When looking for an orbital stretch wrapper, understanding its price is crucial for making the right investment. This machine can significantly impact your packaging process, but before diving into the market, it’s important to know what factors influence its cost.

The price of an orbital stretch wrapper depends on various factors like machine size, features, and manufacturer reputation. Understanding these aspects will help you make an informed decision.

There are several aspects to consider when buying an orbital stretch wrapper. A cheap wrapper might seem appealing initially, but it’s essential to evaluate what you’re getting for the price. Let’s dive into what affects the price and how to find the best deal for your needs.

Factors Affecting the Price of Orbital Stretch Wrappers?

Are you wondering what drives the price of orbital stretch wrappers? While the price tag may vary, there are several key factors that contribute to cost differences. Let’s take a look at what drives the pricing of these machines.

The price of orbital stretch wrappers is influenced by factors such as build quality, features, and customizability. High-end models tend to offer more advanced features, but it’s important to evaluate your actual needs.

In the world of packaging machinery, orbital stretch wrappers can be found in a wide range of prices. Understanding what factors contribute to this variation will help you identify the right option for your business. Let’s take a deeper look.

1. Machine Size and Capacity

Machine size and capacity play a significant role in pricing. Larger machines, designed to handle heavier and more complex loads, tend to come with a higher price tag. When considering the size, think about the volume of packaging you need to handle daily. A higher capacity wrapper will naturally cost more, but it will pay off in efficiency for larger operations.

2. Features and Customization

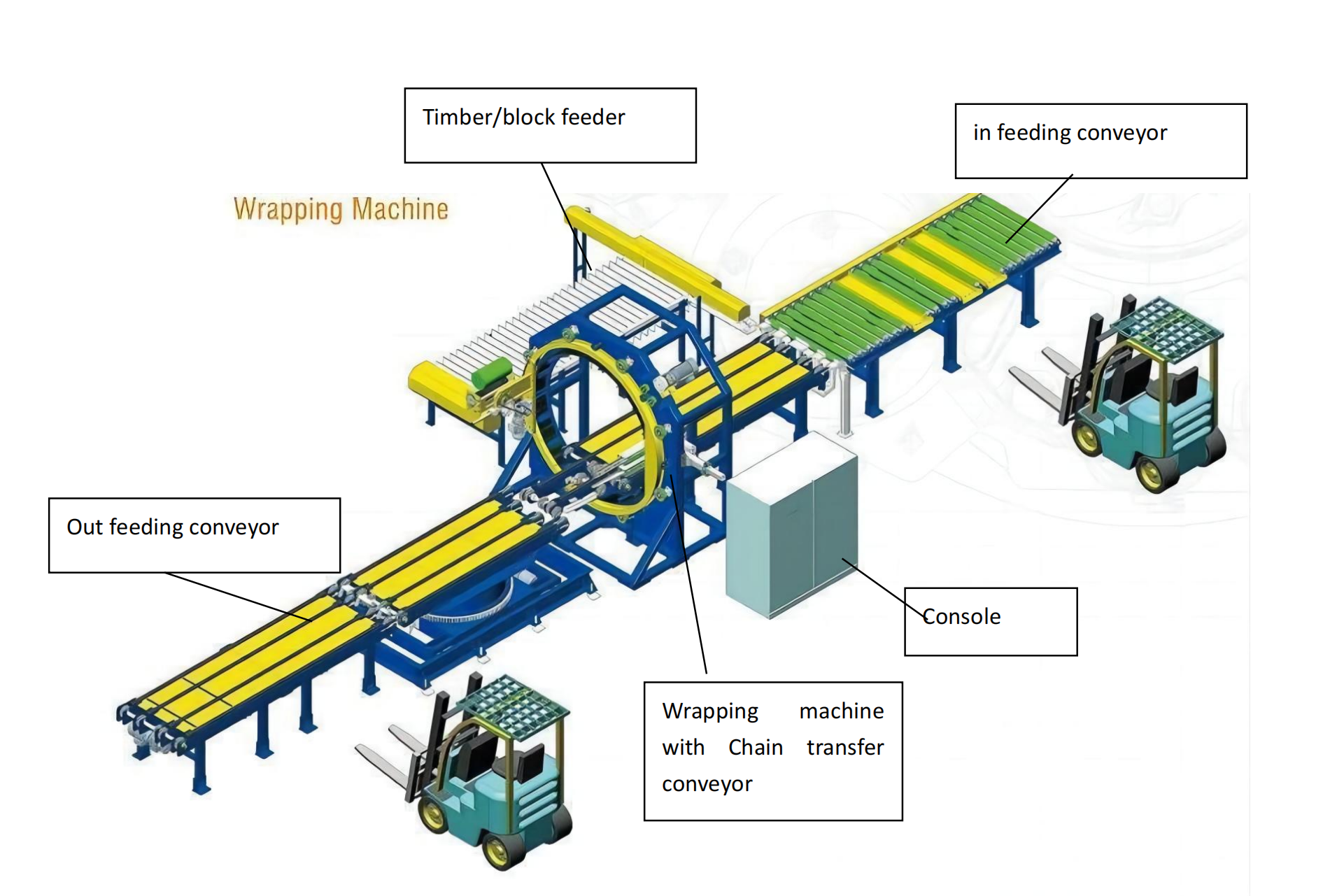

Standard orbital stretch wrappers come with basic features like adjustable tension and variable speeds. However, many manufacturers offer customized machines that include additional features like automatic film cut-off, integrated conveyors, and enhanced controls. These added features increase the cost, but they might be necessary if your operations require extra automation or precision.

3. Manufacturer Reputation

Just like in other industries, brand reputation matters in the packaging machinery market. Well-established manufacturers often provide higher-quality machines, better customer service, and a longer lifespan. These premium wrappers are priced higher, but the investment can result in fewer maintenance issues and a better return on investment in the long run.

4. Durability and Build Quality

The materials and construction of the orbital stretch wrapper determine its durability. Machines built with high-quality materials can withstand more stress, leading to a higher cost. However, investing in a durable machine can help you avoid frequent repairs or replacements, which could be costly in the future.

How to Find the Best Deals on Orbital Stretch Wrappers?

Finding the best deals on orbital stretch wrappers doesn’t mean compromising quality. Instead, it’s about being smart with your purchasing decisions and knowing where to look.

Finding the best deals involves researching various suppliers, comparing features, and considering financing options. It’s important to make sure the machine will meet your long-term needs, not just your immediate cost concerns.

When you’re hunting for the best deals, the process isn’t as simple as just picking the lowest price. Let’s explore some strategies to get the most value for your money when buying an orbital stretch wrapper.

1. Research Multiple Suppliers

Not all suppliers offer the same pricing for the same machines. Different suppliers might have exclusive deals or discounts. By researching multiple options, you can get a sense of what the going rate is and identify any special offers or promotions. Additionally, don’t be afraid to negotiate with suppliers, especially if you’re purchasing multiple units.

2. Consider Used or Refurbished Options

If you’re looking for a more affordable option, consider purchasing a used or refurbished orbital stretch wrapper. Many suppliers offer pre-owned machines that have been fully inspected and restored to good working condition. This can be a great way to get a high-quality machine at a lower price, especially if you’re just starting out and don’t need a brand-new model.

3. Look for Financing and Leasing Options

Sometimes, the best deal isn’t about the upfront price, but rather the payment terms. Many manufacturers and suppliers offer financing or leasing options. These arrangements can help you spread out the cost of the machine over time, making it more manageable for your cash flow. Be sure to inquire about interest rates and repayment schedules.

4. Check for Warranty and Support

A machine’s initial price is important, but it’s also crucial to factor in after-purchase support. Many suppliers offer warranties and maintenance packages, which can save you money in the long run by covering repairs and servicing. Be sure to ask about warranty periods and what’s included in the support package.

Is Investing in a High-End Orbital Stretch Wrapper Worth the Price?

Are the extra features and durability of high-end orbital stretch wrappers really worth the price? While it might seem tempting to opt for a budget-friendly machine, sometimes investing in a higher-end model can pay off in the long run.

Investing in a high-end orbital stretch wrapper can be worth the price, especially if your operations demand high efficiency, minimal downtime, and enhanced automation. However, the decision depends on your specific business needs.

While high-end orbital stretch wrappers come with a higher price, they often provide more reliability and productivity. Let’s explore the advantages of investing in a more expensive model and whether it’s a good fit for your business.

1. Enhanced Automation

High-end orbital stretch wrappers often come with more automated features, reducing the need for manual labor. This could significantly boost efficiency in your packaging process, allowing your employees to focus on other tasks. If your production line is fast-paced and requires high throughput, a more automated machine can lead to better productivity and fewer human errors.

2. Longer Lifespan

Though a premium machine costs more upfront, it can last significantly longer than lower-end models. High-quality materials and components are built to withstand the rigors of heavy use. In the long run, a high-end orbital stretch wrapper may require fewer repairs and replacements, offering you better value over time.

3. Advanced Features

High-end models often come equipped with advanced features that improve efficiency, such as better load stabilization, improved tension control, and automatic film cutting. If these features align with your packaging needs, the investment in a more expensive machine can result in better performance and reduced operational costs.

4. Reduced Maintenance Costs

A higher-end orbital stretch wrapper typically requires less maintenance due to its superior build quality and advanced technology. This can lead to reduced downtime and lower costs associated with repairs, ultimately saving your company money in the long run.

Conclusion

In conclusion, the price of an orbital stretch wrapper is influenced by various factors, including size, features, and manufacturer reputation. By carefully considering these elements and evaluating your specific needs, you can find the right wrapper that offers the best value for your investment.