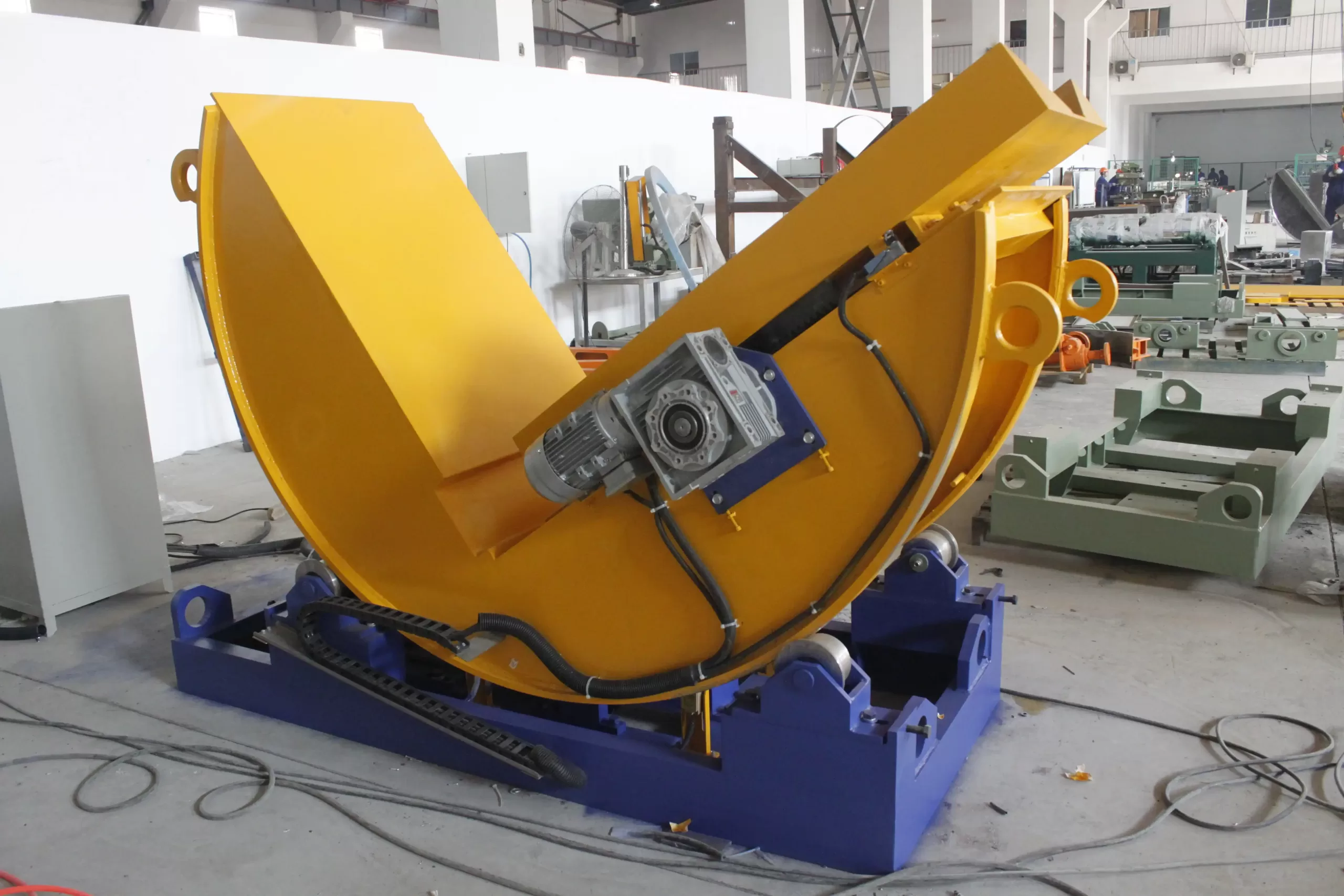

Setting up a steel coil upender can be the difference between operational efficiency and frustrating delays. Imagine your workflow running like a well-oiled machine with seamless steel coil transitions. The challenge, however, is getting the setup right. Here, we unveil the essential steps to transform your current process into a streamlined powerhouse of productivity.

To properly set up and install a steel coil upender, you must first assess your space to ensure it can accommodate the machinery, considering factors like weight capacity and dimensions. Next, prepare the area by removing any obstruction and ensuring a stable, level surface. This will provide a safe and stable environment for your new equipment.

As we dive deeper into setting up a steel coil upender, it’s crucial to recognize the preparatory phases. These steps are not just checklist items—they are transformative tactics that can reshape your material handling efficiency. Holding onto this understanding, let’s explore the preparations that lay the groundwork for success.

1. What are the necessary preparations before installing a steel coil upender?

You might think setting up an upender is simply about placing it on the floor. Yet, without the right groundwork, you risk jeopardizing safety and efficiency. Imagine the potential setbacks from an improper setup, from workflow disruptions to costly maintenance. So, what does it take to do it right?

Before installing a steel coil upender, start by analyzing your current facility setup. Ensure the area is clear of any machinery that could impede the installation. Confirm that the floor is even and can support the upender’s weight. Additionally, allocate adequate space for operational and maintenance tasks, keeping long-term efficiency in mind.

Preparing Your Facility

Understanding facility readiness is not merely a task but an investment in your operational success. Here’s how to ensure your space is primed for a new steel coil upender.

-

Infrastructure Assessment: Perform a detailed analysis of your infrastructure. Take measurements and verify weight restrictions. The load-bearing capacity of your floor is paramount.

-

Spatial Layout Planning: Consider the flow of operations. Map out buffer zones around the upender, creating clear paths for material movement.

-

Safety Protocols: Safety should be integrated from the onset. Develop a checklist that includes emergency shut-off accessibility, staff training plans, and protective barriers.

-

Utility Services Alignment: Ensure electrical and other utility connections align with the equipment requirements. Long-term, efficient power sources are non-negotiable for continuous operations.

These aspects, meticulously handled, set the stage for maximizing your steel coil upender’s impact on your operational workflow. Such preparation may seem extensive but is crucial for achieving seamless integration and operational prowess—qualities that directly contribute to reduced downtime and enhanced productivity.

Perform these steps not because they are required, but because they pivot your manufacturing processes onto a path of growth and resilience. With those taken care of, you’re ready to move forward with confidence, knowing that your new coil upender will seamlessly integrate into your productive unit.

2. How to install a steel coil upender step-by-step?

Precision in installing a steel coil upender is key to achieving operational efficiency. Ignoring proper installation can lead to equipment failure, safety hazards, and decreased productivity. Experience has shown that a systematic approach ensures success, making the initial setup crucial for long-term operation and maintenance.

Installing a steel coil upender involves a series of meticulous steps tailored to ensure effectiveness and safety. Begin by selecting an appropriate location, ensuring the ground is level and stable. During installation, secure the upender using anchor bolts and confirm all electrical connections align with manufacturer’s instructions. Calibration and testing follow to verify functionality and safety standards compliance.

Common Challenges and Solutions

The loading process introduces unique challenges in installing a coil upender. Many factors need to be considered. Equipment design, environment, and operator handling play significant roles in efficiency and safety. Despite these challenges, attention to details and adjustments in installation can lead to impressive productivity boosts.

| Challenges | Solutions |

|---|---|

| Uneven surface | Level the area before installation begins. |

| Electrical misalignments | Double-check all electric connections as per manufacturer’s instructions. |

| Incorrect calibration | Follow the manufacturer’s guide meticulously and verify all settings. |

The journey of mastering the working of a steel coil upender reflects my years of experience in the packaging industry. Each installation has been a learning ladder for upgrading processes and technologies. Implementing structured steps in coil upender installations balances the operational rhythm and maintains safety as the ultimate goal. This knowledge-sharing emphasis ensures long-term operational benefits for everyone involved.

3. What safety measures are crucial during and after installation?

The installation of a steel coil upender isn’t just about setting machinery in place. It’s about prioritizing safety. The hazards in industrial environments demand a comprehensive understanding of safety measures to build and maintain a secure workspace. Every precaution taken could potentially prevent accidents and ensure equipment longevity.

Key safety measures during and after installation focus on securing equipment, conducting regular checks, and ensuring operator training. Initially, ensure all connections are firmly set. Post-installation, implement ongoing maintenance schedules, and continually update safety protocols based on manufacturer guidelines. This consolidated approach minimizes risks associated with operation.

Importance of Continual Maintenance and Training

Once installation is complete, maintaining a streamlined process ensures both efficiency and safety. Properly trained operators are essential. Comprehensive training and regular equipment assessments reduce risks and ensure smooth operations.

| Safety Aspect | Recommendation |

|---|---|

| Regular Maintenance | Schedule routine checks to preempt failures. |

| Operator Training | Implement robust training programs. |

| Emergency Protocols | Define clear emergency procedures and drills. |

From personal observation, scheduling regular reviews of equipment operational status and holding periodic training sessions for staff always generate positive outcomes. Knowing how to respond swiftly in emergencies builds confidence and competence within the team. This structured communication and preparedness escalate efficiency, contributing significantly to productivity. Understanding and applying adequate safety measures are crucial to maintaining a safe working environment, especially in settings where heavy machinery and rapid production activities converge.

Conclusion

Understanding the preparation, installation, and safety measures ensures effective and secure use of a steel coil upender, enhancing productivity in mechanical engineering tasks. Proper installation coupled with continuous training creates an environment where equipment not only meets current needs but adapts to future demands, ensuring long-lasting operational success.

Understanding the preparation, installation, and safety measures ensures effective and secure use of a steel coil upender, enhancing productivity in mechanical engineering tasks.