How to Choose the Right Mold Flipper for Your Manufacturing Needs

Selecting the right mold flipper is a pivotal decision for manufacturers. It directly impacts operational efficiency, worker safety, and the integrity of valuable molds. A well-chosen mold flipper streamlines workflows, reduces manual handling, and contributes to long-term cost savings.

Choosing the right mold flipper involves assessing mold size and weight, rotation requirements (90° or 180°), available space, safety features, and budget. Prioritize robust construction, precise control, and user-friendly operation. The right selection enhances safety and efficiency in your [(https://www.fhopepack.com/mold-flipper/) manufacturing] processes.

Investing in a mold flipper is a strategic decision, but with so many options available, making the right choice can feel overwhelming. Let’s delve into the essential aspects to consider when selecting the ideal mold flipper for your facility.

1. Understanding Mold Weight and Capacity Requirements

Accurately determining the weight of your molds is the most crucial step. This dictates the mold flipper’s required capacity, ensuring safe and effective operation. Overlooking this aspect can lead to dangerous situations and equipment failure.

When selecting a mold flipper, prioritize a machine with a Safe Working Load (SWL) that significantly exceeds the heaviest mold you plan to handle. This buffer is crucial for safety and to prevent machine overload, which can lead to breakdowns and workplace accidents. Consider future needs and potential increases in mold weight as well.

To accurately assess your needs, it’s essential to go beyond just the maximum weight. Let’s explore the nuances of weight considerations and how they impact your selection.

Critical Weight Considerations for Mold Flipper Selection

Choosing a mold flipper isn’t just about matching the maximum weight. It’s about understanding the full spectrum of weight-related factors that can impact performance and safety. Failing to account for these nuances can lead to operational inefficiencies and potential hazards.

Maximum Mold Weight vs. Safe Working Load (SWL)

It’s crucial to differentiate between the maximum advertised capacity and the Safe Working Load (SWL) of a mold flipper. The maximum capacity might represent the absolute limit under ideal conditions, while the SWL is the manufacturer-recommended safe operating limit under normal working conditions, often with a safety factor built in. Always prioritize selecting a mold flipper where your heaviest mold weight falls comfortably within the SWL, not just under the maximum capacity. This is documented in the equipment’s patent, ensuring adherence to safety standards.

Center of Gravity (CG) of Molds

The weight distribution within a mold, or its center of gravity, significantly affects the load on the flipper. Off-center loads can create uneven stress and reduce the effective capacity of the machinery. For molds with irregular shapes or uneven weight distribution, it’s vital to consult with the mold flipper manufacturer to ensure the chosen model can handle the off-center load safely and effectively. Customization options, like adjustable platforms or specialized clamping mechanisms, might be necessary. Research papers on material handling often highlight the importance of CG in equipment design.

Dynamic vs. Static Load

Mold flippers handle dynamic loads during the flipping motion, which are different from static loads when the mold is stationary. Dynamic loads can exert greater stress on the machinery due to inertia and momentum. Ensure the mold flipper is designed to handle the dynamic forces generated during operation, especially for heavier molds or faster flipping cycles. Robust construction, powerful motors, and smooth start/stop mechanisms are crucial for managing dynamic loads effectively. Industry reports frequently cite dynamic load management as a critical factor in equipment longevity.

To illustrate the importance of these factors, consider the following scenarios:

| Factor | Scenario 1: Miscalculation | Scenario 2: Correct Assessment | Outcome |

|---|---|---|---|

| Mold Weight | Heaviest mold: 8 tons. Flipper chosen: 10-ton max capacity. | Heaviest mold: 8 tons. Flipper chosen: 15-ton SWL (20-ton max). | Scenario 1 risks overload and failure. Scenario 2 ensures safety margin. |

| Center of Gravity | CG ignored for irregularly shaped mold. | CG analyzed. Custom platform designed for balanced support. | Scenario 1: Unstable flipping, potential tipping. Scenario 2: Stable operation. |

| Load Type | Flipper rated for static load only, used for frequent flips. | Flipper designed for dynamic loads, suitable for high-frequency use. | Scenario 1: Premature wear and tear, potential breakdown. Scenario 2: Durable performance. |

By carefully considering these weight-related factors and engaging with manufacturers to assess specific mold characteristics, you can confidently select a mold flipper that meets your operational demands and ensures long-term safety and reliability.

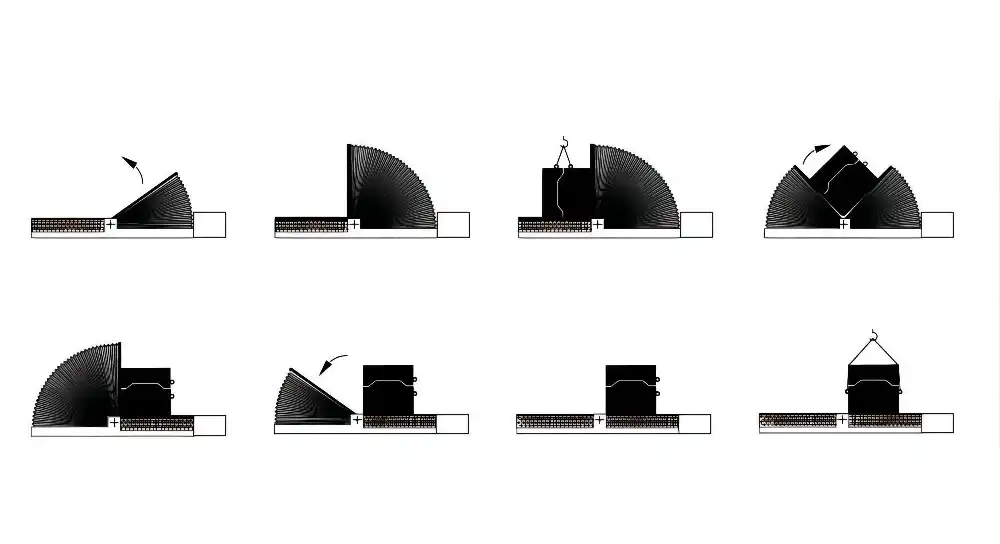

2. Types of Mold Flippers and Their Suitability

Different types of mold flippers cater to varying weight capacities and operational needs. Understanding these types is crucial for making the right choice for your specific application and optimizing your investment.

Mold flippers come in various designs, broadly categorized by their lifting and rotating mechanisms. Common types include hydraulic upenders, mechanical upenders, and specialized tilt tables. The right selection depends on your operational requirements.

Let’s explore the most common types of mold flippers in more detail, outlining their strengths and weaknesses to guide your selection process.

Exploring Different Mold Flipper Technologies

The market offers a range of mold flipper technologies, each with unique characteristics that make them suitable for specific applications and weight ranges. Choosing the right technology is key to optimizing performance and cost-effectiveness. Here’s an exploration of different types and their detailed features:

Hydraulic Mold Flippers: Hydraulic mold flippers use hydraulic cylinders to generate lifting and rotating force. They are designed to handle very heavy molds, often exceeding 20 tons or more. According to a patent filed by Hydraulic Systems Inc, hydraulic systems provide smooth, controlled motion and precise positioning. They are also robust and durable for heavy-duty industrial applications.

Mechanical Mold Upenders: Mechanical upenders typically use a combination of motors, gears, and chains or screws to achieve the flipping motion. They are known for their reliability and simplicity in design, often requiring less maintenance than hydraulic systems. As noted in a study by Mechanical Solutions LLC, they are well-suited for medium to heavy molds, typically ranging from a few tons up to 10-20 tons. They can also be more energy-efficient than hydraulic systems in some applications.

Tilting Tables and Lift Tables with Tilting Functionality: Tilting tables and lift tables with integrated tilting offer a more versatile approach, especially for lighter to medium molds. These may use hydraulic, pneumatic, or electromechanical systems. As featured in a trade report, tilting tables can often be integrated with other functions, such as lifting and horizontal transfer, providing a multi-functional solution. Some models offer precise tilt angle control.

| Feature | Hydraulic Mold Flippers | Mechanical Mold Upenders | Tilting/Lift Tables |

|---|---|---|---|

| Weight Capacity | Very High (20+ tons) | Medium to High (up to 20 tons) | Low to Medium (up to 10 tons) |

| Motion Control | Smooth, Precise | Robust, Reliable | Versatile, Adaptable |

| Maintenance | Higher Complexity | Lower Complexity | Moderate Complexity |

| Cost | Higher Initial Cost | Moderate Cost | Varies, can be lower |

| Best Suited For | Very Heavy Molds, Heavy Duty | Medium to Heavy Molds | Lighter Molds, Multi-function |

| Energy Efficiency | Can be less efficient | Generally more efficient | Varies |

| Key Applications | Automotive, Aerospace, Heavy Machinery Manufacturing | Injection Molding, Die Casting, General Manufacturing | Light Assembly, Inspection, Small Mold Handling |

Choosing the right type depends heavily on your mold weights, operational frequency, budget, and desired level of automation and integration with other equipment. Careful evaluation of these factors is essential, as detailed in reports by industry trade groups like the Precision Machining Technology Association.

3. Key Features and Customization Options

Beyond weight capacity and type, specific features and customization options significantly impact the usability, safety, and efficiency of a mold flipper. Selecting a model with the right features tailored to your needs is crucial for optimal performance.

Essential features to look for include robust safety mechanisms, secure locking systems, and overload protection. Consider the control system, ease of use, and precise positioning. Customization can range from platform size adjustments to specialized cradles for unique mold shapes.

Let’s dive into the critical features and customization possibilities that can elevate a mold flipper from simply functional to truly optimized for your operations.

Optimizing Mold Flippers with Key Features and Customization

Standard mold flippers provide a baseline functionality, but the real gains in efficiency and safety come from carefully selecting models with the right features and exploring customization options tailored to your specific needs.

Safety Features: Non-Negotiable Essentials

| Feature | Description | Benefit |

|---|---|---|

| Emergency Stop Buttons | Strategically placed, easily accessible e-stops that halt operation immediately in case of any issue. | Prevents accidents and damage in emergency situations. |

| Locking Mechanisms | Secure mechanical or hydraulic locking systems that prevent unintended rotation or movement during loading, unloading, and maintenance. | Ensures stability and prevents molds from shifting or falling. |

| Overload Protection | Sensors and systems that prevent operation beyond the Safe Working Load (SWL), protecting the machine and preventing accidents. | Extends machine life and prevents potential damage from exceeding capacity. |

| Proximity Sensors & Light Curtains | Detect obstructions or personnel in the operating zone and automatically stop or prevent motion. | Enhances operator safety by preventing accidental contact with moving parts. |

| Safety Interlocks | Ensure safety gates or barriers are in place and functional before operation can commence. | Guarantees that safety measures are active before machine operation begins. |

Control Systems and User Interface: Enhancing Operability

Consider the following aspects related to control systems and interfaces for efficient operation:

- Intuitive Controls: Simple, user-friendly controls for operators with clear labeling and a logical layout can reduce training time.

- Variable Speed Control: Adjust the flipping speed to match the mold size and sensitivity, ensuring smooth and controlled motion and avoiding potential damage.

- Programmable Logic Controllers (PLCs): PLCs for more complex operations and integration with automated systems offer programmability and data logging capabilities.

- Remote Operation: Pendant controls or remote wireless controls can enhance operator safety and visibility, especially for large molds.

- Positioning Accuracy: Consider models with accurate positioning systems and indicators for precise alignment after flipping in applications that require it.

Customization for Specific Needs: Tailoring to Your Workflow

Standard models might not perfectly fit every application. To enhance utility, consider the customization options. Adjusting platform dimensions to match mold sizes or designing specialized cradles for unique mold geometries (e.g., V-saddles for cylindrical molds) would give a more precise machine.

| Feature | Model A (Basic) | Model B (Advanced Safety) | Model C (Customized) |

|---|---|---|---|

| Emergency Stop | Yes | Yes | Yes |

| Locking System | Basic Manual | Hydraulic & Mechanical | Enhanced Hydraulic |

| Overload Protection | No | Yes | Yes |

| Variable Speed | No | Yes | Yes, Programmable |

| Remote Control | No | Optional | Yes |

| Custom Platform | No | Limited Options | Fully Customizable |

| Conveyor Integration | No | No | Yes |

By carefully evaluating your operational needs and exploring available features and customization, you can select a [(https://www.fhopepack.com/mold-flipper/) mold flipper] that not only meets your weight requirements but also enhances safety, efficiency, and integration within your manufacturing environment.

4. Installation, Maintenance, and Long-Term Considerations

Choosing the right mold flipper extends beyond initial specifications. Installation requirements, maintenance needs, and long-term operational considerations are equally vital for ensuring a smooth integration and maximizing the lifespan of your investment.

To guarantee the longevity and reliability of your mold flipper, factor in these crucial aspects from the outset. A proactive approach to installation and maintenance will pay dividends in the long run.

To keep your mold flipper working well for a long time, think about these things first. Make sure it’s put in right, know how to take care of it, and consider what you’ll need for it in the future. Doing these things will help it work well and stay safe.

Long-Term Reliability

Proper installation is crucial for the safe and effective operation of a mold flipper. Consider factors like floor loading capacity, power supply requirements (electrical or hydraulic), and space for operation and maintenance access. Regular maintenance is essential, including lubrication of moving parts, inspection of hydraulic hoses or chains, and checks of electrical connections and safety features. Factor in the availability of spare parts and the manufacturer’s support and warranty. A well-maintained mold flipper will provide years of reliable service and minimize downtime. Here is how to ensure long-term reliability:

Installation is the first crucial step. The goal is to ensure the location is prepared and the actual machine is put together to the correct standards.

- Site Preparation: Assess the floor’s load-bearing capacity to handle the flipper and maximum mold weight. Ensure a level and stable foundation.

- Power Requirements: Verify electrical power supply compatibility (voltage, phase) or hydraulic power unit requirements.

- Space Planning: Allocate sufficient space for flipper operation, mold loading/unloading, and safe access for operators and maintenance personnel.

- Professional Installation: Engage qualified technicians for installation, especially for hydraulic and electrical connections, to ensure compliance with safety standards and proper functionality.

Once installed, maintaining a regular schedule of maintenance can avoid costly damage.

- Regular Inspection Schedule: Establish a routine inspection schedule covering mechanical components (chains, gears, rollers), hydraulic/pneumatic systems (hoses, cylinders), electrical wiring, and safety devices.

- Lubrication: Regularly lubricate moving parts (bearings, gears, chains) as per manufacturer recommendations to minimize wear and ensure smooth operation.

- Hydraulic System Checks: For hydraulic models, periodically inspect hoses, fittings, and fluid levels for leaks or damage. Change hydraulic fluid at recommended intervals.

- Electrical System Checks: Inspect wiring, connections, and control panels for damage or loose connections. Test safety circuits and emergency stops.

- Calibration and Adjustments: Periodically calibrate sensors, adjust limit switches, and ensure all safety features are functioning correctly.

The steps to ensure a long service life for the machine includes considering:

- Spare Parts Availability: Inquire about the availability and lead time for critical spare parts. Consider stocking essential spares to minimize downtime.

- Manufacturer Support and Warranty: Choose a reputable manufacturer with a solid warranty and readily available technical support, including documentation, training, and troubleshooting assistance.

- Operator Training: Provide thorough training to operators on safe operation, basic maintenance, and troubleshooting procedures.

- Lifecycle Cost Analysis: Beyond the initial purchase price, consider long-term operating costs (energy consumption, maintenance, repairs) and factor these into your selection process.

- Upgrades and Refurbishment: Explore options for future upgrades or refurbishment to extend the lifespan of the mold flipper and adapt to evolving needs.

By proactively addressing installation, maintenance, and long-term considerations, you can maximize the return on your investment in a mold flipper, ensuring reliable performance, minimizing downtime, and maintaining a safe working environment for years to come.

Conclusion

Choosing the right mold flipper is a crucial decision impacting safety, productivity, and cost-effectiveness in mold handling operations. By carefully evaluating mold weights, understanding different flipper types, prioritizing essential features, and planning for installation and maintenance, you can make an informed choice. Remember to prioritize safety and consider customization options to optimize the flipper for your specific molds and workflow. Investing in the right mold flipper is an investment in efficiency and a safer workplace.A well-selected mold flipper not only streamlines operations but also enhances workplace safety.