Confused about the right equipment to efficiently handle heavy loads in your facility? Are you struggling with awkwardly shaped molds or unstable pallets? The world of material handling offers a range of solutions, but two terms often pop up: mold upenders and pallet inverters. Understanding their core functions and key differences is crucial for optimizing your operations and ensuring workplace safety.

Mold upenders and pallet inverters are both material handling machines designed to rotate heavy loads, but they serve distinct purposes. Mold upenders are specifically engineered to tilt or rotate molds, dies, and similar heavy, often awkwardly shaped items. Pallet inverters, on the other hand, are designed to invert or transfer goods loaded on pallets, facilitating pallet exchange, damaged goods removal, or load transfer.

This article dives deep into the functionalities of mold upenders and pallet inverters, highlighting their key differences to help you determine the ideal solution for your specific material handling needs.

Mold Upender: The Heavyweight Champion for Molds and Dies

Dealing with heavy molds and dies can be a cumbersome and risky task. Traditional methods often involve overhead cranes or forklifts, posing safety hazards and potential damage to valuable tooling. Mold upenders emerge as a specialized solution, designed to safely and efficiently tilt and rotate these hefty items, streamlining processes in mold making, die casting, and stamping industries.

A mold upender, also known as a die upender or mold tilter, is a specialized piece of equipment designed to safely and efficiently rotate heavy molds, dies, and similar tooling. These machines are crucial for tasks such as mold maintenance, repair, and adjustments, allowing for ergonomic access to all sides of the mold without manual lifting or dangerous maneuvering.

But how exactly do mold upenders achieve this heavy lifting and precise rotation? Let’s delve deeper into their mechanics and applications:

Diving Deeper into Mold Upender Functionality

Mold upenders are engineered with robust construction to handle the immense weight and specific shapes of molds and dies. Their design and operation focus on providing controlled and safe manipulation of these valuable industrial tools.

Key Design Features of Mold Upenders

- Heavy-Duty Structure: Mold upenders are built with thick steel frames and platforms to withstand extreme loads, often ranging from several tons to tens of tons. This robust construction ensures stability and safety during operation.

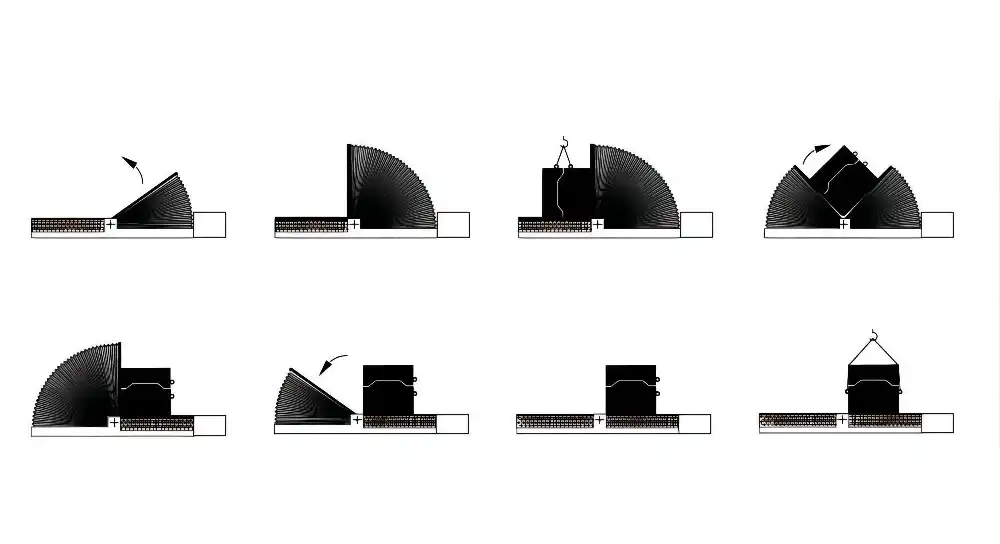

- Tilting or Rotating Platform: The core of a mold upender is its platform, designed to securely hold the mold. These platforms can tilt up to 90 degrees for easy access to the mold’s top and bottom surfaces or rotate 180 degrees for complete inversion.

- Hydraulic or Electromechanical Operation: Most mold upenders utilize hydraulic cylinders or electromechanical systems to power the tilting or rotating motion. Hydraulic systems offer high power and smooth, controlled movement, while electromechanical systems provide precise positioning and energy efficiency.

- Safety Mechanisms: Safety is paramount when handling heavy molds. Mold upenders are equipped with features like:

- Clamping Systems: Hydraulic or mechanical clamps secure the mold to the platform, preventing slippage during rotation.

- Overload Protection: Pressure relief valves in hydraulic systems or torque limiters in electromechanical systems prevent overloading and potential damage.

- Emergency Stop Buttons: Strategically placed emergency stop buttons allow for immediate halting of operation in case of any issue.

- Safety Interlocks and Light Curtains: Some advanced models incorporate safety interlocks that prevent operation if the load is not properly secured or light curtains to create safety zones around the machine.

Applications of Mold Upenders Across Industries

Mold upenders are indispensable in industries that rely heavily on molds and dies:

- Plastic Injection Molding: Mold upenders facilitate mold changes, cleaning, maintenance, and repairs, reducing downtime and improving productivity in plastic part manufacturing.

- Die Casting: In die casting foundries, upenders are used to rotate heavy dies for inspection, repair, and die changes, crucial for producing metal parts under high pressure.

- Metal Stamping: Stamping facilities utilize mold upenders to handle large and heavy stamping dies for maintenance, die changes, and adjustments, ensuring efficient metal forming processes.

- Forging: Forging operations benefit from mold upenders for manipulating forging dies, which are subjected to extreme forces and temperatures, requiring regular maintenance and changes.

- General Manufacturing: Any industry utilizing heavy molds or dies for production processes, such as rubber molding, composite molding, or specialized metal forming, can benefit from the safety and efficiency offered by mold upenders.

| Feature | Hydraulic Mold Upender | Electromechanical Mold Upender |

|---|---|---|

| Power Source | Hydraulic Power Unit | Electric Motor and Gearbox |

| Load Capacity | Very High (up to 50+ tons) | High to Medium (up to 30 tons, typically) |

| Motion Control | Smooth, Variable Speed | Precise Positioning, Programmable Motion |

| Maintenance | Regular Hydraulic System Checks | Less Frequent, Primarily Mechanical |

| Energy Efficiency | Lower Efficiency, Continuous Pump Operation | Higher Efficiency, On-Demand Power Usage |

| Cost | Generally Lower Initial Cost | Generally Higher Initial Cost |

| Best Suited For | Heavy Loads, High Power Applications | Precise Control, Energy Saving Needs |

Choosing between hydraulic and electromechanical mold upenders depends on the specific application requirements, load weight, desired precision, and operational environment. Hydraulic upenders are robust and powerful for the heaviest loads, while electromechanical options excel in precision and energy efficiency for less extreme but still demanding applications.

Pallet Inverter: The Versatile Solution for Palletized Goods

While mold upenders tackle the specialized task of handling molds and dies, pallet inverters address a broader spectrum of material handling needs related to palletized goods. From simple pallet exchange to complex automation integration, pallet inverters offer a versatile approach to improving efficiency and safety in warehouses and production lines.

A pallet inverter, also known as a pallet tilter, pallet changer, or load inverter, is a machine designed to invert or rotate palletized loads. These machines are used for a variety of purposes, including exchanging damaged pallets, transferring loads to different pallet types (e.g., wood to plastic), removing bottom-damaged goods, and rotating products for processing or storage.

Pallet inverters come in various configurations to suit different operational needs. Let’s explore their diverse types and applications:

Exploring the Versatility of Pallet Inverters

Pallet inverters are not a one-size-fits-all solution. Their versatility lies in the range of designs and functionalities available, each catering to specific material handling challenges.

Types of Pallet Inverters

- Clamp Style Inverters: These are the most common type, using a clamping mechanism to secure the load before inverting. They are efficient for stable, uniformly stacked pallet loads. Variations include single clamp, double clamp (for delicate or varying height loads), and ground-level loading models.

- Roller Bed Inverters: Ideal for integration into automated conveyor lines, roller bed inverters use rollers to move pallets into and out of the inversion chamber. This facilitates seamless automation and high-throughput operations.

- Push-Over Inverters: These inverters use a pusher mechanism to gently slide the load onto a second pallet during inversion. They are particularly suitable for fragile goods like packaged foods or pharmaceuticals, minimizing product damage.

- Stationary vs. Mobile Inverters: Stationary inverters are fixed in one location for high-volume, dedicated pallet handling tasks. Mobile inverters, often mounted on wheels or forklifts, offer flexibility to move the inverter to different locations within a facility.

- Manual vs. Automatic Inverters: Manual inverters require operator control for each cycle, while automatic inverters can be programmed for continuous operation, often integrated with sensors and automated systems.

Key Applications of Pallet Inverters

Pallet inverters streamline various material handling processes across diverse industries:

- Pallet Exchange: Quickly and efficiently transfer loads from damaged or unsuitable pallets (e.g., wooden pallets in sanitary environments) to new or different pallet types (e.g., plastic pallets for food or pharmaceutical industries).

- Damaged Goods Removal: Easily access and remove damaged items located at the bottom of a pallet load without manual restacking, reducing labor and product damage.

- Load Transfer: Transfer loads between in-house pallets and shipping pallets, or from pallets to slip sheets, optimizing material flow and reducing pallet costs.

- Product Rotation: Rotate palletized goods for various purposes, such as:

- Mixing or agitating products in drums or containers.

- Inverting stacks of paper or printed materials for double-sided printing or processing.

- Rotating wine bottles for cork management during long-term storage.

- Freezer Spacer Removal/Insertion: Automated pallet inverters with freezer spacer handling capabilities can remove or insert spacers used for airflow in freezers, improving efficiency in cold storage facilities.

| Feature | Clamp Style Inverter | Push-Over Inverter | Roller Bed Inverter |

|---|---|---|---|

| Load Stability | Requires Stable Loads | Handles Less Stable Loads | Requires Stable Loads |

| Product Fragility | Suitable for Most Goods | Ideal for Fragile Goods | Suitable for Most Goods |

| Automation Potential | Moderate | Lower | High |

| Cycle Speed | Medium | Medium | High |

| Cost | Medium | Medium to High | High |

| Best Suited For | General Pallet Inverting | Fragile Goods, Gentle Handling | Automated Systems, High Throughput |

The choice of pallet inverter type depends heavily on the type of goods being handled, the desired level of automation, throughput requirements, and budget considerations. Clamp style inverters offer a balance of versatility and cost-effectiveness, while push-over inverters prioritize gentle handling for delicate products, and roller bed inverters excel in automated, high-volume environments.

Key Differences: Mold Upender vs. Pallet Inverter

While both mold upenders and pallet inverters are rotation machines, their core purpose, design, and applications are distinct. Understanding these key differences is essential for selecting the right equipment for your specific material handling challenge.

The primary difference lies in their intended load. Mold upenders are designed for heavy, irregularly shaped molds and dies, focusing on tilting and rotating for maintenance and access. Pallet inverters are designed for palletized goods, focusing on inversion and transfer for pallet exchange, load manipulation, and product rotation.

Let’s break down the key differentiators in more detail:

Side-by-Side Comparison: Mold Upender vs. Pallet Inverter

To clearly illustrate the differences, let’s compare them across several key parameters:

Comparative Analysis Table

| Feature | Mold Upender | Pallet Inverter |

|---|---|---|

| Primary Load | Molds, Dies, Heavy Tooling | Palletized Goods (Boxes, Stacks, Bags) |

| Load Shape | Irregular, Custom Shapes | Uniform, Rectangular (Typically) |

| Load Weight | Very Heavy (Tons to Tens of Tons) | Heavy to Medium (Hundreds to Thousands of lbs) |

| Primary Function | Tilting, Rotating for Access, Maintenance | Inverting, Transferring, Pallet Exchange |

| Rotation Angle | Typically 90° or 180° Tilting/Rotation | 180° Inversion, 90° Rotation Models Available |

| Clamp Type | Specialized Clamps for Mold/Die Shapes | General Clamps for Pallet Loads |

| Automation Level | Typically Standalone Units, Some Automation Options | Wide Range, from Manual to Fully Automated |

| Industry Focus | Mold Making, Die Casting, Stamping, Forging | Warehousing, Logistics, Food, Pharma, General Manufacturing |

| Safety Focus | Heavy Load Stability, Secure Clamping | Load Stability, Product Damage Prevention |

| Portability | Primarily Stationary | Stationary and Mobile Options Available |

This table clearly highlights the distinct focus of each machine. Mold upenders are specialized for the heavy, shape-specific world of tooling, while pallet inverters address the broader needs of palletized material handling. While some pallet inverters can handle heavier loads, their design and functionality are optimized for the typical challenges of palletized goods, not the extreme weight and unique geometry of molds and dies.

Choosing the Right Solution: Upender or Inverter?

Selecting between a mold upender and a pallet inverter boils down to understanding your specific material handling needs. Are you wrestling with heavy molds and dies, or are you looking to streamline pallet handling in your warehouse or production line?

To choose between a mold upender and a pallet inverter, carefully consider the type of load you handle. If you primarily deal with molds, dies, and heavy tooling, a mold upender is the appropriate choice. If your focus is on palletized goods for pallet exchange, load transfer, or product rotation, a pallet inverter is the more versatile and suitable solution.

However, the decision process involves more than just load type. Consider these key factors:

-

Load Characteristics:

- Weight: What is the maximum weight you need to handle? Mold upenders are built for extreme weights, while pallet inverters have varying capacity ranges.

- Shape and Size: Are you handling regular pallet loads or awkwardly shaped molds and dies? Mold upenders are designed for non-uniform shapes.

- Fragility: Are your goods delicate? Push-over pallet inverters offer gentle handling, while mold upenders prioritize secure clamping for heavy tooling.

-

Operational Needs:

- Function: Do you need to tilt, rotate, invert, or transfer loads? Match the machine’s primary function to your needs.

- Throughput: How many cycles per hour or day do you require? Automated pallet inverters offer higher throughput than mold upenders or manual pallet inverters.

- Automation Level: Do you need a standalone unit or integration into an automated line? Pallet inverters offer wider automation options.

- Space Constraints: Do you have limited space? Consider stationary vs. mobile pallet inverters and the footprint of mold upenders.

-

Industry and Application:

- Industry Standards: Does your industry have specific hygiene or safety requirements? Stainless steel pallet inverters are available for sanitary environments. Mold upenders must meet stringent safety standards for heavy tooling handling.

- Specific Tasks: Are you primarily focused on mold maintenance, pallet exchange, damaged goods removal, or product rotation? Choose the machine that best addresses your core tasks.

By carefully evaluating these factors, you can make an informed decision and select the material handling equipment – whether a mold upender or a pallet inverter – that will optimize your operations, enhance safety, and improve efficiency in your workplace. Consulting with a material handling equipment specialist can further refine your choice and ensure you invest in the ideal solution for your unique needs.

Conclusion

In the realm of material handling, precision and specialization are key. While both mold upenders and pallet inverters offer rotation capabilities, their target loads and functionalities diverge significantly. Mold upenders stand as robust solutions for the heavy and specialized world of molds and dies, ensuring safe tilting and rotation for maintenance and access. Pallet inverters, in contrast, provide versatile solutions for the broader spectrum of palletized goods, streamlining pallet exchange, load transfer, and product rotation across diverse industries. Understanding these differences is paramount to selecting the right equipment and achieving optimal efficiency and safety in your material handling processes.