How to Ensure Steel Coils Are Properly Secured for International Shipments

Are you losing sleep over the safety of your steel coil shipments? The nightmare of damaged goods, hefty fines, or worse – accidents – is a real concern in international trade. But what if you could virtually eliminate these risks and ensure your steel coils arrive at their destination in perfect condition, every time? Discover the essential strategies to master international steel coil securement.

Ensuring steel coils are properly secured for international shipments involves meticulous planning, utilizing appropriate securing methods, and adhering to international regulations. This includes selecting the right type of strapping, employing effective blocking and bracing techniques, and understanding the specific requirements of different modes of transport, such as sea or rail.

This comprehensive guide dives deep into the best practices for securing steel coils for international shipments, providing you with actionable insights to protect your valuable cargo and streamline your operations. Keep reading to unlock the secrets of safe and efficient steel coil transportation across borders.

The Critical Importance of Proper Steel Coil Securement for International Shipping

Imagine your steel coils, vital components for a massive construction project overseas, arriving damaged and unusable. Delays, cost overruns, and damaged client relationships – the ripple effects of inadequate securement are substantial. For international shipments, the stakes are even higher.

Proper securement of steel coils for international shipping is paramount due to the extended transit times, varied handling conditions, and stringent international safety standards. It directly impacts material integrity, prevents financial losses from damage and delays, ensures the safety of everyone involved in the supply chain, and maintains compliance with global shipping regulations.

Failing to adequately secure steel coils can lead to a cascade of negative consequences. From minor surface damage to catastrophic shifting during transit, the risks are diverse and costly. Let’s explore why investing in robust securement practices is not just good practice—it’s a business imperative.

Mitigating Risks: Damage, Delays, and Financial Losses

Steel coils are inherently heavy and dense, making them challenging to transport safely. During international voyages, cargo can experience significant forces from vessel motion, including rolling, pitching, and yawing, as well as shocks from waves and rough handling during loading and unloading in different ports. Without proper securement, these forces can cause coils to shift, collide, or even break free, leading to:

- Product Damage: Dents, scratches, and deformations can reduce the value or render the steel coils unusable, leading to rejection by the customer and significant financial loss.

- Shipping Delays: Damage in transit can cause delays for inspections, repackaging, or replacement of goods, disrupting project timelines and incurring penalties.

- Safety Hazards: Shifting coils can destabilize the transport vehicle or vessel, posing serious safety risks to workers and potentially causing accidents.

- Fines and Legal Liabilities: Non-compliance with international cargo securement regulations can result in hefty fines, legal disputes, and damage to reputation.

To quantify the impact, consider the following table illustrating potential costs associated with inadequate steel coil securement:

| Risk | Potential Consequence | Estimated Financial Impact |

|---|---|---|

| Minor Damage | Surface scratches, slight dents | 5-10% reduction in coil value |

| Moderate Damage | Significant dents, edge damage, some deformation | 20-30% reduction in coil value, potential rework costs |

| Severe Damage | Major deformation, coil unwinding, unusable material | 100% loss of coil value, disposal costs, project delays |

| Shipping Delays | Inspections, repackaging, replacement, missed deadlines | Daily demurrage charges, penalty clauses in contracts |

| Safety Incident | Injury to personnel, damage to transport vehicle/vessel | Medical expenses, legal fees, repair costs, insurance claims |

| Regulatory Fines | Non-compliance with IMDG Code, CTU Code, or local regulations | Fines ranging from hundreds to tens of thousands of dollars |

Investing in proper securement is a proactive measure that significantly reduces these risks, safeguarding your investment and ensuring smooth international trade operations.

Essential Methods for Securing Steel Coils for International Shipments

Securing steel coils for international transport is not a one-size-fits-all process. The optimal method depends on factors like coil orientation (eye-to-sky or eye-to-side), weight, dimensions, and the mode of transport. However, several core techniques form the foundation of effective securement.

The primary methods for securing steel coils in international shipments include proper blocking and bracing to prevent movement, robust strapping and lashing to hold coils firmly in place, and the use of dunnage and specialized cradles to protect coils and distribute weight evenly. Combining these methods, tailored to the specific shipment, ensures maximum security.

Let’s delve into the most effective techniques, providing you with a practical toolkit for ensuring your steel coils are ready for the rigors of international travel.

Blocking, Bracing, and Dunnage: The Foundation of Securement

- Blocking: Using strong materials like timber or steel to fill gaps and prevent coils from shifting forward, backward, or sideways. Blocking is crucial in preventing longitudinal and lateral movement, especially during braking or turns.

- Bracing: Employing angled supports to reinforce blocking and provide additional resistance against movement. Bracing is particularly important for preventing coils from tipping or rolling.

- Dunnage: Using materials like timber, rubber mats, or specialized airbags to create friction, protect coils from direct contact with the transport vehicle, and distribute weight evenly. Dunnage also helps to absorb vibrations and shocks during transit.

These techniques work in synergy to create a stable and secure base for the steel coils, minimizing the risk of initial movement that can compromise the entire securement system.

Strapping and Lashing: Binding Coils Firmly

- Steel Strapping: High-tensile steel straps are the industry standard for securing heavy steel coils. They offer exceptional strength and resistance to elongation, maintaining tension throughout the journey. Different grades and widths of steel strapping are available to match the specific load requirements.

steel coil strapping - Lashing: Heavy-duty webbing or chain lashings are used to further secure coils, especially for sea shipments where cargo may experience extreme forces. Lashings are anchored to strong points on the transport vehicle or vessel and tightened to create a robust restraint system.

The effectiveness of strapping and lashing depends on proper tensioning and the correct application technique. Over-tensioning can damage the coils or straps, while under-tensioning provides inadequate security. Regular inspection and re-tensioning during long voyages may be necessary.

Leveraging Automation and Technology for Enhanced Securement Efficiency

Manual steel coil securement can be time-consuming, labor-intensive, and prone to human error. However, advancements in automation and technology are revolutionizing the industry, offering faster, more consistent, and safer solutions.

Automated systems for steel coil securement enhance efficiency and safety by reducing manual labor, ensuring consistent strapping tension and placement, and providing real-time monitoring of cargo conditions during international shipments. These technologies minimize human error and optimize the entire securement process.

Embracing automation is no longer a luxury but a necessity for businesses seeking to optimize their international steel coil shipping operations. Let’s explore the cutting-edge technologies transforming steel coil securement.

Automated Strapping and Wrapping Systems: Speed and Consistency

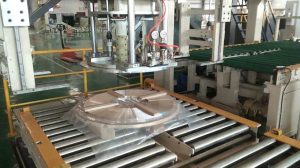

- Automated Strapping Machines: These systems automatically apply steel straps with pre-set tension levels, ensuring consistent and reliable securement across all coils. They significantly reduce strapping time and labor costs compared to manual methods.

- Automated Wrapping Machines: Stretch wrapping or shrink wrapping coils with protective films provides an additional layer of security and protection against environmental factors like moisture and dust. Automated wrapping systems ensure uniform and tight wrapping, enhancing cargo integrity.

automated steel coil strapping system - Integrated Systems: Some advanced systems combine strapping, wrapping, and even labeling functionalities into a single automated line, streamlining the entire coil preparation process for international shipment.

These automated solutions not only increase throughput but also improve the quality and consistency of securement, reducing the risk of human error and ensuring compliance with stringent international standards.

Real-time Monitoring and Tracking: Visibility and Control

- Sensors and IoT Devices: Integrating sensors into strapping or packaging allows for real-time monitoring of parameters like strap tension, temperature, humidity, and shock levels during transit. This data provides valuable insights into cargo conditions and potential risks.

- GPS Tracking: Real-time GPS tracking provides visibility into the location of shipments, allowing for proactive intervention in case of delays or deviations from planned routes.

- Cloud-based Platforms: Data from sensors and tracking systems can be accessed and analyzed through cloud-based platforms, enabling remote monitoring, reporting, and proactive decision-making throughout the international shipping journey.

By leveraging these technologies, businesses gain unprecedented visibility and control over their steel coil shipments, enabling proactive risk management and ensuring timely and damage-free deliveries.

| Feature | Manual Securement | Automated Securement | Benefits of Automation |

|---|---|---|---|

| Speed | Slower, depends on labor and skill | Significantly faster, consistent speed | Increased throughput, reduced loading/unloading times |

| Consistency | Variable tension, prone to human error | Pre-set and consistent tension, highly reliable | Uniform securement, minimized risk of under/over tensioning |

| Labor Costs | Higher labor requirements | Reduced labor requirements | Lower operational costs, optimized resource allocation |

| Safety | Higher risk of worker injury during manual strapping | Reduced risk of injury, safer working environment | Improved worker safety, reduced accident potential |

| Data & Monitoring | Limited data, manual inspections | Real-time data on tension, location, environment | Proactive risk management, enhanced visibility & control |

| Compliance | Requires rigorous training and supervision | Ensures consistent adherence to standards | Easier compliance with international regulations |

Regulatory Landscape and Best Practices for International Compliance

International steel coil shipments are governed by a complex web of regulations and guidelines designed to ensure safety and prevent cargo damage. Navigating this landscape is crucial for compliance and smooth customs clearance.

Adhering to international regulations such as the IMDG Code for maritime transport and the CTU Code for cargo transport units is essential for legal compliance and safety in international steel coil shipments. Implementing industry best practices, like those recommended by organizations such as the World Shipping Council, further enhances securement and minimizes risks.

Understanding and implementing these regulations and best practices is not just about avoiding penalties—it’s about upholding safety standards and ensuring responsible international trade.

Key International Regulations and Guidelines

- International Maritime Dangerous Goods (IMDG) Code: While steel coils are not typically classified as dangerous goods, the IMDG Code provides comprehensive guidelines for cargo securement on ships, which are widely applicable to steel coil shipments. It details requirements for lashing, blocking, and bracing based on cargo type and vessel motion.

- IMO/ILO/UNECE Code of Practice for Packing of Cargo Transport Units (CTU Code): The CTU Code provides detailed guidance on the safe packing and securing of cargo in containers and other cargo transport units, including specific recommendations for steel coils. It emphasizes proper weight distribution, securement methods, and inspection procedures.

- National and Regional Regulations: In addition to international codes, specific countries and regions may have their own regulations governing cargo securement. Shippers must be aware of and comply with these local requirements at both the origin and destination ports.

- Industry Best Practices: Organizations like the World Shipping Council (WSC) and industry-specific associations provide valuable best practice guidelines for steel coil securement, often exceeding minimum regulatory requirements to ensure optimal safety and cargo integrity.

Best Practices Checklist for International Steel Coil Shipments:

- Thorough Risk Assessment: Conduct a comprehensive risk assessment for each shipment, considering coil characteristics, transport mode, route, and potential hazards.

- Detailed Securement Plan: Develop a detailed securement plan based on the risk assessment and applicable regulations, specifying materials, methods, and responsibilities.

- Proper Material Selection: Use high-quality steel strapping, lashings, dunnage, and other securement materials that meet or exceed relevant international standards.

- Trained Personnel: Ensure that personnel involved in packing and securing steel coils are properly trained and competent in relevant techniques and regulations.

- Pre-Shipment Inspection: Conduct thorough pre-shipment inspections to verify that securement is implemented correctly and meets all requirements.

- Documentation and Records: Maintain detailed documentation of the securement process, including materials used, inspection reports, and compliance certifications.

- Continuous Improvement: Regularly review and improve securement procedures based on feedback, incident reports, and evolving best practices.

By proactively adhering to regulations and implementing robust best practices, businesses can ensure compliance, minimize risks, and build a reputation for safe and reliable international steel coil shipments.

Conclusion

Securing steel coils for international shipments is a complex but critical undertaking. By prioritizing proper securement methods, embracing automation, and adhering to international regulations, businesses can significantly mitigate risks, prevent costly damages and delays, and ensure the safe and efficient delivery of their valuable cargo. Investing in robust securement practices is not just a cost of doing business—it’s a strategic investment in operational excellence and customer satisfaction.

Explore advanced coil packing line solutions to enhance your steel coil handling and securement processes.