How to choose the automatic steel wire rewinding solution?

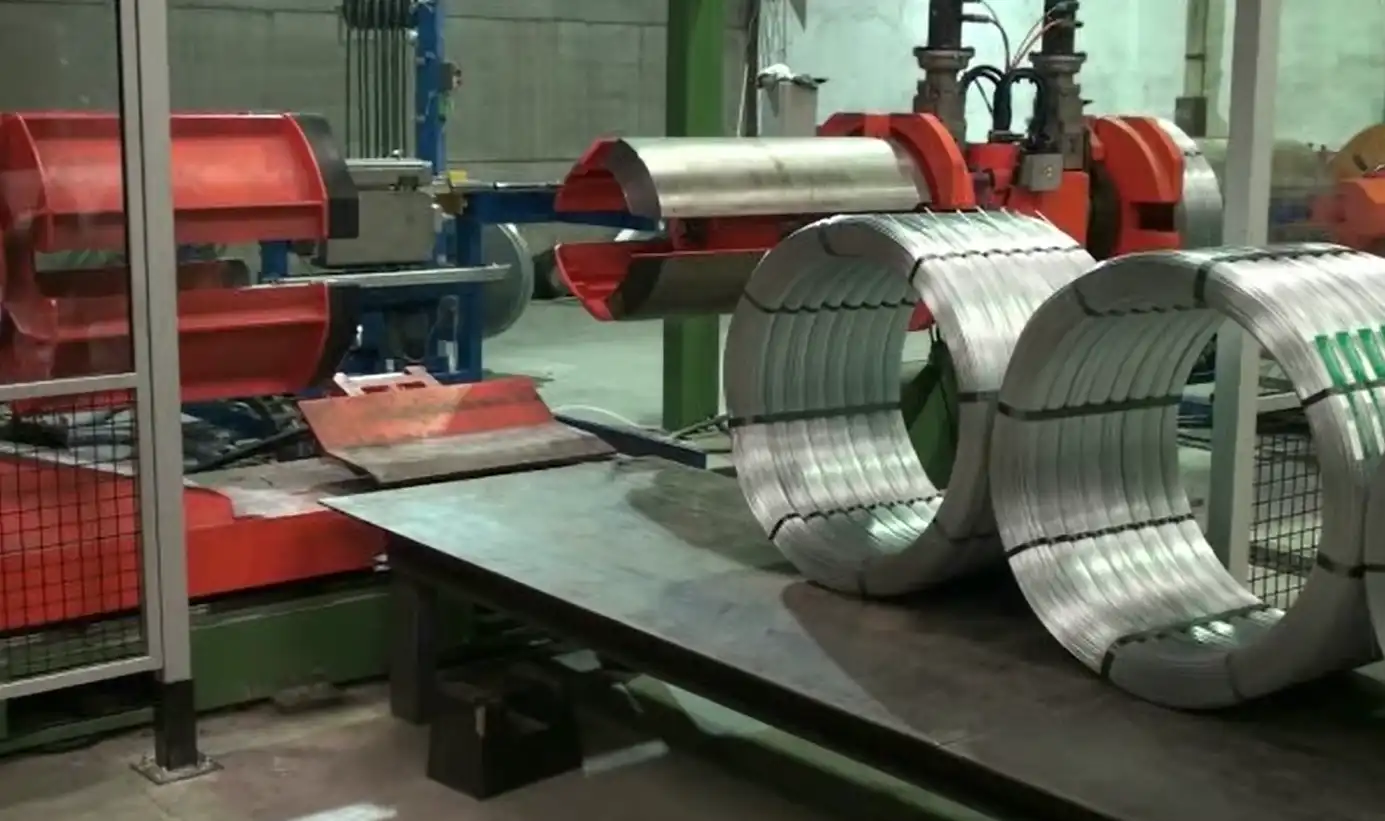

Your factory floor is under constant pressure. You need to increase output, but your current steel wire rewinding process is a major bottleneck. It’s slow, requires a lot of manual work, and creates serious safety risks for your team. Every time a worker has to manually handle a heavy coil, you worry about injuries, and every minute of downtime costs you money and delays shipments. You know automation is the answer, but choosing the wrong machine could make things even worse, leaving you with an expensive piece of equipment that doesn’t solve your core problems.

To choose the right automatic steel wire rewinding solution, you must first evaluate your specific production needs, such as coil size, weight, and desired speed. Next, analyze the machine’s technical features, focusing on its frame construction, tension control system, and safety integrations. Finally, calculate the potential return on investment (ROI) and carefully vet the supplier to ensure they have the engineering expertise and after-sales support you need.

I understand the weight of this decision. An investment in new machinery is not just about the equipment itself; it’s about the future of your production line. It’s about making your factory safer, more efficient, and more profitable. I’ve been in your shoes, managing a factory floor and making these exact kinds of critical choices. Let’s walk through this process step-by-step, so you can feel confident you are selecting a solution that will truly drive your business forward.

What key features define a reliable automatic rewinding machine?

You’ve probably seen equipment specifications that look impressive on paper, but you know from experience that what matters is how the machine performs day in and day out in a demanding environment. A breakdown during a critical production run can cause a domino effect of delays and costs, completely erasing any potential gains. You need a machine that is a workhorse, not a show horse. The key is to look past the marketing and focus on the core engineering features that guarantee reliability and longevity.

A reliable automatic rewinding machine is defined by its robust frame construction, a precise tension control system, an intuitive PLC interface, and integrated safety features. These elements work together to ensure the machine can handle high-volume production safely and consistently for years to come.

When I started my own factory, one of the first lessons I learned was the high cost of "cheap" equipment. A machine I bought early on had a light frame, and under the constant vibration of heavy coil rewinding, the welds started to fail within a year. That experience taught me to look at the bones of a machine first. Let’s dive deeper into the specific features you should scrutinize.

The Foundation: Frame and Construction

The machine’s frame is its skeleton. If the skeleton is weak, the entire system will fail. Don’t just look at the overall weight; ask about the materials used. Is it built from heavy-gauge structural steel? How is it reinforced? A solid, welded steel frame is non-negotiable. It provides the stability needed to handle massive coils at high speeds without vibration or flexing. This stability is not just about the machine’s lifespan; it directly impacts the quality of the rewind. A wobbly frame leads to uneven winding, which can cause issues for your customers. I always tell my clients to think of it like the foundation of a house. You would never build on a weak foundation, and the same principle applies here.

The Heart: Tension Control System

Consistent tension is everything in wire rewinding. If the tension is too loose, the coil will be unstable. If it’s too tight, it can alter the properties of the wire or even cause it to break, leading to waste and downtime. This is where you must really pay attention to the technology.

| Tension Control Type | How it Works | Pros | Cons |

|---|---|---|---|

| Magnetic Powder Clutch | Uses magnetic particles to create resistance and control torque. | Simple, lower cost. | Can wear over time, less precise for sensitive materials. |

| Servo Motor Control | A dedicated motor and drive system actively manages tension based on real-time feedback. | Extremely precise, highly responsive, low maintenance. | Higher initial investment. |

| Dancer Arm System | A weighted or spring-loaded arm moves to physically compensate for tension changes. | Simple mechanical feedback. | Can be slower to react, more moving parts to maintain. |

For most heavy-duty steel wire applications, a servo motor control system is the superior choice. The precision it offers reduces scrap and ensures every coil meets exact specifications. It’s a higher upfront cost, but the long-term savings from reduced waste and improved quality are significant.

The Brain: PLC and Operator Interface

The most powerful machine is useless if your team can’t operate it efficiently and safely. The Programmable Logic Controller (PLC) is the machine’s brain. Look for reputable brands like Siemens, Allen-Bradley, or Mitsubishi. These are industry standards, which means it will be easier to find support and spare parts. More importantly, look at the Human-Machine Interface (HMI). Is it a simple touchscreen? Is the layout logical? Can an operator set up a job with minimal training? A complicated interface increases the chance of human error. I always recommend getting a live or video demonstration of the HMI before buying.

How do you accurately calculate the ROI for your investment?

You have a budget. You have a board or a general manager to report to. You can’t just say a new machine "feels" like a good idea; you need to prove it with numbers. The pressure is on you to justify this significant capital expense. But trying to calculate the Return on Investment (ROI) can feel like guesswork. If your numbers are too optimistic, you lose credibility. If they are too conservative, you might not get the project approved. A clear, data-driven ROI calculation is your most powerful tool for getting the green light and ensuring this investment truly benefits the company’s bottom line.

To accurately calculate the ROI for an automatic rewinding machine, you must first add up all the current annual costs associated with your manual process, including labor, product damage, and downtime. Then, project the savings the new machine will create in these areas. The annual net savings divided by the total investment cost gives you your ROI percentage.

I’ve worked with dozens of factory managers like you, Michael. One, in particular, was facing immense pressure on his margins. He knew automation was the answer, but his CFO was skeptical. Together, we sat down and broke down every single cost, from operator wages to the cost of a single damaged coil. When we presented the final ROI calculation, it wasn’t a sales pitch; it was an undeniable business case. Let’s break down how you can do the same thing.

Step 1: Quantify Your Current Pains (The "Before" Costs)

You need a baseline. This means assigning a dollar value to the inefficiencies of your current process. Be as detailed as possible.

-

Direct Labor Costs: This is the easiest to calculate.

- Number of operators per shift for rewinding:

(e.g., 3) - Their average hourly wage (including benefits):

(e.g., $30/hour) - Hours per shift x Shifts per day x Days per year = Total Annual Labor Cost

3 operators * $30/hr * 8 hours * 250 days = $180,000

- Number of operators per shift for rewinding:

-

Cost of Product Damage (Scrap):

- What percentage of your wire is scrapped due to poor winding or handling damage?

(e.g., 1.5%) - What is the value of that scrap per year?

(e.g., 500,000 lbs * $0.50/lb * 1.5% = $3,750) - This number is often higher than people think.

- What percentage of your wire is scrapped due to poor winding or handling damage?

-

Cost of Downtime:

- How many hours per week is the line stopped due to bottlenecks in the manual rewinding station?

(e.g., 4 hours/week) - What is the value of your factory’s lost production per hour?

(e.g., $1,000/hour) 4 hours * 50 weeks * $1,000/hr = $200,000- This is a hidden cost that kills profitability.

- How many hours per week is the line stopped due to bottlenecks in the manual rewinding station?

Step 2: Project Your Future Gains (The "After" Savings)

Now, let’s look at how an automatic rewinder changes the numbers.

| Cost Category | "Before" Annual Cost | "After" Annual Cost | Annual Savings |

|---|---|---|---|

| Direct Labor | $180,000 (3 operators) | $60,000 (1 operator) | $120,000 |

| Product Damage | $3,750 (1.5% scrap) | $500 (0.2% scrap) | $3,250 |

| Productivity Gain | $0 | $50,000+ | $50,000 |

| Total Annual Savings | $173,250 |

The productivity gain comes from increased throughput. If the machine can rewind 30% faster, that’s 30% more product you can ship without adding shifts. I’ve conservatively valued that here, but for many factories, this is the biggest financial gain.

Step 3: The Final ROI Calculation

Let’s say the total cost of the machine, including installation and training, is $220,000.

- Formula:

ROI (%) = (Total Annual Savings / Total Investment Cost) * 100 - Calculation:

($173,250 / $220,000) * 100 = 78.75% - Payback Period:

$220,000 / $173,250 = 1.27 years

An ROI of nearly 79% with a payback period of just over a year is an incredibly strong argument. This is not a cost; it’s an investment that pays for itself and then continues to generate profit for years to come.

Why is the supplier’s expertise more crucial than the machine’s price?

You’ve been in this industry long enough to have experienced it firsthand. You get a great price on a machine, the salesperson makes a lot of promises, and the equipment is delivered. Then, when a real problem occurs, the supplier is nowhere to be found. The salesperson doesn’t have the technical knowledge to help, and getting support is a nightmare. You’re left with an expensive machine that isn’t running, and the "great deal" you got has become a massive headache. That experience teaches you that the price tag is only one small part of the story.

A supplier’s engineering expertise is more crucial than the machine’s price because a true expert provides a complete solution, not just a piece of hardware. They act as a partner who understands your specific production challenges, can customize the equipment to fit your needs, and provides reliable long-term support to ensure your success.

This is the core reason I started FHOPEPACK. After building my own factory, I realized that my success didn’t just come from the machines I bought; it came from the knowledge I gained and the few key partners who understood my world. They weren’t just selling me things. They were helping me solve problems. A cheap machine from a supplier who doesn’t understand your process is the most expensive mistake you can make. Let’s break down why a true partner is so different.

The Box Mover vs. The Solution Partner

There are two fundamental types of suppliers in this industry. Recognizing the difference is critical to protecting your investment.

| Feature | The Box Mover (Sales-Focused) | The Solution Partner (Engineer-Led) |

|---|---|---|

| Consultation | Asks "What machine do you want to buy?" | Asks "What is the bottleneck you are trying to solve?" |

| Customization | Offers standard, off-the-shelf models only. | Analyzes your line and suggests modifications for perfect integration. |

| Installation | Drops the machine at your dock. | Offers on-site installation, integration, and training. |

| After-Sales Support | Routes you to a generic call center. | Gives you direct access to engineers who know your machine. |

| Industry Knowledge | Knows their product catalog. | Knows your industry, your materials, and your challenges. |

The Box Mover is focused on the transaction. The Solution Partner is focused on your outcome. As a factory manager, your goal is a better outcome—higher efficiency, better safety, lower costs. It’s impossible to achieve that with a supplier who isn’t aligned with that goal.

What Real Expertise Looks Like

When I was running my factory, I had an issue where our strapping material would occasionally snag on the finished coil. It was a minor, but incredibly annoying, problem that caused small delays. I called the machine supplier, and their salesperson had no idea what I was talking about. I then reached out to an old mentor, an engineer who had spent 30 years in packaging. He listened for two minutes and said, "Randal, the issue isn’t the strapper. The issue is the static electricity building up on your film. You need to install an ionization bar right before the wrap." He didn’t sell ionization bars. He sold solutions. That is the kind of expertise you should be looking for.

How to Vet a Supplier’s Expertise

So, how do you find a true partner?

- Talk to their Engineers: Don’t just talk to the sales team. Insist on a technical call with their engineering staff. Ask them deep, probing questions about your specific application. Their answers will quickly reveal their level of knowledge.

- Ask for Case Studies: Don’t just ask for a list of customers. Ask for a detailed case study of a company with a problem similar to yours. How did they diagnose the problem? What was the solution? What were the results?

- Check Their Background: Who founded the company? Are they engineers with factory experience, or are they business people? Someone who has walked in your shoes, like me, will understand your challenges on a much deeper level.

Choosing a supplier is like hiring a key employee. You wouldn’t hire a critical team member based on who asks for the lowest salary. You would hire the one with the most skill and experience. Apply the same logic to your equipment partners.

Conclusion

Choosing the right automatic rewinding solution comes down to a partnership between a reliable machine and an expert supplier who can ensure your factory’s safety, efficiency, and growth.