance of packaging is even more prominent, as any minor damage can cause its value to drop significantly1. Therefore, many companies package products immediately after manufacturing1.

B. Common Challenges: Protecting Value and Ensuring Safety

Despite the clear objectives of steel wire coil packaging, numerous challenges are faced in practice, stemming from the characteristics of the steel coil itself and the complex logistics environment.

Firstly, steel wire coils are usually very heavy and bulky, which brings great difficulties to handling and packaging operations5. Improper handling or insecure packaging can easily cause steel coils to roll or shift during transportation, leading to safety accidents and potentially damaging the product itself. Secondly, steel wire, especially untreated carbon steel, is highly susceptible to corrosion. Moisture and oxygen in the atmosphere are the primary causes of rust, and if packaging cannot provide effective moisture-proof and airtight protection, corrosion is difficult to avoid5. In addition, the circular or irregular shape of steel coils also increases the difficulty of stable packaging5.

Inappropriate packaging can directly lead to serious consequences. Studies show that improper packaging increases the risk of steel coil damage by 40%5. This damage includes not only physical deformation and corrosion but also can affect the mechanical properties of the steel wire, thereby reducing product quality and even rendering it unusable. The resulting direct economic losses (such as product scrap, rework) and indirect losses (such as production schedule delays, decreased customer satisfaction) are considerable. Data shows that returns due to defects can increase operating costs by as much as 20%5.

Safety risks are another severe challenge. Insufficiently packaged steel coils may fall or shift during handling and transportation, posing a serious threat to operators5. According to statistics, approximately 30% of packaging-related accidents are caused by insufficient packaging and handling operations5. Even minor edge scratches or dents can lead to the entire coil of steel wire being scrapped, especially in subsequent drawing or forming processes, where these defects are magnified6.

These challenges combined make steel wire coil packaging a link requiring a high degree of expertise and precision. Companies must seek a balance between protecting product value, ensuring operational safety, and controlling packaging costs, which drives the demand for more advanced packaging materials, technologies, and automation solutions.

III. Steel Wire Production: The Basis for Packaging Requirements

The final characteristics of steel wire, such as diameter, strength, surface condition, and coating type, are determined by its production process. These characteristics directly affect the choice of subsequent packaging methods and the design of automated equipment. Therefore, understanding the main manufacturing processes and variations of steel wire is a prerequisite for discussing corresponding packaging automation requirements.

A. Overview of Key Manufacturing Processes

Steel wire production is a multi-step complex process, starting from the selection and processing of raw materials, up to the formation of finished products with specific specifications and performance.

1. Raw Material Preparation and Smelting:

For stainless steel wire production, it’s necessary to precisely proportion alloying elements like chromium, nickel, carbon, manganese, and iron-based materials7. These mixtures are melted in a highly controlled environment (usually an electric arc furnace), forming a liquid alloy7. For stainless steel wire rod, the typical production route is the "electric arc furnace + AOD refining furnace + continuous casting" process8. The molten steel is then cast into semi-finished products like billets or ingots.

2. Hot Rolling:

Billets or ingots pass through a series of rolling mills at high temperatures, gradually reducing their cross-sectional size to form wire rods7. The hot rolling process helps refine the steel’s grain structure and improve its mechanical properties. Wire rod is the raw material for subsequent drawing operations, typically ranging from 5.5 mm to 30 mm in diameter8.

3. Annealing and Pickling:

Hot-rolled wire rod or wire undergoing drawing may require annealing treatment. Annealing involves heating the steel wire to a specific temperature and holding it for a period to relieve internal stress, soften the material, improve plasticity, and further refine the crystal structure7. Depending on the cooling method, the wire rod may be pickled after annealing or only pickled8. Pickling is done to remove surface oxide scale.

4. Cold Drawing:

This is the core process for steel wire forming. The wire rod passes through one or a series of progressively smaller drawing dies at room temperature, reducing its cross-section while increasing its length7. Cold drawing significantly increases the steel wire’s strength, dimensional accuracy, and surface finish.

- For steel wire with a diameter greater than 0.8 mm, "dry drawing" is usually employed, which may require pre-coating treatments like phosphating on the wire rod before drawing to carry drawing lubricants (such as calcium-based or sodium-based drawing soaps)8.

- For fine steel wire with a diameter less than 0.8 mm, "wet drawing" is often used. In this case, the raw material is typically fully annealed redrawing wire, using diamond drawing dies and performing the process in oil-based lubricants8.

5. Surface Treatment/Coating:

Depending on the final application, steel wire may require additional surface treatments. For instance, oxide scale removal through pickling, and passivation to form a protective oxide film to enhance corrosion resistance7. Galvanizing (such as hot-dip galvanizing2) and polymer coatings are also common surface treatments aimed at providing additional anti-corrosion protection or improving appearance7. Modern steel coil coating lines are highly automated, significantly increasing coating speed and efficiency9.

B. Process Differences for Different Steel Wire Products

The core manufacturing steps described above are adjusted and optimized according to the type and final use of the required steel wire product, resulting in various types of steel wire with unique packaging needs.

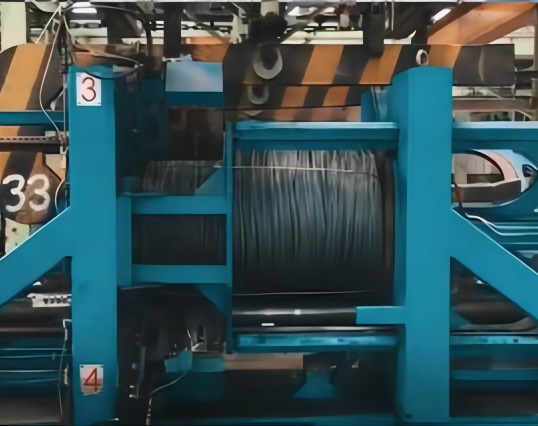

- Carbon Steel Wire: Depending on the carbon content, it is divided into low-carbon steel wire (e.g., for binding, construction) and high-carbon steel wire (e.g., for springs, PC steel strands)10. Production may involve specific annealing and drawing schedules to achieve desired tensile strength and ductility. Hot-rolled wire rod is a common starting material10.

- Stainless Steel Wire: Producing stainless steel wire requires precise control of alloy composition7 and strict management during melting, drawing (fine-gauge wire often uses wet drawing8), and annealing processes to ensure excellent corrosion resistance and mechanical properties7. The surface finish of stainless steel wire is crucial for its application, so packaging requires special attention to prevent scratching and contamination.

- Galvanized Steel Wire: A galvanizing process (e.g., hot-dip galvanizing2) is added after drawing. The zinc coating provides excellent anti-corrosion properties to the steel wire, but careful handling is required during post-treatment and packaging to protect the integrity of the zinc layer and prevent "white rust".

- PC Steel Strand (Prestressed Concrete Steel Strand): This is a high-strength steel wire product, typically produced through specialized drawing and stress-relieving processes. Its packaging must maintain its specific coiling form and protect it from any damage that could compromise its structural integrity11. Specific requirements often exist for coiling and reeling12.

- General Coated Steel Wire: The coating process itself13 adds a surface to the steel wire that needs protection. The type of coating (e.g., polymer, specific paint) determines its sensitivity to scratching, chemicals, and temperature, which directly influences the choice of packaging materials and methods.

Every step in the production process, from the selection of alloy composition to the control of drawing passes, the formulation of heat treatment schedules, and the application of surface coatings, profoundly affects the final physical, chemical, and mechanical properties of the steel wire. For example, stainless steel wire processed through multiple fine drawing passes and bright annealing has an extremely high surface finish, and its packaging requirements for scratch and contamination prevention are far higher than those for ordinary hot-rolled coarse steel wire8. Similarly, steel wire treated with hot-dip galvanizing, while enhancing corrosion resistance, also brings new demands for protecting the coating. Packaging must consider moisture resistance and avoidance of contact with certain substances to prevent the formation of "white rust"2. These characteristics imparted by the production process are the fundamental basis for selecting appropriate packaging solutions and designing automated packaging systems.

Furthermore, the stability and quality control level of the upstream production process have a direct impact on the efficiency and feasibility of downstream automated packaging. For example, if the steel wire diameter fluctuates significantly during the drawing process, or the uniformity of the coating process is poor9, the subsequent automated packaging equipment (such as automatic strapping machines, wrapping machines) will require more complex sensors and adaptive adjustment mechanisms, and may even be unable to achieve efficient and stable automated operation. The complexity of robotic handling systems also increases when dealing with irregularly shaped or inconsistently sized steel coils3. Conversely, strict dimensional control and high-quality surface treatment during production can provide a more ideal and consistent product for downstream packaging automation, thereby simplifying the design of automated systems, reducing their complexity and cost, and improving overall operational efficiency. This indicates that investment in and optimization of upstream production processes can bring significant benefits to the successful implementation of downstream packaging automation.

IV. Comprehensive Analysis of Steel Wire Coil Packaging Methods and Materials

The packaging methods and material choices for steel wire coils are diverse, aiming to balance protective effects, cost, operational convenience, and the increasingly important requirement of sustainability. From traditional manual operations to modern automated production lines, the adopted technologies and materials have distinct characteristics.

A. Manual and Semi-Automated Packaging Technologies

Despite the clear trend towards automation, manual and semi-automated packaging technologies still have applications in specific circumstances, especially in scenarios with lower output or varying product specifications.

- Manual Packaging: This includes manually wrapping, covering, and strapping steel wire coils. For instance, operators use plastic film or non-woven fabric to wrap steel coils, then secure them with wire or strapping tape4. For production lines with low output, equipment like cantilever cranes may be used to assist manual stacking and handling of steel coils14.

- Semi-Automated Packaging: These devices combine manual operation with mechanical automation to improve efficiency and consistency. For example, a semi-automatic steel wire coil wrapping machine, where the operator is responsible for feeding, positioning, and starting the equipment, and the machine automatically completes the wrapping and film cutting actions15. Such equipment is typically used for basic organization, weighing, and wrapping of steel coils.

B. Advanced Packaging Materials: Properties and Applications

The development of modern packaging material technology provides superior protection solutions for steel wire coils, focusing on anti-corrosion, moisture resistance, impact resistance, and suitability for automated application.

- VCI (Volatile Corrosion Inhibitor) Paper and Film: These materials release vapor-phase corrosion inhibitor molecules to form a protective layer on the metal surface, effectively preventing rust1. They are particularly important for corrosion-sensitive products like cold-rolled coils, galvanized coils, and coated steel wire. VCI paper can incorporate scrim reinforcement or polyethylene coating to enhance strength and moisture resistance16. VCI film can be stretch film or shrink film, providing sealed protection16. ZERUST16 and IPG17 are well-known suppliers of such materials.

- Plastic Film (Stretch Film, Shrink Film): Provides physical protection, moisture resistance, and cargo securement. High-strength, weather-resistant films effectively prevent scratches and moisture intrusion4. Can be applied manually or via automatic wrapping machines18.

- Non-woven Fabric: Often used in conjunction with plastic film to provide steel coils with stronger abrasion and impact protection, particularly effective during handling and transportation4.

- Steel Strapping: Provides secure bundling and support for heavy steel coils or palletized cargo19. Requires specialized tensioners and sealers. Signode20 and Lonyou21 are representative suppliers of steel strap.

- PET (Polyester) Strapping: As an alternative to steel strap, PET strap offers advantages such as impact resistance, UV resistance, and good weatherability, with smooth edges for safer handling. Many PET straps are made from recycled materials, making them more environmentally friendly22.

- Wooden Pallets/Reels/Crates: Used for carrying, transporting, and facilitating the handling of steel coils. For large diameter wire ropes, wooden reels are preferred due to their larger inner diameter, which better protects the wire structure1. Wooden packaging for export usually requires ISPM 15 standard heat treatment.

- Metal I-Beams/Reels: Provide higher safety and convenient access to steel wire; typically undergo multi-layer wrapping protection after winding4.

- Plastic Spools (Bobbins): Primarily used for packaging small batches or retail-use steel wire, making it convenient for users4.

- Edge Protectors: Used to protect the edges of steel coils from damage during strapping or impact5.

C. Comparative Evaluation: Advantages, Disadvantages, and Suitability

Various packaging methods and materials have their own strengths and weaknesses in terms of protective performance, cost, operational convenience, automation compatibility, and environmental impact.

- Plastic Film Packaging: Simple, low cost, suitable for short-distance transportation and low-risk scenarios, easy to unpackage. Disadvantage is insufficient protection against sharp objects4.

- Non-woven Composite Packaging: Provides superior protection, significantly reducing handling damage. Disadvantage is relatively high cost, and may not be suitable if the customer requires using steel reels for subsequent production4.

- Metal I-Beam Packaging: High safety, convenient for cutting steel wire. However, for large diameter steel wire, the small inner diameter of metal reels may damage the wire structure4.

- Wooden Reel Packaging: Due to their larger inner diameter, more suitable for large diameter steel wire, effectively protecting the steel wire structure. However, may not be suitable for all situations, and cost and weight are relatively high4.

- Plastic Spool Packaging: Suitable for small batch, lightweight steel wire, convenient for retail. But its sturdiness is not as good as metal reels4.

- Small Coil (Bagged) Packaging: Saves space, reduces transportation costs, suitable for retail and secondary uses (such as clothesline). Disadvantage is weakest protection4.

- Cardboard Box Packaging: Can enhance brand image, professional appearance. But relatively uncommon, may not be practical or cost-effective for large-volume industrial packaging4.

- VCI Paper vs. VCI Film: VCI paper is usually biodegradable23, while VCI film (especially stretch film) can provide more complete sealing and barrier properties24. Both are more cost-effective than traditional rust preventative oil coating and can be reused to some extent25.

- Steel Strapping vs. PET Strapping: Steel strap has the highest strength but poses safety hazards (sharp edges) and has greater environmental impact in production and recycling. PET strap is safer, has better weatherability, is often made from recycled materials, and is more cost-effective in many applications, with a smaller environmental footprint22.

Table 1: Comparison of Steel Wire Coil Packaging Methods and Materials

| Packaging Method/Material | Primary Protective Performance (Moisture-proof, Anti-corrosion, Impact Resistance) | Typical Application (Wire Type, Transport Conditions) | Automation Compatibility | Relative Cost | Main Advantages | Main Disadvantages | Environmental Considerations (Recyclability, Biodegradability) |

|---|---|---|---|---|---|---|---|

| Single Layer Plastic Film | Medium moisture-proof, Low impact resistance, Not anti-corrosion | Short distance, Low risk, Ordinary carbon steel wire with low appearance requirements | Low-Medium | Low | Simple, Low cost, Easy to unpackage | Insufficient protection against sharp objects or multiple transfers | PE/PP film is recyclable, but recycling rate is limited |

| Plastic Film + Non-woven Fabric | Good moisture-proof, Medium-High impact resistance, Not anti-corrosion | Medium-long distance transport, Steel wire with certain surface protection requirements | Low-Medium | Medium | Significantly better protection than single layer film | Increased cost, Not suitable if customer requires steel reel | PE/PP film is recyclable, non-woven fabric (partially) recyclable |

| VCI Paper Wrap | Good moisture-proof, Good anti-corrosion, Low impact resistance | Steel wire requiring corrosion protection (cold-rolled, galvanized, alloy steel), Long-term storage or sea transport | Medium | Medium | Effective anti-corrosion, Partially biodegradable | Physical protection relatively weak, needs to be combined with other materials | VCI paper is recyclable, partially biodegradable |

| VCI Film Wrap (incl. Stretch/Shrink) | Excellent moisture-proof, Excellent anti-corrosion, Medium impact resistance | Same as VCI paper, especially suitable for products requiring sealed packaging | Medium-High | Medium-High | All-around anti-corrosion and moisture protection, Airtight packaging possible | Higher cost than ordinary film, Some VCI additives may affect recycling | PE/PP based VCI film is recyclable, partially biodegradable |

| Metal I-Beam + Multi-layer Wrap | Excellent moisture-proof, Excellent anti-corrosion, High impact resistance | High-value, Heavy weight, Steel wire requiring repeated access, such as welding wire, special alloy wire | Medium-High | High | Excellent protection, Convenient access, Reel is reusable | Reel cost is high, Small inner diameter may damage large diameter steel wire | Metal reel is recyclable, packaging materials depend on specifics |

| Wooden Reel + Wrap | Good moisture-proof, Medium anti-corrosion (with VCI), High impact resistance | Large diameter wire ropes, cables, etc., to avoid small inner diameter reel damage to structure | Low-Medium | Medium-High | Protects integrity of large diameter steel wire structure | Reel is heavier, cost is higher, requires ISPM15 treatment (export) | Wood is recyclable/biodegradable, packaging materials depend on specifics |

| PET Strapping | – (Used for securement and reinforcement) | Strapping of various steel coils, pallet securement, especially suitable for replacing some steel strap applications | High | Medium | Safe (no sharp edges), Weather resistant, Impact resistant, Partially made from recycled materials, Recyclable | Strength limit is below steel strap, not suitable for extremely heavy bundling | Recyclable, partially made from recycled materials |

| Steel Strapping | – (Used for securement and reinforcement) | Bundling of heavy, super heavy steel coils, applications requiring high strength | High | Medium-High | Extremely high strength | Operational safety risks (sharp edges, recoil), High energy consumption for production and recycling, Prone to rust and contaminate product | Recyclable, but recycling process has high energy consumption |

From the analysis above, it is evident that there is no single "perfect" packaging solution applicable to all situations. Factors such as the type of steel wire (e.g., high carbon steel, stainless steel, galvanized wire), value, diameter, final use, transportation distance and conditions, specific customer requirements, and budget all collectively determine the most suitable combination of packaging methods and materials4. For example, for low-risk ordinary steel wire transported over short distances, simple plastic film packaging may suffice4; but for high-value stainless steel wire requiring long-distance sea transport and highly sensitive to corrosion, a complex system combining VCI materials, multi-layer wrapping, and robust reels or pallets may be necessary1.

In the material selection process, there is often a trade-off between cost, protective performance, operational safety, and environmental impact. Taking strapping as an example, while steel strap has the highest strength, its sharp edges pose a safety threat to operators, and its environmental footprint during production and recycling is relatively large; PET strapping, while providing sufficient strength, is safer to handle, is often made from recycled materials, is more cost-effective in many applications, and has a smaller environmental footprint22. Similarly, VCI paper has environmental advantages due to its biodegradability23, but VCI film may perform better in providing an airtight barrier24. This trade-off means companies must comprehensively consider their priorities and external environment (such as regulatory requirements) when making decisions.

It is worth noting that to cope with complex risks, effective steel wire coil packaging often employs a "system" or "multi-layer" approach, rather than relying on a single material1. For example, steel wire on a metal I-beam might first be wrapped with VCI film, followed by a layer of non-woven fabric for physical cushioning, and finally an outer layer of stretch film for securement and dust protection. While this multi-layer protection strategy can significantly enhance protection, it also increases the complexity of packaging operations and the requirement for consistency. Completing such complex packaging manually is not only time-consuming and labor-intensive but also difficult to guarantee that each coil of product achieves the same packaging quality. This precisely highlights the important value of automated packaging in ensuring the correct, efficient, and consistent application of multi-layer packaging systems.

V. The Symbiotic Relationship Between Steel Wire Production and Packaging Automation

There is an inseparable link between the characteristics of steel wire production and the requirements for packaging automation. The production process determines the physical form, surface characteristics, and potential defects of the steel coil, which directly translate into specific requirements for the automated packaging system. Conversely, efficient automated packaging can promote smooth production flow and enhance overall operational efficiency.

A. Current Overview of Steel Wire Coil Packaging Automation Technology

Steel wire coil packaging automation technology has evolved from single-function equipment to highly integrated intelligent production lines, aiming to reduce manual intervention and improve packaging quality and efficiency.

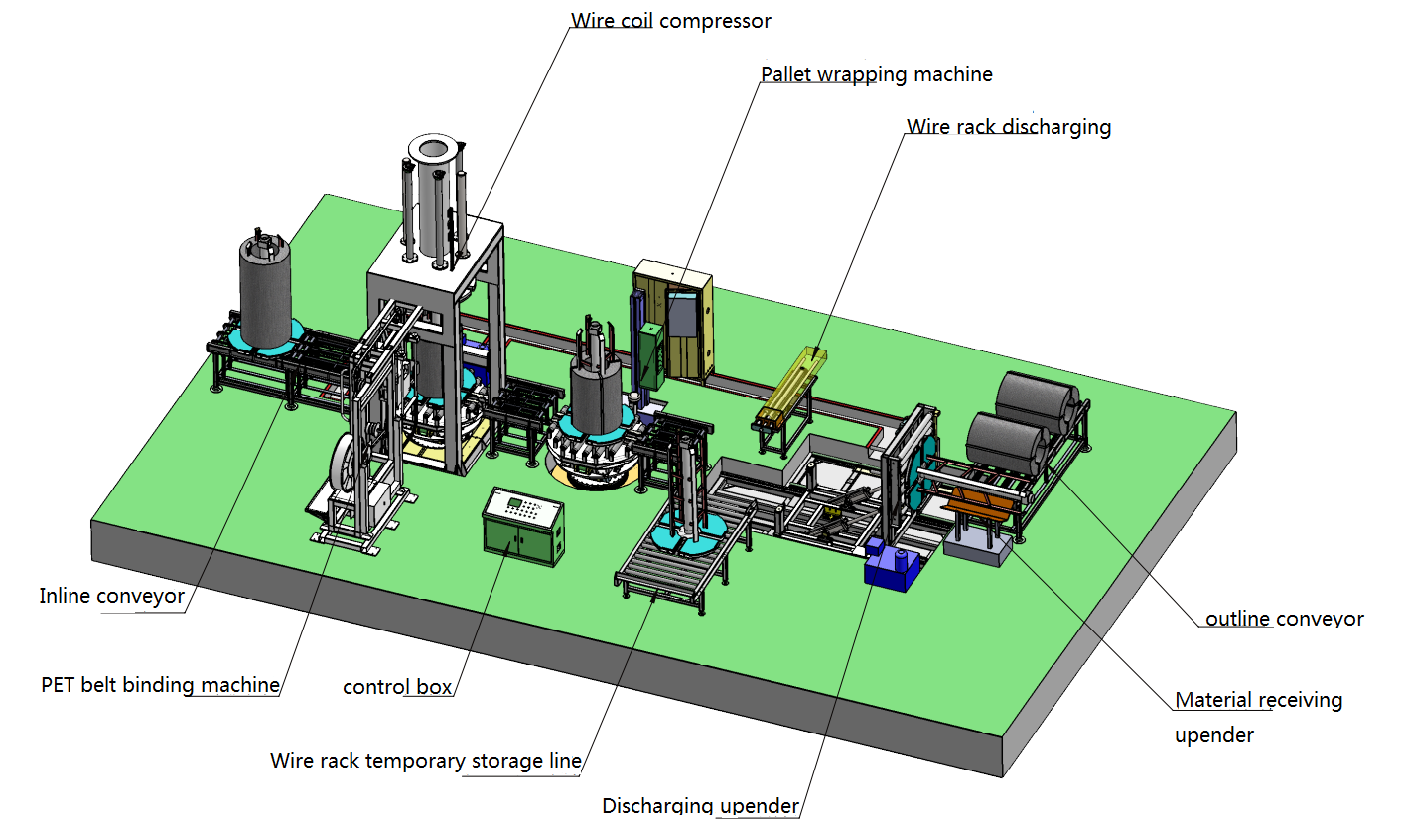

- Automated/Robotic Packaging Equipment: Automated systems specifically designed for steel wire coils can significantly reduce manual operations and enhance packaging consistency and professionalism2. These systems typically include automatic steel coil splitting lines, rewinding lines, coiling lines, and compaction and strapping lines for large coils (bulk) of galvanized steel wire2.

- Robotic Steel Coil Handling and Operation: Industrial robots equipped with advanced sensors and control algorithms can flexibly adapt to steel coils of different sizes, weights, and forms, achieving smooth and efficient grasping, transfer, and stacking throughout the packaging process3.

- Automated Material Application Systems: These systems can accurately dispense, cut, and apply various protective packaging materials, such as plastic wrapping film, cardboard, and strapping3. Steel coil wrapping machines are typical examples, capable of automatically completing circumferential and radial wrapping of steel coils18.

- Automated Uncoilers and Cutting/Welding Machines: Used for pre-processing products like steel wire ropes before packaging, such as precise cutting and end welding to prevent unraveling26.

- Integrated Packaging Production Lines: Seamlessly connecting packaging processes with upstream production stages and downstream inventory management and transportation systems to form end-to-end automated solutions3. For example, automatic wire drawing and packaging integrated lines can achieve full automation from drawing to final packaging15.

- Vision Systems and Sensor Technology: Widely used in defect detection, dimensional measurement, packaging integrity verification, etc., capable of real-time monitoring of packaging quality to ensure compliance with standards3.

- End-of-Line Solutions: Some specialized companies such as DRUIDS2 and Shanghai Jinglin (Shjlpack)18 provide complete end-of-line equipment and systems for steel wire coil packaging.

B. Impact of Steel Wire Characteristics on Automation Design

1. Steel Wire Diameter, Coil Diameter Size, and Weight Considerations

The physical dimensions of the steel wire (diameter) and the geometric parameters (inner diameter, outer diameter, width) and weight of the resulting steel wire coil are the primary basis for the mechanical design and capacity configuration of automated packaging systems.

Automated systems must be able to adapt to steel coils of different specifications3. Robotic systems typically utilize sensors and complex control algorithms to identify and handle steel coils of varying sizes and weights3. Steel wire diameter not only affects coil density and overall weight but also determines its flexibility, which in turn impacts the design of handling equipment (such as grippers, suction cups) and tension control during wrapping27.

For extremely fine diameter steel wire, such as 15-micrometer stainless steel wire used in electronic packaging28, its automated packaging system must possess extremely precise control capabilities. This includes highly sensitive tension control systems to prevent breakage or damage during winding or wrapping; precise robotic pick-and-place motions to avoid mechanical stress on fine wire; and possibly dedicated handling devices for small-sized spools (bobbins).

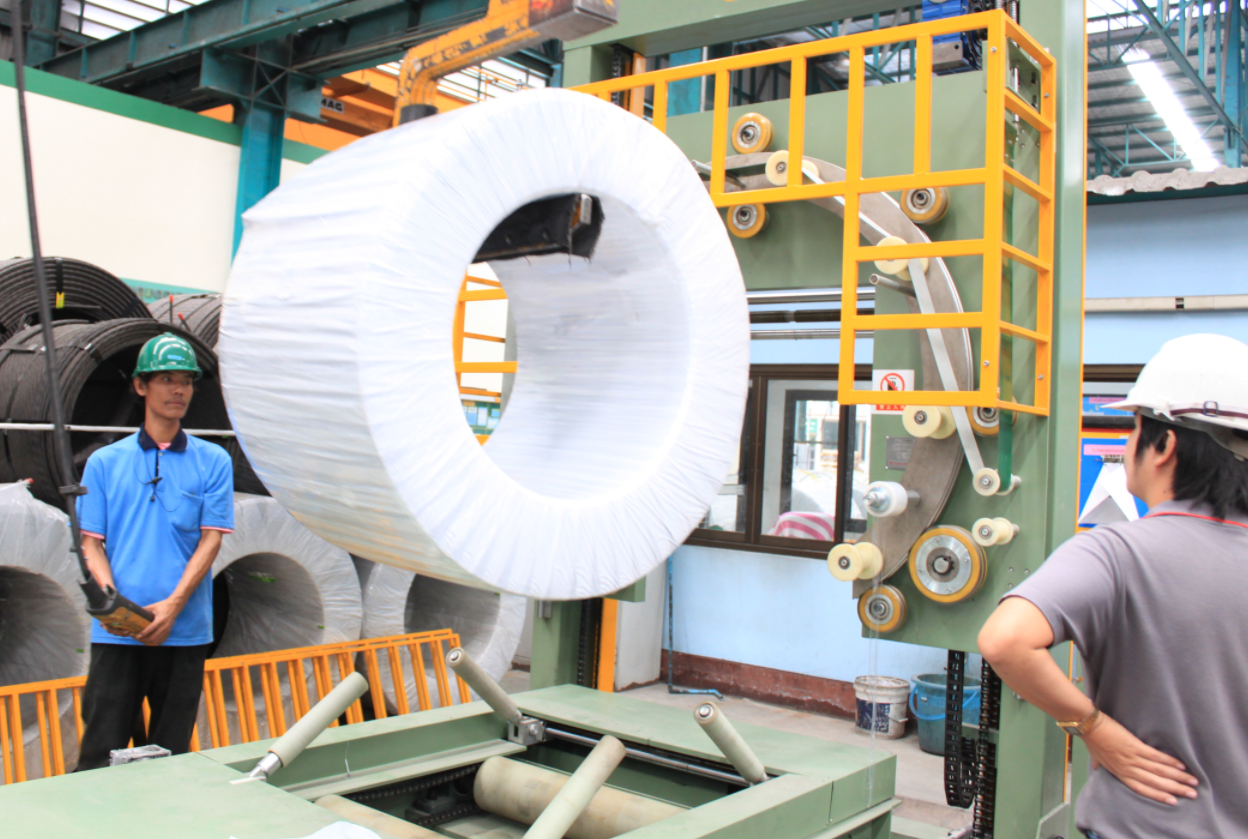

Conversely, heavy steel coils require robust and durable automated equipment, such as heavy-duty pallet inverters and steel coil tilters (vertical to horizontal or vice versa)5. Automatic strapping systems must also be capable of applying and withstanding significant strapping force to ensure the stability of heavy coils during transportation.

2. Coating Type (e.g., Galvanized, Polymer) and Surface Sensitivity Requirements

The coating on the steel wire surface (such as galvanized layer, polymer coating, paint layer) or special treatments (such as mirrored effect after bright annealing) provides specific functions and appearance to the steel wire but also makes its surface more sensitive to scratching, indentation, and contamination1. This places special demands on the design of automated packaging systems.

Parts of the automated equipment that directly contact the steel coil, such as rollers, guides, grippers, etc., must be made of non-abrasive materials, such as polyurethane coated rollers29, to prevent damage to the coating or steel wire surface during conveying and operation. For galvanized steel coils, to prevent "white rust" (zinc layer oxidation), automatic application of VCI (Volatile Corrosion Inhibitor) protective materials may be required during packaging1. Automated compaction and strapping equipment for large galvanized steel coils is also a specific automated solution2.

The type of coating also affects its curing or drying time and conditions13. If the coating process is closely linked to the packaging process, the start/stop and cycle time of the automated packaging line need to be coordinated with the status of the coating line (e.g., exit temperature of the curing oven, cleanliness of the steel wire surface). Packaging of coated products typically requires tight wrapping to prevent moisture intrusion and mechanical damage, which puts higher demands on the tension control of automatic wrapping film, overlap rate, and sealing quality1.

3. Production Line Speed, Output, and Integration Requirements

The processing capacity of the automated packaging system must match the output speed and volume of the upstream steel wire production line to avoid production bottlenecks and ensure smooth and efficient operation of the entire production process3.

For example, the downstream packaging stage of a high-speed wire rod block mill30 or steel coil coating line9 must possess correspondingly high-speed processing capabilities. High-volume packaging lines usually integrate automatic stacking and sorting systems to quickly and orderly handle large quantities of finished steel coils14.

Modern automated packaging systems increasingly emphasize integration with enterprise manufacturing execution systems (MES) and enterprise resource planning (ERP) systems3. This integration enables real-time tracking of production data (such as steel coil specifications, weight, production batch, packaging parameters, etc.), remote quality monitoring, dynamic inventory management, and precise statistics on packaging material consumption.

Furthermore, if a production line needs to process multiple specifications or types of steel wire products (i.e., there are product changeovers), the automated packaging system should also possess rapid and flexible product changeover capabilities to minimize downtime and adjustment time31.

C. Customized Automatic Solutions for Specific Steel Wire Categories

Automated solutions are also showing a trend towards customization to address the unique attributes and packaging requirements of different types of steel wire.

- Fine Diameter Stainless Steel Wire (e.g., for Electronics): This type of steel wire is typically extremely small in diameter (e.g., micron scale28), requires high cleanliness, and is very prone to breakage or deformation. Its automated packaging system needs:

- Extremely precise tension control system for winding and packaging processes.

- Gentle and precise robotic grasping and placement mechanisms.

- Dedicated small spool (bobbin) automatic loading/unloading and handling system.

- May need to operate in a cleanroom environment to prevent particulate contamination8.

- High Carbon Steel Wire (e.g., Spring Steel Wire, PC Steel Strand): These steel coils are typically dense, heavy, and have high requirements for shape retention. Automated solutions include:

- Robust steel coil handling, lifting, and tilting equipment.

- Efficient steel coil compaction and heavy-duty strapping (steel strap or high-strength PET strap) automatic strapping systems.

- For PC steel strand, specific requirements for coiling diameter control and robust protective wrapping are often needed to prevent unraveling and damage11. Automated production lines often integrate drawing, winding, and strapping processes32.

- Coated Steel Wire (e.g., Galvanized Wire, PVC Coated Wire): The core of automated packaging is protecting the integrity of the coating.

- High-Speed Production Lines (e.g., Wire Rod Production Lines): Require packaging automation systems with extremely high operating speed, continuity, and reliability.

- Typically integrate online weighing, automatic labeling, robotic palletizing, and other functions to form a complete unmanned packaging process30.

Table 2: Steel Wire Production Characteristics and Corresponding Packaging Automation Requirements

| Steel Wire Characteristic (Example) | Impact on Packaging | Key Automation Function Requirements |

|---|---|---|

| Fine Diameter (<0.8mm, e.g., for Electronics) | Easy to break, easy to deform, sensitive to tension, requires precise winding, contamination prevention | Precision coiler, Micro-tension control system, Gentle robotic grippers, Small spool automatic loading/unloading, Vision inspection system, Possible cleanroom compatible design |

| Large Diameter (>10mm, e.g., coarse structural wire) | Heavy weight, coil shape may be irregular, requires secure strapping | Heavy-duty steel coil handling robots/equipment, Automatic compactor, Heavy-duty strapping machine (steel strap/PET strap), Robust palletizing system |

| Galvanized Coating | Requires prevention of zinc layer scratching, prevention of "white rust" (wet storage corrosion) | Non-abrasive contact surfaces (e.g., polyurethane rollers), Automatic VCI anti-rust material application device, Precise stretch film wrapping (moisture-proof), Gentle handling system |

| Polymer Coating (e.g., PVC, PE) | Requires prevention of coating scratching, indentation, chemical contamination | Same as galvanized coating, may require specific temperature control (if packaging immediately follows coating curing), avoid packaging materials with chemical reactions to the coating |

| High Tensile Strength (e.g., PC steel strand, spring wire) | Large recoil force after coiling, requires strong fixation, shape retention | Heavy-duty automatic strapping machine (multi-strap bundling), Coil shape stabilization device, Precise length measurement and cutting, Robust reels or reel-less packaging forming |

| High Production Speed (e.g., high-speed wire rod line) | Packaging cycle must synchronize with production line, avoid bottlenecks, requires continuous stable operation | High-speed automatic wrapping machine, High-speed strapping machine, Online weighing and labeling system, Robotic fast palletizing system, Real-time data exchange with MES/ERP systems, Fast changeover capability |

| High Surface Finish Requirements (e.g., bright stainless steel wire) | Highly prone to scratching, contamination, affects appearance and performance | Ultra-smooth/non-contact conveying system, Automatic application of special protective film, Precise positioning and application of packaging materials, Controlled cleanliness of operating environment |

| Special Winding Requirements (e.g., layer winding, reel-less) | Requires precise control of wire arrangement and coil shape to meet specific applications or customer needs | Advanced servo-controlled layer winder, Special coiling and forming equipment, Robot-assisted unloading and transfer |

The increasing diversity of steel wire products (reflected in dimensions like diameter, coating, coil weight, coil diameter) and the scale of modern steel production (high speed, large volume) pose significant challenges to traditional manual packaging methods in terms of efficiency, consistency, and cost control. Automated packaging is not merely about reducing labor costs; it is a necessary choice for effectively managing this complexity and large-scale production. If a production line is very fast9 and product varieties are numerous, manual methods14 clearly cannot keep pace and cannot guarantee uniform standard packaging quality for every coil. Automated systems2, on the other hand, can bridge this gap through precise control and standardized operating procedures.

It’s worth noting that the trend towards packaging automation is not solely the automation of mechanical movements; it is increasingly reflected in the enhancement of data integration and intelligence. Integrating packaging lines with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems3 means that packaging operations are shifting towards a data-driven model. For example, the system can utilize sensors, vision systems, and machine learning algorithms for real-time quality monitoring and defect identification3, and optimize packaging material usage based on real-time data to achieve full traceability of the production process31. This smooth flow of information makes the packaging process more "intelligent" and flexible, capable of quickly responding to changes in production and the market.

For steel wire products with high surface sensitivity, such as coated steel wire, fine wire, or highly polished wire, the core constraint in automated design has shifted from simply pursuing speed and power to ensuring utmost gentle handling and a contamination-free environment. This requires automated systems to use special grippers, non-abrasive contact surfaces (e.g., polyurethane rollers29), and may even require packaging operations to be conducted in a controlled environment. These special requirements undoubtedly increase the complexity and initial investment for automated packaging systems for such products, but for ensuring product quality and meeting the demands of high-end markets, this investment is necessary and worthwhile.

VI. Economic Feasibility: Cost-Effectiveness and ROI Analysis of Packaging Automation

In the field of steel wire coil packaging, the decision to transition from manual or semi-automatic to fully automated production lines is largely dependent on economic feasibility assessment. This includes a comprehensive consideration of packaging material costs, labor and efficiency differences, and the return on investment (ROI) of automation.

A. Packaging Material Cost Comparison

The cost difference between different packaging materials is significant, and the level of automation also affects the final consumption of materials.

- VCI Materials: Compared to traditional rust preventive oils or coatings, VCI paper and VCI film are generally considered more cost-effective options because they reduce the need for repeated application, and metal components can be used directly without cleaning25. VCI stretch film can achieve the same protective effect by allowing the use of thinner gauge film (down-gauging), thus reducing material costs24.

- Strapping: Steel strapping is typically the most expensive option due to its high strength and durability. PET (polyester) strapping strikes a good balance between strength and cost, while PP (polypropylene) strapping is the most economical option for lighter applications22. Compared to steel strapping, PET strapping can save 30% or more in cost33.

- Impact of Automation on Material Costs: Automated packaging lines can optimize the use of packaging materials, for example, by precisely cutting packaging materials according to the actual size of the steel coil, rather than using materials of preset specifications, which can significantly reduce waste. Research indicates that automated packaging can reduce packaging material costs by up to 30%34. Although automated production lines have higher initial investment, their operating costs (including material consumption) can be lower35.

B. Labor, Efficiency, and Output: Manual vs. Automated Production Line Comparison

Automation’s impact on labor costs, production efficiency, and output is its core advantage.

- Labor Costs: Equipment such as automated steel coil wrapping machines significantly reduces labor costs by replacing a large amount of manual operation14. Analysis shows that automation can reduce labor costs by 40-60%36. For example, manual packaging may require 1 operator to package 1 coil per hour, while an automated production line can package over 20 coils per hour with 1 supervisor34. Some fully automated production lines even require only 1-2 supervisors34.

- Efficiency and Output: Automation significantly accelerates packaging speed (single coil packaging time can be reduced by up to 50% or more), thereby increasing overall output29. An automated packaging line can serve multiple slitting lines or production lines34. At the same time, automation also reduces human errors and ensures consistency in packaging quality5.

- Limitations of Manual/Semi-Automatic: Manual systems have low initial investment but high ongoing labor costs37. Semi-automatic systems offer a cost-effective compromise but their speed and degree of automation are still lower than fully automatic systems15.

C. Automation Investment: ROI Case Studies and Predictions

The return on investment for automated packaging systems is a key consideration for business decisions.

- ROI Realization Period: The payback period for automated packaging investment can typically be achieved within 1 to 3 years36.

- Factors Influencing ROI: Includes initial investment, operating costs (labor, materials, energy), labor savings, scalability, production batch size, packaging complexity, reduction in material waste, and reduction in transportation costs37.

- Case Studies: Numerous case studies demonstrate that automation leads to significant labor cost reductions, efficiency improvements, and improved quality consistency15. For example:

- Robotic palletizing systems have increased packaging speed and stacking accuracy while reducing labor15.

- Integrated automatic wire drawing and packaging lines have improved efficiency and reduced labor costs15.

- Even semi-automatic wrapping machines have improved productivity and reduced manual labor intensity15.

- Specific Benefit Data: Automated packaging can save up to 20 packaging positions, reduce transportation volume by up to 50% (by optimizing packaging box dimensions), reduce transportation costs by 32%, and reduce material costs by 30%38. Furthermore, by using advanced materials (often applied by automated equipment) and automated packaging, returns due to defects can be reduced by 20% to 30%5.

Table 3: ROI Metrics for Automated Steel Wire Coil Packaging Systems

| Automation Level | Typical Initial Investment Range (USD) | Main Savings Areas (Example) | Estimated ROI Period (Years, based on cases) | Other Qualitative Benefits (Example) |

|---|---|---|---|---|

| Semi-Automatic Wrapper/Strapping Machine | 10,000 – 50,000 | Reduction of 1-2 operators, Material waste reduced by 5-10%, Slight increase in output | 2 – 4 | Improved packaging consistency, Improved working environment |

| Modular Automatic Packaging Unit (e.g., Auto Wrapping) | 50,000 – 150,000 | Reduction of 2-4 operators, Material cost reduced by 10-20%, Output increased by 20-50%, Damage/return rate reduced by 5-10% | 1.5 – 3 | Improved packaging quality, Reduced human errors, Partially scalable |

| Full Automatic Packaging Line (incl. Robotic Handling/Palletizing) | 150,000 – 500,000+ | Reduction of 4-8+ operators, Material cost reduced by 20-30%, Output increased by 50-200%+, Damage/return rate reduced by 15-25%, Reduced transportation costs | 1 – 3 | High consistency, Significant improvement in safety, Good scalability |

The return on investment in packaging automation is not solely reflected in direct labor cost reduction. It is a multifaceted comprehensive benefit that includes savings in packaging materials (through precise control of usage and reduction of waste)34, significant improvements in production efficiency and output (through faster cycle times and continuous operation capability)36, reduced product damage and return rates due to improved packaging quality5, and decreased risk of occupational injuries and improved safety due to reduced manual handling of heavy objects5. Furthermore, automation ensures high consistency in packaging appearance and quality36, which is crucial for maintaining brand image and customer satisfaction. Therefore, when conducting ROI evaluation, all these direct and indirect economic benefits must be comprehensively considered.

Beyond mere cost savings, automated packaging lines also provide companies with numerous strategic advantages. For example, their inherent scalability makes it easier for companies to respond to fluctuations in market demand or future production growth3. Advanced automated systems typically have the capability to handle diverse products, flexibly adapting to the packaging needs of steel coils of different specifications and types3. Integrated quality control modules (such as vision inspection) can monitor the packaging process in real-time, ensuring products meet standards and thereby improving overall quality levels3. These strategic values, difficult to quantify simply but crucial for long-term competitiveness, further enhance the attractiveness of automation investment.

It is worth emphasizing that the optimization of packaging material costs is an indispensable part of automation benefits. Automated systems34 can not only apply packaging materials faster but, more importantly, can operate with extreme precision, for example, precisely cutting and wrapping film according to the actual size of each steel coil, thereby minimizing material overuse and waste (as mentioned in ^42, a 30% reduction in material costs). This dual improvement in speed and material efficiency constitutes a powerful impetus for companies to adopt automated packaging, especially in the context of volatile raw material prices and increasing pressure for sustainable development, its significance is even more prominent.

VII. Striving for Excellence: Industry Standards and Best Practices

In the field of steel wire coil packaging, adhering to recognized industry standards and implementing best practices is the foundation for ensuring product quality, enhancing operational efficiency, guaranteeing transportation safety, and meeting customer expectations. International and regional standards such as ASTM, ISO, and DIN provide important guidance frameworks for steel wire quality, packaging material performance, and packaging operational procedures.

A. Navigating ASTM, ISO, and DIN Steel Wire and Packaging Standards

- ASTM (American Society for Testing and Materials) Standards:

- ASTM A700: Standard Practices for Packaging, Marking, and Loading Methods for Steel Products for Domestic Shipment. This standard is a guiding document for the packaging and transportation of steel products in North America, with Part 9 specifically addressing the packaging requirements for wire rods, steel wires, and steel wire products39. Its goal is to achieve uniformity, simplicity, sufficiency, and economy in packaging and includes definitions of related terms.

- ASTM A641/A641M: Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire. This standard specifies the temper of galvanized steel wire, coating grades, and mentions packaging in coils, while citing ASTM A700 as the basis for packaging methods40.

- Other ASTM standards define the grades and performance requirements for different types of steel wire, such as ASTM A510 for bright ordinary industrial quality wire41, ASTM F2282 for cold heading quality wire41, and ASTM A313 for stainless steel spring wire42. The characteristics of these wires indirectly affect their packaging needs.

- ASTM D3953 specifies the technical requirements for flat steel strapping and seals39.

- ISO (International Organization for Standardization) Standards:

- ISO 9001 (Quality Management Systems), AS9100 (Aerospace Quality Management Systems), ISO 13485 (Medical Devices Quality Management Systems), etc., are quality system certifications held by some steel wire manufacturers, indicating that their production and processing processes comply with internationally recognized quality standards. This standardized management concept extends to the packaging stage43.

- ISO 14021:2016/Amd:2021 is used to regulate recycled content declarations44.

- Although specific ISO standards for steel wire coil packaging are not detailed in the research materials, companies obtaining ISO certification (such as product certification45 or as an ISO 9001:2015 certified processor and distributor46) generally implies their commitment to complying with quality specifications in all operations, including packaging.

- DIN (German Institute for Standardization) Standards:

- DIN standards are widely used to specify spool/reel dimensions, such as DIN 100, 125, 160, 200, 250, 355, 500, etc., detailing the bore diameter, width, outer diameter, and load capacity of the spool47. This ensures interchangeability of reels supplied by different vendors.

- DIN 17223-1 specifies the grade, surface condition, mechanical properties, and coil conditions (such as inner diameter, coil state, etc.) for spring steel wire48.

- EN 10270-1:2011 (European Standard, often related to or adopted by DIN standards) specifies the chemical composition and packaging forms (such as coils, Z-coils, plastic or metal reels, and their maximum load capacity) for hard drawn steel wire49.

- Regional Standards: For example, Ukraine’s DSTU 3058-95 (GOST 7566) is a national standard for packaging of metal products1.

B. Implementing Best Practices for Optimal Product Protection and Operational Efficiency

Based on adherence to the above standards, a series of proven best practices can further enhance the actual effectiveness of steel wire coil packaging.

- Material Selection and Use: Select robust, high-strength, weather-resistant films and edge protector materials5. Before using VCI materials, ensure the steel wire surface is clean and dry to maximize VCI effectiveness19.

- Correct Wrapping Techniques: Ensure strapping is secure but does not excessively constrict the product19. For reel packaging, use a multi-layer wrapping method for maximum protection4. Correctly use VCI paper or film, ensuring effective coverage and sealing.

- Palletizing and Crating: Use sturdy and appropriately sized pallets or crates. Use cushioning materials inside the crate to absorb impact19. Specifically designed pallets, such as saddle pallets or box pallets, can be used to better secure steel coils50.

- Promoting Automation Application: Automated systems can ensure consistency and accuracy in packaging operations, reduce human errors, and improve overall efficiency and packaging quality3.

- Training and Skill Development: Continuous training for operators on new materials, technologies, and correct operating procedures is crucial5. Awareness is needed to avoid complacency arising from routine operations6.

- Handling Operations: Minimize the number of lifts and transfers of steel coils to reduce the risk of damage6. Use appropriate handling equipment, such as forklifts, cranes, etc., and ensure proper operation19.

- Documentation and Compliance: Ensure all shipping documents are accurate and complete, and comply with relevant transportation regulations (such as weight limits, packaging requirements, safety standards)19.

Table 4: Overview of Key International Standards for Steel Wire Coil Packaging

| Standard Number (Example) | Issuing Body | Primary Focus Area | Key Relevance/Requirements for Steel Coil Packaging (Example) |

|---|---|---|---|

| ASTM A700 Section 9 | ASTM | General packaging, marking, and loading methods for steel wire, rod, and products (domestic shipment) | Bundling methods for steel coils, covering requirements, marking content, loading securement, etc. |

| ASTM A641/A641M | ASTM | Specification for zinc–coated (galvanized) carbon steel wire | Coil packaging of galvanized steel wire, referencing A700 for packaging methods |

| DIN [Specific reel standards, e.g., DIN 160, 200] | DIN | Dimensions for spools/reels for winding steel wire | Bore diameter, outer diameter, width, load capacity of reels, ensuring interchangeability and equipment compatibility |

| DIN 17223-1 | DIN | Technical conditions for spring steel wire | Requirements for inner diameter of spring steel wire coils, coil condition, surface quality |

| EN 10270-1 | CEN (Europe) | Hard drawn carbon spring steel wire | Specifies packaging forms for different wire types (coils, Z-coils, specific DIN reels) and their maximum weight |

| ISO 9001 | ISO | Quality management systems | Ensures packaging processes and materials meet quality control requirements, is part of overall quality assurance |

| ISO 14021 | ISO | Environmental labels and declarations – Self-declared environmental claims (Type II environmental labeling) | Regulates recycled content declarations, used for promoting the environmental characteristics of packaging materials |

| ISPM 15 | IPPC (International) | Guidelines for regulating wood packaging material in international trade | Export wood pallets, reels, crates, etc., must be heat treated or fumigated and marked to prevent the spread of forest pests |

Adherence to industry standards is not merely about meeting regulatory requirements; it is the fundamental framework for building product quality assurance, operational safety, and smooth domestic and international trade. For example, standardized DIN reel dimensions51 ensure that reels supplied by different vendors are compatible with customer unwinding equipment, while ASTM A70039 provides a common "language" and operational guidelines for packaging operations, aiming for "uniformity, simplicity, sufficiency, and economy." This uniformity is crucial for building an efficient supply chain, avoiding issues like handling difficulties, equipment incompatibility, and product damage caused by varied packaging.

However, standards themselves usually provide norms and goals, while best practices translate these norms into effective methods and processes in actual operation5. For instance, a standard might require the use of VCI materials for anti-corrosion, but best practice would further specify that before using VCI, the steel wire surface must be clean and dry for VCI to be most effective. This indicates that simply complying with the standard text is not enough; high-quality execution and attention to detail are key to ensuring effective packaging. Continuous employee training5 is an important guarantee for ensuring these best practices are executed correctly and consistently.

Despite increasing automation levels, in manual or semi-automatic packaging environments, and even in the daily operation and maintenance of automated equipment, the "human factor" still plays a vital role. Well-trained and responsible operators are the cornerstone of ensuring packaging quality and implementing best practices5. As cautioned in6, long-term repetitive operations are prone to complacency and negligence. Therefore, equally important as investing in advanced technology is continuous investment in human capital, through training, incentives, and building a positive safety and quality culture, to compensate for and strengthen the "soft links" in the packaging system.

VIII. Sustainable Packaging in the Steel Wire Industry

With growing global environmental awareness and increasingly stringent regulations, sustainability has become a crucial issue in the packaging sector of the steel wire industry. This includes focusing on the life cycle assessment (LCA) of packaging materials, increasing material recyclability, reducing waste, and promoting circular economy models.

A. Life Cycle Assessment (LCA) Perspective on Packaging Materials

Life Cycle Assessment (LCA) is a systematic method for evaluating the environmental impact of a product or service throughout its entire life cycle (from raw material extraction, production, transportation, use, to final disposal or recycling)52. Key LCA considerations include greenhouse gas emissions (carbon footprint), fossil energy consumption, water consumption, mineral resource consumption, and eco-toxicity53.

- Steel Itself: As the carrier of packaging or part of the packaging material (such as steel strap, metal reels), steel is highly recyclable and retains its intrinsic value during recycling52. LCA studies of metal packaging (such as steel cans) show that due to increased recycling rates and lightweight design, their greenhouse gas emissions have significantly reduced54.

- VCI Paper: Many types of VCI paper are biodegradable23. Some VCI paper products have obtained USDA BioPreferred certification, indicating that their raw materials are derived from renewable resources55.

- VCI Film: VCI film based on polyethylene (PE) or polypropylene (PP) is typically recyclable56. Some innovative VCI films are designed to be biodegradable under landfill conditions and do not decompose into harmful microplastics55. Additionally, VCI films containing recycled content (PCR – Post-Consumer Recycled) are also appearing on the market55.

- Stretch Film (Plastic): An LCA study comparing paper pallet stretch wrap (Advantage StretchWrap) with traditional plastic stretch film showed that paper packaging performed better in terms of greenhouse gas emissions, but across all 16 environmental impact categories, neither had an absolute advantage. For both materials, recycling is the best end-of-life treatment option57. Energy consumption during the production phase and material usage per pallet are key factors influencing their environmental footprint57.

- PET Strapping: Compared to steel strapping, PET strap generally has a lower environmental impact. Its production energy consumption is lower, it is often made from post-consumer recycled materials like plastic bottles, and it is itself recyclable22.

- Steel Strapping: While steel strap is recyclable, its production and recycling processes require significant energy consumption22.

B. Recyclability, Waste Reduction, and Circular Economy Initiatives

At the operational level, the steel wire industry is actively taking measures to improve the sustainability of packaging.

- Improving Recyclability:

- The recycling system for steel is relatively mature, and the recycling rate of packaging steel is also high (for example, the recycling rate of packaging steel in the US is between 58-62%)52.

- VCI film (PE/PP substrate) can be recycled in specialized plastic recycling facilities. Some VCI suppliers like ZERUST have launched closed-loop recycling programs (such as the ZeCycle program) to recycle used VCI packaging into new VCI film containing PCR content56.

- VCI paper is generally recyclable and biodegradable23.

- PET strapping and PP strapping are both highly recyclable, and PET strap often contains recycled content22.

- Reducing Waste:

- Minimizing material use through optimizing packaging design, such as adopting minimalist design, optimizing packaging dimensions to reduce empty space, and promoting reusable packaging solutions58. Automated packaging lines can also effectively reduce material waste by precisely cutting materials on demand34.

- Avoiding over-specification in design and inefficient purchasing, controlling material consumption from the source59.

- Improving changeover efficiency during the production process to reduce waste generated during changeovers59.

- Establishing effective waste stream management systems to classify and process different types of packaging waste to increase recycling value and efficiency59.

- Precisely controlling finished product length during production to avoid unnecessary short ends59.

- Promoting Circular Economy:

- Industry Initiatives: The steel and related industries are gradually shifting towards more environmentally friendly coating technologies (such as water-based coatings, powder coatings)58, and increasing numbers of companies are proactively adopting and promoting sustainable packaging practices60.

Table 5: Sustainability Overview of Common Steel Wire Coil Packaging Materials

| Material | Primary Raw Material Source (Virgin/Recycled Potential) | Recyclability (Yes/No/Limited, Depends on Facility) | Typical Recycling Rate (If known) | Biodegradability (Yes/No/Specific Conditions) | Main LCA Impact Highlights (Carbon Footprint, Water Consumption, Energy Consumption – Relative or Specific Data) | End-of-Life Management Options (Recycling, Landfill, Incineration, Composting) |

|---|---|---|---|---|---|---|

| VCI Paper | Virgin pulp, partially contains recycled fibers | Yes | Higher for paper generally, may differ after VCI treatment | Yes (Partially, depends on specific additives) | Usually lower carbon footprint than plastic film57, Bio-based source55 | Recycling, Composting (if certified), Landfill |

| VCI Film (PE based) | Virgin or contains recycled PE resin | Yes | Medium for PE film, VCI additives may affect; closed-loop programs exist56 | No (unless specially designed to be biodegradable55) | Carbon footprint higher than VCI paper but possibly lower than virgin plastic film (if containing recycled content); production energy consumption | Recycling, Landfill, Incineration |

| PET Strapping | Virgin or significant recycled PET | Yes | PET recycling system relatively mature | No | Production energy consumption and carbon footprint significantly lower than steel strap22 | Recycling, Landfill, Incineration |

| Steel Strapping | Virgin iron ore, contains recycled steel | Yes | High for steel61 | No | High energy consumption for production and recycling, relatively higher carbon footprint22 | Recycling, Landfill |

| Wooden Pallets/Reels (untreated/heat treated) | Virgin wood | Yes | Wood is recyclable | Yes | Lower carbon footprint if from sustainably managed forests; heat treatment consumes energy | Recycling, Reuse, Biomass energy, Composting, Landfill |

| Stretch Film (LLDPE) | Virgin LLDPE resin | Yes (technically feasible) | Actual recycling rate limited by collection and processing facilities, often low | No | LCA shows it’s better than paper alternatives in some metrics, but potentially worse in others like climate change; material usage is key57 | Recycling (difficult), Landfill, Incineration |

The shift towards a sustainable model in the steel wire packaging industry is not merely a passive response to environmental pressure but also reflects an active pursuit of resource efficiency and long-term economic benefits. By promoting the use of recyclable materials22, increasing the content of recycled components55, and establishing innovative mechanisms like closed-loop recycling56, the industry is evolving from a traditional "take-make-dispose" linear model to a circular model where resources are continuously recycled. This not only helps reduce reliance on virgin resources but also alleviates the pressure of waste disposal.

Reducing packaging material waste34 brings a double dividend: on the one hand, it directly reduces business operating costs, including material procurement and waste disposal fees; on the other hand, it significantly improves the company’s environmental performance. Automation technology plays a key role in this process by precisely controlling the amount of material applied and cutting dimensions, minimizing unnecessary waste (as mentioned in ^42, a 30% reduction in material costs). This dual improvement in speed and material efficiency constitutes a powerful impetus for companies to adopt automated packaging, especially in the context of fluctuating raw material prices and increasing pressure for sustainable development, its significance is even more prominent.

However, evaluating the "environmental friendliness" of packaging materials is not always black and white. Life Cycle Assessment (LCA) results57 indicate that a material may perform well in certain environmental metrics (such as greenhouse gas emissions) but may be inferior in others (such as land use or water eutrophication). This means that when companies choose "greener" packaging solutions, they need to consider comprehensively and from multiple dimensions, rather than relying solely on a single environmental label or one-sided publicity. For example, the study in57 shows that although paper pallet packaging is superior to virgin plastic stretch film in greenhouse gas emissions, when considering all 16 environmental indicators comprehensively, neither has an absolute overall advantage. This reminds us that true sustainable development decisions need to be based on rigorous scientific assessment and a deep understanding of various potential trade-offs, to avoid "greenwashing" and ensure that the chosen solution indeed brings positive environmental benefits throughout its life cycle.

IX. Future Trajectory: Innovation and Trends in Steel Wire Coil Packaging (2024-2025 Outlook)

Looking ahead to the next few years, the field of steel wire coil packaging will continue to be profoundly influenced by technological innovation, sustainability requirements, and the wave of intelligence. Emerging materials, advanced automation technologies, and increasing emphasis on environmental responsibility will jointly shape the industry’s development direction.

A. Emerging Packaging Materials and Smart Packaging Solutions

Advances in materials science and the integration of information technology are giving rise to more efficient, environmentally friendly, and intelligent packaging materials.

- Environmentally Friendly Coatings and Materials: For the protection of steel itself and auxiliary packaging materials, the industry is actively transitioning to low-VOC (volatile organic compound) or zero-VOC environmentally friendly coatings such as water-based coatings and powder coatings58.

- Lightweight Packaging: Without sacrificing protective performance, reducing the weight of the packaging itself by using higher strength, thinner materials or optimizing structural design, thereby lowering transportation costs and energy consumption58.

- Smart Packaging Integration: Integrating technologies such as QR codes, NFC (Near Field Communication) tags, RFID (Radio Frequency Identification) into packaging to achieve real-time product traceability, intelligent inventory management, anti-counterfeiting verification, and interaction with consumers58. This aligns with the concept of "smart steel" integrating IoT (Internet of Things) monitoring62.

- Bio-based VCI Films: Developing VCI films that do not contain traditional harmful substances like nitrites, using plant extracts and other renewable resources as active corrosion inhibitor components, such as Daubert Cromwell’s Clear Pak BIO series55.

- Enhanced Barrier VCI Films: Developing VCI films with stronger gas barrier properties for extreme long-term storage or harsh transportation environments (such as high humidity, acidic gases, marine environments) to ensure the effectiveness and durability of the corrosion inhibitor, such as ZERUST’s ICT540-SDA series16.

- Advanced VCI Formulations: Continuously improving VCI chemical formulations to meet stricter international environmental regulations (such as the RoHS directive, nitrite restrictions, etc.)55.

B. Next Generation Automation Wave: AI, Robotics, and Integrated Systems

Advanced automation technologies, particularly the deep integration of Artificial Intelligence (AI) and robotics, will make steel wire coil packaging lines more intelligent, efficient, and flexible.

- Application of Artificial Intelligence and Machine Learning: AI algorithms will be widely used in predictive maintenance for packaging lines (can reduce equipment failures by up to 30%62), optimization of robotic path planning and control, machine vision-based automated quality control (such as high-speed detection of tiny defects, uneven coating), and optimization of parameters for the entire packaging process (such as material usage, machine speed)63.

- Advanced Robotic Technology: In addition to traditional handling and palletizing, more advanced robots will have higher precision, stronger environmental perception capabilities, and more flexible operational capabilities, able to accurately handle steel coils of various sizes and types, and coordinate more closely with other equipment on the packaging line3.

- Intelligent and Adaptive Automation: Future packaging lines will integrate more smart sensors and self-adjusting mechanisms, capable of real-time monitoring of operating status, automatic correction of deviations, and automatic adjustment of packaging parameters based on the actual characteristics of the steel coil (e.g., identified by vision systems), achieving truly "unmanned" or "low-manned" efficient operation63.

- Deeply Integrated Systems: Packaging production lines will achieve a deeper level of seamless integration with upper-level information systems such as enterprise MES (Manufacturing Execution System), ERP (Enterprise Resource Planning System), and WMS (Warehouse Management System), forming end-to-end digital management and data traceability from order to delivery3.

- Customization and Flexible Automation: Future packaging machinery will focus more on modular design and flexible configuration, able to quickly adapt to steel coils of different sizes, specifications, and packaging requirements, and even achieve fast changeover for small batches and multiple varieties, meeting the growing demand for personalized markets63.

C. Enhanced Focus on Sustainability and Green Packaging

Environmental protection and sustainable development will continue to be core drivers of packaging innovation.

- Extension of "Green Steel" and Decarbonization Trends: The overall trend of the steel industry transitioning towards green and low-carbon production62 will inevitably extend to all supporting环节, including packaging, driving the greening of packaging materials and processes.

- Continued Demand for Environmentally Friendly Materials: Market demand for packaging solutions that minimize environmental impact will continue to grow, including the application of renewable materials, recyclable materials, biodegradable materials, and low-carbon footprint materials63.

- Increasing Recycling Rates and Recycled Content: The industry will strive to achieve higher packaging material recycling standards, reduce waste emissions, and actively adopt packaging materials containing post-consumer recycled (PCR) content55.

- Responding to Regulatory Pressure: Increasingly stringent environmental regulations globally will continue to drive companies to make compliance improvements and innovations in packaging58.

- Meeting Consumer Preferences: Consumers’ awareness of product packaging transparency and environmental impact is growing, which will push companies to choose and showcase more sustainable packaging solutions58.

A significant feature of the steel wire coil packaging sector in the coming years will be the deep integration of digital technology and physical operations. The advancement of Artificial Intelligence (AI) and robotics63 will combine with smart packaging materials (such as packaging integrated with QR codes or NFC tags58) and comprehensive interconnectivity of production data (through MES/ERP system integration3). This will create a highly efficient, transparent, and rapidly responsive packaging ecosystem. In this system, AI can analyze data from smart packaging and integrated systems to further optimize robot movements, adjust packaging parameters, predict maintenance needs, forming a continuously improving intelligent closed loop.

Sustainability will no longer be just a chapter in corporate social responsibility reports or a passive measure to comply with regulations, but will be internalized as a core principle in the design of packaging materials and automated processes. Whether it is developing new bio-based VCI materials55, promoting lightweight packaging design58, or integrating energy-saving technologies into automated equipment and optimizing algorithms to minimize material waste63, all reflect the proactive eco-design concept of minimizing environmental impact from the source. This marks a shift from compliance-driven to value-driven sustainable development in the industry.

Furthermore, with increasing market demand for product diversity and personalization, "hyper-customization" of packaging will become possible. Advanced automation technologies, particularly AI-driven robotic systems and flexible modular equipment63, will enable packaging lines to provide highly customized packaging solutions for individual steel coils or small-batch orders without sacrificing the efficiency of mass production. This means packaging can be finely adjusted according to the specific characteristics of each steel coil (such as size, coating, destination climate conditions, specific customer requirements, etc.), for example, using unique winding methods, applying specific types of VCI protection, or printing custom labels containing traceability information. This will drive steel wire coil packaging from a "one-size-fits-all" standardized model to a "tailored" precision service.

X. Strategic Recommendations for Optimizing Steel Wire Coil Packaging

To address current challenges and seize future opportunities, steel wire companies should consider the following strategic recommendations when optimizing their steel wire coil packaging operations:

1. Conduct a Comprehensive Needs Assessment:

- Systematically analyze the types, specifications, and output of existing steel wire products, current packaging methods, transportation conditions, and packaging-related product damage rates and customer feedback.

- Accurately calculate the current packaging cost breakdown, including materials, labor, equipment depreciation, and losses due to improper packaging, to identify pain points and potential benefits of improvement.

2. Strategically Prioritize Automation:

- Based on the needs assessment results, identify areas where the highest ROI can be achieved by introducing automation (from single semi-automatic machines to fully integrated production lines).